Clutch Brake Measure . Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. The torque capacity of a clutch depends on a series of factors: The brakes are used far more and are loaded much more, and thus they wear out much quicker. “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. Calculation of the kinetic energy and loading moments of the mechanisms. Total area of the friction surface; Normal force acting on the clutch; This lost energy needs to be absorbed by the clutch or. During clutching or braking, the mechanical energy is through friction transformed into heat. Design, calculation and validation of four basic types of friction brakes and clutches. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. The material of a clutch is designed to withstand wear by friction, and it gets used relatively little.

from www.machiii.com

“so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. Design, calculation and validation of four basic types of friction brakes and clutches. Normal force acting on the clutch; During clutching or braking, the mechanical energy is through friction transformed into heat. This lost energy needs to be absorbed by the clutch or. “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. Calculation of the kinetic energy and loading moments of the mechanisms. Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Total area of the friction surface; The brakes are used far more and are loaded much more, and thus they wear out much quicker.

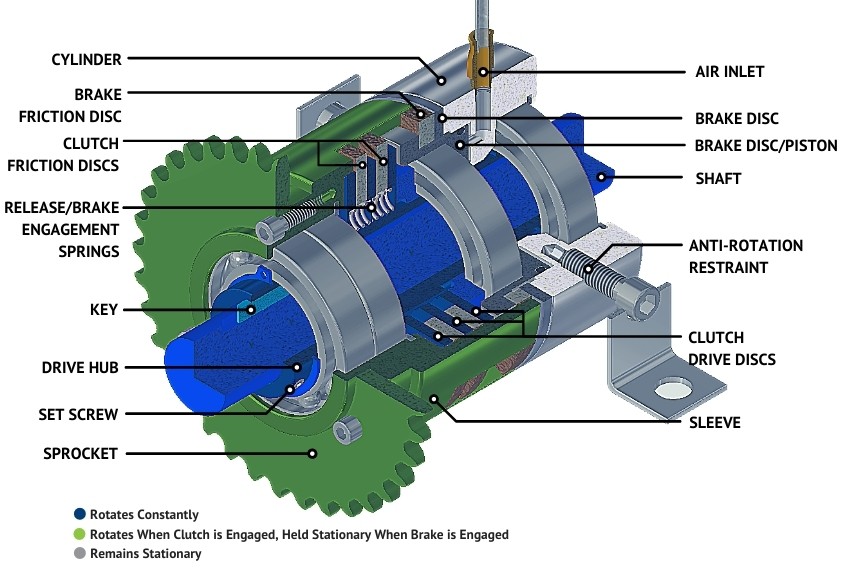

How It Works Air/Spring Stop and Start the Pilot ClutchBrake Mach III

Clutch Brake Measure Calculation of the kinetic energy and loading moments of the mechanisms. The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. Total area of the friction surface; “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. Calculation of the kinetic energy and loading moments of the mechanisms. Normal force acting on the clutch; The torque capacity of a clutch depends on a series of factors: Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. The brakes are used far more and are loaded much more, and thus they wear out much quicker. During clutching or braking, the mechanical energy is through friction transformed into heat. This lost energy needs to be absorbed by the clutch or. Design, calculation and validation of four basic types of friction brakes and clutches.

From www.ortlinghaus.com

Ortlinghaus. Clutchbrake units Clutch Brake Measure Calculation of the kinetic energy and loading moments of the mechanisms. Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Normal force acting on the clutch; The brakes are used far more and are loaded much more, and thus they wear out much quicker. “so when you combine that with. Clutch Brake Measure.

From www.beachsideauto.com.au

Brake & Clutch BEACHSIDE AUTOMOTIVE Clutch Brake Measure Design, calculation and validation of four basic types of friction brakes and clutches. The torque capacity of a clutch depends on a series of factors: The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. The brakes are used far more and are loaded much more, and thus they wear out much. Clutch Brake Measure.

From www.youtube.com

Drum Brake Measurement YouTube Clutch Brake Measure Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Design, calculation and validation of four basic types of friction brakes and clutches. The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. Normal force acting on the clutch; Calculation of the kinetic. Clutch Brake Measure.

From www.machiii.com

How It Works Air/Spring Stop and Start the Pilot ClutchBrake Mach III Clutch Brake Measure Normal force acting on the clutch; The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. This lost energy needs to be absorbed by the clutch or. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow. Clutch Brake Measure.

From www.dyclutch.co.kr

DCB 양축형 clutch&brake DCB 양축형 clutch&brake 동양클러치 Clutch Brake Measure Normal force acting on the clutch; During clutching or braking, the mechanical energy is through friction transformed into heat. Total area of the friction surface; Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. “so when you combine that with the thickness of the brake and add the amount that. Clutch Brake Measure.

From www.beachsideauto.com.au

Brake & Clutch BEACHSIDE AUTOMOTIVE Clutch Brake Measure “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. Total area of the friction surface; Calculation of the kinetic energy and loading moments of the mechanisms. This lost energy needs to be absorbed by the clutch or. The brakes are used far more and are loaded much more, and thus they wear out much quicker. During clutching or. Clutch Brake Measure.

From www.youtube.com

Car clutch control TIPS for learners Clutch brake accelerator control Clutch Brake Measure Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Calculation of the kinetic energy and loading moments of the mechanisms. This lost energy needs to be absorbed by the clutch or. Normal force acting on the clutch; The brakes are used far more and are loaded much more, and thus. Clutch Brake Measure.

From knowhow.napaonline.com

How To Measure Brake Pedal Ratio Clutch Brake Measure This lost energy needs to be absorbed by the clutch or. The brakes are used far more and are loaded much more, and thus they wear out much quicker. During clutching or braking, the mechanical energy is through friction transformed into heat. The torque capacity of a clutch depends on a series of factors: Total area of the friction surface;. Clutch Brake Measure.

From www.youtube.com

Learn how to use Clutch, Brake and Accelerator for beginners. YouTube Clutch Brake Measure The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. Design, calculation and validation of four basic types of friction brakes and clutches. Normal force acting on the clutch; “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. During clutching or braking, the mechanical energy is through friction transformed into. Clutch Brake Measure.

From www.pjpower.com

Airflex Clutch/Brake Combinations Clutch Brake Measure “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. Calculation of the kinetic energy and loading moments of the mechanisms. Design, calculation and validation of four basic types of friction brakes and clutches. Total area of the friction surface; This lost energy. Clutch Brake Measure.

From www.etrailer.com

How to Measure Trailer Brake Drum for Electric Trailer Brake Assemblies Clutch Brake Measure This lost energy needs to be absorbed by the clutch or. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. Normal force acting on the clutch; The brakes are used far more and are loaded much more, and thus they wear out. Clutch Brake Measure.

From www.astrobrake.co.za

Clutch Adjustment Importance Of Clutch Pedal FreePlay Clutch Brake Measure Total area of the friction surface; Design, calculation and validation of four basic types of friction brakes and clutches. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. During clutching or braking, the mechanical energy is through friction transformed into heat. This. Clutch Brake Measure.

From www.brakeclutchpro.com.au

Brake Clutch Pro Australia The Brake and Clutch Professionals Clutch Brake Measure Design, calculation and validation of four basic types of friction brakes and clutches. The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. During clutching or braking, the mechanical energy is through friction transformed into heat. “so when you combine that with the thickness of the brake and add the amount that. Clutch Brake Measure.

From www.youtube.com

Truck Tips MarkandMeasure Brake Adjustment YouTube Clutch Brake Measure Total area of the friction surface; The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. Design, calculation and validation of four basic types of. Clutch Brake Measure.

From www.designworldonline.com

What are common modes of industrial clutch and brake engagement? Clutch Brake Measure Normal force acting on the clutch; The torque capacity of a clutch depends on a series of factors: Design, calculation and validation of four basic types of friction brakes and clutches. “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. This lost energy needs to be absorbed by the clutch or. The material of a clutch is designed. Clutch Brake Measure.

From wptpower.com

Clutch and Brake Alignment WPT Power Corp. Clutch Brake Measure “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. Normal force acting on the clutch; The brakes are used far more and are loaded much more, and thus they wear out much quicker. The material of a clutch is designed to withstand. Clutch Brake Measure.

From www.youtube.com

Clutch brake and accelerator control tutorial कार चलाना सीखे TIPS Clutch Brake Measure Total area of the friction surface; This lost energy needs to be absorbed by the clutch or. Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. The torque capacity of a clutch depends on a series of factors: The material of a clutch is designed to withstand wear by friction,. Clutch Brake Measure.

From www.ortlinghaus.com

Ortlinghaus. Clutchbrake units Clutch Brake Measure Design, calculation and validation of four basic types of friction brakes and clutches. Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Normal force acting on the clutch; Calculation of the kinetic energy and loading moments of the mechanisms. Total area of the friction surface; The torque capacity of a. Clutch Brake Measure.

From www.colemanmachinery.com

Clutch / Brake Control Coleman Machinery Clutch Brake Measure The brakes are used far more and are loaded much more, and thus they wear out much quicker. The torque capacity of a clutch depends on a series of factors: “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. Design, calculation and. Clutch Brake Measure.

From www.motiontechnique.com

OMPI Clutch Brake Motion Technique Clutch Brake Measure The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. This lost energy needs to be absorbed by the clutch or. During clutching or braking, the mechanical energy is through friction transformed into heat. Design, calculation and validation of four basic types of friction brakes and clutches. The torque capacity of a. Clutch Brake Measure.

From www.youtube.com

Clutch Vs Brake Difference Between Clutch And Brake Brake Vs Clutch Clutch Brake Measure Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Normal force acting on the clutch; Calculation of the kinetic energy and loading moments of the mechanisms. Total area of the friction surface; “so when you combine that with the thickness of the brake and add the amount that has been. Clutch Brake Measure.

From www.machiii.com

How It Works Air/Air Stop and Start the Shaft ClutchBrake Mach III Clutch Brake Measure Design, calculation and validation of four basic types of friction brakes and clutches. The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. This lost energy needs to be absorbed by the clutch or. “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. Calculation of the kinetic energy and loading. Clutch Brake Measure.

From www.youtube.com

Gas, Brake and clutch control explained YouTube Clutch Brake Measure During clutching or braking, the mechanical energy is through friction transformed into heat. Design, calculation and validation of four basic types of friction brakes and clutches. “a standard clutch brake is 3/8’ thick (9.53 mm),” mark said. The torque capacity of a clutch depends on a series of factors: Total area of the friction surface; “so when you combine that. Clutch Brake Measure.

From www.youtube.com

PTO Clutch/Brakes How they work YouTube Clutch Brake Measure Normal force acting on the clutch; Design, calculation and validation of four basic types of friction brakes and clutches. Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Calculation of the kinetic energy and loading moments of the mechanisms. The brakes are used far more and are loaded much more,. Clutch Brake Measure.

From hoppers.com.au

How To Calculate Your Pedal Ratio Hoppers Stoppers Custom Brake Clutch Brake Measure This lost energy needs to be absorbed by the clutch or. Normal force acting on the clutch; The brakes are used far more and are loaded much more, and thus they wear out much quicker. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow. Clutch Brake Measure.

From www.nayagi.in

Clutch Brake Combination Nayagi Industrial Technologies Clutch Brake Measure During clutching or braking, the mechanical energy is through friction transformed into heat. Design, calculation and validation of four basic types of friction brakes and clutches. The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. The brakes are used far more and are loaded much more, and thus they wear out. Clutch Brake Measure.

From www.scribd.com

Clutches & Brakes PDF Clutch Brake Clutch Brake Measure Total area of the friction surface; The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. Calculation of the kinetic energy and loading moments of the mechanisms. This lost energy needs to be absorbed by the clutch or. During clutching or braking, the mechanical energy is through friction transformed into heat. The. Clutch Brake Measure.

From www.nexengroup.com

Motor/Foot Mount ClutchBrake Clutch Brake Measure Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. During clutching or braking, the mechanical energy is through friction transformed into heat. Total area of the friction surface; This lost energy needs to be absorbed by the clutch or. “so when you combine that with the thickness of the brake. Clutch Brake Measure.

From www.youtube.com

Using Clutch,Brake and Accelerator effectively in Car Clutch,Brake Clutch Brake Measure During clutching or braking, the mechanical energy is through friction transformed into heat. Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Calculation of the kinetic energy and loading moments of the mechanisms. Total area of the friction surface; “so when you combine that with the thickness of the brake. Clutch Brake Measure.

From www.nexengroup.com

Clutches and brakes for start and stop applications Clutch Brake Measure The brakes are used far more and are loaded much more, and thus they wear out much quicker. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. The material of a clutch is designed to withstand wear by friction, and it gets. Clutch Brake Measure.

From www.slideserve.com

PPT Chapter 14 PowerPoint Presentation, free download ID1004957 Clutch Brake Measure Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. “so when you combine that with the thickness of the brake and add the amount that has been ground from the flywheel, it will allow you to. The torque capacity of a clutch depends on a series of factors: Total area. Clutch Brake Measure.

From www.allclutchandbrake.com.au

All Clutch & Brake Clutch Brake Measure During clutching or braking, the mechanical energy is through friction transformed into heat. The brakes are used far more and are loaded much more, and thus they wear out much quicker. This lost energy needs to be absorbed by the clutch or. The material of a clutch is designed to withstand wear by friction, and it gets used relatively little.. Clutch Brake Measure.

From www.youtube.com

clutch brake replacement and clutch adjustment eaton fuller YouTube Clutch Brake Measure The material of a clutch is designed to withstand wear by friction, and it gets used relatively little. Calculation of the kinetic energy and loading moments of the mechanisms. Clutches and brakes are sized based on shaft speed and the horsepower of the motor to which they attach. Normal force acting on the clutch; The torque capacity of a clutch. Clutch Brake Measure.

From blog.doral360.com

Gearhead 101 Understanding Automatic Transmission Lifestyle Blog for Clutch Brake Measure Total area of the friction surface; The brakes are used far more and are loaded much more, and thus they wear out much quicker. The torque capacity of a clutch depends on a series of factors: During clutching or braking, the mechanical energy is through friction transformed into heat. This lost energy needs to be absorbed by the clutch or.. Clutch Brake Measure.

From www.youtube.com

Clutch Brake 101 YouTube Clutch Brake Measure The brakes are used far more and are loaded much more, and thus they wear out much quicker. Design, calculation and validation of four basic types of friction brakes and clutches. The torque capacity of a clutch depends on a series of factors: During clutching or braking, the mechanical energy is through friction transformed into heat. Normal force acting on. Clutch Brake Measure.