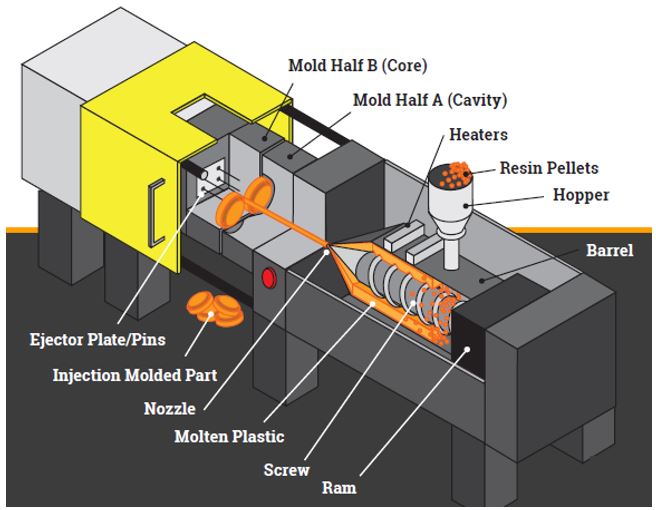

Injection Molding Description . Injection molding is a manufacturing process used to produce plastic parts in large volumes. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. This article will explain how injection molding works and how experienced manufacturers control the process to produce. In injection molding, polymer granules are first. Injection molding is a forming process using molds. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould.

from www.xcentricmold.com

This article will explain how injection molding works and how experienced manufacturers control the process to produce. Injection molding is a manufacturing process used to produce plastic parts in large volumes. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is a forming process using molds. In injection molding, polymer granules are first. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould.

Adding Injection Molding Features to Your Part Xcentric Mold

Injection Molding Description Injection molding is a forming process using molds. Finally, the moulded part, known typically as moulding, is extracted from the mould. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is a manufacturing process used to produce plastic parts in large volumes. Injection molding is a forming process using molds. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. In injection molding, polymer granules are first. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create.

From prototechasia.com

What is Plastic Injection Molding? Our Comprehensive Overview Injection Molding Description Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding is a manufacturing process used to produce. Injection Molding Description.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer Injection Molding Description Finally, the moulded part, known typically as moulding, is extracted from the mould. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection molding is a manufacturing process used to produce plastic parts in large. Injection Molding Description.

From www.immould.com

What is Injection Molding Splay and How to Avoid it FOW Mould Injection Molding Description This article will explain how injection molding works and how experienced manufacturers control the process to produce. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Finally, the moulded part, known typically as moulding, is extracted from the mould. Materials such as synthetic resins (plastics) are heated and melted, and then sent. Injection Molding Description.

From themechanicalengineering.com

Injection Molding Definition, Construction, Working Process Injection Molding Description Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is a forming process using molds. Injection. Injection Molding Description.

From www.acomold.com

Glossary of plastic injection molding terms Injection Molding Description Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould. This article will explain how injection molding works and how experienced manufacturers control the process to produce. In injection. Injection Molding Description.

From www.plasticmoulds.net

Various Plastic Molding Process Injection Molding Description Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Finally, the moulded part, known typically as moulding, is extracted from the mould. This article will explain how injection molding works and how experienced manufacturers control the process to produce. In injection molding, polymer granules are first.. Injection Molding Description.

From mavink.com

Types Of Plastic Injection Molding Injection Molding Description Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection molding is a manufacturing process used to produce plastic parts in large volumes. In injection molding, polymer granules are first. This article will. Injection Molding Description.

From www.slideserve.com

PPT Injection Molding Molds PowerPoint Presentation, free download Injection Molding Description In injection molding, polymer granules are first. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is a manufacturing process used to produce plastic parts in large volumes. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection molding is. Injection Molding Description.

From www.nexpcb.com

One Picture to Understand the Structure of an Injection Mold Injection Molding Description Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding is a manufacturing process used to produce plastic parts in large volumes. Materials. Injection Molding Description.

From www.rnaautomation.com

Robotics in Injection Moulding RNA Automation Injection Molding Description Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection molding is a forming process using molds. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is a manufacturing process used to produce plastic parts in. Injection Molding Description.

From www.plasticmoulds.net

Injection Molding Process Topworks Plastic Molding Injection Molding Description Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. This article will explain how injection molding works and how experienced manufacturers control the process. Injection Molding Description.

From cooling-tower.my

Injection molding working principle JH Cooling Machine Injection Molding Description Injection molding is a manufacturing process used to produce plastic parts in large volumes. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Injection moulding (im) is a manufacturing process in which a polymer is. Injection Molding Description.

From www.plasticmoulds.net

Injection Molding Process Injection Molding Description Injection molding is a forming process using molds. In injection molding, polymer granules are first. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Materials such as synthetic. Injection Molding Description.

From www.wundermold.com

3 Components of Injection Molding 🥇 Injection Molding Applications Injection Molding Description Finally, the moulded part, known typically as moulding, is extracted from the mould. In injection molding, polymer granules are first. Injection molding is a manufacturing process used to produce plastic parts in large volumes. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into. Injection Molding Description.

From www.spark-mould.com

The best multimaterial injection molding solution for plastic products Injection Molding Description Injection molding is a forming process using molds. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. In injection molding, polymer granules are first. Injection moulding (im) is a manufacturing process in which a polymer. Injection Molding Description.

From predictabledesigns.com

Introduction to Injection Molding Injection Molding Description In injection molding, polymer granules are first. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding is a manufacturing process used to. Injection Molding Description.

From www.cavitymold.com

Introduction to Injection Molding Plastic Injection Molding and Mold Injection Molding Description Injection molding is a manufacturing process used to produce plastic parts in large volumes. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is a forming process using molds. Finally, the moulded part, known typically as moulding, is extracted from the mould. In injection. Injection Molding Description.

From www.echosupply.com

Injection Molding Basics Hot Runner Systems Echo Supply Injection Molding Description Finally, the moulded part, known typically as moulding, is extracted from the mould. In injection molding, polymer granules are first. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection molding is a manufacturing process. Injection Molding Description.

From www.3erp.com

What is Injection Molding and How Does it Work Definition & Working Injection Molding Description Injection molding is a manufacturing process used to produce plastic parts in large volumes. In injection molding, polymer granules are first. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding, a transformative manufacturing technique, makes this possible by injecting. Injection Molding Description.

From www.elastomer.kuraray.com

What is injection molding? Kuraray Elastomer Injection Molding Description Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are. Injection Molding Description.

From www.simcobox.com

Plastic Injection Molding an Introduction by SimcoBox Injection Molding Description Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Finally, the moulded part, known typically as moulding, is extracted from the mould. In injection molding, polymer granules are first. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under. Injection Molding Description.

From www.plasticomould.com

Description of injection molding parameters Knowledge Odin Mould Co Injection Molding Description Injection molding is a manufacturing process used to produce plastic parts in large volumes. In injection molding, polymer granules are first. Finally, the moulded part, known typically as moulding, is extracted from the mould. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is. Injection Molding Description.

From www.wevolver.com

What are injection mold sprues, runners, and gates? Injection Molding Description Injection molding is a manufacturing process used to produce plastic parts in large volumes. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Finally, the moulded part, known typically. Injection Molding Description.

From techsavvy.co.in

Sole Guide about PLASTIC INJECTION MOLDS TechSavvy Engineers Injection Molding Description Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. In injection molding, polymer granules are first. Finally, the moulded part, known typically as moulding, is extracted from the mould. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the.. Injection Molding Description.

From www.kaysun.com

Injection Molding Step by Step How Are Plastic Parts Made? Injection Molding Description Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. Injection molding is a forming process using molds. In injection molding, polymer granules are first. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection molding is a manufacturing process used to produce. Injection Molding Description.

From www.magneticplaten.com

Injection Molding Basics What Is It and How Does It Work HVR MAG Injection Molding Description Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Injection molding is a forming process using molds. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they. Injection Molding Description.

From www.plasticmoulds.net

Structure Of Injection MoldTopworks Plastic Mold Injection Molding Description Injection molding is a forming process using molds. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form the. In injection molding, polymer granules are first. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection molding is a manufacturing process used to produce. Injection Molding Description.

From www.xcentricmold.com

Injection Molding Process Xcentric Mold & Engineering Injection Molding Description Injection molding is a forming process using molds. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Materials such as synthetic resins (plastics) are. Injection Molding Description.

From www.mdpi.com

Metals Free FullText An Overview of Highly Porous Titanium Injection Molding Description Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the. Injection Molding Description.

From www.ennomotive.com

Revolutionizing the Injection Molding Process Injection Molding Description Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection molding is a forming process using molds. This article will explain how injection molding works and how experienced manufacturers control the process to produce. Materials such as synthetic resins (plastics) are heated and melted, and then sent to the mold where they are cooled to form. Injection Molding Description.

From www.treatstock.fr

Des guides A Closer Look at Reaction Injection Molding Injection Molding Description Injection molding is a forming process using molds. Injection molding is a manufacturing process used to produce plastic parts in large volumes. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure. Injection Molding Description.

From go4mould.com

Automotive Injection Molding Manufacturer Go4 Mould Injection Molding Description Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Finally, the moulded part, known typically as moulding, is extracted from the mould. Injection molding. Injection Molding Description.

From www.xcentricmold.com

Adding Injection Molding Features to Your Part Xcentric Mold Injection Molding Description Injection molding is a forming process using molds. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. This article will explain how injection molding. Injection Molding Description.

From www.shidarubber.com

Rubber Compression and Injection Molding Process Hebei Shida Seal Injection Molding Description In injection molding, polymer granules are first. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding is a forming process using molds. Injection molding is a manufacturing process used to produce plastic parts in large volumes. Finally, the moulded. Injection Molding Description.

From www.scribd.com

Injection MoldingInjection Molding Process Description PDF Injection Molding Description Injection molding is a manufacturing process used to produce plastic parts in large volumes. Injection moulding (im) is a manufacturing process in which a polymer is heated to a highly molten state and forced to flow under high pressure into a mould. Injection molding, a transformative manufacturing technique, makes this possible by injecting molten material into molds to create. This. Injection Molding Description.