Temperature Control System Reactor . Reactor temperature control typically is very important to product quality, production rate and operating costs. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Often, quite complex systems are needed for tempering a reactor. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Therefore, it is important to design an effective control. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders.

from blog.isa.org

Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Reactor temperature control typically is very important to product quality, production rate and operating costs. Precise temperature control has a significant influence on performance and quality in chemical process engineering. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Therefore, it is important to design an effective control. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Often, quite complex systems are needed for tempering a reactor. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control.

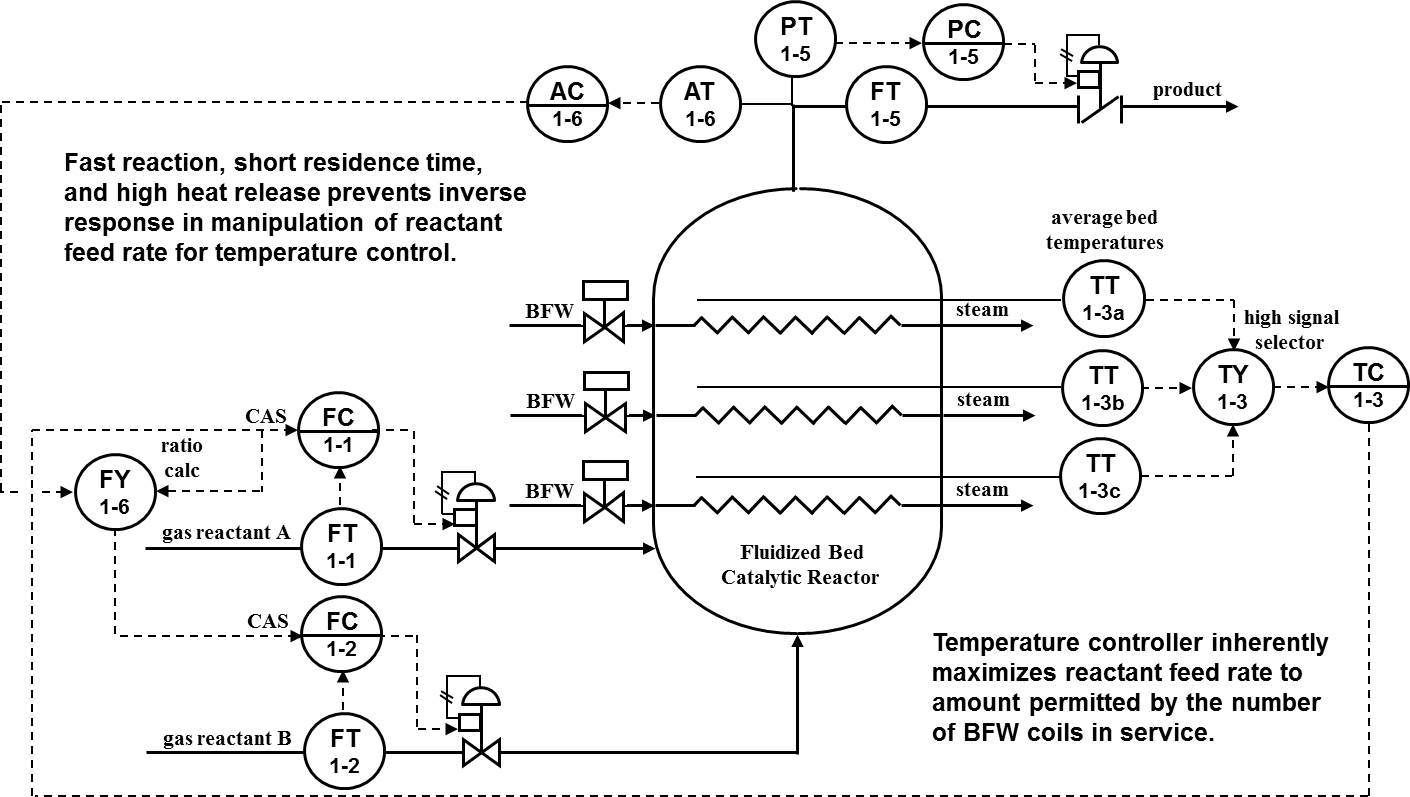

Getting the Most Out of Fluidized Bed Reactors

Temperature Control System Reactor Precise temperature control has a significant influence on performance and quality in chemical process engineering. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Often, quite complex systems are needed for tempering a reactor. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Reactor temperature control typically is very important to product quality, production rate and operating costs. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Therefore, it is important to design an effective control.

From www.azom.com

Ensuring Process Stability with Reactor Temperature Control Systems Temperature Control System Reactor Precise temperature control has a significant influence on performance and quality in chemical process engineering. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. The purpose of this control system is to ensure the chemical. Temperature Control System Reactor.

From kedayq.en.made-in-china.com

Platinum Resistance Temperature Control System High Safety Level MCR3 Temperature Control System Reactor Reactor temperature control typically is very important to product quality, production rate and operating costs. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Temperature control in a reactor is important to avoid a runaway reaction and obtain. Temperature Control System Reactor.

From www.chemengonline.com

Sensing Change in Batch Reactors Chemical Engineering Page 1 Temperature Control System Reactor Therefore, it is important to design an effective control. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Reactor temperature control typically is very important to product quality, production rate and operating costs. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. The purpose of this control. Temperature Control System Reactor.

From deltatsys.com

Reactor Temperature Control Reactor Temperature Control System Temperature Control System Reactor Therefore, it is important to design an effective control. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Reactor temperature control typically is very important to product quality, production rate and operating costs. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Temperature control in a reactor. Temperature Control System Reactor.

From www.semanticscholar.org

Batch reactor temperature control based on DMCoptimization PID Temperature Control System Reactor Often, quite complex systems are needed for tempering a reactor. Therefore, it is important to design an effective control. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Reactor temperature control typically is very important to. Temperature Control System Reactor.

From www.nandantechnicals.com

Cascade control strategy used for control of temperature in an Temperature Control System Reactor Reactor temperature control typically is very important to product quality, production rate and operating costs. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Therefore, it is important to design an effective control. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant. Temperature Control System Reactor.

From www.lneya.com

Multi reactor temperature control unit TCULNEYA Chiller Units Temperature Control System Reactor Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Reactor temperature control typically is very important to product quality, production rate and operating costs. A process control system monitors the temperature of a reaction and either. Temperature Control System Reactor.

From www.chemengghelp.com

Automation and Controls for Batch Reactor ChemEnggHelp Temperature Control System Reactor Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Precise temperature control has a significant influence on performance and quality. Temperature Control System Reactor.

From www.mtixtl.com

100 ml NiBased Superalloy High Pressure Hydrothermal Reactor 1100°C Temperature Control System Reactor Reactor temperature control typically is very important to product quality, production rate and operating costs. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Therefore, it is important to design an effective control. Often, quite complex systems are needed for tempering a reactor. A process control system. Temperature Control System Reactor.

From www.lneya.com

Why is there air in the reactor temperature control system?LNEYA Air Temperature Control System Reactor Therefore, it is important to design an effective control. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Reactor temperature control typically is very important to product quality, production rate and operating costs. Often, quite complex systems are needed for tempering a reactor. Temperature control units are used mostly for controlling. Temperature Control System Reactor.

From procure-net.com

Superior Quality Temperature Control System for GlassLined Reactors Temperature Control System Reactor A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Therefore, it is important to design an effective control. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is. Temperature Control System Reactor.

From dlu.com.ua

High Dynamic Closed Temperature Control Systems Temperature Control System Reactor Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Therefore, it is important. Temperature Control System Reactor.

From www.controlglobal.com

Ask the Experts Cascade reactor temperature control Control Global Temperature Control System Reactor Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Therefore, it is important to design an effective control. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. A major challenge for temperature control is handling the nonlinear nature of. Temperature Control System Reactor.

From instrumentationtools.com

Chemical Reactor Temperature Control System Inst Tools Temperature Control System Reactor The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Reactor temperature control typically is very important to product quality, production rate and operating costs. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Often, quite complex systems are needed for. Temperature Control System Reactor.

From www.mdpi.com

Processes Free FullText Reactor Temperature Control Based on Temperature Control System Reactor A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Temperature control in a reactor is. Temperature Control System Reactor.

From engineeringoperations.blogspot.com

Reactor Temperature control by regulating the boiling pressure BASIC Temperature Control System Reactor A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Therefore, it is important to design an effective control. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Often, quite complex systems are needed for tempering a reactor. Temperature control units. Temperature Control System Reactor.

From in.pinterest.com

PID Temperature Controller Temperature control, Control, Control system Temperature Control System Reactor Reactor temperature control typically is very important to product quality, production rate and operating costs. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Therefore, it is important to design an effective control. Temperature control. Temperature Control System Reactor.

From www.swep.com.br

Temperature control systems SWEP Temperature Control System Reactor The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Reactor temperature control typically is very important to product quality, production rate and operating costs. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Therefore, it is important to design. Temperature Control System Reactor.

From www.chemengghelp.com

Process Control in Chemical Plant ChemEnggHelp Temperature Control System Reactor A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Therefore, it is important to design an effective control. Reactor temperature control typically is very important to product quality, production rate and operating costs. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained. Temperature Control System Reactor.

From ldsmachinery.com

Temperature Control Unit For Reactor In The Pharmaceutical Industry Temperature Control System Reactor Precise temperature control has a significant influence on performance and quality in chemical process engineering. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. The purpose of this control system is to ensure the chemical. Temperature Control System Reactor.

From www.slideshare.net

Temperature Control for Reactors a Huber Whitepaper Temperature Control System Reactor A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Temperature control in a reactor is important to avoid a runaway. Temperature Control System Reactor.

From procure-net.com

Advanced Dynamic Temperature Control System for GlassLined Reactors Temperature Control System Reactor Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Therefore, it is important to design an effective control. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Often, quite complex systems are needed for tempering a reactor. Reactor temperature control typically is very important to product. Temperature Control System Reactor.

From file.scirp.org

ModelBased SplitRange Algorithm for the Temperature Control of a Temperature Control System Reactor Precise temperature control has a significant influence on performance and quality in chemical process engineering. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Therefore, it is important to design. Temperature Control System Reactor.

From www.reactormixer.com

Features and control methods of glass reactor temperature control Temperature Control System Reactor The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Therefore, it is important to design an effective control. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Reactor temperature control typically is very important to product quality, production rate and. Temperature Control System Reactor.

From www.shimaden.co.jp

Reactor Control│工業用温度、湿度制御機器|株式会社シマデン Temperature Control System Reactor Often, quite complex systems are needed for tempering a reactor. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Therefore,. Temperature Control System Reactor.

From process-technology-online.com

Temperature control of production reactors Temperature Control System Reactor The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Therefore, it is important to design an effective control. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Precise temperature control has a significant influence on performance and quality in. Temperature Control System Reactor.

From www.slideshare.net

Temperature Control for Reactors a Huber Whitepaper Temperature Control System Reactor Therefore, it is important to design an effective control. Precise temperature control has a significant influence on performance and quality in chemical process engineering. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Reactor temperature control typically is very important to product quality, production rate and operating costs. The purpose of. Temperature Control System Reactor.

From blog.isa.org

Getting the Most Out of Fluidized Bed Reactors Temperature Control System Reactor A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Temperature control units are used mostly for controlling the temperature of molds,. Temperature Control System Reactor.

From www.chegg.com

Solved 4. The reactor temperature in an exothermic reactor Temperature Control System Reactor Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. A process control system monitors the. Temperature Control System Reactor.

From www.youtube.com

How to draw P&ID of Temperature Control of Chemical Reactor using Temperature Control System Reactor Often, quite complex systems are needed for tempering a reactor. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control.. Temperature Control System Reactor.

From www.gmmpfaudler.com

Temperature control units manufacturer TCU temperature control unit Temperature Control System Reactor The purpose of this control system is to ensure the chemical solution inside the reactor vessel is maintained at a constant temperature. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Reactor temperature control typically is. Temperature Control System Reactor.

From process-technology-online.com

Temperature control of production reactors Temperature Control System Reactor Therefore, it is important to design an effective control. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Precise temperature control has a significant influence on performance and quality in chemical process engineering. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Reactor temperature control typically. Temperature Control System Reactor.

From newdrugapprovals.org

Ensuring Process Stability with Reactor Temperature Control Systems Temperature Control System Reactor A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Temperature control units are used mostly for controlling the temperature of molds, tanks, rollers or cylinders. Temperature control in a reactor is important to avoid a. Temperature Control System Reactor.

From blog.isa.org

How to Improve Batch Reactor Temperature Control Temperature Control System Reactor Temperature control in a reactor is important to avoid a runaway reaction and obtain the desired yield. Therefore, it is important to design an effective control. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. Reactor temperature control typically is very important to product quality, production rate and operating costs. The purpose of. Temperature Control System Reactor.

From www.researchgate.net

Schematic view of a modular high temperature gascooled reactor Temperature Control System Reactor Reactor temperature control typically is very important to product quality, production rate and operating costs. A major challenge for temperature control is handling the nonlinear nature of temperature inside most reactors. A process control system monitors the temperature of a reaction and either manually or automatically initiates temperature control. Therefore, it is important to design an effective control. Precise temperature. Temperature Control System Reactor.