Motor Pump Coupling Parts . Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. Two hubs and a central disc. Compare rigid, flexible and magnetic couplings and their. Elastomeric, grid, disc and gear. This article will explore the. These couplings consist of three parts: Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Learn about the four most common types of pump couplings: The central disc engages with the hubs, allowing for angular misalignment. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Find out their advantages, disadvantages, and applications for various pump and motor shafts.

from ar.inspiredpencil.com

Elastomeric, grid, disc and gear. These couplings consist of three parts: Two hubs and a central disc. Compare rigid, flexible and magnetic couplings and their. The central disc engages with the hubs, allowing for angular misalignment. This article will explore the. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Learn about the four most common types of pump couplings: Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings.

Different Types Of Couplings

Motor Pump Coupling Parts Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Compare rigid, flexible and magnetic couplings and their. The central disc engages with the hubs, allowing for angular misalignment. Two hubs and a central disc. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. These couplings consist of three parts: Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Elastomeric, grid, disc and gear. Find out their advantages, disadvantages, and applications for various pump and motor shafts. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. Learn about the four most common types of pump couplings: This article will explore the.

From mungfali.com

Types Of Shaft Couplings Motor Pump Coupling Parts This article will explore the. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the four most common types of pump couplings: Learn about the types and functions of pump. Motor Pump Coupling Parts.

From www.ameridrives.com

Coupling Types for Different Applications Motor Pump Coupling Parts Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Compare rigid, flexible and magnetic couplings and their. Learn about the four most common types of pump couplings: Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Elastomeric, grid, disc. Motor Pump Coupling Parts.

From www.wholesalebeerparts.com

Nylon Pump Saver Motor Coupling Assembly Wholesale Beer Parts Motor Pump Coupling Parts Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. This article will explore the. These couplings consist of three parts: Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft.. Motor Pump Coupling Parts.

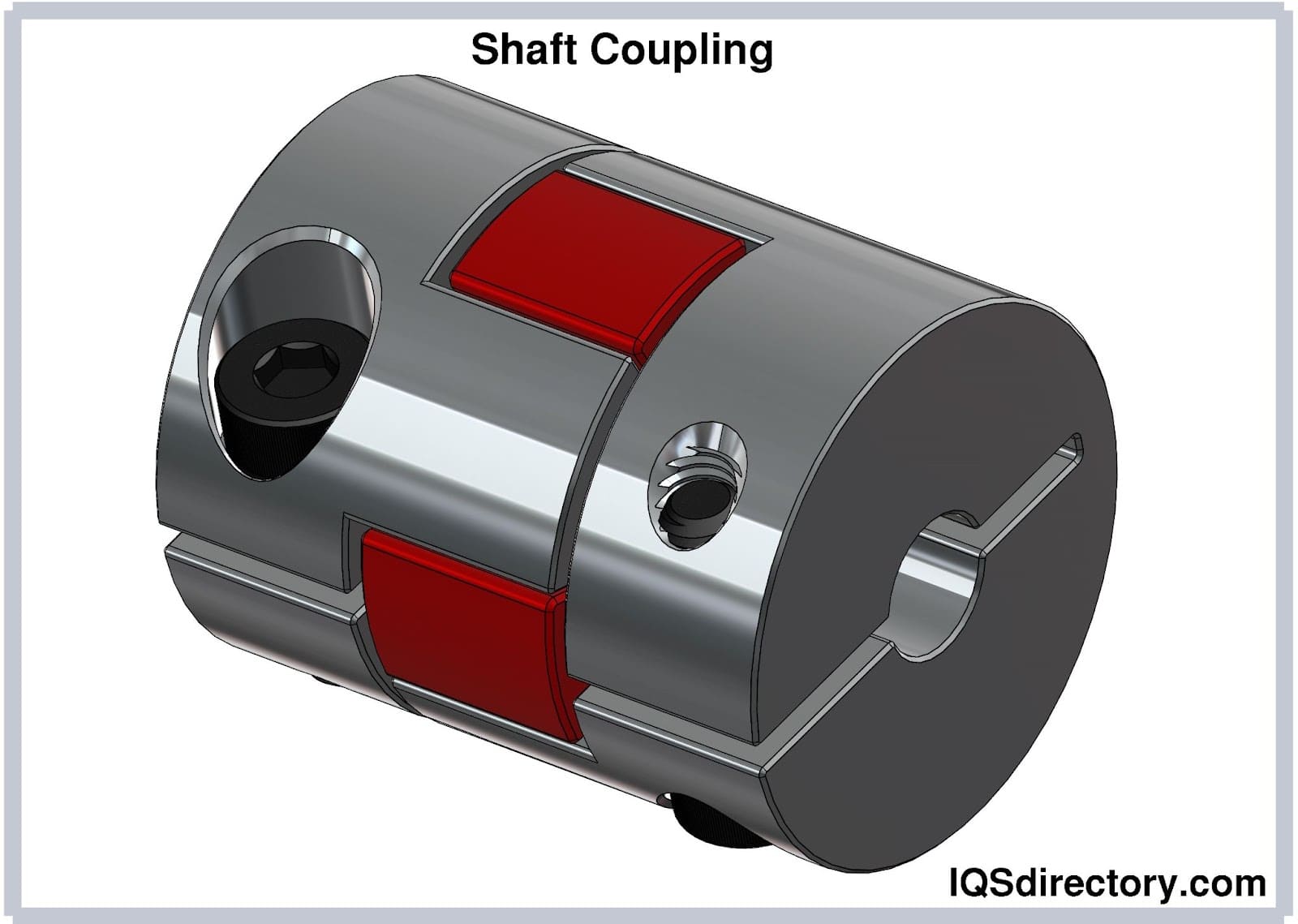

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Motor Pump Coupling Parts Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. This article will explore the. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in. Motor Pump Coupling Parts.

From www.amazon.ca

11/2" to 1" Inch Bore Engine Motor Drive Shaft Coupling Flexible L100 Motor Pump Coupling Parts Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Learn about the four most common types of pump couplings: Find out their advantages, disadvantages, and applications for various pump and motor shafts. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and. Motor Pump Coupling Parts.

From www.flowfitonline.com

"Petrol Engine Drive Coupling, Motor Half for Group 2 Pump to 1"" (25 Motor Pump Coupling Parts Two hubs and a central disc. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. This article will explore the. These couplings consist of three parts: The. Motor Pump Coupling Parts.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Motor Pump Coupling Parts This article will explore the. Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Elastomeric, grid, disc and gear. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Learn. Motor Pump Coupling Parts.

From www.excavatorspare-parts.com

Excavator Coupling for John Deere 790D Motor Hydraulic Pump Driven Coupling Motor Pump Coupling Parts Find out their advantages, disadvantages, and applications for various pump and motor shafts. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and. Motor Pump Coupling Parts.

From www.johncrane.com

C Series General Industrial Couplings John Crane Power Transmission Motor Pump Coupling Parts Compare rigid, flexible and magnetic couplings and their. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. Two hubs and a central disc. Learn about the different types of pump couplings, such as flexible, rigid,. Motor Pump Coupling Parts.

From engineeringlearn.com

Types of Mechanical Coupling and Their Uses [with Pictures Motor Pump Coupling Parts Elastomeric, grid, disc and gear. The central disc engages with the hubs, allowing for angular misalignment. Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. This article will explore the. Compare rigid, flexible and. Motor Pump Coupling Parts.

From in.pinterest.com

Different Types of Couplings and Their Applications Explained Motor Pump Coupling Parts Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Learn about the four most common types of pump couplings: Compare rigid, flexible and magnetic couplings and their. These couplings consist of three parts: Learn about the types and functions of pump couplings, which connect the pump shaft with the motor. Motor Pump Coupling Parts.

From www.sydensen.com

Densen customized rubber coupling,motor coupling,pump coupling Buy Motor Pump Coupling Parts Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Elastomeric, grid, disc and gear. Two hubs and a central disc. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Learn about the types and functions of pump couplings, which. Motor Pump Coupling Parts.

From www.linquip.com

What Are The Different Types of Pump Couplings? Linquip Motor Pump Coupling Parts Find out their advantages, disadvantages, and applications for various pump and motor shafts. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. This article will explore the. Learn about the four most common types of pump couplings: Learn about the types and functions of pump couplings,. Motor Pump Coupling Parts.

From ar.inspiredpencil.com

Different Types Of Couplings Motor Pump Coupling Parts Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. These couplings consist of three parts: Two hubs and a central disc. Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. The central disc engages with the. Motor Pump Coupling Parts.

From mungfali.com

Hydraulic Pump Coupling Motor Pump Coupling Parts These couplings consist of three parts: Learn about the four most common types of pump couplings: Compare rigid, flexible and magnetic couplings and their. The central disc engages with the hubs, allowing for angular misalignment. This article will explore the. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions. Motor Pump Coupling Parts.

From repairfixsolorzanori.z21.web.core.windows.net

Pump Motor Coupling Types Motor Pump Coupling Parts Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Elastomeric, grid, disc and gear. Two hubs and a central disc. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads.. Motor Pump Coupling Parts.

From www.lsyongrun.com

Flexible Coupling Flange Spacer Rigid Motor Drum Pump Rubber Nylon Motor Pump Coupling Parts Find out their advantages, disadvantages, and applications for various pump and motor shafts. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the four most common types of pump couplings: The central disc engages with the hubs, allowing for angular misalignment. Motor coupling is an essential component used in pump applications to connect. Motor Pump Coupling Parts.

From www.idealvac.com

Ideal Vacuum Motor Coupling Spider for Agilent Varian TriScroll 300 Motor Pump Coupling Parts Learn about the four most common types of pump couplings: Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Elastomeric, grid, disc and gear. Learn about the types and functions of pump couplings, which. Motor Pump Coupling Parts.

From www.idealvac.com

Ideal Vacuum Motor Shaft Coupling Kit for Edwards E2M30, E2M28, E2M18 Motor Pump Coupling Parts These couplings consist of three parts: This article will explore the. Elastomeric, grid, disc and gear. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. The central disc engages with the hubs, allowing for angular misalignment. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their. Motor Pump Coupling Parts.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Motor Pump Coupling Parts Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. The central disc engages with the hubs, allowing for angular misalignment. Learn about the different types of pump couplings, such as rigid, flexible,. Motor Pump Coupling Parts.

From www.hydrokit.com

PUMP COUPLING GROUP 2 Motor Pump Coupling Parts Find out their advantages, disadvantages, and applications for various pump and motor shafts. Two hubs and a central disc. The central disc engages with the hubs, allowing for angular misalignment. This article will explore the. Elastomeric, grid, disc and gear. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. These couplings consist of three parts:. Motor Pump Coupling Parts.

From mavink.com

Pump Coupling Types Motor Pump Coupling Parts The central disc engages with the hubs, allowing for angular misalignment. Learn about the four most common types of pump couplings: Compare rigid, flexible and magnetic couplings and their. Two hubs and a central disc. Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. This article will explore the. Find. Motor Pump Coupling Parts.

From www.couplinganswers.com

Coupling Answers Where the World Turns for Coupling Knowledge Motor Pump Coupling Parts Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Find out their advantages,. Motor Pump Coupling Parts.

From whatispiping.com

What is a Pump Coupling? Its Types, Functions, Applications (PDF Motor Pump Coupling Parts Compare rigid, flexible and magnetic couplings and their. These couplings consist of three parts: Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Learn about the different types of pump couplings, such as flexible, rigid,. Motor Pump Coupling Parts.

From www.youtube.com

KTR couplings for PumpMotor applications YouTube Motor Pump Coupling Parts Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Find out their advantages, disadvantages, and applications for various pump and motor shafts. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and. Motor Pump Coupling Parts.

From www.northerntool.com

Standard Half Coupling — 3/4in. Size Northern Tool Motor Pump Coupling Parts Learn about the four most common types of pump couplings: These couplings consist of three parts: Find out their advantages, disadvantages, and applications for various pump and motor shafts. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. This article will explore the. Learn about the different types of pump couplings,. Motor Pump Coupling Parts.

From www.theengineerspost.com

13 Types of Coupling Definition, Drawings, Uses & (PDF) Motor Pump Coupling Parts Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. These couplings consist of three parts: Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Motor coupling is an essential component used in pump applications to connect the motor shaft. Motor Pump Coupling Parts.

From www.pumpsandsystems.com

Selecting Bearing Systems in Vertical Motors Pumps & Systems Motor Pump Coupling Parts Elastomeric, grid, disc and gear. This article will explore the. Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Find out their advantages, disadvantages, and applications for various pump and motor shafts. Two hubs and a central disc. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Compare. Motor Pump Coupling Parts.

From heidyfersli.blogspot.com

Explain Different Types of Coupling With Suitable Example Motor Pump Coupling Parts Find out their advantages, disadvantages, and applications for various pump and motor shafts. The central disc engages with the hubs, allowing for angular misalignment. Learn about the four most common types of pump couplings: Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Elastomeric, grid, disc. Motor Pump Coupling Parts.

From www.reddit.com

Different Types of Couplings r/coolguides Motor Pump Coupling Parts These couplings consist of three parts: Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. The central disc engages with the hubs, allowing for angular misalignment. Compare rigid, flexible and magnetic couplings and their. This article will explore the. Two hubs and a central disc. Motor coupling is an essential component used in. Motor Pump Coupling Parts.

From www.sydensen.com

Densen customized rubber coupling,motor coupling,pump coupling Buy Motor Pump Coupling Parts Find out their advantages, disadvantages, and applications for various pump and motor shafts. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the types and functions of pump couplings, which connect the pump shaft with the motor shaft. Compare rigid, flexible and magnetic couplings and their. Elastomeric, grid, disc and gear. The central. Motor Pump Coupling Parts.

From www.slideserve.com

PPT Couplings PowerPoint Presentation, free download ID9472255 Motor Pump Coupling Parts Learn about the four most common types of pump couplings: Learn about the different types of pump couplings, such as rigid, flexible, magnetic, and gear couplings. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions. Motor Pump Coupling Parts.

From www.flex-couplings.com

Double Disc Pack Coupling / High Speed Flexible Coupling For Pumps Motor Pump Coupling Parts Motor coupling is an essential component used in pump applications to connect the motor shaft to the pump shaft. This article will explore the. Two hubs and a central disc. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads. Learn about the four most common types of pump couplings: Learn about the different types of. Motor Pump Coupling Parts.

From cimotransmission.en.made-in-china.com

Hydraulic Pump Motor Coupling Nm Flexible Rubber Shaft Coupling China Motor Pump Coupling Parts Compare rigid, flexible and magnetic couplings and their. Learn about the four most common types of pump couplings: This article will explore the. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Find out how they transmit power, compensate misalignment, dampen vibrations, and absorb shock loads.. Motor Pump Coupling Parts.

From www.alibaba.com

Flexible Hydraulic Pump Motor Couplings Pump Parts Shaft Coupling Buy Motor Pump Coupling Parts These couplings consist of three parts: Compare rigid, flexible and magnetic couplings and their. Learn about the different types of pump couplings, such as flexible, rigid, flange, sleeve, and fluid couplings, and their functions in fluid systems. Learn about the four most common types of pump couplings: Elastomeric, grid, disc and gear. Find out how they transmit power, compensate misalignment,. Motor Pump Coupling Parts.