Cutting Heat Sink Fins . In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. The goal is to optimize. This feature can easily be. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat.

from www.heatsinksmfg.com

In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. The goal is to optimize. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. This feature can easily be.

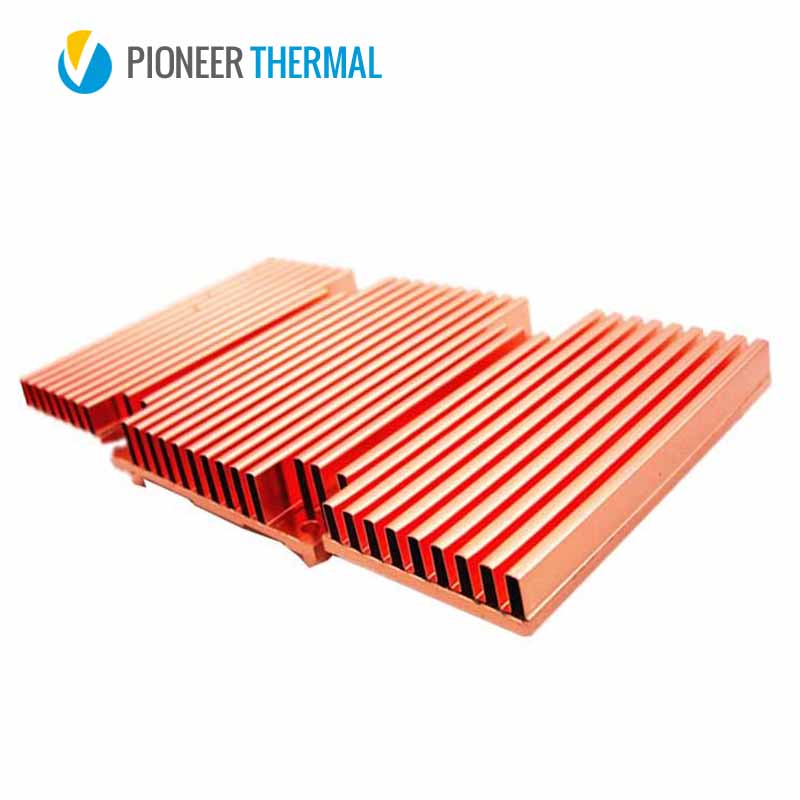

Copper Heat Sinks,Folded Fin Heat Sinks Pioneer Thermal Heat Sinks

Cutting Heat Sink Fins Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. The goal is to optimize. This feature can easily be. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins.

From www.lorithermal.com

Professional Finned Aluminum Heat Sink & Copper Heat Sink Manufacture Cutting Heat Sink Fins This feature can easily be. In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. In a heat sink. Cutting Heat Sink Fins.

From www.alibaba.com

High Power Copper Wavy Fins Folded Fin Heatsink Brass Profiles Cutting Heat Sink Fins In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. The heat sink fins are perforated with perforation number np (4, 8,. Cutting Heat Sink Fins.

From www.lorithermal.com

Folded Fin Heat Sinks Aluminumlori Heat Sink Cutting Heat Sink Fins The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. In a heat sink application, conduction is critical for transferring heat from the heat. Cutting Heat Sink Fins.

From www.kingkatech.com

Bonded Fins Heat Sink Kingka Cutting Heat Sink Fins This feature can easily be. The goal is to optimize. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. The heat sink fins are perforated. Cutting Heat Sink Fins.

From www.lorithermal.com

Plate Fin Heat Sink Manufacturer Lori Cutting Heat Sink Fins Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. This feature can easily be. The goal is to optimize. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent. Cutting Heat Sink Fins.

From www.diytrade.com

big heat sink high fins aluminum heatsink high density heatsinks sz Cutting Heat Sink Fins Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. The goal is to optimize. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. Tapping a. Cutting Heat Sink Fins.

From www.indiamart.com

Straight Fin Heat Sink, Thickness 3 To 5 Mm at Rs 350/piece in Cutting Heat Sink Fins Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. This feature can easily be. Fins can be cut or constructed. Cutting Heat Sink Fins.

From www.finskiving.com

Heat sink fin skiving technology,Fin skiving machines,heat sink fin Cutting Heat Sink Fins This feature can easily be. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. In a. Cutting Heat Sink Fins.

From thermocoolcorp.com

Thermo Cool Folded Fins Cutting Heat Sink Fins The goal is to optimize. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by. Cutting Heat Sink Fins.

From bangteng.en.made-in-china.com

Transformer Cooling Fins Aluminum Sheet for Plannar Transformer Heat Cutting Heat Sink Fins Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In a heat sink application, conduction is critical for transferring heat from the heat source (e.g.,. Cutting Heat Sink Fins.

From www.qats.com

What are the benefits of using Pin Fin Heat Sinks in thermal management Cutting Heat Sink Fins Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. The goal is to optimize. In a. Cutting Heat Sink Fins.

From www.semanticscholar.org

Figure 2 from Improved thermal design of fin heat sink for highpower Cutting Heat Sink Fins In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). The goal is to optimize. Tapping a hole through the heat sink,. Cutting Heat Sink Fins.

From www.lorithermal.com

Plate Fin Heat Sink Manufacturer Lori Cutting Heat Sink Fins The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. Skived heat sinks are produced using a sharp knive that, as. Cutting Heat Sink Fins.

From www.rapiddirect.com

Optimize Your Heat Sink Design Principles and Practical Tips RapidDirect Cutting Heat Sink Fins In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. This feature can easily be. In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. The heat sink fins are perforated with. Cutting Heat Sink Fins.

From www.finskiving.com

Fin skiving machines, Heat sink Fins skiving machines, heat sink fin Cutting Heat Sink Fins In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. The goal is to optimize. In a heat sink, conduction occurs as heat moves from. Cutting Heat Sink Fins.

From www.youtube.com

how to make skived fins heatsink YouTube Cutting Heat Sink Fins Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. In a heat sink application,. Cutting Heat Sink Fins.

From www.lorithermal.com

Custom Aluminum Skived Fin Heat Sink, Greenhouse heat sink manufacturer Cutting Heat Sink Fins In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. The goal is to optimize. In a heat sink, conduction occurs as heat moves from. Cutting Heat Sink Fins.

From www.amazon.com

Hobbypark 2Pack Aluminum Electric Motor Heat Sink Cooling Cutting Heat Sink Fins Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. In a heat sink application,. Cutting Heat Sink Fins.

From www.eenewseurope.com

Pinfin heatsinks minimise thermal resistance in forcedair coo... Cutting Heat Sink Fins Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. In general, a wavy fin heat sink should perform better under natural and forced convection due. Cutting Heat Sink Fins.

From rqdiecasting.en.made-in-china.com

Custom Aluminum Extrusion Dens Fins Heatsink Cutting Profile Chamfer Cutting Heat Sink Fins This feature can easily be. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). The goal is to optimize. Fins. Cutting Heat Sink Fins.

From www.heatsinksmfg.com

Copper Heat Sinks,Folded Fin Heat Sinks Pioneer Thermal Heat Sinks Cutting Heat Sink Fins The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. In general, a wavy fin heat sink should perform better under natural and forced convection due. Cutting Heat Sink Fins.

From www.mdpi.com

Materials Free FullText Evaluation of Active Heat Sinks Design Cutting Heat Sink Fins Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. In general, a wavy fin heat sink. Cutting Heat Sink Fins.

From www.mdpi.com

Inventions Free FullText A Quick Overview of Compact AirCooled Cutting Heat Sink Fins This feature can easily be. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. The goal is to optimize. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. In general, a wavy fin heat. Cutting Heat Sink Fins.

From www.diabatix.com

Pin Fin Heat Sink Applications Enhancing Thermal Management for Cutting Heat Sink Fins The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. This feature can easily be. Tapping a hole through the heat sink,. Cutting Heat Sink Fins.

From www.finskiving.com

Skived Fins Benefits, skived fins Advantages, advantages of heat sinks Cutting Heat Sink Fins Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. This feature can easily be. In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. Fins. Cutting Heat Sink Fins.

From tongchuangdg.en.made-in-china.com

Aluminum Profile Die Casting Extrusion Pin Fin Heat Sinks Customization Cutting Heat Sink Fins Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. The goal is to optimize. The heat sink fins are perforated with perforation number np (4, 8, 12, and 16) and perforation diameter dp (0.5 and 1 cm). Skived heat sinks are produced using a sharp knive. Cutting Heat Sink Fins.

From www.mdpi.com

Applied Sciences Free FullText A Modification of Offset Strip Fin Cutting Heat Sink Fins The goal is to optimize. This feature can easily be. In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. Skived heat. Cutting Heat Sink Fins.

From thermocoolcorp.com

Thermo Cool Skived fin heat sink Cutting Heat Sink Fins Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. This feature can easily be. The goal is to optimize. Skived heat sinks. Cutting Heat Sink Fins.

From tongchuangdg.en.made-in-china.com

Customizable Copper Fin Heat Sinks CNC Machining Quick Proofing China Cutting Heat Sink Fins In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface material (s), the heat sink’s base, and the fins. Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. The heat sink fins are perforated with perforation number np (4,. Cutting Heat Sink Fins.

From www.researchgate.net

continuous rectangular fins heat sink. Download Scientific Diagram Cutting Heat Sink Fins In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. The goal is to optimize. In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. Tapping a hole through the heat sink, without. Cutting Heat Sink Fins.

From www.indiamart.com

Square Fin Heat Sinks at best price in Vasai ID 11170466312 Cutting Heat Sink Fins Tapping a hole through the heat sink, without intersecting any part of a fin, is the easiest and most trouble free tapping process. This feature can easily be. The goal is to optimize. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. The heat sink fins are perforated. Cutting Heat Sink Fins.

From www.researchgate.net

(a). Plate fin heat sink. (b). Plate fin heat sink with inline dimples Cutting Heat Sink Fins In a heat sink application, conduction is critical for transferring heat from the heat source (e.g., electronic component) to the heat sink. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. In a heat sink, conduction occurs as heat moves from the electronic component through the thermal interface. Cutting Heat Sink Fins.

From www.researchgate.net

(a) Porous heat sink. (b) Plain view of a vertical fins heat sink. (c Cutting Heat Sink Fins In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. The heat sink. Cutting Heat Sink Fins.

From formalmetal.en.made-in-china.com

Aluminum Copper Pipe Heat Sink Fins CNC Machining Heat Sink China Cutting Heat Sink Fins Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. In general, a wavy fin heat sink should perform better under natural and forced convection due to the increased surface area created by the fins. Skived heat sinks are produced using a sharp knive that, as it passes over. Cutting Heat Sink Fins.

From heatsinkchina.com

kind of bonded fin heat sink type swaged heatsink Cutting Heat Sink Fins This feature can easily be. Fins can be cut or constructed in any number of geometries which often run perpendicular to the base to disperse heat. Skived heat sinks are produced using a sharp knive that, as it passes over the material, curl up a small thickness of metal which is then bent vertically to form the fin. The goal. Cutting Heat Sink Fins.