Crankshaft Induction Hardening . This article will explain how. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Induction hardening can be used for a wide. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines.

from dw-inductionheater.com

Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. This article will explain how. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction hardening can be used for a wide. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100.

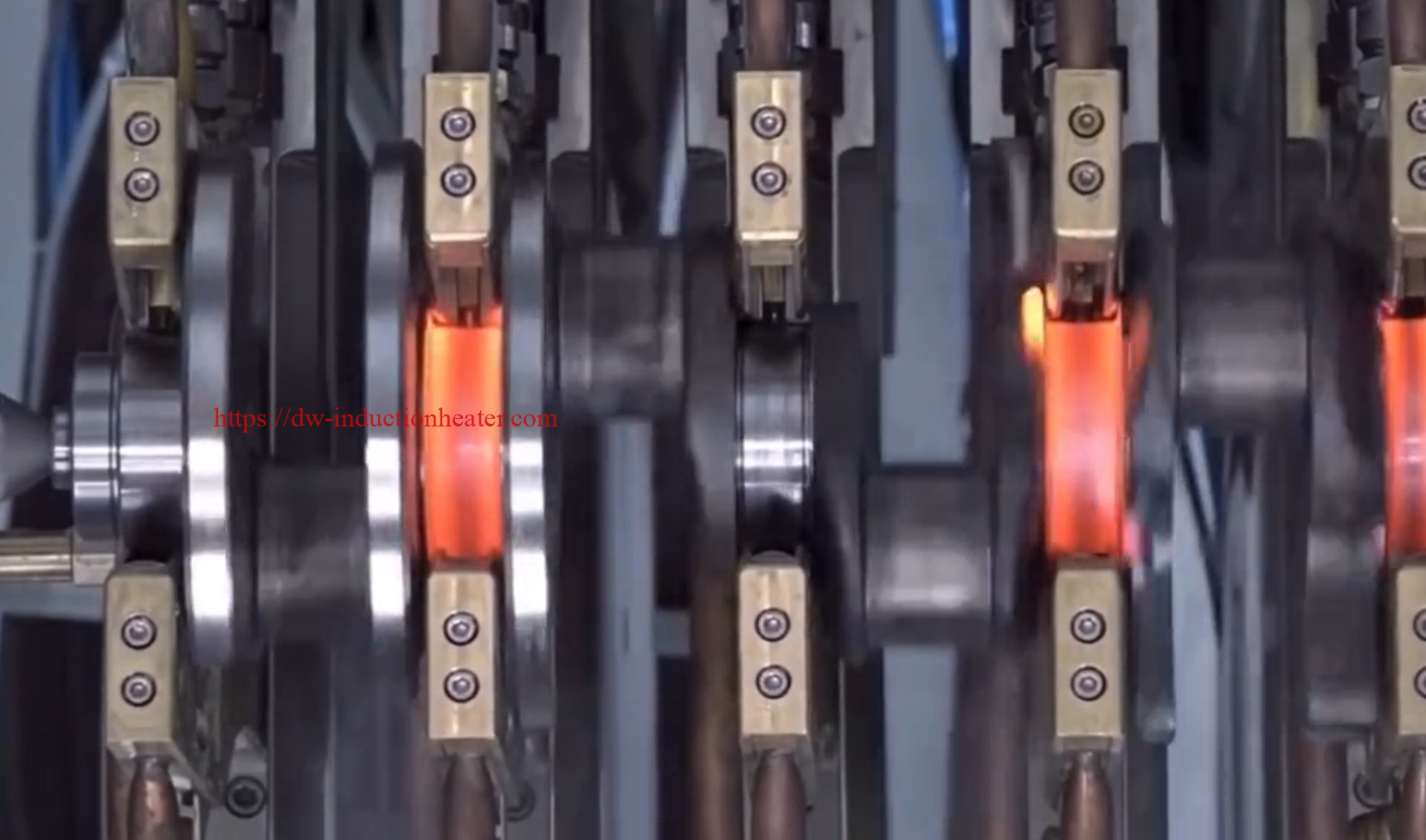

Induction crankshaft hardening surface to increase the durability

Crankshaft Induction Hardening Induction hardening can be used for a wide. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. This article will explain how. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Induction hardening can be used for a wide. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel.

From www.youtube.com

NSI Crankshaft Induction Hardening_3 YouTube Crankshaft Induction Hardening Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Induction hardening can be used for a wide. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100.. Crankshaft Induction Hardening.

From fluxtrol.com

Fluxtrol Optimizing Performance of Crankshaft Hardening Inductors Crankshaft Induction Hardening This article will explain how. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Induction hardening can be used for a wide. Induction heat treatment is a common method for. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction hardening can be used for a wide. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Efd induction crankshaft hardening systems are a proven way. Crankshaft Induction Hardening.

From www.youtube.com

Crankshaft induction hardening quenchinginductionheating Crankshaft Induction Hardening This article will explain how. Induction hardening can be used for a wide. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Efd induction. Crankshaft Induction Hardening.

From www.scantechlaser.com

Laser Surface Hardening of crankshaft Scantech Laser Crankshaft Induction Hardening Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. This article will explain how. Induction hardening can be used for a wide. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability. Crankshaft Induction Hardening.

From www.youtube.com

crankshaft hardening by induction heating YouTube Crankshaft Induction Hardening This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction hardening can be used for a wide. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction heat treatment is a common method for hardening and tempering. Crankshaft Induction Hardening.

From www.youtube.com

Crankshaft Hardening The Crankshaft Heat Treatment Process YouTube Crankshaft Induction Hardening Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. This revolutionary approach enables faster part production while delivering superior hardness quality. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components. Crankshaft Induction Hardening.

From gamma.app

Proses Induction Hardening Crankshaft Crankshaft Induction Hardening Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction hardening can be used for. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. This revolutionary approach enables faster part production while delivering superior hardness. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction hardening can be used for a wide. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. This revolutionary approach enables faster part production while delivering superior hardness quality over. Crankshaft Induction Hardening.

From www.youtube.com

induction hardening of crankshaft YouTube Crankshaft Induction Hardening This article will explain how. Induction hardening can be used for a wide. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts.. Crankshaft Induction Hardening.

From www.youtube.com

NSI Crankshaft Induction Hardening YouTube Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality. Crankshaft Induction Hardening.

From www.youtube.com

6BT Crankshaft High Frequency Induction Hardening Quenching Machine Crankshaft Induction Hardening Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction hardening can be used for a wide. This article will explain how. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment. Crankshaft Induction Hardening.

From www.youtube.com

NSI Crankshaft Induction Hardening_2 YouTube Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Induction heat treatment is. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Efd induction crankshaft hardening systems are. Crankshaft Induction Hardening.

From www.youtube.com

Crankshaft Induction Hardening Quenching Machine Shaft Heat Treatment Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. This article will explain how. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction heat treatment is traditionally a popular choice for hardening and. Crankshaft Induction Hardening.

From www.youtube.com

Crankshaft induction hardening Quenching machineshorts Crankshaft Induction Hardening Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. This article will explain how. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every. Crankshaft Induction Hardening.

From www.researchgate.net

(PDF) 3D simulation of induction hardening on truck crankshaft Crankshaft Induction Hardening Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Induction hardening uses induced heat and rapid cooling (quenching) to. Crankshaft Induction Hardening.

From www.youtube.com

High Frequency Induction Crankshaft Hardening Quenching System YouTube Crankshaft Induction Hardening This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction hardening can be used for a wide. This article will explain. Crankshaft Induction Hardening.

From www.youtube.com

6BT Crankshaft High Frequency Induction Hardening Quenching System Crankshaft Induction Hardening Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction heat treatment is. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Induction Hardening Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Induction hardening can be used for a wide. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Induction Hardening Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. This article will explain how. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised. Crankshaft Induction Hardening.

From inductionheattreatment.com

Crankshaft Induction Hardening Machine The Leading Induction Heating Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. This article will explain how. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Efd induction crankshaft hardening systems are a proven way to meet stringent. Crankshaft Induction Hardening.

From www.youtube.com

Crankshaft Hardening The benefits of induction heating YouTube Crankshaft Induction Hardening Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Hardline includes vertical, horizontal centreless, rotary table,. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction Hardening of Crankshafts Machine for Engine Crankshaft Crankshaft Induction Hardening This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. This article will explain how. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Induction hardening can be used for a wide. Induction heat treatment. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts.. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening This article will explain how. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary. Crankshaft Induction Hardening.

From www.youtube.com

Induction hardening crankshaft hardening Engineering YouTube Crankshaft Induction Hardening Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications,. Crankshaft Induction Hardening.

From www.youtube.com

Crank Shaft Hardening with Induction Heating Equipment YouTube Crankshaft Induction Hardening Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. This article will explain how. Used in induction hardening are sae 4140, 4150,. Crankshaft Induction Hardening.

From www.youtube.com

Crankshaft Induction Hardening By 120kw Induction Heating Machine YouTube Crankshaft Induction Hardening Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Induction heat treatment is a common method for hardening and tempering of crankshafts, which are necessary components in almost every internal. This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. This article will explain how. Induction hardening. Crankshaft Induction Hardening.

From inductionheattreatment.com

Crankshaft Induction Hardening Machine The Leading Induction Heating Crankshaft Induction Hardening Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. This article will explain how. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality. Crankshaft Induction Hardening.

From dw-inductionheater.com

Induction crankshaft hardening surface to increase the durability Crankshaft Induction Hardening This revolutionary approach enables faster part production while delivering superior hardness quality over other methods. Induction heat treatment is traditionally a popular choice for hardening and tempering of quality crankshafts. This article will explain how. Hardline includes vertical, horizontal centreless, rotary table, crankshaft, and customised machines. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while. Crankshaft Induction Hardening.

From www.youtube.com

Crankshaft Induction Hardening YouTube Crankshaft Induction Hardening This article will explain how. Used in induction hardening are sae 4140, 4150, 4340, 5150, 5140, and 52100. Efd induction crankshaft hardening systems are a proven way to meet stringent specifications, while at the same time. Induction hardening uses induced heat and rapid cooling (quenching) to increase the hardness and durability of steel. Hardline includes vertical, horizontal centreless, rotary table,. Crankshaft Induction Hardening.