Centrifugal Pump Design Calculations . How to do details calculations that will allow you to size and select a centrifugal pump? In order to understand how a fluid system. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. It is used to classify pump impellers as to. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. It is good practice to examine several performance. In selecting a pump, one of the concerns is to optimize pumping efficiency. Centrifugal pumps are one of the most common components inserted in fluid systems. The difference lies on one. In other words, the outlet flowrate of. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. How to verify that your centrifugal pump is providing. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. Of rotodynamic pump is the centrifugal pump (figure 1).

from chemicalprocessengineering.com

The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. In order to understand how a fluid system. It is good practice to examine several performance. It is used to classify pump impellers as to. How to do details calculations that will allow you to size and select a centrifugal pump? Centrifugal pumps are one of the most common components inserted in fluid systems. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. How to verify that your centrifugal pump is providing. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. In other words, the outlet flowrate of.

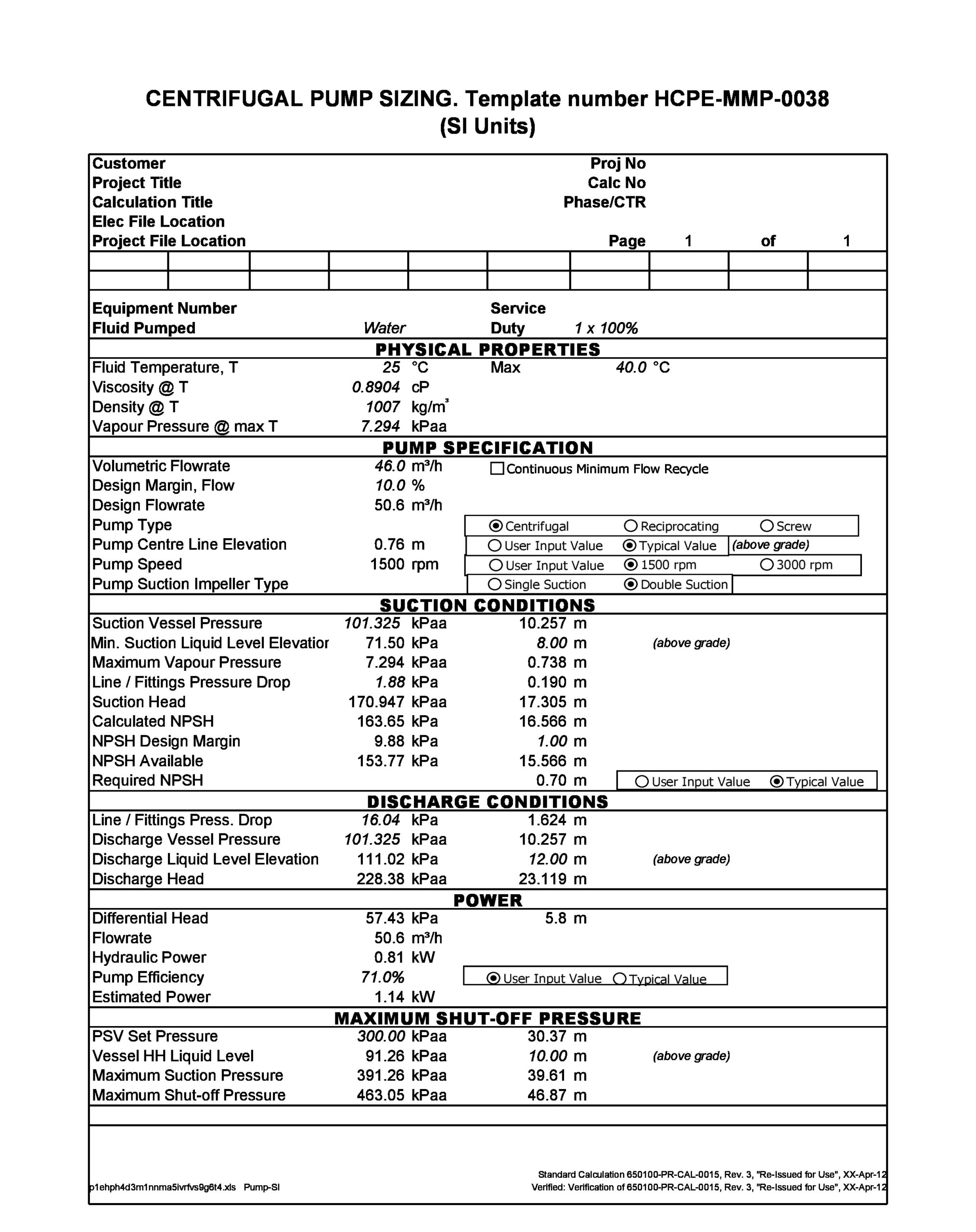

Calculation of centrifugal pump Excelsheet Template

Centrifugal Pump Design Calculations The difference lies on one. How to do details calculations that will allow you to size and select a centrifugal pump? In order to understand how a fluid system. The difference lies on one. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. Centrifugal pumps are one of the most common components inserted in fluid systems. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. In other words, the outlet flowrate of. How to verify that your centrifugal pump is providing. It is good practice to examine several performance. It is used to classify pump impellers as to. Of rotodynamic pump is the centrifugal pump (figure 1). In selecting a pump, one of the concerns is to optimize pumping efficiency. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping.

From www.youtube.com

centrifugal pump reading with calculation (mechanical engineering Centrifugal Pump Design Calculations How to verify that your centrifugal pump is providing. In order to understand how a fluid system. Centrifugal pumps are one of the most common components inserted in fluid systems. How to do details calculations that will allow you to size and select a centrifugal pump? In other words, the outlet flowrate of. It is used to classify pump impellers. Centrifugal Pump Design Calculations.

From theconstructor.org

Centrifugal Pump Components, Working, Types and Application Centrifugal Pump Design Calculations In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. It is used to classify pump impellers as to. The difference lies on one. The amount of liquid that. Centrifugal Pump Design Calculations.

From mavink.com

Centrifugal Pump Calculations Centrifugal Pump Design Calculations How to verify that your centrifugal pump is providing. Centrifugal pumps are one of the most common components inserted in fluid systems. Of rotodynamic pump is the centrifugal pump (figure 1). In selecting a pump, one of the concerns is to optimize pumping efficiency. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied. Centrifugal Pump Design Calculations.

From design.udlvirtual.edu.pe

Centrifugal Pump Suction Head Calculation Design Talk Centrifugal Pump Design Calculations It is used to classify pump impellers as to. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. Centrifugal pumps are one of the most common components inserted in fluid systems. In order to understand how a fluid system. How to do details calculations that will allow you to size. Centrifugal Pump Design Calculations.

From www.researchgate.net

1. Main components of a centrifugal pump (Taken from [47]) Download Centrifugal Pump Design Calculations How to do details calculations that will allow you to size and select a centrifugal pump? In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. It is good practice to examine several performance. The amount of liquid that passes through the pump is inversely proportional to the pressure at the. Centrifugal Pump Design Calculations.

From theengineeringmindset.com

Pump calculations The Engineering Mindset Centrifugal Pump Design Calculations In selecting a pump, one of the concerns is to optimize pumping efficiency. In other words, the outlet flowrate of. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. It is used to classify pump impellers as to. How to do details calculations that will allow you to size and. Centrifugal Pump Design Calculations.

From www.scribd.com

Centrifugal Pump Calculations Pump Dynamics (Mechanics) Centrifugal Pump Design Calculations In other words, the outlet flowrate of. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. Of rotodynamic pump is the centrifugal pump (figure 1). In selecting a pump, one of the concerns is to optimize pumping efficiency. It is used. Centrifugal Pump Design Calculations.

From www.mechanical-knowledge.com

Centrifugal pump calculation pdf Centrifugal Pump Design Calculations Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. Centrifugal pumps are one of the most common components inserted in fluid systems. In order to understand how a fluid system. It is used to classify pump impellers as to. How to. Centrifugal Pump Design Calculations.

From chemicalprocessengineering.com

Calculation of centrifugal pump Excelsheet Template Centrifugal Pump Design Calculations Of rotodynamic pump is the centrifugal pump (figure 1). In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. Centrifugal pumps are one. Centrifugal Pump Design Calculations.

From www.studypool.com

SOLUTION Centrifugal pump calculation Studypool Centrifugal Pump Design Calculations The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. In other words, the outlet flowrate of. How to do. Centrifugal Pump Design Calculations.

From www.youtube.com

Heads and Efficiencies of Centrifugal Pump Centrifugal pump Fluid Centrifugal Pump Design Calculations In other words, the outlet flowrate of. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. How to do. Centrifugal Pump Design Calculations.

From extrudesign.com

Heads And Efficiencies of a Centrifugal Pump ExtruDesign Centrifugal Pump Design Calculations Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. The first step on the way to the optimal pump is the selection. Centrifugal Pump Design Calculations.

From theengineeringmindset.com

Pump calculations The Engineering Mindset Centrifugal Pump Design Calculations Of rotodynamic pump is the centrifugal pump (figure 1). In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. How to verify that your centrifugal pump is providing. In other words, the outlet flowrate of. It is used to classify pump impellers as to. The amount of liquid that passes through. Centrifugal Pump Design Calculations.

From exyaljard.blob.core.windows.net

Centrifugal Pump Power Calculation Example at Bonnie Orr blog Centrifugal Pump Design Calculations How to do details calculations that will allow you to size and select a centrifugal pump? In other words, the outlet flowrate of. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. It is good practice to examine several performance. Variables evaluated by design engineers to determine this relationship include. Centrifugal Pump Design Calculations.

From www.academia.edu

(PDF) Design and Calculation of Centrifugal Pump (Impeller) For Water Centrifugal Pump Design Calculations The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. In other words, the outlet flowrate of. How to verify that your centrifugal pump is providing. In order to understand how a fluid system. The first step on the way to the optimal pump is the selection between a centrifugal pump. Centrifugal Pump Design Calculations.

From paseefm.weebly.com

Centrifugal Pump Sizing Calculation Pdf To Jpg paseefm Centrifugal Pump Design Calculations In other words, the outlet flowrate of. How to verify that your centrifugal pump is providing. In order to understand how a fluid system. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. The first step on the way to the optimal pump is the selection between a centrifugal pump. Centrifugal Pump Design Calculations.

From chemicalprocessengineering.com

Centrifugal Pump Calculation Excel Template Centrifugal Pump Design Calculations Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. It is good practice to examine several performance. Of rotodynamic pump is the centrifugal pump (figure 1). The first step on the way to the optimal pump is the selection between a. Centrifugal Pump Design Calculations.

From www.scribd.com

Centrifugal Pumps Calculations PDF Centrifugal Pump Design Calculations In selecting a pump, one of the concerns is to optimize pumping efficiency. How to do details calculations that will allow you to size and select a centrifugal pump? The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. Centrifugal pumps are one of the most common components. Centrifugal Pump Design Calculations.

From theengineeringmindset.com

Pump calculations The Engineering Mindset Centrifugal Pump Design Calculations How to do details calculations that will allow you to size and select a centrifugal pump? Centrifugal pumps are one of the most common components inserted in fluid systems. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. The difference lies on one. Variables evaluated by design engineers to determine. Centrifugal Pump Design Calculations.

From joihpjmxx.blob.core.windows.net

Power Calculation For Centrifugal Pump at Virginia Gies blog Centrifugal Pump Design Calculations How to do details calculations that will allow you to size and select a centrifugal pump? Of rotodynamic pump is the centrifugal pump (figure 1). It is used to classify pump impellers as to. Centrifugal pumps are one of the most common components inserted in fluid systems. In order to understand how a fluid system. Variables evaluated by design engineers. Centrifugal Pump Design Calculations.

From www.pumpsandsystems.com

How to Define & Measure Centrifugal Pump Efficiency Part 1 Pumps Centrifugal Pump Design Calculations How to verify that your centrifugal pump is providing. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. How to do details calculations that will allow you to size and select a centrifugal pump? The amount of liquid that passes through the pump is inversely proportional to the pressure at. Centrifugal Pump Design Calculations.

From www.rotechpumps.com

Understanding Centrifugal Pump Flow Rate Formula and Calculation Centrifugal Pump Design Calculations In selecting a pump, one of the concerns is to optimize pumping efficiency. Of rotodynamic pump is the centrifugal pump (figure 1). The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. How to verify that your centrifugal pump is providing. The difference lies on one. The amount. Centrifugal Pump Design Calculations.

From www.rotechpumps.com

Understanding Pump Curves for Centrifugal Pumps A Comprehensive Guide Centrifugal Pump Design Calculations The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. In other words, the outlet flowrate of. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. It is used to classify pump impellers as to. The first step on the way. Centrifugal Pump Design Calculations.

From www.electroniclinic.com

Centrifugal Pump Working with impeller types explained Centrifugal Pump Design Calculations In other words, the outlet flowrate of. The difference lies on one. In order to understand how a fluid system. Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. It is good practice to examine several performance. How to do details. Centrifugal Pump Design Calculations.

From mavink.com

Centrifugal Pump Calculations Centrifugal Pump Design Calculations Variables evaluated by design engineers to determine this relationship include the pump efficiency, the power supplied to the pump, the rotational speed, the diameter of the impeller and. How to verify that your centrifugal pump is providing. In order to understand how a fluid system. Of rotodynamic pump is the centrifugal pump (figure 1). Centrifugal pumps are one of the. Centrifugal Pump Design Calculations.

From www.semanticscholar.org

Figure 2 from Numerical Calculation of the Flow in a Centrifugal Pump Centrifugal Pump Design Calculations It is good practice to examine several performance. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. It is used to classify pump impellers as to. In other words, the outlet flowrate of. Of rotodynamic pump is the centrifugal pump (figure 1). The difference lies on one. Variables evaluated by. Centrifugal Pump Design Calculations.

From www.sintechpumps.com

Calculating the Efficiency of Centrifugal Pumps Sintech Blog Centrifugal Pump Design Calculations Of rotodynamic pump is the centrifugal pump (figure 1). In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. In order to understand how a fluid system. Centrifugal pumps are one of the most common components inserted in fluid systems. In selecting a pump, one of the concerns is to optimize. Centrifugal Pump Design Calculations.

From blog.softinway.com

An Introduction to Centrifugal Pumps Turbomachinery blog Centrifugal Pump Design Calculations The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. How to do details calculations that will allow you to size and select a centrifugal pump? In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. Of rotodynamic pump is the centrifugal. Centrifugal Pump Design Calculations.

From www.mechanicalbooster.com

Centrifugal Pump Working Principle, Main Parts with Application Centrifugal Pump Design Calculations How to verify that your centrifugal pump is providing. Of rotodynamic pump is the centrifugal pump (figure 1). In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. In selecting a pump, one of the concerns is to optimize pumping efficiency. How to do details calculations that will allow you to. Centrifugal Pump Design Calculations.

From cermrmlq.blob.core.windows.net

Centrifugal Pump Working Animation Video at Ronald Pancoast blog Centrifugal Pump Design Calculations In selecting a pump, one of the concerns is to optimize pumping efficiency. It is good practice to examine several performance. The difference lies on one. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. How to verify that your centrifugal pump is providing. Variables evaluated by. Centrifugal Pump Design Calculations.

From es.scribd.com

Centrifugal Pumps & Fluid Flow Practical Calculations Course Centrifugal Pump Design Calculations It is used to classify pump impellers as to. In other words, the outlet flowrate of. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. In order to understand how a. Centrifugal Pump Design Calculations.

From silkhead.weebly.com

Centrifugal Pump Sizing Calculation Pdf To Jpg silkhead Centrifugal Pump Design Calculations How to do details calculations that will allow you to size and select a centrifugal pump? It is used to classify pump impellers as to. In selecting a pump, one of the concerns is to optimize pumping efficiency. It is good practice to examine several performance. The difference lies on one. In other words, the outlet flowrate of. Centrifugal pumps. Centrifugal Pump Design Calculations.

From mavink.com

Centrifugal Pump Calculations Centrifugal Pump Design Calculations The difference lies on one. In this article we learn how to perform pump calculations in both imperial and metric units to assess pumping. How to verify that your centrifugal pump is providing. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. How to do details calculations. Centrifugal Pump Design Calculations.

From exyaljard.blob.core.windows.net

Centrifugal Pump Power Calculation Example at Bonnie Orr blog Centrifugal Pump Design Calculations In selecting a pump, one of the concerns is to optimize pumping efficiency. In other words, the outlet flowrate of. The amount of liquid that passes through the pump is inversely proportional to the pressure at the pump outlet. It is good practice to examine several performance. The first step on the way to the optimal pump is the selection. Centrifugal Pump Design Calculations.

From www.researchgate.net

Centrifugal pump design (a) geometry; (b) impeller blade profile Centrifugal Pump Design Calculations It is used to classify pump impellers as to. The first step on the way to the optimal pump is the selection between a centrifugal pump or a positive displacement pump. The difference lies on one. In selecting a pump, one of the concerns is to optimize pumping efficiency. In order to understand how a fluid system. Centrifugal pumps are. Centrifugal Pump Design Calculations.