Wire Rope Breaks . one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! what can cause a wire rope to break? Wear on areas that are in contact with hoist sheaves and drums. The most difficult to detect wire rope deterioration. Corrosion from lack of lubrication and. the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter. wire rope in continuous service should be checked daily during normal operation and inspected weekly.

from oliverrandall.z13.web.core.windows.net

one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Wear on areas that are in contact with hoist sheaves and drums. the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. what can cause a wire rope to break? The most difficult to detect wire rope deterioration. wire rope in continuous service should be checked daily during normal operation and inspected weekly. Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter. Corrosion from lack of lubrication and.

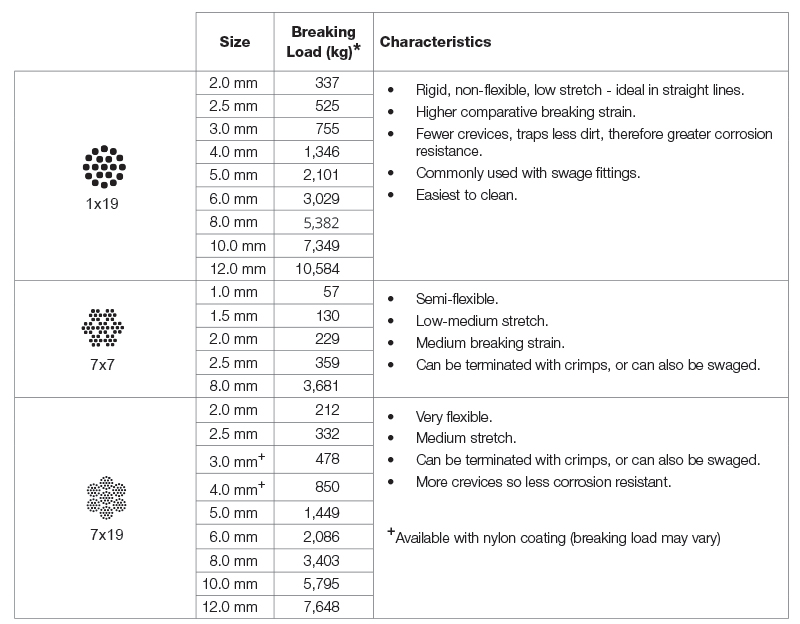

Wire Rope Breaking Strength Chart

Wire Rope Breaks The most difficult to detect wire rope deterioration. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. The most difficult to detect wire rope deterioration. what can cause a wire rope to break? crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. wire rope in continuous service should be checked daily during normal operation and inspected weekly. Wear on areas that are in contact with hoist sheaves and drums. Corrosion from lack of lubrication and. Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter.

From www.ropeiq.co.uk

Rope IQ Termination Wire Breaks in Wire Rope Wire Rope Breaks Corrosion from lack of lubrication and. Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter. Wear on areas that are in contact with hoist sheaves and drums. The most difficult to detect wire rope deterioration. crane wire ropes are regarded as an expendable component and we need to take proper. Wire Rope Breaks.

From oliverrandall.z13.web.core.windows.net

Wire Rope Breaking Strength Chart Wire Rope Breaks what can cause a wire rope to break? the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. Corrosion from. Wire Rope Breaks.

From mininglifeonline.net

Cable Safety Lock CSL001 (Rope Break) Wire Rope Breaks crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Corrosion from lack of lubrication and. the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. wire rope in continuous service should. Wire Rope Breaks.

From www.youtube.com

Wire Rope Break Test YouTube Wire Rope Breaks what can cause a wire rope to break? if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! Corrosion from lack of lubrication and. The most difficult to detect wire rope deterioration. crane wire ropes are regarded as an expendable component and we need to take proper care of them. Wire Rope Breaks.

From www.equipmentandcontracting.com

How to Prevent Hoist Wire Rope Failures Equipment & Contracting Wire Rope Breaks Wear on areas that are in contact with hoist sheaves and drums. wire rope in continuous service should be checked daily during normal operation and inspected weekly. Corrosion from lack of lubrication and. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! what can cause a wire rope to. Wire Rope Breaks.

From www.researchgate.net

Bending fatigue breaks on ropes made out of compacted outer strands Wire Rope Breaks crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Corrosion from lack of lubrication and. wire rope in continuous service should be checked daily during normal operation and inspected weekly. Check to see if the groove diameter is no greater than 15% greater. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Check to see if the groove diameter is. Wire Rope Breaks.

From www.iqsdirectory.com

Wire Rope What Is It? How Is It Made? Uses, Metals Wire Rope Breaks if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! wire rope in continuous service should be checked daily during normal operation and inspected weekly. Corrosion from lack of lubrication and. Wear on areas that are in contact with hoist sheaves and drums. Check to see if the groove diameter is. Wire Rope Breaks.

From wirerope.net

Wire Breaks Arizona Wire Rope Wire Rope Breaks Corrosion from lack of lubrication and. the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! Wear on areas that are in contact with hoist sheaves and drums. The most. Wire Rope Breaks.

From crane.pk

Wire Rope Abuse AICRANE Pakistan Wire Rope Breaks Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter. Wear on areas that are in contact with hoist sheaves and drums. what can cause a wire rope to break? if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! The most difficult. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks Corrosion from lack of lubrication and. crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. The most. Wire Rope Breaks.

From southwestwirerope.com

Break Testing of Wire Rope Southwest Wire Rope Wire Rope Breaks wire rope in continuous service should be checked daily during normal operation and inspected weekly. Wear on areas that are in contact with hoist sheaves and drums. the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. if you're using or inspecting wire rope, it's important. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks what can cause a wire rope to break? the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter. wire rope in continuous service should be checked daily during. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! The most difficult to detect wire rope deterioration. the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. Check to see if the groove diameter is no greater than 15%. Wire Rope Breaks.

From www.equipmentandcontracting.com

How to Prevent Hoist Wire Rope Failures Equipment & Contracting Wire Rope Breaks if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. Corrosion from lack of lubrication and. crane wire ropes are regarded as an expendable component and we need to. Wire Rope Breaks.

From www.shenwei-steelwirerope.com

Why Does Galvanized Steel Wire Rope Break? News Nantong Shenwei Wire Rope Breaks The most difficult to detect wire rope deterioration. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. what can cause a wire rope to break? crane wire ropes are regarded as an expendable component and we need to take proper. Wire Rope Breaks.

From www.gsproducts.co.uk

wireropebreak GS Products Blog Wire Rope Breaks The most difficult to detect wire rope deterioration. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter. if you're using or inspecting wire. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks wire rope in continuous service should be checked daily during normal operation and inspected weekly. Corrosion from lack of lubrication and. Wear on areas that are in contact with hoist sheaves and drums. crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. The. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. wire rope in continuous service should be checked daily during normal operation and inspected weekly. Corrosion from lack of lubrication and. what can cause a wire rope to break? if. Wire Rope Breaks.

From studycampuslemann.z19.web.core.windows.net

Wire Rope Breaking Strength Chart Wire Rope Breaks wire rope in continuous service should be checked daily during normal operation and inspected weekly. Wear on areas that are in contact with hoist sheaves and drums. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. the number and type. Wire Rope Breaks.

From www.maintworld.com

Steel Wire Rope Failures Who Is Accountable? HSE Maintworld Wire Rope Breaks crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. what can cause a wire rope to break? the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. Corrosion from lack of. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks wire rope in continuous service should be checked daily during normal operation and inspected weekly. Wear on areas that are in contact with hoist sheaves and drums. The most difficult to detect wire rope deterioration. what can cause a wire rope to break? one line of broken wires running along the length of the rope indicating insufficient. Wire Rope Breaks.

From www.youtube.com

Wire Rope Break YouTube Wire Rope Breaks crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! one line of broken wires running along the length of the rope indicating insufficient support for. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! Corrosion from lack of lubrication and. The most difficult to detect wire rope deterioration. Wear on areas that are in contact with hoist sheaves and drums. Check to see if the groove diameter is no greater than 15% greater than the nominal. Wire Rope Breaks.

From www.youtube.com

Chant Engineering Wire Rope Break Test YouTube Wire Rope Breaks Check to see if the groove diameter is no greater than 15% greater than the nominal rope diameter. wire rope in continuous service should be checked daily during normal operation and inspected weekly. The most difficult to detect wire rope deterioration. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks!. Wire Rope Breaks.

From www.dgcrane.com

Inspection And Discard Criteria of Wire Ropes DGCRANE Wire Rope Breaks Corrosion from lack of lubrication and. crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Wear on areas that are in contact with hoist sheaves and drums. the number and type of broken wires are an indication of the rope’s general condition and. Wire Rope Breaks.

From www.alllifting.com.au

Fraying Wire Rope All Lifting Wire Rope Breaks crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. if you're using or inspecting wire rope, it's important to know about. Wire Rope Breaks.

From mungfali.com

Wire Rope Strand Wire Rope Breaks Wear on areas that are in contact with hoist sheaves and drums. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. wire rope in continuous service should be checked daily during normal operation and inspected weekly. the number and type. Wire Rope Breaks.

From ceqhhtmz.blob.core.windows.net

Wire Crimping Defects at Lawrence Cano blog Wire Rope Breaks crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Wear on areas that are in contact with hoist sheaves and drums. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! what can cause a. Wire Rope Breaks.

From www.pinterest.com

The rope life is finite and the safety is only ensured by inspection Wire Rope Breaks wire rope in continuous service should be checked daily during normal operation and inspected weekly. The most difficult to detect wire rope deterioration. Corrosion from lack of lubrication and. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. crane wire. Wire Rope Breaks.

From www.pinterest.com

Chant Engineering 850K Wire Rope Break Test Final inhouse test Wire Rope Breaks Wear on areas that are in contact with hoist sheaves and drums. if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! The most difficult to detect wire rope deterioration. what can cause a wire rope to break? one line of broken wires running along the length of the rope. Wire Rope Breaks.

From www.youtube.com

Calculate Breaking Strength of wire rope Sling Calculate Factor of Wire Rope Breaks if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. crane wire ropes are regarded as an expendable component and we need to take. Wire Rope Breaks.

From www.ntmetalmill.com

News The introduction of steel wire rope Wire Rope Breaks wire rope in continuous service should be checked daily during normal operation and inspected weekly. The most difficult to detect wire rope deterioration. one line of broken wires running along the length of the rope indicating insufficient support for the rope, generally caused by oversize sheave or drum grooving. Corrosion from lack of lubrication and. the number. Wire Rope Breaks.

From liftingandrigging.com.my

lifting and rigging Crane wire rope findings and failures Wire Rope Breaks if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! the number and type of broken wires are an indication of the rope’s general condition and a benchmark for its replacement. Wear on areas that are in contact with hoist sheaves and drums. Corrosion from lack of lubrication and. The most. Wire Rope Breaks.

From wirerope-sling.com

Commercial Grade Aircraft Wire Cable , Galvanized Wire Rope Break Wire Rope Breaks if you're using or inspecting wire rope, it's important to know about crown and valley wire breaks! Wear on areas that are in contact with hoist sheaves and drums. wire rope in continuous service should be checked daily during normal operation and inspected weekly. The most difficult to detect wire rope deterioration. crane wire ropes are regarded. Wire Rope Breaks.