G Code Lathe Peck . The peck depth is set using the q code. The g83 peck drilling cycle retracts above the surface of the component after each peck. The retracted height is controlled by the value r within. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. G73 tells the cnc to retract a small amount after each peck. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. Ready to master cnc programming? Here is a cnc programming example for simple drilling on a cnc lathe machine. This time, he will be talking. The bigger the depth of peck is, the faster the drilling operation will be. Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. If the control has a. Cnc fanuc control has a very powerful and versatile peck drilling. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. So, in this sense, choosing an appropriate peck distance can speed up machining time.

from gcodetutor.com

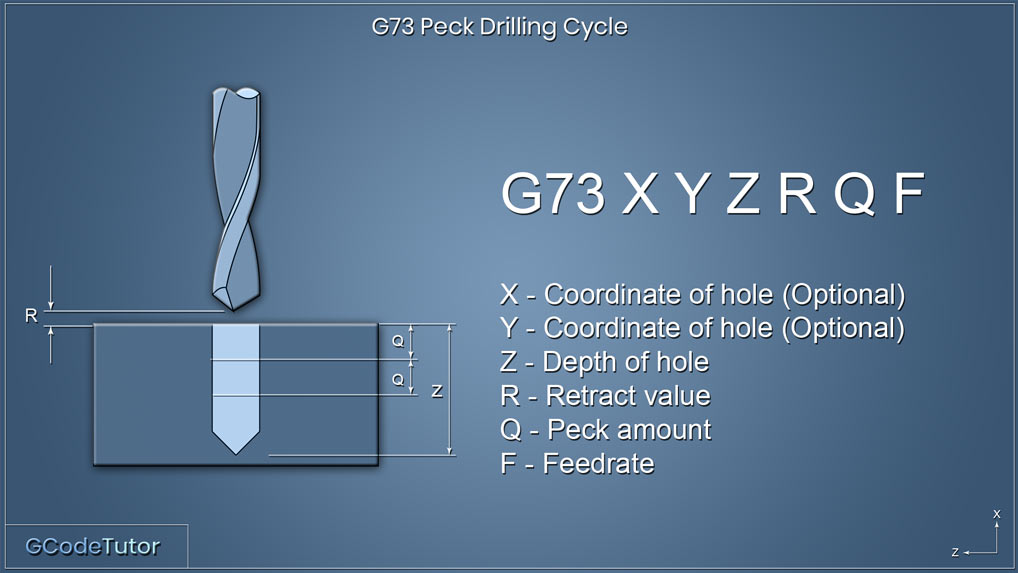

Cnc fanuc control has a very powerful and versatile peck drilling. G73 tells the cnc to retract a small amount after each peck. The retracted height is controlled by the value r within. The bigger the depth of peck is, the faster the drilling operation will be. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. The g83 peck drilling cycle retracts above the surface of the component after each peck. So, in this sense, choosing an appropriate peck distance can speed up machining time. The peck depth is set using the q code. Ready to master cnc programming? This is a lesson on programming peck drilling cycles from the online course cnc lathe programming.

G73 and G83 Peck Drilling Cycles

G Code Lathe Peck This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. If the control has a. This time, he will be talking. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. G73 tells the cnc to retract a small amount after each peck. The peck depth is set using the q code. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. Ready to master cnc programming? So, in this sense, choosing an appropriate peck distance can speed up machining time. Here is a cnc programming example for simple drilling on a cnc lathe machine. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. The retracted height is controlled by the value r within. Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. Many controls have a peck option on the g75 grooving code, which is also used for parting off. Cnc fanuc control has a very powerful and versatile peck drilling. The g83 peck drilling cycle retracts above the surface of the component after each peck.

From gcodetutor.com

CNC G Codes Learn how to program CNC machines with GCode G Code Lathe Peck The bigger the depth of peck is, the faster the drilling operation will be. Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. If the control has a. The peck depth is set using the q code.. G Code Lathe Peck.

From www.youtube.com

The G83 & G73 Peck drilling cycles on a CNC lathe or machining centre G Code Lathe Peck The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. Ready to master cnc programming? Cnc fanuc control has a very powerful and versatile peck drilling. Many controls have a peck option on the g75 grooving code, which is also used. G Code Lathe Peck.

From suudavidmcgrath.blogspot.com

lathe boring g code David McGrath G Code Lathe Peck So, in this sense, choosing an appropriate peck distance can speed up machining time. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. Here is a cnc programming example for simple drilling on a cnc lathe machine. If the control. G Code Lathe Peck.

From www.youtube.com

CNC Lathe GCode programming course Advert YouTube G Code Lathe Peck The bigger the depth of peck is, the faster the drilling operation will be. Many controls have a peck option on the g75 grooving code, which is also used for parting off. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. The g83 peck drilling cycle retracts above the surface of the component. G Code Lathe Peck.

From cncprogrammingx.blogspot.com

Cnc Programming G Code Lathe Peck The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. So, in this sense, choosing an appropriate peck distance can speed up machining time. Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. Here. G Code Lathe Peck.

From www.youtube.com

CNC PROGRAMMING How to Use GCodes in CNC Program. G41 and G42 Use in G Code Lathe Peck Here is a cnc programming example for simple drilling on a cnc lathe machine. Ready to master cnc programming? This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. The retracted height is controlled by the value r within. If the control has a. The practice of peck drilling refers to drilling a hole. G Code Lathe Peck.

From suudavidmcgrath.blogspot.com

lathe boring g code David McGrath G Code Lathe Peck So, in this sense, choosing an appropriate peck distance can speed up machining time. The bigger the depth of peck is, the faster the drilling operation will be. Many controls have a peck option on the g75 grooving code, which is also used for parting off. Cnc fanuc control has a very powerful and versatile peck drilling. G73 is a. G Code Lathe Peck.

From www.semanticscholar.org

DESIGN AND IMPLEMENTATION OF FPGA BASED G CODE COMPATIBLE CNC LATHE G Code Lathe Peck So, in this sense, choosing an appropriate peck distance can speed up machining time. The g83 peck drilling cycle retracts above the surface of the component after each peck. The retracted height is controlled by the value r within. The peck depth is set using the q code. This is a lesson on programming peck drilling cycles from the online. G Code Lathe Peck.

From www.machinistguides.com

Quick Guide to the G84 CNC Code [Tapping] G Code Lathe Peck This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. So, in this sense, choosing an appropriate peck distance can speed up machining time. Here is a cnc programming example for simple drilling on a cnc lathe machine. The bigger the depth of peck is, the faster the drilling operation will be. Cnc fanuc. G Code Lathe Peck.

From www.scribd.com

A Comprehensive Guide to CNC G Codes and M Codes for Milling and Lathe G Code Lathe Peck The peck depth is set using the q code. The g83 peck drilling cycle retracts above the surface of the component after each peck. So, in this sense, choosing an appropriate peck distance can speed up machining time. Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. G73 tells the cnc to retract. G Code Lathe Peck.

From gcodetutor.com

G75 Groove Cycle CNC Lathe GCode tutorial G Code Lathe Peck So, in this sense, choosing an appropriate peck distance can speed up machining time. Many controls have a peck option on the g75 grooving code, which is also used for parting off. G73 tells the cnc to retract a small amount after each peck. Here is a cnc programming example for simple drilling on a cnc lathe machine. This is. G Code Lathe Peck.

From gcodetutor.com

CNC G Codes Learn how to program CNC machines with GCode G Code Lathe Peck Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. The g83 peck drilling cycle retracts above the surface of the component after each peck.. G Code Lathe Peck.

From www.intexspeed.com

CNC Machine G Codes and M Codes full explanation tutorial G Code Lathe Peck The peck depth is set using the q code. Cnc fanuc control has a very powerful and versatile peck drilling. This time, he will be talking. The g83 peck drilling cycle retracts above the surface of the component after each peck. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. Here is a. G Code Lathe Peck.

From www.youtube.com

Programming Peck Drilling Cycles with GCode YouTube G Code Lathe Peck If the control has a. Many controls have a peck option on the g75 grooving code, which is also used for parting off. Ready to master cnc programming? This time, he will be talking. The retracted height is controlled by the value r within. Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter.. G Code Lathe Peck.

From www.youtube.com

G code Generation CNC Programming Lathe YouTube G Code Lathe Peck Ready to master cnc programming? G73 is a modal command that sets the cnc machine to run a peck drilling cycle. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. The retracted height is controlled by the value r within. Cnc fanuc control has a very powerful and versatile peck drilling. Usually, when. G Code Lathe Peck.

From www.youtube.com

CNC LATHE PROGRAMMING G74 PECK DRILLING CYCLE HOW TO DRILL IN CNC G Code Lathe Peck If the control has a. Ready to master cnc programming? Here is a cnc programming example for simple drilling on a cnc lathe machine. The peck depth is set using the q code. So, in this sense, choosing an appropriate peck distance can speed up machining time. G73 is a modal command that sets the cnc machine to run a. G Code Lathe Peck.

From gcodetutor.com

G73 and G83 Peck Drilling Cycles G Code Lathe Peck The peck depth is set using the q code. The retracted height is controlled by the value r within. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole. G Code Lathe Peck.

From www.pinterest.com

Programming Peck Drilling Cycles with GCode Coding, Drill, Tutor G Code Lathe Peck Ready to master cnc programming? Many controls have a peck option on the g75 grooving code, which is also used for parting off. The g83 peck drilling cycle retracts above the surface of the component after each peck. The peck depth is set using the q code. G73 is a modal command that sets the cnc machine to run a. G Code Lathe Peck.

From www.machinistguides.com

Quick Guide to the G83 CNC G Code [Peck Drilling] Machinist Guides G Code Lathe Peck This time, he will be talking. Ready to master cnc programming? G73 tells the cnc to retract a small amount after each peck. The bigger the depth of peck is, the faster the drilling operation will be. The g83 peck drilling cycle retracts above the surface of the component after each peck. So, in this sense, choosing an appropriate peck. G Code Lathe Peck.

From www.pinterest.com

CNC Programming Courses in 2020 Cnc programming, Cnc milling machine G Code Lathe Peck G73 tells the cnc to retract a small amount after each peck. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. Many controls have a peck option on the g75 grooving code, which is also used for parting off. The. G Code Lathe Peck.

From www.artofit.org

G82 counter boring cycle on a cnc lathe Artofit G Code Lathe Peck The g83 peck drilling cycle retracts above the surface of the component after each peck. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. If the control has a. So, in this sense, choosing an appropriate peck distance can speed. G Code Lathe Peck.

From www.cnctrainingcentre.com

G73 Peck Drilling Example (Canned Cycle) CNC Training Centre G Code Lathe Peck The retracted height is controlled by the value r within. The peck depth is set using the q code. Ready to master cnc programming? Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. This time, he will be talking. Many controls have a peck option on the g75 grooving code, which is also. G Code Lathe Peck.

From www.youtube.com

Mastercam Tips and Tricks 6 Peck Tapping, Rigid Peck Tapping Cycle G Code Lathe Peck G73 tells the cnc to retract a small amount after each peck. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. The g83 peck drilling cycle retracts above the surface of the component after each peck. Ready to master cnc programming? Here is a cnc programming example for simple drilling on a cnc. G Code Lathe Peck.

From www.youtube.com

G code for beginners part 3 G83 Peck Drilling and M98 M99 subprogram G Code Lathe Peck Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. Many controls have a peck option on the g75 grooving code, which is also used for parting off. G73 tells the cnc to retract a small amount after each peck. This time, he will be talking. So, in this sense, choosing an appropriate peck. G Code Lathe Peck.

From www.liveauctionworld.com

HAAS TL1 CNC LATHE, PROGRAMMABLE, POSITION TURRET, QUICK CODE, G CODE G Code Lathe Peck The retracted height is controlled by the value r within. So, in this sense, choosing an appropriate peck distance can speed up machining time. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. The g83 peck drilling. G Code Lathe Peck.

From shuntool.com

Understanding G Codes The Basics Of Lathe Programming ShunTool G Code Lathe Peck Ready to master cnc programming? The retracted height is controlled by the value r within. Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. Cnc fanuc control has a very powerful and versatile peck drilling. G73 tells the cnc to retract a small amount after each peck. The g83 peck drilling cycle retracts. G Code Lathe Peck.

From www.xecnc.com

Let's write GCode Programming a CNC Lathe to make a bush part 4 G Code Lathe Peck This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. The bigger the depth of peck is, the faster the drilling operation will be. G73 tells the cnc to retract a small amount after each peck. The retracted height is controlled by the value r within. The peck depth is set using the q. G Code Lathe Peck.

From www.cncknowledge.in

CNC KNOWLEDGE G Code Lathe Peck This time, he will be talking. The bigger the depth of peck is, the faster the drilling operation will be. If the control has a. Many controls have a peck option on the g75 grooving code, which is also used for parting off. The peck depth is set using the q code. G73 tells the cnc to retract a small. G Code Lathe Peck.

From www.machinistguides.com

Quick Guide to the G98 CNC Code [Return to Initial Plane G Code Lathe Peck G73 is a modal command that sets the cnc machine to run a peck drilling cycle. The g83 peck drilling cycle retracts above the surface of the component after each peck. The bigger the depth of peck is, the faster the drilling operation will be. This time, he will be talking. This is a lesson on programming peck drilling cycles. G Code Lathe Peck.

From gcodetutor.com

CNC G Codes Learn how to program CNC machines with GCode G Code Lathe Peck Usually, when using g83, the maximum peck distance recommended will be equal to the hole’s diameter. This time, he will be talking. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. If the control has a. Here is a cnc programming example for simple drilling on a cnc lathe machine. Ready to master. G Code Lathe Peck.

From www.scribd.com

GCode Quick Reference Lathe PDF G Code Lathe Peck Cnc fanuc control has a very powerful and versatile peck drilling. The retracted height is controlled by the value r within. Ready to master cnc programming? Many controls have a peck option on the g75 grooving code, which is also used for parting off. Here is a cnc programming example for simple drilling on a cnc lathe machine. The g83. G Code Lathe Peck.

From latheinfo.com

Mastering Haas Lathe G Codes Your Professional Guide G Code Lathe Peck Ready to master cnc programming? Cnc fanuc control has a very powerful and versatile peck drilling. This is a lesson on programming peck drilling cycles from the online course cnc lathe programming. The peck depth is set using the q code. If the control has a. The g83 peck drilling cycle retracts above the surface of the component after each. G Code Lathe Peck.

From www.micoope.com.gt

G84 GCode Programming Tapping Cycles In CNC, 52 OFF G Code Lathe Peck The bigger the depth of peck is, the faster the drilling operation will be. The practice of peck drilling refers to drilling a hole in a series of steps (pecks) instead of drilling the complete depth of the hole in a single pass. So, in this sense, choosing an appropriate peck distance can speed up machining time. G73 is a. G Code Lathe Peck.

From cewhwirr.blob.core.windows.net

Tapping Cycle GCode Lathe at Benjamin Sweeney blog G Code Lathe Peck So, in this sense, choosing an appropriate peck distance can speed up machining time. The g83 peck drilling cycle retracts above the surface of the component after each peck. G73 is a modal command that sets the cnc machine to run a peck drilling cycle. The practice of peck drilling refers to drilling a hole in a series of steps. G Code Lathe Peck.

From www.autodesk.com

GCode for CNC Programming Fusion 360 Blog G Code Lathe Peck Here is a cnc programming example for simple drilling on a cnc lathe machine. The peck depth is set using the q code. So, in this sense, choosing an appropriate peck distance can speed up machining time. The bigger the depth of peck is, the faster the drilling operation will be. This time, he will be talking. The retracted height. G Code Lathe Peck.