Laser Marking Quality Control . In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Laser marking at a glance marking lasers perform more and more tasks in the industry. Verification uses a set of quality measures developed specifically for dpmi. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Critical components are marked with. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. In this manual, you can find out what role marking lasers play in.

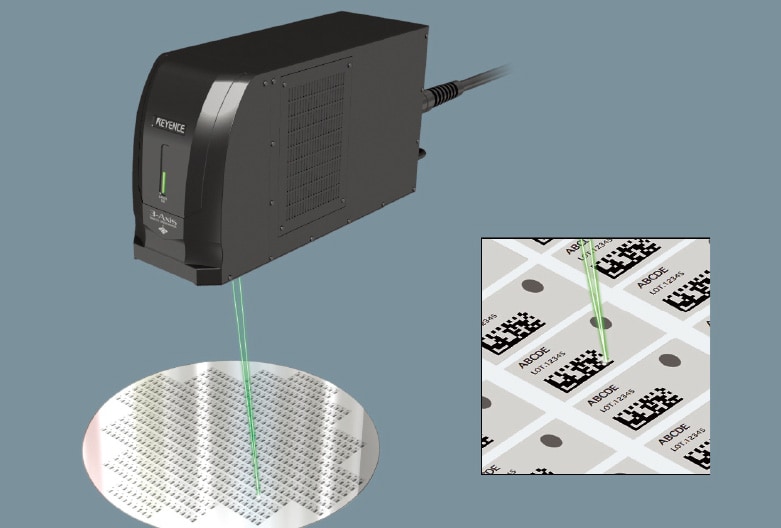

from www.keyence.com

Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. In the automotive industry, laser marking is essential for parts identification and traceability. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Critical components are marked with. In this manual, you can find out what role marking lasers play in. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Verification uses a set of quality measures developed specifically for dpmi. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Laser marking at a glance marking lasers perform more and more tasks in the industry.

Electronic Industry Specific Applications KEYENCE Laser Marking

Laser Marking Quality Control Verification uses a set of quality measures developed specifically for dpmi. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Laser marking at a glance marking lasers perform more and more tasks in the industry. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. Critical components are marked with. Verification uses a set of quality measures developed specifically for dpmi. In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. In this manual, you can find out what role marking lasers play in.

From kobot.com.au

LASER MARKING SYSTEMS Kobot Laser Marking Quality Control In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking at a glance marking lasers perform more and more tasks in the industry. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Critical components are marked with. Laser marking automation stands. Laser Marking Quality Control.

From www.hindcam.com

Marking Principle of Laser Marking Hindcam Pvt. Ltd. Laser Marking Quality Control Critical components are marked with. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. When you introduce laser marking product quality control, you're bound to find benefits such as. Laser Marking Quality Control.

From www.atdprecision.com

Laser Marking ATD Precision Precision Machined Parts Laser Marking Quality Control Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. In this manual, you can find out what role marking lasers play in. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Critical components are marked with. Verification. Laser Marking Quality Control.

From www.rapiddirect.com

Laser Marking What Is It and How It Works Basic Knowledge RapidDirect Laser Marking Quality Control Critical components are marked with. Verification uses a set of quality measures developed specifically for dpmi. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking automation stands as a revolutionary advancement in the manufacturing sector,. Laser Marking Quality Control.

From websta.me

How to Use Fiber Laser Marking Machine 2024 Guide Sta.ME Laser Marking Quality Control Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Critical components are marked with. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity. Laser Marking Quality Control.

From phasiumpower.com

metallasermarkingmachine PHASIUM Laser Marking Quality Control When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and. Laser Marking Quality Control.

From laserbeamcut.com

What is Laser Marking and its Types? ( A Definitive Guide) Laser Marking Quality Control When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. In this manual, you can find out what role marking lasers play in. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Verification uses a. Laser Marking Quality Control.

From virmer.com

Laser marking machine, how does it work and what is it capable of? — Virmer Laser Marking Quality Control In this manual, you can find out what role marking lasers play in. In the automotive industry, laser marking is essential for parts identification and traceability. Critical components are marked with. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. When you introduce laser marking product quality control, you're bound. Laser Marking Quality Control.

From www.rapiddirect.com

Laser Marking What Is It and How It Works Basic Knowledge RapidDirect Laser Marking Quality Control Critical components are marked with. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. In the automotive industry, laser marking is essential for parts identification and traceability. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on. Laser Marking Quality Control.

From virmer.com

Laser marking machine, how does it work and what is it capable of? — Virmer Laser Marking Quality Control Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and. Laser Marking Quality Control.

From www.coherent.com

Laser Marking and Engraving Machines Coherent Laser Marking Quality Control In this manual, you can find out what role marking lasers play in. Verification uses a set of quality measures developed specifically for dpmi. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Laser marking at a glance marking lasers perform more and more tasks in the industry. Each character. Laser Marking Quality Control.

From www.mac-laser.com

UV Laser Marking Machine Complete Guide 2023 MAC LASER Laser Marking Quality Control When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. In this manual, you can find out what role marking lasers play in. Critical components are marked with. In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking automation stands as a. Laser Marking Quality Control.

From www.chandlerindustries.com

Chandler Industries Adds New Laser Marking System Chandler Industries Laser Marking Quality Control Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Verification uses a set of quality measures developed specifically for dpmi. When you introduce laser marking product quality control,. Laser Marking Quality Control.

From www.nortechengineering.co.uk

Bespoke Keyence Laser Marking Systems Nortech Engineering Laser Marking Quality Control In the automotive industry, laser marking is essential for parts identification and traceability. In this manual, you can find out what role marking lasers play in. Laser marking at a glance marking lasers perform more and more tasks in the industry. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria. Laser Marking Quality Control.

From www.iqsdirectory.com

Laser Marking & Engraving Machinery What Is It? Types, Uses Laser Marking Quality Control Laser marking at a glance marking lasers perform more and more tasks in the industry. Verification uses a set of quality measures developed specifically for dpmi. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Critical components are marked with. When you introduce laser marking product quality control,. Laser Marking Quality Control.

From www.medital.com

KEYENCE Laser Marking Systems Medital Laser Marking Quality Control Verification uses a set of quality measures developed specifically for dpmi. In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to. Laser Marking Quality Control.

From gncmachine.com

Laser Marking Machine GNC MACHINE Laser Marking Quality Control Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Critical components are marked with. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity. Laser Marking Quality Control.

From www.permanentmarking.com

Standard Laser Marking Machines Standard Laser Marking Systems Laser Marking Quality Control Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency. Laser Marking Quality Control.

From www.keyence.com

Electronic Industry Specific Applications KEYENCE Laser Marking Laser Marking Quality Control In this manual, you can find out what role marking lasers play in. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. In the automotive. Laser Marking Quality Control.

From www.yourhop.com

What Is Laser Marking? Your Hop Laser Marking Quality Control Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. In the automotive industry, laser marking is essential for parts identification and traceability. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Laser marking. Laser Marking Quality Control.

From www.mdi-llc.net

Laser Marking Annealing Medical Device & Implants Laser Marking Quality Control Critical components are marked with. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. When you introduce laser marking product quality control, you're bound to find benefits such as. Laser Marking Quality Control.

From techround.co.uk

What is Laser Marking and How Does it Work? TechRound Laser Marking Quality Control Verification uses a set of quality measures developed specifically for dpmi. Laser marking at a glance marking lasers perform more and more tasks in the industry. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Laser marking has been useful for quality control as it can mark permanent. Laser Marking Quality Control.

From www.mscdirect.com

Tykma Electrox QUBE 60W Laser Marking System Package, 4"x4" Marking Laser Marking Quality Control In the automotive industry, laser marking is essential for parts identification and traceability. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Critical components are marked with. Laser. Laser Marking Quality Control.

From tri-star-technologies.com

How 8 Industries Use Laser Marking Systems Laser Marking Quality Control Verification uses a set of quality measures developed specifically for dpmi. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. In this manual, you can find out. Laser Marking Quality Control.

From www.markingmachinery.com

Laser Marking Companies Laser Marking Services Laser Marking Quality Control In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Verification uses a set of quality measures developed specifically for dpmi. Critical components are marked with. Laser marking at a glance marking lasers perform more and more tasks. Laser Marking Quality Control.

From www.mdi-llc.net

Laser Marking Annealing Medical Device & Implants Laser Marking Quality Control Verification uses a set of quality measures developed specifically for dpmi. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. In this manual, you can find out what role marking lasers play in. Laser marking at a glance marking lasers perform more and more tasks in the industry. When you. Laser Marking Quality Control.

From lasermarktech.com

Insights Laser Marking Technologies Laser Marking Quality Control Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. In the automotive industry, laser marking is essential for parts identification and traceability. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Verification uses. Laser Marking Quality Control.

From www.meenjet.net

High Quality 20W 30W Handheld Laser Marking Machine for Metal Laser Marking Quality Control Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Critical components are marked with. Laser marking at a glance marking lasers perform more and more tasks in the industry. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces.. Laser Marking Quality Control.

From www.rfm.co.th

Laser Marking 30 W Laser Marking Quality Control Critical components are marked with. In the automotive industry, laser marking is essential for parts identification and traceability. When you introduce laser marking product quality control, you're bound to find benefits such as time and cost efficiency and a newfound competitive. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces.. Laser Marking Quality Control.

From antbot2u.com

Laser Marking machine ANTBOT Laser Marking & Laser Engraving & Laser Laser Marking Quality Control Critical components are marked with. Verification uses a set of quality measures developed specifically for dpmi. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. In the automotive industry,. Laser Marking Quality Control.

From www.schmidt-bartl.de

Laser Marking Laser Marking Quality Control In this manual, you can find out what role marking lasers play in. Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. In the automotive industry, laser marking is essential for parts identification and traceability. When you introduce laser marking product quality control, you're bound to find benefits. Laser Marking Quality Control.

From kyoritsuelectric.com

Inline Laser Marking Machine PCB Laser Marking Equipment Laser Marking Quality Control In the automotive industry, laser marking is essential for parts identification and traceability. Laser marking at a glance marking lasers perform more and more tasks in the industry. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. Laser marking has been useful for quality control as it. Laser Marking Quality Control.

From www.nordsystems.eu

CO2 laser marking machine 30W NordSystems Laser Marking Quality Control Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. In this manual, you can find out what role marking lasers play in. Verification uses a set of quality measures developed specifically for dpmi. When you introduce laser marking product quality control, you're bound to find benefits such. Laser Marking Quality Control.

From cmslaser.com

Laser Marking Techniques & Capabilities CMS Laser Laser Marking Quality Control Laser marking automation stands as a revolutionary advancement in the manufacturing sector, delivering high precision, speed, adaptability, and superior quality control. Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based. Laser Marking Quality Control.

From www.fiberlasermarkermachine.com

Rotary 20W 30W 50W Mini Portable Laser Marking Machine Laser Marking Quality Control Laser marking at a glance marking lasers perform more and more tasks in the industry. Each character and contour is evaluated with regard to completeness, contrast, edge width and homogeneity according to quality criteria based on the. In this manual, you can find out what role marking lasers play in. Laser marking has been useful for quality control as it. Laser Marking Quality Control.