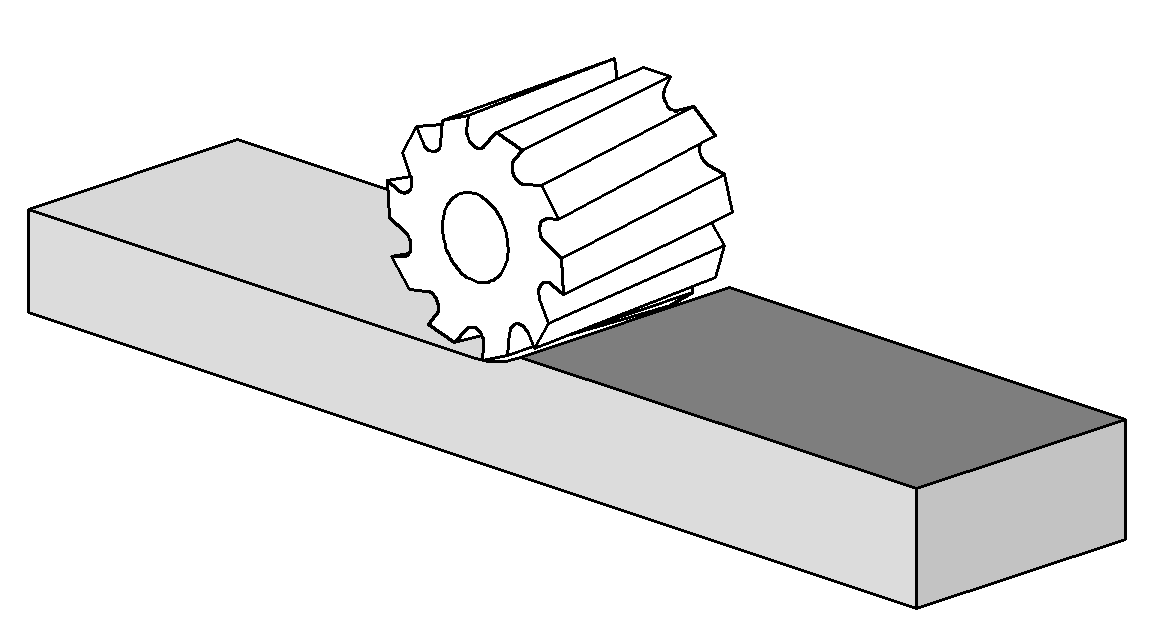

Slab Mill Function . Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. To operate, the work and the cutter are secured properly on the machine. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Plain milling is the most common type of milling machine operation. It involves using a milling cutter which rotates on. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. 0.25 mm/tooth and a depth of. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. The operation is also known as slab milling. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. Slab milling is similar to face milling in that it removes material to.

from toolnotes.com

Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. Plain milling is the most common type of milling machine operation. It involves using a milling cutter which rotates on. To operate, the work and the cutter are secured properly on the machine. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. The operation is also known as slab milling. Slab milling is similar to face milling in that it removes material to.

Milling Operations ToolNotes

Slab Mill Function Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. To operate, the work and the cutter are secured properly on the machine. 0.25 mm/tooth and a depth of. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Slab milling is similar to face milling in that it removes material to. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. Plain milling is the most common type of milling machine operation. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. The operation is also known as slab milling. It involves using a milling cutter which rotates on. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor.

From www.pinterest.co.uk

A steel slab passes through the hot strip mill of ArcelorMittal Slab Mill Function Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. It involves using a milling cutter which rotates on. Plain or slab milling. Slab Mill Function.

From www.pinterest.com

Slab Flattening Mill Live Edge Slab Slab, Live edge slab, Slab Slab Mill Function Plain milling is the most common type of milling machine operation. 0.25 mm/tooth and a depth of. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis. Slab Mill Function.

From www.gereedschappro.nl

Woodpeckers Slab Flattening Mill Pro Extended SLBFPROXL Slab Mill Function Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. 0.25 mm/tooth and a depth of. The operation is also known as slab. Slab Mill Function.

From www.slideserve.com

PPT Milling Machine PowerPoint Presentation, free download ID9172901 Slab Mill Function Plain milling is the most common type of milling machine operation. Slab milling is similar to face milling in that it removes material to. 0.25 mm/tooth and a depth of. It involves using a milling cutter which rotates on. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain. Slab Mill Function.

From kjpselecthardwoods.com

Slab Flattening Mill Pro — KJP Select Hardwoods Slab Mill Function Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. To operate, the work and the cutter are secured properly on the machine. Slab milling is similar to face milling in that it removes material to. Plain milling is performed to produce. Slab Mill Function.

From civiltech9.blogspot.com

Civil Engineering Portal What is SLAB its Function, Design and and Slab Mill Function 0.25 mm/tooth and a depth of. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. It involves using a milling cutter which rotates on. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter. Slab Mill Function.

From machiningtoday.com

CNC Machine Tools How to Choose the Right Tools? Machiningtoday Slab Mill Function Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. To operate, the work and the cutter are secured properly on the machine. The operation is also known as slab milling. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel. Slab Mill Function.

From yesheng.en.made-in-china.com

Horizontal DoubleFace Aluminium Slab Milling Machine for Aluminium Slab Mill Function Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Slab milling is similar. Slab Mill Function.

From www.rmttools.com

Steel Mill, Rebar Rolling Mill Machinery Hot Steel Rolling Mill Plant Slab Mill Function 0.25 mm/tooth and a depth of. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. To operate, the work and the cutter are secured properly on the machine.. Slab Mill Function.

From gertnergroup.com

Slab milling machines (MFL) Gertnergroup Slab Mill Function 0.25 mm/tooth and a depth of. The operation is also known as slab milling. To operate, the work and the cutter are secured properly on the machine. Plain milling is the most common type of milling machine operation. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the. Slab Mill Function.

From slideplayer.com

Milling machine & Milling work ppt download Slab Mill Function Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. 0.25 mm/tooth and a depth of. To operate, the work and the cutter are secured properly on the machine. Plain milling is the most common type of milling machine operation. It involves using a milling cutter which rotates on. Plain or slab milling is. Slab Mill Function.

From www.youtube.com

Heavy Duty Slab Milling Machine YouTube Slab Mill Function The operation is also known as slab milling. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. To operate, the work and the cutter are. Slab Mill Function.

From www.woodworkersjournal.com

Woodpeckers Slab Flattening Mill Router Woodworker's Journal Slab Mill Function It involves using a milling cutter which rotates on. Slab milling is similar to face milling in that it removes material to. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter.. Slab Mill Function.

From proleantech.com

Understanding Milling Cutters in CNC Machining Slab Mill Function Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. It involves using a milling cutter which rotates on. Plain milling, also known as slab milling or surface milling, the process of. Slab Mill Function.

From www.youtube.com

SlabMizer MB200 Slab Flattening Mill Walkthrough WoodMizer YouTube Slab Mill Function Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is the most common type of milling machine operation. To operate, the work and the cutter are secured properly on the machine. 0.25 mm/tooth and a depth of. It involves using a milling cutter which rotates on. Also referred. Slab Mill Function.

From kjpselecthardwoods.com

Slab Flattening Mill Pro KJP Select Hardwoods Slab Mill Function 0.25 mm/tooth and a depth of. It involves using a milling cutter which rotates on. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced,. Slab Mill Function.

From kjpselecthardwoods.com

Slab Flattening Mill Pro — KJP Select Hardwoods Slab Mill Function Slab milling is similar to face milling in that it removes material to. Plain milling is the most common type of milling machine operation. 0.25 mm/tooth and a depth of. It involves using a milling cutter which rotates on. The operation is also known as slab milling. Plain milling, also known as slab milling or surface milling, the process of. Slab Mill Function.

From www.youtube.com

Crafted Elements Router Sled Wood Slab Flattening Mill Assembly Slab Mill Function Slab milling is similar to face milling in that it removes material to. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. 0.25 mm/tooth and a depth of. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface.. Slab Mill Function.

From talk.dallasmakerspace.org

New Woodpecker Slab mill Dallas Makerspace Talk Slab Mill Function Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. The operation is also known as slab milling. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Slab milling. Slab Mill Function.

From wilkerdos.com

Chainsaw Mill How To Slab Logs Wilker Do's Slab Mill Function Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Plain milling is the most common type of milling machine operation. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. To operate, the work and the cutter are secured properly on the machine. Plain. Slab Mill Function.

From woodmizer.com

MB100 SlabMizer Slab Flattening Mill Portable Sawmills & Wood Slab Mill Function To operate, the work and the cutter are secured properly on the machine. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Slab milling is similar to face milling in that. Slab Mill Function.

From woodmizer.com

MB100 SlabMizer Slab Flattening Mill Portable Sawmills & Wood Slab Mill Function The operation is also known as slab milling. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Slab milling. Slab Mill Function.

From www.chinawoodsawmill.com

Horizontal Wood Slab Mill Large Bandsaw Mill 2500mm Max Log Diameter Slab Mill Function Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. It involves using a milling cutter which rotates on. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Slab. Slab Mill Function.

From www.woodworkersjournal.com

Woodpeckers Slab Flattening Mill Router Woodworker's Journal Slab Mill Function Plain milling is the most common type of milling machine operation. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also referred to as slab milling or surface milling, the operation is done on. Slab Mill Function.

From tsoproducts.com

Slab Flattening Mill Plans TSO Products LLC. Slab Mill Function Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted. Slab Mill Function.

From www.semanticscholar.org

[PDF] Transient FluidFlow Phenomena in the Continuous SteelSlab Slab Mill Function Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Slab milling is similar to face milling in that it removes material to.. Slab Mill Function.

From thehomewoodworker.com

The Best Slab Flattening Jigs and Router Sleds (Buy or Build) Slab Mill Function Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. 0.25 mm/tooth and a depth of. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. Also referred to as slab milling or. Slab Mill Function.

From www.youtube.com

Insider Tips For Slab Flattening Mill PRO Deep Dive Woodpeckers Slab Mill Function Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. It involves using a milling cutter which rotates on. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis. Slab Mill Function.

From atelier-yuwa.ciao.jp

Diy Slab Flattening Mill atelieryuwa.ciao.jp Slab Mill Function Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Plain milling is performed. Slab Mill Function.

From toolnotes.com

Milling Operations ToolNotes Slab Mill Function 0.25 mm/tooth and a depth of. Plain milling is the most common type of milling machine operation. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal. Slab Mill Function.

From kjpselecthardwoods.com

Slab Flattening Mill Pro — KJP Select Hardwoods Slab Mill Function To operate, the work and the cutter are secured properly on the machine. The operation is also known as slab milling. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. Plain milling, also known as slab or surface milling, is a process used when. Slab Mill Function.

From www.youtube.com

Slab milling or plain milling YouTube Slab Mill Function Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. Plain milling is the most common type of milling machine operation. Plain milling, also known as slab milling or surface milling, the process of milling flat surface with the axis of cutting tool parallel to the surface being machined. Plain milling, also known as. Slab Mill Function.

From www.youtube.com

Slab Flattening MillPRO Woodpeckers Tools YouTube Slab Mill Function Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. Plain milling is performed to produce a plain, flat, horizontal surface parallel to the axis of rotation of a plain milling cutter. To operate, the work and the cutter are secured properly on the machine.. Slab Mill Function.

From www.chegg.com

Solved A slab mill operation is being carried out on a 305 Slab Mill Function Plain milling, also known as slab or surface milling, is a process used when machining a flat, horizontal surface. The operation is also known as slab milling. Plain or slab milling is a process in which the plain, horizontal or flat surfaces are produced, which are parallel to the axis of the. Slab milling is similar to face milling in. Slab Mill Function.

From www.china-machining.com

Plain Milling Understanding this Fascinating Production Process Slab Mill Function Also referred to as slab milling or surface milling, the operation is done on a horizontal milling machine with the plain milling cutter adequately mounted on an arbor. Peripheral milling can be used in slabbing operations, profile milling, slotting, straddle milling and slitting operations. The operation is also known as slab milling. Plain milling, also known as slab milling or. Slab Mill Function.