Importance Of Lubrication System . Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. An automatic lubrication system has many. This article delves into the critical role of mechanical equipment lubrication, detailing its. These lubricants help to reduce friction between sliding or rolling. Ever wondered how proper lubrication can make or break industrial equipment? Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother.

from www.merchantnavydecoded.com

Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. An automatic lubrication system has many. Ever wondered how proper lubrication can make or break industrial equipment? It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. This article delves into the critical role of mechanical equipment lubrication, detailing its. These lubricants help to reduce friction between sliding or rolling.

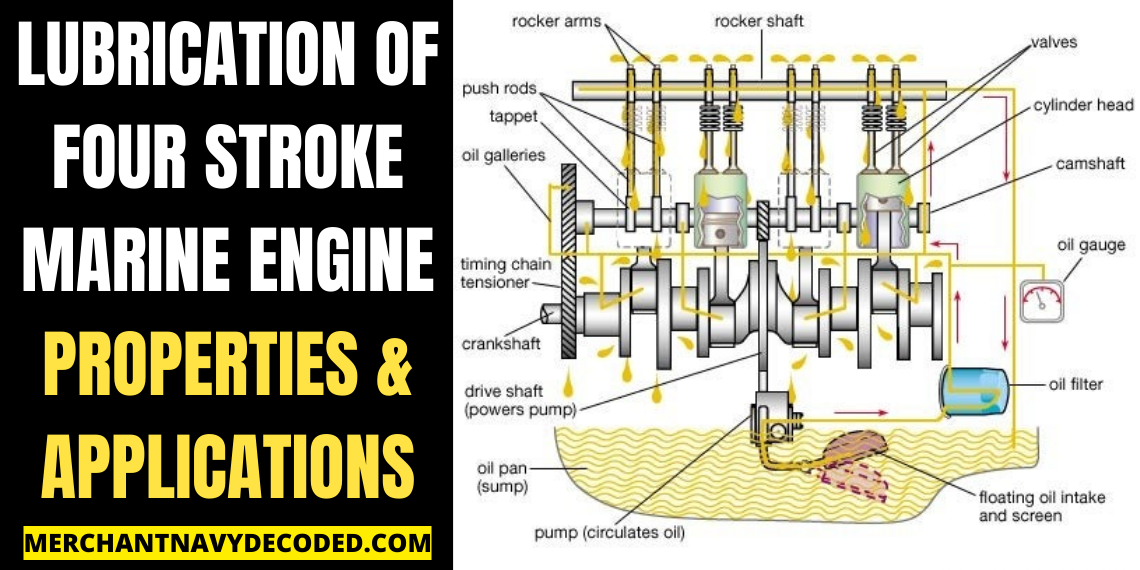

Lubrication of Four Stroke Marine Engine Properties & Applications

Importance Of Lubrication System Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. An automatic lubrication system has many. Ever wondered how proper lubrication can make or break industrial equipment? This article delves into the critical role of mechanical equipment lubrication, detailing its. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. These lubricants help to reduce friction between sliding or rolling. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid.

From tikweld.com

Importance of Lubricants for Machine Maintenance Tikweld products and Importance Of Lubrication System Ever wondered how proper lubrication can make or break industrial equipment? Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. These lubricants help to reduce friction between sliding or rolling. It serves many purposes, but the ultimate. Importance Of Lubrication System.

From www.youtube.com

Engine Oil Lubrication System How does Engine Lubrication System Work Importance Of Lubrication System Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. Ever wondered how proper lubrication can make or break industrial equipment? Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the. Importance Of Lubrication System.

From www.youtube.com

Lubrication System Manufacturers, Suppliers, and Industry Information Importance Of Lubrication System It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. An automatic lubrication system has many. This article delves into the critical role of mechanical equipment lubrication, detailing its. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. These lubricants. Importance Of Lubrication System.

From www.slideserve.com

PPT LUBRICATION SYSTEM PowerPoint Presentation ID839588 Importance Of Lubrication System Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. An automatic lubrication system has many. Ever wondered how proper lubrication can make or break industrial equipment? These lubricants help to reduce friction between sliding or rolling. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. This article. Importance Of Lubrication System.

From howjoin.weebly.com

Types of lubrication system in ic engines pdf howjoin Importance Of Lubrication System The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Ever wondered how proper lubrication can make or break industrial equipment? Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other.. Importance Of Lubrication System.

From www.iqsdirectory.com

Industrial Lubricants Types, Uses, Features and Benefits Importance Of Lubrication System Ever wondered how proper lubrication can make or break industrial equipment? Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. These lubricants help to reduce friction between sliding or rolling. This article delves into the critical role of mechanical equipment lubrication, detailing its. Lubrication reduces friction and allows moving machine parts. Importance Of Lubrication System.

From iselinc.com

Explore The Many Benefits Of Lubrication Isel Importance Of Lubrication System The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. These lubricants help to reduce friction between sliding or rolling. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. An. Importance Of Lubrication System.

From mungfali.com

Types Of Lubrication System Importance Of Lubrication System These lubricants help to reduce friction between sliding or rolling. An automatic lubrication system has many. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. Lubrication reduces friction and allows moving machine parts. Importance Of Lubrication System.

From interflon.com

Did you know 4 lubrication facts Importance Of Lubrication System It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. Ever wondered how proper. Importance Of Lubrication System.

From innovationdiscoveries.space

What is a lubrication system? Types of lubrication systems. Importance Of Lubrication System These lubricants help to reduce friction between sliding or rolling. This article delves into the critical role of mechanical equipment lubrication, detailing its. An automatic lubrication system has many. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. The primary role of a lubrication system is to reduce friction between moving. Importance Of Lubrication System.

From www.slideserve.com

PPT Engine Maintenance PowerPoint Presentation, free download ID Importance Of Lubrication System An automatic lubrication system has many. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. These lubricants help to reduce friction between sliding or rolling. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. It serves many purposes, but the ultimate goal of. Importance Of Lubrication System.

From innovationdiscoveries.space

What is a lubrication system? Types of lubrication systems. Importance Of Lubrication System Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. An automatic lubrication system has many. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. Ever. Importance Of Lubrication System.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Importance Of Lubrication System The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. These lubricants help to reduce friction between sliding or rolling. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. This article delves into the critical role of mechanical equipment lubrication, detailing its. Lubrication systems. Importance Of Lubrication System.

From www.slideserve.com

PPT Engine Lubrication System PowerPoint Presentation ID5713487 Importance Of Lubrication System Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. An automatic lubrication system has many. These lubricants help to reduce friction between sliding or rolling. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. Ever wondered how proper lubrication can make or. Importance Of Lubrication System.

From www.hls.ie

What is a Lubrication System? HLS Explains Importance Of Lubrication System Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. This article delves into the critical role of mechanical equipment lubrication, detailing its. An automatic lubrication system has many. Lubrication reduces. Importance Of Lubrication System.

From mavink.com

What Is Lubrication System Importance Of Lubrication System Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. An automatic lubrication system has many. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. Ever. Importance Of Lubrication System.

From www.merchantnavydecoded.com

Lubrication of Four Stroke Marine Engine Properties & Applications Importance Of Lubrication System Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. An automatic lubrication system has many. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered. Importance Of Lubrication System.

From ocsaly.com

The Importance of Proper Engine Lubrication Ocsaly Importance Of Lubrication System An automatic lubrication system has many. Ever wondered how proper lubrication can make or break industrial equipment? These lubricants help to reduce friction between sliding or rolling. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. This article delves into the critical role of mechanical equipment lubrication, detailing its. Lubrication systems are. Importance Of Lubrication System.

From learnmechanical.com

Lubrication System Petroil, Splash, Pressure, SemiPressure, Dry & Wet Importance Of Lubrication System An automatic lubrication system has many. These lubricants help to reduce friction between sliding or rolling. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. Ever wondered how proper lubrication can make or break industrial equipment? Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. Lubrication. Importance Of Lubrication System.

From www.flosolve.co.za

What is Lubrication and Why is it Important? FloSolve (Pty) Ltd Importance Of Lubrication System Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. This article delves into the critical role of mechanical equipment lubrication, detailing its. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. Ever wondered how proper lubrication can make or break industrial equipment?. Importance Of Lubrication System.

From mavink.com

What Is Lubrication System Importance Of Lubrication System It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. These lubricants help to reduce friction between sliding or rolling. Ever wondered how proper lubrication can make or break industrial equipment? Lubrication. Importance Of Lubrication System.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Importance Of Lubrication System An automatic lubrication system has many. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. This article delves into the critical role of mechanical equipment lubrication, detailing its. Lubrication reduces. Importance Of Lubrication System.

From www.researchgate.net

Various field of applications of lubricants. Download Scientific Diagram Importance Of Lubrication System The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Ever wondered how proper lubrication can make or break industrial equipment? These lubricants help to reduce friction between sliding or rolling. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. This article delves into. Importance Of Lubrication System.

From mavink.com

Types Of Lubrication System Importance Of Lubrication System Ever wondered how proper lubrication can make or break industrial equipment? An automatic lubrication system has many. Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. These lubricants help to reduce friction between sliding or rolling. The. Importance Of Lubrication System.

From www.getredlist.com

The Fundamentals of Lubrication Systems A Beginner's Guide Redlist Importance Of Lubrication System Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. An automatic lubrication system has many. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered. Importance Of Lubrication System.

From www.heritagepartscentre.com

Lessons in lubrication Engine Oil Explained Importance Of Lubrication System An automatic lubrication system has many. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. This article delves into the critical role of mechanical equipment lubrication, detailing its. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Ever wondered how. Importance Of Lubrication System.

From www.slideserve.com

PPT Advantages of Lubrication System PowerPoint Presentation, free Importance Of Lubrication System Ever wondered how proper lubrication can make or break industrial equipment? It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Lubrication systems are designed to distribute lubricant to moving machine parts. Importance Of Lubrication System.

From www.knowledgepeoplecreators.com

what is lubrication system in engine and why we use lubrication oil K P C Importance Of Lubrication System Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. An automatic lubrication system has many. These lubricants help to reduce friction between sliding or rolling. This article delves into the critical role of mechanical equipment lubrication, detailing its. It serves many purposes, but the ultimate goal of a lubricant is to. Importance Of Lubrication System.

From blog.slsbearings.com

The Importance of Lubrication in Bearings and Other Components Importance Of Lubrication System An automatic lubrication system has many. These lubricants help to reduce friction between sliding or rolling. Ever wondered how proper lubrication can make or break industrial equipment? Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. The primary role of a lubrication system is to reduce friction between moving parts, making. Importance Of Lubrication System.

From www.avanalubricant.com

Importance of Lubrication for Engines Importance Of Lubrication System An automatic lubrication system has many. These lubricants help to reduce friction between sliding or rolling. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. This article delves into the critical role of mechanical equipment lubrication, detailing its. Lubrication plays an indispensable role in enhancing machine reliability by. Importance Of Lubrication System.

From www.mkkhanduja.com

Importance of Lubrication Reduces breakdowns and increases productivity Importance Of Lubrication System This article delves into the critical role of mechanical equipment lubrication, detailing its. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. These lubricants help to reduce friction between sliding or rolling. Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with. Importance Of Lubrication System.

From mappingmemories.ca

Perforar depositar Travieso why is lubrication important Abundante Importance Of Lubrication System Lubrication reduces friction and allows moving machine parts to slide smoothly past each other. An automatic lubrication system has many. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Lubrication systems are designed to. Importance Of Lubrication System.

From mungfali.com

Types Of Lubrication System Importance Of Lubrication System This article delves into the critical role of mechanical equipment lubrication, detailing its. These lubricants help to reduce friction between sliding or rolling. Lubrication plays an indispensable role in enhancing machine reliability by reducing friction, preventing wear, and mitigating the risk. An automatic lubrication system has many. Lubrication reduces friction and allows moving machine parts to slide smoothly past each. Importance Of Lubrication System.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Importance Of Lubrication System Lubrication systems are designed to distribute lubricant to moving machine parts that come into contact with each other. It serves many purposes, but the ultimate goal of a lubricant is to reduce unwanted friction (the resistance encountered when solid. Ever wondered how proper lubrication can make or break industrial equipment? These lubricants help to reduce friction between sliding or rolling.. Importance Of Lubrication System.

From www.slideserve.com

PPT Lubrication PowerPoint Presentation, free download ID226723 Importance Of Lubrication System An automatic lubrication system has many. This article delves into the critical role of mechanical equipment lubrication, detailing its. Ever wondered how proper lubrication can make or break industrial equipment? The primary role of a lubrication system is to reduce friction between moving parts, making operations smoother. Lubrication reduces friction and allows moving machine parts to slide smoothly past each. Importance Of Lubrication System.