Power Loom Diagram . Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. Weaving fabric is made using a loom, a machine that has different parts. In general, looms were used to weave. One of the key developments during the early industrial revolution was. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. Each part has a distinct function. There are many types of looms are available in this era. Functions of different parts of loom with specific figures: The warp beam, which holds the warp yarns, is located at the. The device which is used to produce woven fabric is called loom. The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods.

from enginerileynervules.z14.web.core.windows.net

In general, looms were used to weave. There are many types of looms are available in this era. Weaving fabric is made using a loom, a machine that has different parts. Functions of different parts of loom with specific figures: The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods. The warp beam, which holds the warp yarns, is located at the. The device which is used to produce woven fabric is called loom. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. One of the key developments during the early industrial revolution was.

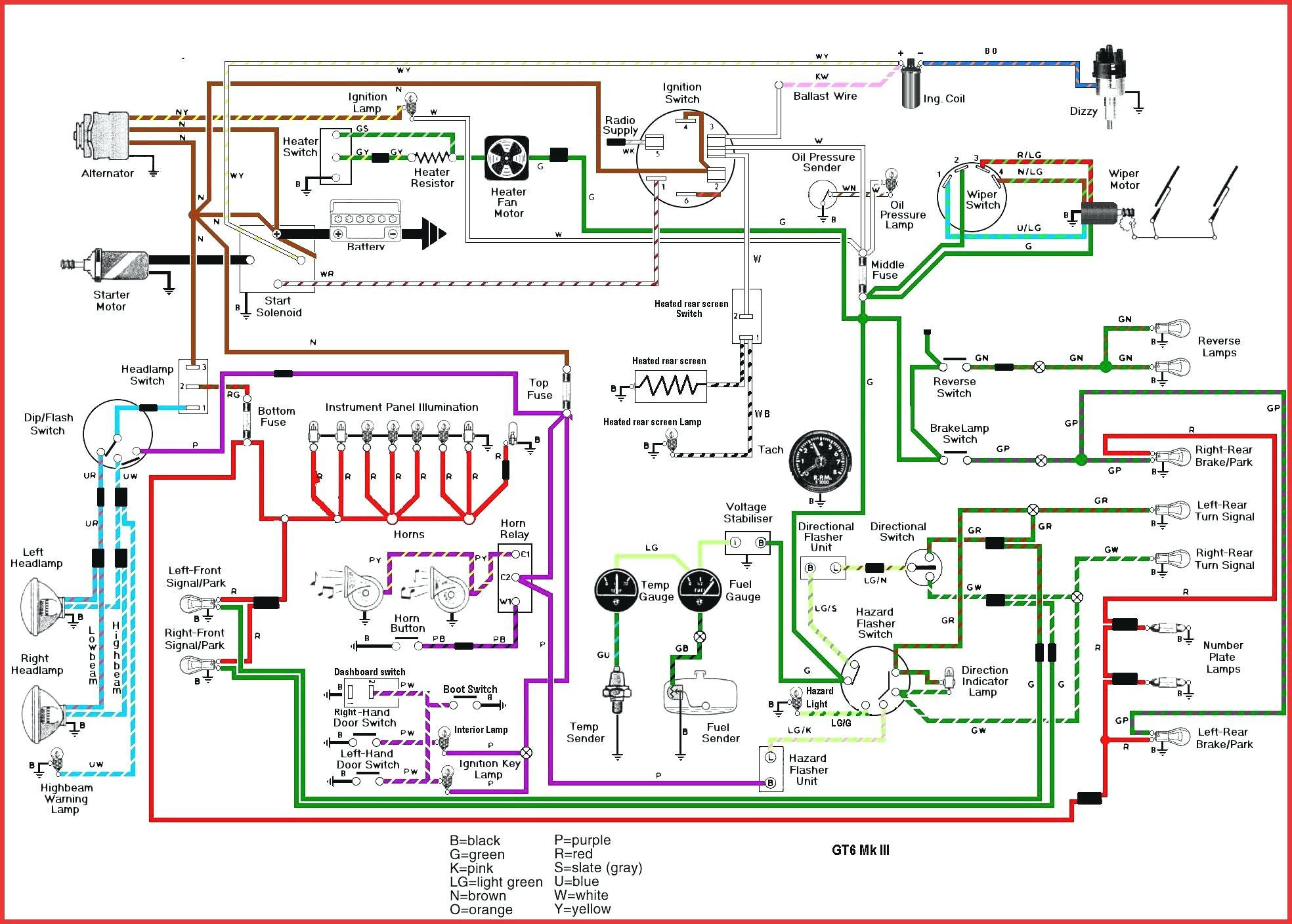

Race Car Wiring Loom

Power Loom Diagram There are many types of looms are available in this era. In general, looms were used to weave. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. The device which is used to produce woven fabric is called loom. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. Each part has a distinct function. Weaving fabric is made using a loom, a machine that has different parts. The warp beam, which holds the warp yarns, is located at the. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. One of the key developments during the early industrial revolution was. Functions of different parts of loom with specific figures: There are many types of looms are available in this era. The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods.

From circuitenginecawed88.z21.web.core.windows.net

What Is A Wiring Loom Power Loom Diagram Functions of different parts of loom with specific figures: Weaving fabric is made using a loom, a machine that has different parts. One of the key developments during the early industrial revolution was. The warp beam, which holds the warp yarns, is located at the. The power loom was first invented by edmund cartwright in 1785 and it doubled the. Power Loom Diagram.

From schematicnaudinnbgar.z13.web.core.windows.net

Bmw E46 Wiring Loom Diagram Power Loom Diagram The device which is used to produce woven fabric is called loom. The warp beam, which holds the warp yarns, is located at the. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. Weaving fabric is made using a. Power Loom Diagram.

From www.pinterest.com

rainbow loom instructions printable Google Search Rainbow loom Power Loom Diagram The device which is used to produce woven fabric is called loom. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. Weaving fabric is made using a loom, a machine that has different parts. One of the key developments during the early industrial revolution was. The. Power Loom Diagram.

From repairfixchapinsye.z21.web.core.windows.net

Parts Of A Floor Loom Power Loom Diagram In general, looms were used to weave. Weaving fabric is made using a loom, a machine that has different parts. Each part has a distinct function. One of the key developments during the early industrial revolution was. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing.. Power Loom Diagram.

From www.evolutionm.net

Power wire loom diagram EvolutionM Mitsubishi Lancer and Lancer Power Loom Diagram One of the key developments during the early industrial revolution was. The warp beam, which holds the warp yarns, is located at the. The device which is used to produce woven fabric is called loom. The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods. Each part. Power Loom Diagram.

From peggyosterkamp.com

Extra! Extra! Read All About It!Big Chapter on Adjusting Looms in Book Power Loom Diagram The warp beam, which holds the warp yarns, is located at the. Functions of different parts of loom with specific figures: There are many types of looms are available in this era. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. Unlike the earlier handloom, which required human energy. Power Loom Diagram.

From leartex.com

Leartex Magazine Learn Textile step by step click by click Power Loom Diagram One of the key developments during the early industrial revolution was. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam. Power Loom Diagram.

From schematicnaudinnbgar.z13.web.core.windows.net

Bmw E46 Wiring Loom Diagram Power Loom Diagram The warp beam, which holds the warp yarns, is located at the. One of the key developments during the early industrial revolution was. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. In general, looms were used to weave. The device which is used to produce. Power Loom Diagram.

From schematicnaudinnbgar.z13.web.core.windows.net

Bmw E46 Power Mirror Wiring Diagram Power Loom Diagram Functions of different parts of loom with specific figures: The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods. The warp beam, which holds the warp yarns, is located at the. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a. Power Loom Diagram.

From atleadsandlooms.co.uk

wiring loom A.T. Leads & Looms Power Loom Diagram Each part has a distinct function. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. In general, looms were used to weave. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine. Power Loom Diagram.

From class.textile-academy.org

8. Open Source Hardware From Fibers to Fabric Tania Velasquez Power Loom Diagram Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. There are many types of looms are available in this era. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the. Power Loom Diagram.

From tofua61gguidediagram.z14.web.core.windows.net

No Power Options Available Windows 11 Power Loom Diagram In general, looms were used to weave. Weaving fabric is made using a loom, a machine that has different parts. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. Each part has a distinct function. Essentially, the power loom. Power Loom Diagram.

From industrialrevolution.org

Power Loom and Parts Power Loom Diagram One of the key developments during the early industrial revolution was. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. There are many types of looms are available in this era. The basic purpose of any loom is to. Power Loom Diagram.

From www.textilemachinerychina.com

Power loom Power Loom Diagram In general, looms were used to weave. Each part has a distinct function. Weaving fabric is made using a loom, a machine that has different parts. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. The power loom was. Power Loom Diagram.

From schematicpiscardixf.z4.web.core.windows.net

Parts Of A Loom Diagram Power Loom Diagram The device which is used to produce woven fabric is called loom. Each part has a distinct function. Weaving fabric is made using a loom, a machine that has different parts. The warp beam, which holds the warp yarns, is located at the. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving. Power Loom Diagram.

From enginedatanichered.z21.web.core.windows.net

Parts Of A Loom Diagram Power Loom Diagram Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. In general, looms were used to weave. The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods. Unlike the earlier handloom, which required human. Power Loom Diagram.

From hxefugdfe.blob.core.windows.net

Power Loom History at Fred Rodriguez blog Power Loom Diagram The device which is used to produce woven fabric is called loom. Each part has a distinct function. In general, looms were used to weave. The warp beam, which holds the warp yarns, is located at the. Weaving fabric is made using a loom, a machine that has different parts. Functions of different parts of loom with specific figures: The. Power Loom Diagram.

From guidemanualeruptivity.z14.web.core.windows.net

Parts Of A Loom Diagram Power Loom Diagram Weaving fabric is made using a loom, a machine that has different parts. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. The power loom was. Power Loom Diagram.

From limebug.com

Wiring Loom Diagrams Limebug Power Loom Diagram Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. Functions of different parts of loom with specific figures: The warp beam, which holds the warp yarns, is located at the. Each part has a distinct function. There are many. Power Loom Diagram.

From guidemanualmanganites.z21.web.core.windows.net

Power Mirror Wiring Schematic 7 Pin Power Loom Diagram Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. Functions of different parts of loom with specific figures: The warp beam, which holds the warp yarns, is located at the. The basic purpose of any loom is to hold warp threads under tension to facilitate the. Power Loom Diagram.

From enginerileynervules.z14.web.core.windows.net

Race Car Wiring Loom Power Loom Diagram One of the key developments during the early industrial revolution was. There are many types of looms are available in this era. The device which is used to produce woven fabric is called loom. Functions of different parts of loom with specific figures: The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving. Power Loom Diagram.

From userlibraryheike.z19.web.core.windows.net

Kit Car Wiring Loom Diagrams Power Loom Diagram The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. Each part has a distinct function. The warp beam, which holds the warp yarns, is located at the. In general, looms were used to weave. Essentially, the power loom mechanized the function of a loom by use of large shaft. Power Loom Diagram.

From schoolhistory.co.uk

Power Loom Facts, Summary, Inventor, Uses, & Improvements Over Time Power Loom Diagram One of the key developments during the early industrial revolution was. The device which is used to produce woven fabric is called loom. There are many types of looms are available in this era. Functions of different parts of loom with specific figures: Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system. Power Loom Diagram.

From tecnico.aspillagahornauer.cl

Power Loom Invention In The Industrial Revolution HISTORY, 58 OFF Power Loom Diagram Weaving fabric is made using a loom, a machine that has different parts. The device which is used to produce woven fabric is called loom. The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods. The warp beam, which holds the warp yarns, is located at the.. Power Loom Diagram.

From www.pinterest.com

Schacht Mighty Wolf diagram. Solid maple, great loom Schacht looms Power Loom Diagram The warp beam, which holds the warp yarns, is located at the. Functions of different parts of loom with specific figures: Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. Weaving fabric is made using a loom, a machine that has different parts. Each part has. Power Loom Diagram.

From www.pinterest.com

Diagram of a manual loom, showing how it works and names the parts of Power Loom Diagram The warp beam, which holds the warp yarns, is located at the. The device which is used to produce woven fabric is called loom. Functions of different parts of loom with specific figures: The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. Weaving fabric is made using a loom,. Power Loom Diagram.

From diesilajguidediagram.z14.web.core.windows.net

Truck Camper Inverter Wiring Power Loom Diagram Each part has a distinct function. Weaving fabric is made using a loom, a machine that has different parts. The warp beam, which holds the warp yarns, is located at the. There are many types of looms are available in this era. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of. Power Loom Diagram.

From www.etsy.com

Floor Loom Weaving Tutorial Beginner Handweaving Looms Set Up Etsy Power Loom Diagram Functions of different parts of loom with specific figures: The warp beam, which holds the warp yarns, is located at the. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. Each part has a distinct function. The device which. Power Loom Diagram.

From learnmechanical.com

Water Jet Machining Definition, Working Principle, Applications Power Loom Diagram Functions of different parts of loom with specific figures: The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. One of the key developments during the early industrial revolution was. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys,. Power Loom Diagram.

From slidesharedocs.blogspot.com

Parts Of A Loom Diagram slidesharedocs Power Loom Diagram In general, looms were used to weave. Weaving fabric is made using a loom, a machine that has different parts. Functions of different parts of loom with specific figures: Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. There. Power Loom Diagram.

From www.textileadvisor.com

Textile Adviser Structure and working principle of waterjet loom weft Power Loom Diagram The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. In general, looms were used to weave. Each part has a distinct function. Functions of different parts of loom with specific figures: The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile. Power Loom Diagram.

From limebug.com

Wiring Loom Diagrams Limebug Power Loom Diagram Weaving fabric is made using a loom, a machine that has different parts. Essentially, the power loom mechanized the function of a loom by use of large shaft and sped up the process of textile manufacturing. The warp beam, which holds the warp yarns, is located at the. Each part has a distinct function. One of the key developments during. Power Loom Diagram.

From www.researchgate.net

The traditional loom The traditional or Kente loom as shown in Fig. 1 Power Loom Diagram The power loom was first invented by edmund cartwright in 1785 and it doubled the speed of textile production compared to traditional methods. The device which is used to produce woven fabric is called loom. The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. The warp beam, which holds. Power Loom Diagram.

From schoolhistory.co.uk

Power Loom Facts, Worksheets, Edmund Cartwright, Invention Power Loom Diagram There are many types of looms are available in this era. Weaving fabric is made using a loom, a machine that has different parts. One of the key developments during the early industrial revolution was. The warp beam, which holds the warp yarns, is located at the. Functions of different parts of loom with specific figures: The basic purpose of. Power Loom Diagram.

From magnipak.com

Power Looms A Historical Breakthrough in Weaving MagniPak Power Loom Diagram The basic purpose of any loom is to hold warp threads under tension to facilitate the interweaving of the weft. Unlike the earlier handloom, which required human energy to weave cloth, the power loom utilized a system of gears, pulleys, and belts connected to a steam engine or other power. The warp beam, which holds the warp yarns, is located. Power Loom Diagram.