Lumber Manufacturing Process . Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Explore the intricacies of wood production, from lumber milling to kiln drying. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Learn how moisture content defines wood quality & durability.

from www.wainwrightfacades.com

Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Explore the intricacies of wood production, from lumber milling to kiln drying. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Learn how moisture content defines wood quality & durability.

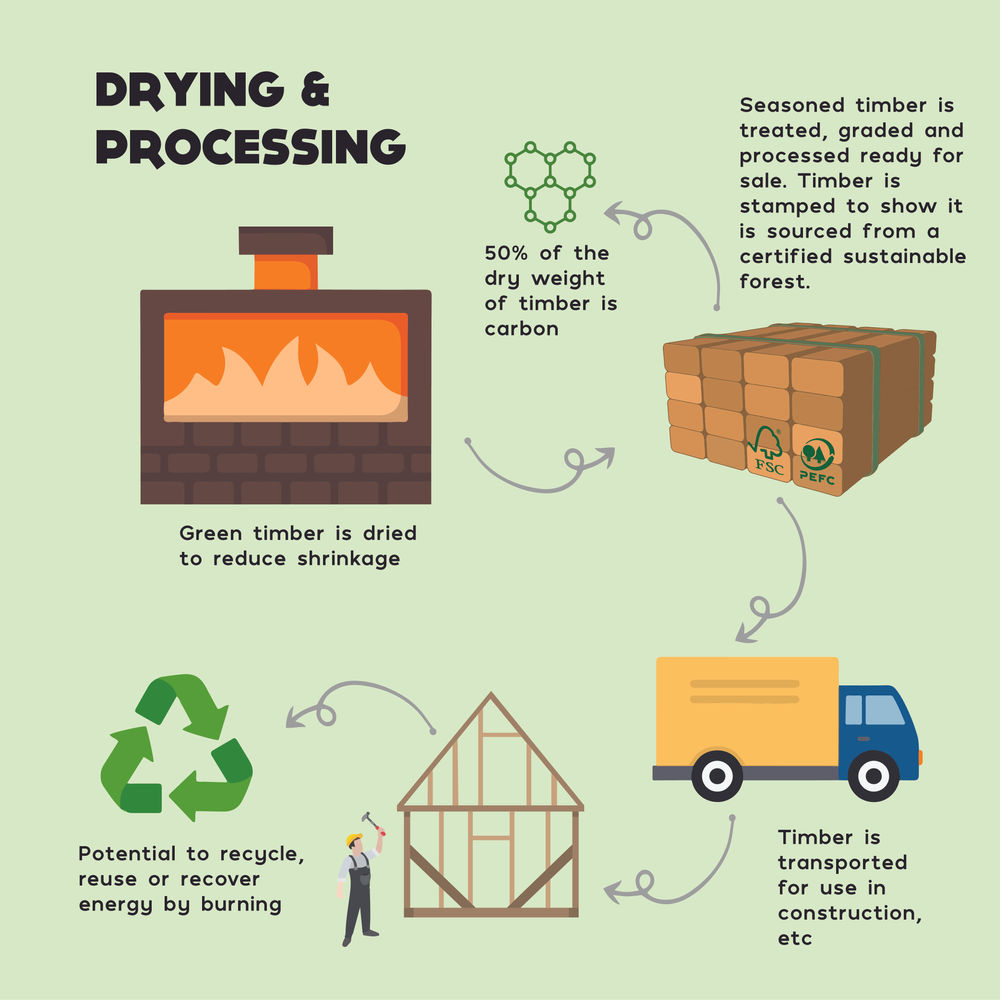

Timber Production Process

Lumber Manufacturing Process Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Explore the intricacies of wood production, from lumber milling to kiln drying. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality & durability. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of.

From www.quantumautomation.com

Turning Logs into Lumber at a Sawmill Quantum Automation Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality & durability. Wood manufacturing refers to the process of turning. Lumber Manufacturing Process.

From thehabitofwoodworking.com

How Is Plywood Manufactured Step By Step? The Habit of Woodworking Lumber Manufacturing Process Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from. Lumber Manufacturing Process.

From thehabitofwoodworking.com

How Is Plywood Manufactured Step By Step? The Habit of Woodworking Lumber Manufacturing Process Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality & durability. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Explore the intricacies of wood. Lumber Manufacturing Process.

From extension.okstate.edu

Laminated Veneer Lumber (LVL) as a Construction Material Oklahoma Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Learn how moisture content defines wood quality & durability. Wood manufacturing refers to the process of turning raw wood into a finished product. Lumber Manufacturing Process.

From www.pinterest.ca

Vector set plat de la production de bois. Abattage, Sciage camions, le Lumber Manufacturing Process Learn how moisture content defines wood quality & durability. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Pieces of lumber that are. Lumber Manufacturing Process.

From www.swedishwood.com

From raw material to wood product Swedish Wood Lumber Manufacturing Process Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber. Lumber Manufacturing Process.

From cameroontimberexport.com

Delving into Wood Manufacturing Process and Methods Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Learn how moisture content defines wood quality & durability. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s. Lumber Manufacturing Process.

From mcguirebearing.com

Wood Processing Industry Case Study McGuire Lumber Manufacturing Process Learn how moisture content defines wood quality & durability. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from lumber milling to kiln drying. Tracing the production of today's 2xs to their origins for a fuller understanding of. Lumber Manufacturing Process.

From www.researchgate.net

Production process of wood panels. Download Scientific Diagram Lumber Manufacturing Process Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Explore the intricacies of wood production, from lumber milling to kiln drying. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Wood manufacturing refers to the process of turning. Lumber Manufacturing Process.

From www.researchgate.net

Process flow diagram for the production of planed, kilndry hardwood Lumber Manufacturing Process Learn how moisture content defines wood quality & durability. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from lumber milling to kiln drying. Tracing the production of today's 2xs to their origins for a fuller understanding of. Lumber Manufacturing Process.

From www.researchgate.net

1 Material flow for the three unit processes of softwood lumber Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local. Lumber Manufacturing Process.

From www.cannondigi.com

Glulam Beam Manufacturing Process The Best Picture Of Beam Lumber Manufacturing Process Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality & durability. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Wood manufacturing refers to the process of turning raw wood into. Lumber Manufacturing Process.

From www.youtube.com

Extremely Modern Wood Production Process, Firewood Processing Machine Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality & durability. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at. Lumber Manufacturing Process.

From www.wainwrightfacades.com

Timber Production Process Lumber Manufacturing Process Learn how moisture content defines wood quality & durability. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from lumber milling to kiln drying. Wood manufacturing refers to the process of turning raw wood into a finished product. Lumber Manufacturing Process.

From lightwood.org

Engineered Timber Products Lightwood Lumber Manufacturing Process Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional. Lumber Manufacturing Process.

From www.esshelf.com

What is preservative treated wood and manufacturing process how it was made Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Learn how moisture content defines wood quality & durability. Tracing the production of. Lumber Manufacturing Process.

From www.youtube.com

Paper and Timber Processing from Source Material YouTube Lumber Manufacturing Process Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Tracing the production of today's 2xs to their origins for a fuller understanding. Lumber Manufacturing Process.

From lightwood.org

Engineered Timber Products Lightwood Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality &. Lumber Manufacturing Process.

From www.wellingtonarchitectural.co.uk

Timber Production Process Lumber Manufacturing Process Learn how moisture content defines wood quality & durability. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Wood manufacturing refers to. Lumber Manufacturing Process.

From www.youtube.com

Futurebuild LVL Laminated Veneer Lumber Manufacturing Process YouTube Lumber Manufacturing Process Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from. Lumber Manufacturing Process.

From www.swedishwood.com

From raw material to wood product Swedish Wood Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional. Lumber Manufacturing Process.

From www.wellingtonarchitectural.co.uk

Timber Production Process Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality & durability. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at. Lumber Manufacturing Process.

From www.youtube.com

Ply Wood Manufacturing Process Local Manufacturing YouTube Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Explore the intricacies of wood production, from lumber milling to kiln drying. Wood manufacturing refers to the. Lumber Manufacturing Process.

From sears-trostel.com

Our Process Custom Millwork Services Sears Trostel Lumber Lumber Manufacturing Process Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Tracing the production of today's 2xs to their origins for a fuller understanding. Lumber Manufacturing Process.

From most-wood.com

Production process Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from lumber milling to kiln drying. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local. Lumber Manufacturing Process.

From www.vrogue.co

Marks Lumber Manufacturing Process Part 1 Sawmill Mar vrogue.co Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Learn how moisture content defines wood quality & durability. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Explore the intricacies of wood production, from lumber. Lumber Manufacturing Process.

From markslumber.us

Marks Lumber Manufacturing Process Part 3 OTHER AREAS OF THE MILL Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from lumber milling to kiln drying. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Learn. Lumber Manufacturing Process.

From www.deskera.com

Wood Manufacturing Process A Complete Guide Lumber Manufacturing Process Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Learn how moisture content defines wood quality & durability. Explore the intricacies of wood. Lumber Manufacturing Process.

From www.researchgate.net

Flow diagram for lumber production. Bold borders indicate the four unit Lumber Manufacturing Process Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Learn how moisture content defines wood quality & durability. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Two or three months of. Lumber Manufacturing Process.

From extension.okstate.edu

Laminated Veneer Lumber (LVL) as a Construction Material Oklahoma Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from lumber milling to kiln drying. Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Wood manufacturing refers to the. Lumber Manufacturing Process.

From www.wainwrightfacades.com

Timber Production Process Lumber Manufacturing Process Explore the intricacies of wood production, from lumber milling to kiln drying. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Learn how moisture content defines wood quality & durability. Pieces of lumber that are not only surfaced, but also machined. Lumber Manufacturing Process.

From www.researchgate.net

Flow chart of activities in timber production stages and production of Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local diy store, a piece of. Explore the intricacies of wood production, from. Lumber Manufacturing Process.

From www.fao.org

1. Descriptions of manufacturing processes Lumber Manufacturing Process Tracing the production of today's 2xs to their origins for a fuller understanding of contemporary forest management practices. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber. Lumber Manufacturing Process.

From www.wainwrightfacades.com

Timber Production Process Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Explore the intricacies of wood production, from lumber milling to kiln drying. Wood manufacturing refers to the process of turning raw wood into a finished product — whether that’s some sawn timber at your local. Lumber Manufacturing Process.

From www.dreamstime.com

Wooden Furniture for Home Production Process. Wood Industry Stock Lumber Manufacturing Process Two or three months of air drying followed by several days in a steam heated kiln has been the traditional procedure used by wood product. Pieces of lumber that are not only surfaced, but also machined to produce a specific cross sectional shape are classified as worked. Wood manufacturing refers to the process of turning raw wood into a finished. Lumber Manufacturing Process.