Press Brake Minimum Bend Radius . The inside bend radius should be 1.5 times the metal thickness. The harder and thicker the metal, the greater the minimum bend radius. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how to calculate the press brake bend radius for accurate metal bending. V opening is actually 6 mm, or 0.236 in. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The flange length should be at least six times the metal. Master your projects with precision.

from www.scpressbrake.com

The inside bend radius should be 1.5 times the metal thickness. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. V opening is actually 6 mm, or 0.236 in. Master your projects with precision. The harder and thicker the metal, the greater the minimum bend radius. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The flange length should be at least six times the metal. Learn how to calculate the press brake bend radius for accurate metal bending.

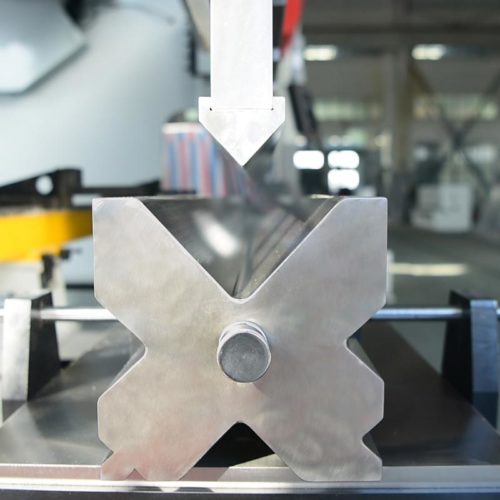

What is Brake Press Dies Minimum Bending Size? Metalforming

Press Brake Minimum Bend Radius The harder and thicker the metal, the greater the minimum bend radius. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how to calculate the press brake bend radius for accurate metal bending. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The inside bend radius should be 1.5 times the metal thickness. The harder and thicker the metal, the greater the minimum bend radius. The flange length should be at least six times the metal. Master your projects with precision. V opening is actually 6 mm, or 0.236 in.

From www.thefabricator.com

Press brake basics Bending across the hem Press Brake Minimum Bend Radius The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. The flange length should be at least six times the metal. Master your projects with precision. The harder and thicker the metal, the greater the minimum bend radius. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only. Press Brake Minimum Bend Radius.

From www.adhmt.com

Press Brake Bend Radius Ultimate Guide ADH Machine Tool Press Brake Minimum Bend Radius The flange length should be at least six times the metal. V opening is actually 6 mm, or 0.236 in. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how. Press Brake Minimum Bend Radius.

From willardkbrooks.blob.core.windows.net

Press Brake Bend Chart at willardkbrooks blog Press Brake Minimum Bend Radius Learn how to calculate the press brake bend radius for accurate metal bending. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The inside bend radius should be 1.5 times the metal thickness. V opening is actually 6 mm, or 0.236 in. Master your projects with precision. The harder and. Press Brake Minimum Bend Radius.

From www.adhmt.com

Press Brake Bend Radius Ultimate Guide ADH Machine Tool Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. The harder and thicker the metal, the greater the minimum bend radius. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to. Press Brake Minimum Bend Radius.

From www.pinterest.com

Press Brake Allowance Chart Allowance chart, Press brake, Welding and Press Brake Minimum Bend Radius Learn how to calculate the press brake bend radius for accurate metal bending. V opening is actually 6 mm, or 0.236 in. The harder and thicker the metal, the greater the minimum bend radius. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Moreover, bends in sheet metal have slightly. Press Brake Minimum Bend Radius.

From selmach.com

Press Brake Toolings, A Guide to Punches and Dies Selmach™ Press Brake Minimum Bend Radius Master your projects with precision. V opening is actually 6 mm, or 0.236 in. Learn how to calculate the press brake bend radius for accurate metal bending. The flange length should be at least six times the metal. The harder and thicker the metal, the greater the minimum bend radius. Moreover, bends in sheet metal have slightly elliptical corner radii,. Press Brake Minimum Bend Radius.

From classlibraryfruehauf.z19.web.core.windows.net

Press Brake Bend Radius Chart Press Brake Minimum Bend Radius V opening is actually 6 mm, or 0.236 in. The flange length should be at least six times the metal. Master your projects with precision. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality. Press Brake Minimum Bend Radius.

From www.powerbrakedies.com

FAQ — Power Brake Dies Press Brake Minimum Bend Radius V opening is actually 6 mm, or 0.236 in. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. Master your projects with precision. Learn how to calculate the press brake bend radius for accurate metal bending. The inside bend radius should be 1.5 times the metal thickness. The minimum acceptable. Press Brake Minimum Bend Radius.

From favpng.com

Bending Sheet Metal Press Brake Allowance Bend Radius, PNG, 1093x1024px Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The flange length should be at least six times the metal. V opening is actually 6 mm, or 0.236 in. The minimum acceptable bending radius for sheet steel ranges from. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Press brake bending basics Die angles, tonnage, and Kfactors Press Brake Minimum Bend Radius The harder and thicker the metal, the greater the minimum bend radius. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. Learn how to calculate the press brake bend radius for accurate metal bending. The inside bend radius should be 1.5 times the metal thickness. V opening is actually 6. Press Brake Minimum Bend Radius.

From www.scpressbrake.com

What is Brake Press Dies Minimum Bending Size? Metalforming Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. The harder and thicker the metal, the greater the minimum bend radius. The flange length should be at least six times the metal. Learn how to calculate the press brake bend radius for accurate metal bending. Master your projects with precision. Moreover, bends in sheet metal have slightly elliptical. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Reasonable tolerancing for press brake bending Press Brake Minimum Bend Radius Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The harder and thicker the metal, the greater the minimum bend radius. The flange length should be at least six times the metal. Learn how to calculate the press brake bend radius for accurate metal bending. The minimum acceptable bending radius. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Press brake bending tips for forming tapered bends and determining Press Brake Minimum Bend Radius Learn how to calculate the press brake bend radius for accurate metal bending. Master your projects with precision. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The flange length should be at least six times the metal. The minimum acceptable bending radius for sheet steel ranges from 0.8s to. Press Brake Minimum Bend Radius.

From midwestpressbrake.com

Radius Forming Midwest Press Brake Dies Inc. Press Brake Minimum Bend Radius The flange length should be at least six times the metal. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. Learn how to calculate the press brake bend radius for accurate metal bending. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays. Press Brake Minimum Bend Radius.

From www.machinemfg.com

How to Calculate Press Brake Bending Force? MachineMFG Press Brake Minimum Bend Radius Learn how to calculate the press brake bend radius for accurate metal bending. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. The flange length should be at least six times the metal. The inside bend radius should be 1.5 times the metal thickness. Master your projects with precision. The. Press Brake Minimum Bend Radius.

From www.machinemfg.com

How to Determine the Bending Radius of Sheet Metal? MachineMfg Press Brake Minimum Bend Radius Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The inside bend radius should be 1.5 times the metal thickness. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Master your projects with precision. V opening is actually 6 mm,. Press Brake Minimum Bend Radius.

From amada.de

Hydraulic PressBrake Press Brake Minimum Bend Radius Master your projects with precision. The inside bend radius should be 1.5 times the metal thickness. The harder and thicker the metal, the greater the minimum bend radius. The flange length should be at least six times the metal. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how. Press Brake Minimum Bend Radius.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Press Brake Minimum Bend Radius The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how to calculate the press brake bend radius for accurate metal bending. Master your projects with precision. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The flange length should. Press Brake Minimum Bend Radius.

From mavink.com

Sheet Metal Minimum Bend Radius Chart Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. Master your projects with precision. Learn how to calculate the press brake bend radius for accurate metal bending. The flange length should be at least six times the metal. V opening is actually 6 mm, or 0.236 in. The harder and thicker the metal, the greater the minimum bend. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Kfactors, Yfactors, and press brake bending precision Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. V opening is actually 6 mm, or 0.236 in. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. Master your. Press Brake Minimum Bend Radius.

From www.merchantsfabrication.com

Understanding Bend Tests & Radius Merchants Fabrication, Inc Press Brake Minimum Bend Radius Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The harder and thicker the metal, the greater the minimum bend radius. The inside bend radius should be 1.5 times the metal thickness. Learn how to calculate the press brake bend radius for accurate metal bending. The minimum acceptable bending radius. Press Brake Minimum Bend Radius.

From www.machinemfg.com

How to determine the bending radius of sheet metal? MachineMfg Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. The flange length should be at least six times the metal. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how to calculate the press brake bend radius for accurate metal bending. Master your projects with precision. Moreover,. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Radius types formed by air bending on a press brake Press Brake Minimum Bend Radius The harder and thicker the metal, the greater the minimum bend radius. V opening is actually 6 mm, or 0.236 in. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The inside bend radius should be 1.5 times the metal thickness. Master your projects with precision. The minimum acceptable bending. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Formable aluminum Press brake bending 6061 with the 20 rule Press Brake Minimum Bend Radius The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. The inside bend radius should be 1.5 times the metal thickness. Master your projects with precision. The flange length should be at least six times the metal. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have. Press Brake Minimum Bend Radius.

From www.youtube.com

Press Brake Large Radius Tool YouTube Press Brake Minimum Bend Radius V opening is actually 6 mm, or 0.236 in. Master your projects with precision. The harder and thicker the metal, the greater the minimum bend radius. Learn how to calculate the press brake bend radius for accurate metal bending. The flange length should be at least six times the metal. Moreover, bends in sheet metal have slightly elliptical corner radii,. Press Brake Minimum Bend Radius.

From www.undergraceovercoffee.com

Amada Press Brake Bending Chart Reviews Of Chart Press Brake Minimum Bend Radius Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The inside bend radius should be 1.5 times the metal thickness. Master your projects with precision. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. The flange length should be at. Press Brake Minimum Bend Radius.

From nyc3.digitaloceanspaces.com

Single Cylinder Press Brake Bend Radius Chart Press Brake Minimum Bend Radius Master your projects with precision. The harder and thicker the metal, the greater the minimum bend radius. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The flange length should be at least six times the metal. The inside bend radius should be 1.5 times the metal thickness. V opening. Press Brake Minimum Bend Radius.

From www.thefabricator.com

The press brake questions keep coming Press Brake Minimum Bend Radius The flange length should be at least six times the metal. Learn how to calculate the press brake bend radius for accurate metal bending. V opening is actually 6 mm, or 0.236 in. The harder and thicker the metal, the greater the minimum bend radius. The inside bend radius should be 1.5 times the metal thickness. Master your projects with. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Press brake bending tips for forming tapered bends and determining Press Brake Minimum Bend Radius Master your projects with precision. The flange length should be at least six times the metal. The inside bend radius should be 1.5 times the metal thickness. The harder and thicker the metal, the greater the minimum bend radius. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. V opening. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Getting back to air forming and bending basics on the press brake Press Brake Minimum Bend Radius The flange length should be at least six times the metal. Learn how to calculate the press brake bend radius for accurate metal bending. Master your projects with precision. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get close to get. The harder and thicker the metal, the greater the minimum bend radius.. Press Brake Minimum Bend Radius.

From www.thefabricator.com

Radius types formed by air bending on a press brake Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Master your projects with precision. V opening is actually 6 mm, or 0.236 in. Moreover, bends in sheet metal have slightly elliptical corner radii, so you only have to get. Press Brake Minimum Bend Radius.

From video.harsle.com

How to make large radius pumping on DA66T Touch controller, Press Press Brake Minimum Bend Radius The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how to calculate the press brake bend radius for accurate metal bending. The inside bend radius should be 1.5 times the metal thickness. The flange length should be at least six times the metal. V opening is actually 6 mm,. Press Brake Minimum Bend Radius.

From www.chegg.com

Consider the chart “Minimum Bend Radius for Maximum Press Brake Minimum Bend Radius The harder and thicker the metal, the greater the minimum bend radius. Master your projects with precision. The flange length should be at least six times the metal. The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how to calculate the press brake bend radius for accurate metal bending.. Press Brake Minimum Bend Radius.

From willardkbrooks.blob.core.windows.net

Press Brake Bend Chart at willardkbrooks blog Press Brake Minimum Bend Radius The inside bend radius should be 1.5 times the metal thickness. Learn how to calculate the press brake bend radius for accurate metal bending. The harder and thicker the metal, the greater the minimum bend radius. Master your projects with precision. V opening is actually 6 mm, or 0.236 in. The minimum acceptable bending radius for sheet steel ranges from. Press Brake Minimum Bend Radius.

From www.machines4u.com.au

New CMT Press Brake Tooling Radius Bar 6mm Radius CMT Press Brake Press Brake Minimum Bend Radius The minimum acceptable bending radius for sheet steel ranges from 0.8s to 2s, although material quality plays a role. Learn how to calculate the press brake bend radius for accurate metal bending. The harder and thicker the metal, the greater the minimum bend radius. The flange length should be at least six times the metal. V opening is actually 6. Press Brake Minimum Bend Radius.