Finished Products And Raw Materials Difference . Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. This includes items that will eventually be part of the finished product. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. Inventory is classified as falling within three general categories: Finished inventory differs from raw materials and work in progress (wip) inventory. While raw materials are the inputs used in. Direct raw materials are placed in current assets and are. Raw materials, work in progress, and finished goods. Raw materials are the primary. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Raw materials are all the essential items needed to create whatever good you offer. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the.

from www.inflowinventory.com

While raw materials are the inputs used in. Raw materials are all the essential items needed to create whatever good you offer. Inventory is classified as falling within three general categories: Raw materials, work in progress, and finished goods. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. This includes items that will eventually be part of the finished product. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Direct raw materials are placed in current assets and are.

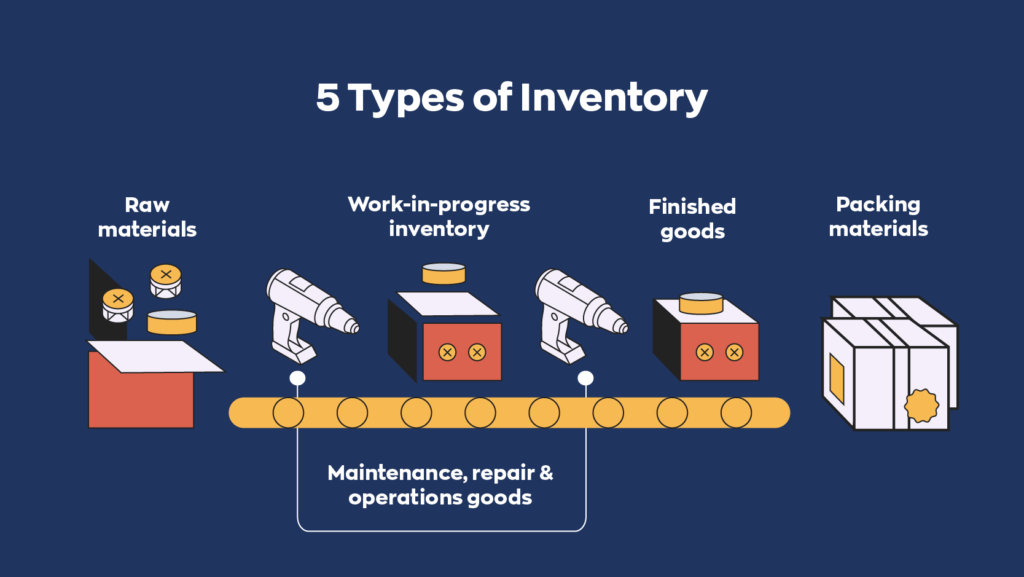

The 5 Fundamental Types of Inventory Everyone Should Know

Finished Products And Raw Materials Difference Direct raw materials are placed in current assets and are. Raw materials are the primary. While raw materials are the inputs used in. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. Finished inventory differs from raw materials and work in progress (wip) inventory. Raw materials, work in progress, and finished goods. This includes items that will eventually be part of the finished product. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Inventory is classified as falling within three general categories: The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Raw materials are all the essential items needed to create whatever good you offer. Direct raw materials are placed in current assets and are.

From www.bol.com

Raw and Finished Materials, Brian Dureu 9781606500736 Boeken Finished Products And Raw Materials Difference Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. Finished inventory differs from raw materials and work in progress (wip) inventory. Direct raw materials are placed in current assets and are. Inventory is classified as falling within three general categories: Raw. Finished Products And Raw Materials Difference.

From ar.inspiredpencil.com

Raw Materials Examples Finished Products And Raw Materials Difference This includes items that will eventually be part of the finished product. Raw materials, work in progress, and finished goods. Raw materials are all the essential items needed to create whatever good you offer. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to. Finished Products And Raw Materials Difference.

From www.principlesofaccounting.com

Process Costing Finished Products And Raw Materials Difference Raw materials are the primary. While raw materials are the inputs used in. Raw materials, work in progress, and finished goods. Raw materials are all the essential items needed to create whatever good you offer. Inventory is classified as falling within three general categories: Finished inventory differs from raw materials and work in progress (wip) inventory. Direct raw materials are. Finished Products And Raw Materials Difference.

From suppliers.sourcingsupport.metro.de

What is the difference between Raw material and Finished products Finished Products And Raw Materials Difference While raw materials are the inputs used in. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Raw materials. Finished Products And Raw Materials Difference.

From adynamics.com.my

What is Inventory? Definitions, Examples, Types, Valuation, and More Finished Products And Raw Materials Difference Raw materials are the primary. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. The three types of inventories are direct material inventory, work in. Finished Products And Raw Materials Difference.

From www.youtube.com

Types of InventoryRaw Materials, WorkinProgress(WIP), Finished Goods Finished Products And Raw Materials Difference Finished inventory differs from raw materials and work in progress (wip) inventory. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a. Finished Products And Raw Materials Difference.

From blog.megaventory.com

Raw Materials Definition, Types, and Accounting The Megaventory Blog Finished Products And Raw Materials Difference Raw materials are all the essential items needed to create whatever good you offer. Raw materials, work in progress, and finished goods. Direct raw materials are placed in current assets and are. Finished inventory differs from raw materials and work in progress (wip) inventory. The three types of inventories are direct material inventory, work in progress inventory and the finished. Finished Products And Raw Materials Difference.

From www.arenasolutions.com

Finished Goods (FG) Definition Arena Finished Products And Raw Materials Difference Finished inventory differs from raw materials and work in progress (wip) inventory. Raw materials, work in progress, and finished goods. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. While raw materials are the inputs used in. Raw materials are the. Finished Products And Raw Materials Difference.

From www.netsuite.com

Finished Goods Inventory Explained NetSuite Finished Products And Raw Materials Difference Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. The three types of inventories are direct material inventory, work. Finished Products And Raw Materials Difference.

From giobioeae.blob.core.windows.net

What Are Raw Agricultural Products at James Slater blog Finished Products And Raw Materials Difference Finished inventory differs from raw materials and work in progress (wip) inventory. Raw materials are the primary. Raw materials, work in progress, and finished goods. This includes items that will eventually be part of the finished product. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that. Finished Products And Raw Materials Difference.

From www.slideserve.com

PPT Source of Raw Material PowerPoint Presentation, free download Finished Products And Raw Materials Difference Raw materials are all the essential items needed to create whatever good you offer. While raw materials are the inputs used in. Raw materials are the primary. Finished inventory differs from raw materials and work in progress (wip) inventory. Direct raw materials are placed in current assets and are. The primary difference is that raw materials inventory is used in. Finished Products And Raw Materials Difference.

From collectionperformance.com

Managing Raw Materials Logistics and Classification! Finished Products And Raw Materials Difference Inventory is classified as falling within three general categories: The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are. Finished Products And Raw Materials Difference.

From brainly.in

create a flow is showing a transformation of any article from the raw Finished Products And Raw Materials Difference The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. This includes items that will eventually be part of the finished product. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock. Finished Products And Raw Materials Difference.

From www.investopedia.com

Raw Materials Definition, Accounting, and Direct vs. Indirect Finished Products And Raw Materials Difference Raw materials, work in progress, and finished goods. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. This includes items that will eventually be part of the finished product. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory. Finished Products And Raw Materials Difference.

From www.slideshare.net

Raw and manufactured materials 5º Finished Products And Raw Materials Difference Raw materials, work in progress, and finished goods. Inventory is classified as falling within three general categories: Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. Raw materials are all the essential items needed to create whatever good you offer. While. Finished Products And Raw Materials Difference.

From www.slideshare.net

Raw material Finished Products And Raw Materials Difference Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. While raw materials are the inputs used in. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. Raw materials. Finished Products And Raw Materials Difference.

From www.inflowinventory.com

The 5 Fundamental Types of Inventory Everyone Should Know Finished Products And Raw Materials Difference Inventory is classified as falling within three general categories: Raw materials, work in progress, and finished goods. Direct raw materials are placed in current assets and are. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Finished inventory differs from raw materials and work in progress (wip). Finished Products And Raw Materials Difference.

From www.pinterest.com

We test your food at every stage, from raw materials to finished Finished Products And Raw Materials Difference While raw materials are the inputs used in. Finished inventory differs from raw materials and work in progress (wip) inventory. Raw materials are all the essential items needed to create whatever good you offer. Raw materials, work in progress, and finished goods. Raw materials are the primary. The three types of inventories are direct material inventory, work in progress inventory. Finished Products And Raw Materials Difference.

From www.pinterest.com

Production & manufacturing are often used interchangeably, as people Finished Products And Raw Materials Difference Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Raw materials, work in progress,. Finished Products And Raw Materials Difference.

From blog.megaventory.com

Finished Goods Definition Finished Products And Raw Materials Difference Direct raw materials are placed in current assets and are. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Raw materials, work in progress, and finished goods. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies,. Finished Products And Raw Materials Difference.

From loeoyxykn.blob.core.windows.net

What Is Raw Material With Example at Douglas Keller blog Finished Products And Raw Materials Difference The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Raw materials, work in progress, and finished goods. Raw materials are the primary. This includes items that will eventually be part of the finished product. While raw materials are the inputs used in.. Finished Products And Raw Materials Difference.

From gioibjqhg.blob.core.windows.net

Raw Materials Vs Direct Materials at Daniel Richards blog Finished Products And Raw Materials Difference The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Direct raw materials are placed in current assets and are. Raw materials are the primary. Raw materials are all the essential items needed to create whatever good you offer. The primary difference is. Finished Products And Raw Materials Difference.

From www.researchgate.net

a) Manufacturing floor plan showing the location of the raw materials Finished Products And Raw Materials Difference The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. This includes items that will eventually be part of the finished. Finished Products And Raw Materials Difference.

From www.slideteam.net

Raw Materials Finished Products Ppt Powerpoint Presentation Ideas Finished Products And Raw Materials Difference Direct raw materials are placed in current assets and are. While raw materials are the inputs used in. Raw materials are the primary. Inventory is classified as falling within three general categories: The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Raw materials are all the essential. Finished Products And Raw Materials Difference.

From www.liveworksheets.com

Raw materials, processed materials and finished Finished Products And Raw Materials Difference Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Finished inventory differs from raw materials and work in progress. Finished Products And Raw Materials Difference.

From www.slideshare.net

Raw materials Finished Products And Raw Materials Difference The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Raw materials are the primary. Direct raw materials are placed in current assets and are. While raw materials are the inputs used in. Direct raw materials are materials that companies directly use in the manufacturing of a finished. Finished Products And Raw Materials Difference.

From www.vem-tooling.com

Raw Material Procurement in Manufacturing Finished Products And Raw Materials Difference Finished inventory differs from raw materials and work in progress (wip) inventory. This includes items that will eventually be part of the finished product. Inventory is classified as falling within three general categories: While raw materials are the inputs used in. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where. Finished Products And Raw Materials Difference.

From klavhzvhx.blob.core.windows.net

What Are Company Materials at Gerald Pletcher blog Finished Products And Raw Materials Difference Direct raw materials are placed in current assets and are. This includes items that will eventually be part of the finished product. Finished goods inventory is the third and final classification of inventory that is used for accounting purposes by manufacturing companies, the items that are sold to the customer. Inventory is classified as falling within three general categories: The. Finished Products And Raw Materials Difference.

From www.researchgate.net

Estimates on raw materials, semifinished and finished products (a Finished Products And Raw Materials Difference While raw materials are the inputs used in. Raw materials, work in progress, and finished goods. Raw materials are the primary. Raw materials are all the essential items needed to create whatever good you offer. The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the. Finished Products And Raw Materials Difference.

From exorcidmv.blob.core.windows.net

What Is The Difference Between Raw Materials And Finished Goods at Finished Products And Raw Materials Difference Direct raw materials are placed in current assets and are. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Raw materials are the primary. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. Raw. Finished Products And Raw Materials Difference.

From cedrftzk.blob.core.windows.net

Finished Products And Raw Materials Difference at Herbert Therrien blog Finished Products And Raw Materials Difference The three types of inventories are direct material inventory, work in progress inventory and the finished goods inventory where the direct material inventory includes the stock of. Raw materials are all the essential items needed to create whatever good you offer. This includes items that will eventually be part of the finished product. The primary difference is that raw materials. Finished Products And Raw Materials Difference.

From cedrftzk.blob.core.windows.net

Finished Products And Raw Materials Difference at Herbert Therrien blog Finished Products And Raw Materials Difference Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. Raw materials are all the essential items needed to create whatever good you offer. While raw materials are the inputs used in. This includes items that will eventually be part of the finished product. Inventory is classified as. Finished Products And Raw Materials Difference.

From cedrftzk.blob.core.windows.net

Finished Products And Raw Materials Difference at Herbert Therrien blog Finished Products And Raw Materials Difference While raw materials are the inputs used in. The primary difference is that raw materials inventory is used in the production of goods and finished goods inventory is what the. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. Direct raw materials are placed in current assets. Finished Products And Raw Materials Difference.

From techbriefly.com

What Is the difference between raw material inventory & finished goods Finished Products And Raw Materials Difference This includes items that will eventually be part of the finished product. Finished inventory differs from raw materials and work in progress (wip) inventory. Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. Inventory is classified as falling within three general categories: Direct raw materials are placed. Finished Products And Raw Materials Difference.

From exojccmfr.blob.core.windows.net

Final Products And Raw Materials at Walter Wagner blog Finished Products And Raw Materials Difference Direct raw materials are materials that companies directly use in the manufacturing of a finished product, such as wood for a chair. Raw materials are the primary. Inventory is classified as falling within three general categories: Direct raw materials are placed in current assets and are. Raw materials, work in progress, and finished goods. Raw materials are all the essential. Finished Products And Raw Materials Difference.