Row Cycle Time (Tracking) . key features of manufacturing cycle time tracking. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. Cycle time includes processing, moving, inspection and queue time for the item. Our cycle time tracking solution seamlessly captures workshop data, historical. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. one of the principles of lean thinking is to eliminate delays which consume up to 95% of the total cycle time. cycle time captures all operational tasks required to complete a production unit. The minimum time in cycles it takes a row to complete a full cycle.

from econoshift.com

key features of manufacturing cycle time tracking. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. one of the principles of lean thinking is to eliminate delays which consume up to 95% of the total cycle time. cycle time captures all operational tasks required to complete a production unit. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. Our cycle time tracking solution seamlessly captures workshop data, historical. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. The minimum time in cycles it takes a row to complete a full cycle. Cycle time includes processing, moving, inspection and queue time for the item.

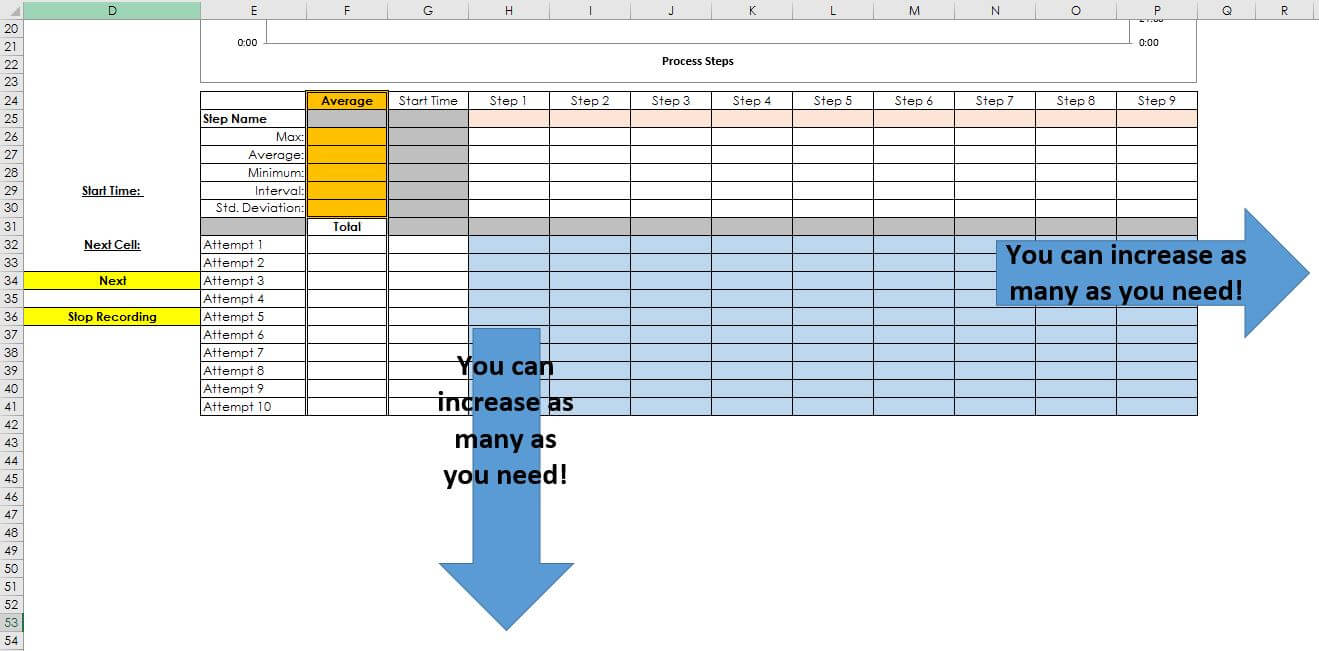

【Improved!】Cycle Time Measuring Excel Tool Measure multiple operators

Row Cycle Time (Tracking) determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. cycle time captures all operational tasks required to complete a production unit. The minimum time in cycles it takes a row to complete a full cycle. one of the principles of lean thinking is to eliminate delays which consume up to 95% of the total cycle time. Cycle time includes processing, moving, inspection and queue time for the item. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. Our cycle time tracking solution seamlessly captures workshop data, historical. key features of manufacturing cycle time tracking. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as.

From blog.coupler.io

Time Tracking Spreadsheet in Excel Coupler.io Blog Row Cycle Time (Tracking) The minimum time in cycles it takes a row to complete a full cycle. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. Our cycle time tracking solution. Row Cycle Time (Tracking).

From katprotech.com

Cycle Time Tracking Solution Process Management Katpro Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. Cycle time includes processing, moving, inspection and queue time for the item. key features. Row Cycle Time (Tracking).

From katprotech.com

Cycle Time Tracking Solution Process Management Katpro Row Cycle Time (Tracking) key features of manufacturing cycle time tracking. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. Our cycle time tracking solution seamlessly captures workshop data, historical. Cycle time includes processing, moving, inspection and queue time for the item. cycle time captures all operational tasks required to complete a. Row Cycle Time (Tracking).

From www.pivotaltracker.com

Cycle Time report Row Cycle Time (Tracking) Our cycle time tracking solution seamlessly captures workshop data, historical. cycle time captures all operational tasks required to complete a production unit. key features of manufacturing cycle time tracking. Cycle time includes processing, moving, inspection and queue time for the item. The minimum time in cycles it takes a row to complete a full cycle. knowing the. Row Cycle Time (Tracking).

From www.scribd.com

Cycle Time Tracking Variance Analysis in Excel 1 PDF Mean Row Cycle Time (Tracking) knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. key features of manufacturing cycle time tracking. The minimum time in cycles it takes a row to complete. Row Cycle Time (Tracking).

From www.7pace.com

Velocity Management in Agile 7pace Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. key features of manufacturing cycle time tracking. one of the principles of lean thinking is to eliminate delays which consume up to 95% of the total cycle time. The minimum time in. Row Cycle Time (Tracking).

From www.amper.xyz

Digital Tally Sheet Tool Automate OEE & Cycle Time Tracking Row Cycle Time (Tracking) key features of manufacturing cycle time tracking. Cycle time includes processing, moving, inspection and queue time for the item. The minimum time in cycles it takes a row to complete a full cycle. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. cycle time captures. Row Cycle Time (Tracking).

From templatelab.com

40 Useful Time Study Templates (Excel / Word) ᐅ TemplateLab Row Cycle Time (Tracking) cycle time captures all operational tasks required to complete a production unit. The minimum time in cycles it takes a row to complete a full cycle. one of the principles of lean thinking is to eliminate delays which consume up to 95% of the total cycle time. key features of manufacturing cycle time tracking. knowing the. Row Cycle Time (Tracking).

From www.vertex42.com

Bike Race Timeline in Excel Row Cycle Time (Tracking) cycle time captures all operational tasks required to complete a production unit. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. Our cycle time tracking solution seamlessly captures workshop data, historical. key features of manufacturing cycle time tracking. one of. Row Cycle Time (Tracking).

From katprotech.com

Cycle Time Tracking Solution Process Management Katpro Row Cycle Time (Tracking) Our cycle time tracking solution seamlessly captures workshop data, historical. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. The minimum time in cycles it takes a row to complete a full cycle. one of the principles of lean thinking is to eliminate delays which consume up to 95%. Row Cycle Time (Tracking).

From www.leanstrategiesinternational.com

Cycle Time Template Row Cycle Time (Tracking) Our cycle time tracking solution seamlessly captures workshop data, historical. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. The minimum time in cycles it takes a row to complete a full cycle. manufacturing cycle time, also referred to as throughput time, is the amount of. Row Cycle Time (Tracking).

From monday.com

What is cycle time? Blog Row Cycle Time (Tracking) cycle time captures all operational tasks required to complete a production unit. Cycle time includes processing, moving, inspection and queue time for the item. Our cycle time tracking solution seamlessly captures workshop data, historical. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. knowing the most common cycle. Row Cycle Time (Tracking).

From screenful.com

Cycle Time Agile & Lean Metrics Blog de Screenful Row Cycle Time (Tracking) Cycle time includes processing, moving, inspection and queue time for the item. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. key features of manufacturing cycle time tracking. Our cycle time tracking solution seamlessly captures workshop data, historical. manufacturing cycle time, also referred to as throughput time, is. Row Cycle Time (Tracking).

From quickbooks.intuit.com

Excel Time Sheet Guide Free Templates Download QuickBooks Row Cycle Time (Tracking) key features of manufacturing cycle time tracking. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. Our cycle time tracking solution seamlessly captures workshop data, historical. one of the principles of lean thinking is to eliminate delays which consume up to. Row Cycle Time (Tracking).

From www.shortcut.com

Gain insights and plan more effectively with Cycle Time and Lead Time Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. Cycle time includes processing, moving, inspection and queue time for the item. Our cycle time. Row Cycle Time (Tracking).

From ahealthylifeforme.com

15 Minute Rowing Workout A Healthy Life For Me Row Cycle Time (Tracking) knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. The minimum time in cycles it takes a row to complete a full cycle. Cycle time includes processing, moving,. Row Cycle Time (Tracking).

From www.template.net

12+ Sample Time Tracking Templates Row Cycle Time (Tracking) determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. cycle time captures all operational tasks required to complete a production unit. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. key features of manufacturing cycle. Row Cycle Time (Tracking).

From medium.com

Cycle Time — Using data to help empower and create powerful agile teams Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. Our cycle time tracking solution seamlessly captures workshop data, historical. Cycle time includes processing, moving, inspection and queue time for the item. The minimum time in cycles it takes a row to complete a. Row Cycle Time (Tracking).

From getnave.com

Cycle Time Scatterplot Nave Row Cycle Time (Tracking) Our cycle time tracking solution seamlessly captures workshop data, historical. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. key features of manufacturing cycle time tracking. The minimum time in cycles it takes a row to complete a full cycle. manufacturing cycle time, also referred to as throughput. Row Cycle Time (Tracking).

From www.projectmanager.com

15 Excel Spreadsheet Templates for Tracking Tasks, Costs and Time Row Cycle Time (Tracking) knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. key features of manufacturing cycle time tracking. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. cycle time captures. Row Cycle Time (Tracking).

From www.smartsheet.com

Free Project Tracking Templates Smartsheet Row Cycle Time (Tracking) key features of manufacturing cycle time tracking. cycle time captures all operational tasks required to complete a production unit. Our cycle time tracking solution seamlessly captures workshop data, historical. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. knowing the most common cycle time of user stories. Row Cycle Time (Tracking).

From www.presentationeze.com

Cycle Time Definition Analyse Cycle Time Analysis Row Cycle Time (Tracking) Our cycle time tracking solution seamlessly captures workshop data, historical. Cycle time includes processing, moving, inspection and queue time for the item. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. key features of manufacturing cycle time tracking. The minimum time in. Row Cycle Time (Tracking).

From alectena.com

Cycle Time Optimization Strategies Easy Steps to Boost Efficiency Row Cycle Time (Tracking) The minimum time in cycles it takes a row to complete a full cycle. key features of manufacturing cycle time tracking. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. Cycle time includes processing, moving, inspection and queue time for the item. Our cycle time tracking solution seamlessly captures. Row Cycle Time (Tracking).

From toggl.com

Project Time Tracking Spreadsheet (Excel + Google Sheets) Toggl Blog Row Cycle Time (Tracking) knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. key features of manufacturing cycle time tracking. cycle time captures all operational tasks required to complete a production unit. The minimum time in cycles it takes a row to complete a full cycle. manufacturing cycle. Row Cycle Time (Tracking).

From templatelab.com

47 Free Time Tracking Spreadsheets [Excel] ᐅ TemplateLab Row Cycle Time (Tracking) The minimum time in cycles it takes a row to complete a full cycle. one of the principles of lean thinking is to eliminate delays which consume up to 95% of the total cycle time. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to. Row Cycle Time (Tracking).

From 7pace.com

How Do Sprint Cycles Work in Agile Development? 7pace Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. Our cycle time tracking solution seamlessly captures workshop data, historical. cycle time captures all operational tasks required to complete a production unit. determines the minimum number of clock cycles a memory row. Row Cycle Time (Tracking).

From blog.csdn.net

DRAM知识整理系列(三):部分时序参数整理_read command to 1st data out timingCSDN博客 Row Cycle Time (Tracking) determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. cycle time captures all operational tasks required to complete a production unit. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. Our cycle time tracking solution seamlessly. Row Cycle Time (Tracking).

From monday.com

What is cycle time? Blog Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. Our cycle time tracking solution seamlessly captures workshop data, historical. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. knowing the most common. Row Cycle Time (Tracking).

From www.goretro.ai

How to measure cycle time in JIRA Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. one of the principles of lean thinking is to eliminate delays which consume up. Row Cycle Time (Tracking).

From getnave.com

Cycle Time Scatterplot for Trello Nave Row Cycle Time (Tracking) The minimum time in cycles it takes a row to complete a full cycle. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. Our cycle time tracking solution seamlessly captures workshop data, historical. determines the minimum number of clock cycles a memory. Row Cycle Time (Tracking).

From econoshift.com

【Improved!】Cycle Time Measuring Excel Tool Measure multiple operators Row Cycle Time (Tracking) cycle time captures all operational tasks required to complete a production unit. The minimum time in cycles it takes a row to complete a full cycle. Our cycle time tracking solution seamlessly captures workshop data, historical. manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials. Row Cycle Time (Tracking).

From monday.com

What is a project management life cycle? Blog Row Cycle Time (Tracking) knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as well as. The minimum time in cycles it takes a row to complete a full cycle. key features of manufacturing cycle time tracking. Cycle time includes processing, moving, inspection and queue time for the item. Our cycle time tracking. Row Cycle Time (Tracking).

From katprotech.com

Cycle Time Tracking Solution Process Management Katpro Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. The minimum time in cycles it takes a row to complete a full cycle. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as. Row Cycle Time (Tracking).

From templatelab.com

47 Free Time Tracking Spreadsheets [Excel] ᐅ TemplateLab Row Cycle Time (Tracking) manufacturing cycle time, also referred to as throughput time, is the amount of time spent working on an item from raw materials to finished product. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. one of the principles of lean thinking is to eliminate delays which consume up. Row Cycle Time (Tracking).

From www.smartsheet.com

Free Project Tracking Templates Smartsheet Row Cycle Time (Tracking) key features of manufacturing cycle time tracking. determines the minimum number of clock cycles a memory row takes to complete a full cycle, from row. cycle time captures all operational tasks required to complete a production unit. knowing the most common cycle time of user stories you’ve completed can help you to become more consistent, as. Row Cycle Time (Tracking).