Gasket Design For Pressure Vessel . Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. The flat gasket is the oldest and most popular way to seal a flange or joint. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. The asme code for pressure vessels, section viii, div. 2, is the most commonly used design method for gasketed joints where important. Construction must be commensurate with the design pressure of the vessel. Lower pressure systems must incorporate a softer, more easily. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under.

from www.chegg.com

New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. The asme code for pressure vessels, section viii, div. 2, is the most commonly used design method for gasketed joints where important. Lower pressure systems must incorporate a softer, more easily. Construction must be commensurate with the design pressure of the vessel. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. The flat gasket is the oldest and most popular way to seal a flange or joint. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels.

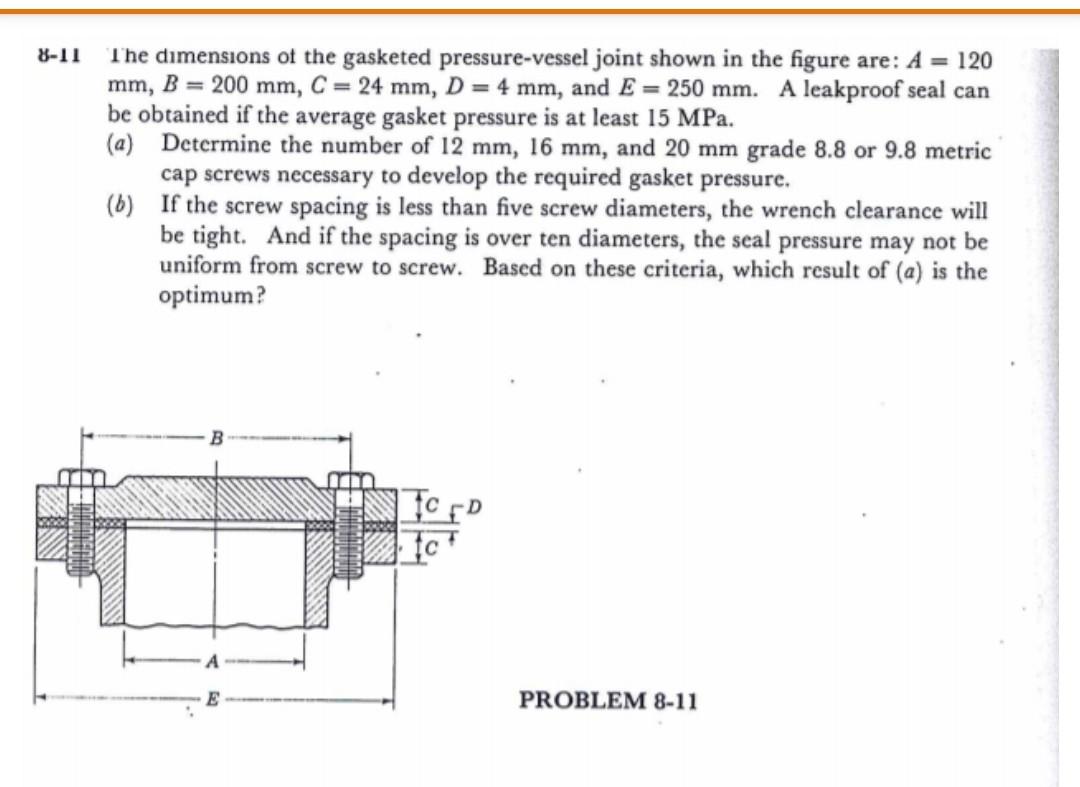

Solved 811 The dimensions of the gasketed pressurevessel

Gasket Design For Pressure Vessel New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Lower pressure systems must incorporate a softer, more easily. 2, is the most commonly used design method for gasketed joints where important. Construction must be commensurate with the design pressure of the vessel. The asme code for pressure vessels, section viii, div. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. The flat gasket is the oldest and most popular way to seal a flange or joint. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels.

From www.chegg.com

4.[40p.] The end cap of an aluminum pressure vessel Gasket Design For Pressure Vessel The flat gasket is the oldest and most popular way to seal a flange or joint. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Construction must be commensurate with the design pressure of the vessel. 2, is the most commonly used design method for. Gasket Design For Pressure Vessel.

From elliottingrid.blogspot.com

12+ Pressure Vessel Manway Covers ElliottIngrid Gasket Design For Pressure Vessel Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. The flat gasket is the oldest and most popular way to seal a flange or joint. Construction must be commensurate with the design pressure of the vessel. Physical properties are important factors when considering gasket design and the. Gasket Design For Pressure Vessel.

From servcocanada.com

Pressure Vessel Design & Repair ServcoCanada Gasket Design For Pressure Vessel Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. The asme code for pressure vessels, section viii, div. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. Physical properties are important factors when considering gasket design and the primary selection. Gasket Design For Pressure Vessel.

From www.numerade.com

The figure illustrates the nonpermanent connection of a steel cylinder Gasket Design For Pressure Vessel Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. Lower pressure systems must incorporate a softer, more easily. 2, is the most commonly used design method for gasketed joints where important.. Gasket Design For Pressure Vessel.

From www.youtube.com

Pressure vessel Design Standard Part2 YouTube Gasket Design For Pressure Vessel 2, is the most commonly used design method for gasketed joints where important. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Lower. Gasket Design For Pressure Vessel.

From ezotank.en.made-in-china.com

Stainless Steel Sanitary Round Outward Pressure Tank Vessel Manhole Gasket Design For Pressure Vessel Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. The flat gasket is the oldest and most popular way to seal a flange or joint.. Gasket Design For Pressure Vessel.

From www.vrogue.co

Pressure Vessel Design Using Composite Materials Oddf vrogue.co Gasket Design For Pressure Vessel Lower pressure systems must incorporate a softer, more easily. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. Construction must be commensurate with the design pressure of the vessel. The flat. Gasket Design For Pressure Vessel.

From howtoglowupbeforehighschool.blogspot.com

gasket design for pressure vessel howtoglowupbeforehighschool Gasket Design For Pressure Vessel Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. The asme code for pressure vessels, section viii, div. The flat gasket is the oldest and most popular way to seal a. Gasket Design For Pressure Vessel.

From www.chegg.com

The figure below shows the connection of a steel Gasket Design For Pressure Vessel 2, is the most commonly used design method for gasketed joints where important. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. The asme code for pressure vessels, section viii, div. Physical properties are important factors when considering gasket design and the primary selection of. Gasket Design For Pressure Vessel.

From oldvolkswagenvanforsale.blogspot.com

gasket design for pressure vessel oldvolkswagenvanforsale Gasket Design For Pressure Vessel The asme code for pressure vessels, section viii, div. 2, is the most commonly used design method for gasketed joints where important. Lower pressure systems must incorporate a softer, more easily. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. New gasket design factors being developed by asme are for bolted joint designs. Gasket Design For Pressure Vessel.

From www.specialistsealingproducts.co.uk

What Are The Best Gaskets for High Pressure Vessels? Gasket Design For Pressure Vessel Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Construction must be commensurate with the design pressure of the vessel. 2, is the most commonly used design method for gasketed joints. Gasket Design For Pressure Vessel.

From pveng.com

Nozzle Design Pressure Vessel Engineering Gasket Design For Pressure Vessel The asme code for pressure vessels, section viii, div. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. The flat gasket is the oldest and most popular way to seal a flange or joint. Gaskets are used to create a static seal between two stationary. Gasket Design For Pressure Vessel.

From cierne.en.made-in-china.com

Spiral Wound Gasket Gaskets for Pressure Vessels China Gasket and Gasket Design For Pressure Vessel 2, is the most commonly used design method for gasketed joints where important. Lower pressure systems must incorporate a softer, more easily. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. The flat gasket is the oldest and most popular way to seal a flange or joint. Physical properties are important factors when. Gasket Design For Pressure Vessel.

From www.scribd.com

CH1 Pressure Vessel Design1 PDF Strength Of Materials Stress Gasket Design For Pressure Vessel Lower pressure systems must incorporate a softer, more easily. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. 2, is the most commonly. Gasket Design For Pressure Vessel.

From mavink.com

Pressure Vessel Installation Gasket Design For Pressure Vessel Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. The flat gasket is the oldest and most popular way to seal a flange or joint. Lower pressure systems must incorporate a softer, more easily. Construction must be commensurate with the design pressure of the vessel. Gaskets are used to create a static seal. Gasket Design For Pressure Vessel.

From qrcvalves.com

Pressure Seal Valves Working Principle, vs. Bolted, Gaskets Gasket Design For Pressure Vessel New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. The flat gasket is the oldest and most popular way to seal a flange or joint. 2, is the most commonly used design method for gasketed joints where important. Lower pressure systems must incorporate a softer,. Gasket Design For Pressure Vessel.

From www.parrinst.com

Series 4790 Pressure Vessel Systems, 25100 mL Parr Instrument Company Gasket Design For Pressure Vessel Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Construction must be commensurate with the design pressure of the vessel. The flat gasket is the oldest and most popular way to seal a flange or joint. Boiler and pressure vessel code contains rules for the design and. Gasket Design For Pressure Vessel.

From design.udlvirtual.edu.pe

How To Design Pressure Vessel Asme Design Talk Gasket Design For Pressure Vessel Lower pressure systems must incorporate a softer, more easily. The asme code for pressure vessels, section viii, div. Construction must be commensurate with the design pressure of the vessel. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. New gasket design factors being developed by asme are. Gasket Design For Pressure Vessel.

From engineeringlearn.com

What is Gaskets? Types of Gaskets, Function, Quality & Selection Gasket Design For Pressure Vessel Lower pressure systems must incorporate a softer, more easily. The flat gasket is the oldest and most popular way to seal a flange or joint. The asme code for pressure vessels, section viii, div. Construction must be commensurate with the design pressure of the vessel. New gasket design factors being developed by asme are for bolted joint designs where it. Gasket Design For Pressure Vessel.

From mungfali.com

Pressure Vessel Design Gasket Design For Pressure Vessel The flat gasket is the oldest and most popular way to seal a flange or joint. Construction must be commensurate with the design pressure of the vessel. 2, is the most commonly used design method for gasketed joints where important. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that. Gasket Design For Pressure Vessel.

From www.mdpi.com

Designs Free FullText Design and Analysis of a Typical Vertical Gasket Design For Pressure Vessel Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. Construction must be commensurate with the design pressure of the vessel. The asme code for pressure vessels, section viii, div. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Gaskets are. Gasket Design For Pressure Vessel.

From www.chegg.com

Solved 811 The dimensions of the gasketed pressurevessel Gasket Design For Pressure Vessel Construction must be commensurate with the design pressure of the vessel. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. 2, is the most commonly. Gasket Design For Pressure Vessel.

From www.codeware.com

Automatic Pressure Vessel, Heat Exchanger and Piping Drawings Codeware Gasket Design For Pressure Vessel 2, is the most commonly used design method for gasketed joints where important. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. The asme code for pressure vessels, section viii, div.. Gasket Design For Pressure Vessel.

From www.semanticscholar.org

Figure 1 from Design of the Reactor Pressure Vessel and Internals of Gasket Design For Pressure Vessel The asme code for pressure vessels, section viii, div. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. Boiler and pressure vessel code. Gasket Design For Pressure Vessel.

From www.vrogue.co

Pressure Vessel And Tank Design Fe Consultants vrogue.co Gasket Design For Pressure Vessel Construction must be commensurate with the design pressure of the vessel. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. The flat gasket is the oldest and most popular. Gasket Design For Pressure Vessel.

From www.youtube.com

Pressure Vessel Fabrication Vessels Supports Detailing Part7 Let Gasket Design For Pressure Vessel Construction must be commensurate with the design pressure of the vessel. Lower pressure systems must incorporate a softer, more easily. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is. Gasket Design For Pressure Vessel.

From blog.thepipingmart.com

Pressure Vessels Types, Design, Supports, Applications, Materials Gasket Design For Pressure Vessel Construction must be commensurate with the design pressure of the vessel. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. The flat gasket is the oldest and most popular way to seal a flange or joint. Boiler and pressure vessel code contains rules for the. Gasket Design For Pressure Vessel.

From www.vrogue.co

Pressure Vessel Design Creo 3d Design Ltd vrogue.co Gasket Design For Pressure Vessel The flat gasket is the oldest and most popular way to seal a flange or joint. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that. Gasket Design For Pressure Vessel.

From cierne.en.made-in-china.com

Modified PTFE Gasket for High Pressure Vessels China Gasket for Valve Gasket Design For Pressure Vessel 2, is the most commonly used design method for gasketed joints where important. The asme code for pressure vessels, section viii, div. Construction must be commensurate with the design pressure of the vessel. Gaskets are used to create a static seal between two stationary members of a mechanical assembly and to maintain that seal under. New gasket design factors being. Gasket Design For Pressure Vessel.

From howtoglowupbeforehighschool.blogspot.com

gasket design for pressure vessel howtoglowupbeforehighschool Gasket Design For Pressure Vessel Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. Gaskets are used to create a static seal between two stationary members of a. Gasket Design For Pressure Vessel.

From pveng.com

Nozzle Design Pressure Vessel Engineering Gasket Design For Pressure Vessel Lower pressure systems must incorporate a softer, more easily. The flat gasket is the oldest and most popular way to seal a flange or joint. 2, is the most commonly used design method for gasketed joints where important. The asme code for pressure vessels, section viii, div. New gasket design factors being developed by asme are for bolted joint designs. Gasket Design For Pressure Vessel.

From www.youtube.com

Pressure Vessel Fabrication Nozzle Marking on Shell and Dish ends in Gasket Design For Pressure Vessel Construction must be commensurate with the design pressure of the vessel. 2, is the most commonly used design method for gasketed joints where important. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. Lower pressure systems must incorporate a softer, more easily. New gasket design factors being developed by asme are for bolted. Gasket Design For Pressure Vessel.

From atrinsanat.com

Pressure Vessels Components Atrin Sanat Gasket Design For Pressure Vessel New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. The asme code for pressure vessels, section viii, div. Construction must be commensurate with the design pressure of the vessel. Lower pressure systems must incorporate a softer, more easily. 2, is the most commonly used design. Gasket Design For Pressure Vessel.

From www.youtube.com

What is Operating pressure, Design Pressure, MAWP,MOP Design Hub Gasket Design For Pressure Vessel New gasket design factors being developed by asme are for bolted joint designs where it is important that a desired level of tightness be. 2, is the most commonly used design method for gasketed joints where important. Physical properties are important factors when considering gasket design and the primary selection of a gasket type is based on the fol. Gaskets. Gasket Design For Pressure Vessel.

From pardisfoolad.com

انواع واشر آب بند و آشنایی با واشر لاستیکی آب بند پردیس فولاد Gasket Design For Pressure Vessel The asme code for pressure vessels, section viii, div. Boiler and pressure vessel code contains rules for the design and construction of unfired pressure vessels. The flat gasket is the oldest and most popular way to seal a flange or joint. Construction must be commensurate with the design pressure of the vessel. 2, is the most commonly used design method. Gasket Design For Pressure Vessel.