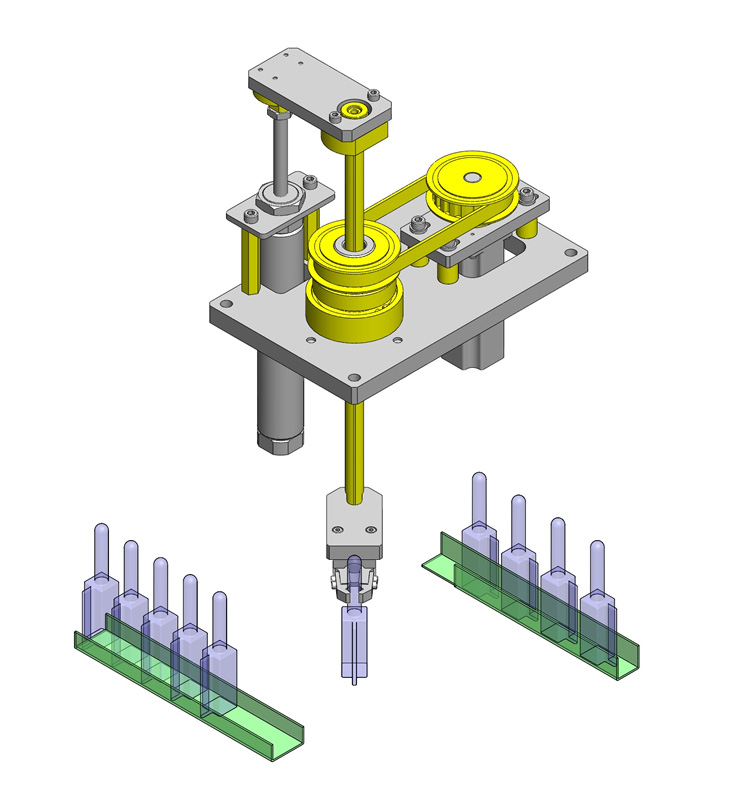

Ball Spline Applications . Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. • automation and packaging equipment. Common ball spline applications include: The path of the bearing balls is straight, not helical, which allows for a very. • oil, gas, and water exploration. Unlike ball bushings, the ball spline. A grooved shaft, a spline nut, and ball bearings. The ball spline has larger load ratings compared to ball bush. Splines are vital in mechanical design, enabling efficient torque transmission across industries. Also, the ball spline can sustain radial load, moment (bending moment) and torque. A ball spline is constructed with 3 basic components: They are used in systems. In this example, ball splines are used in a paper manufacturing application.

from www.linearmotiontips.com

Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Unlike ball bushings, the ball spline. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. • automation and packaging equipment. A ball spline is constructed with 3 basic components: The ball spline has larger load ratings compared to ball bush. Also, the ball spline can sustain radial load, moment (bending moment) and torque. They are used in systems. The path of the bearing balls is straight, not helical, which allows for a very. In this example, ball splines are used in a paper manufacturing application.

When should you use a ball spline?

Ball Spline Applications Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. • oil, gas, and water exploration. A grooved shaft, a spline nut, and ball bearings. Unlike ball bushings, the ball spline. Common ball spline applications include: Also, the ball spline can sustain radial load, moment (bending moment) and torque. Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. They are used in systems. Splines are vital in mechanical design, enabling efficient torque transmission across industries. In this example, ball splines are used in a paper manufacturing application. The path of the bearing balls is straight, not helical, which allows for a very. A ball spline is constructed with 3 basic components: • automation and packaging equipment. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. The ball spline has larger load ratings compared to ball bush.

From www.aerospacemanufacturinganddesign.com

NB’s rotary ball spline Aerospace Manufacturing and Design Ball Spline Applications Unlike ball bushings, the ball spline. The ball spline has larger load ratings compared to ball bush. A ball spline is constructed with 3 basic components: Common ball spline applications include: They are used in systems. Also, the ball spline can sustain radial load, moment (bending moment) and torque. A grooved shaft, a spline nut, and ball bearings. In this. Ball Spline Applications.

From www.linearmotiontips.com

Rediscovering ball splines for robust linear and rotary motion Ball Spline Applications The ball spline has larger load ratings compared to ball bush. They are used in systems. The path of the bearing balls is straight, not helical, which allows for a very. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or.. Ball Spline Applications.

From www.statewidebearings.com.au

Ball Splines Australia Wide Range Statewide Bearings Ball Spline Applications The path of the bearing balls is straight, not helical, which allows for a very. • oil, gas, and water exploration. Also, the ball spline can sustain radial load, moment (bending moment) and torque. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high. Ball Spline Applications.

From www.ikont.co.jp

Linear Ball Spline G Series IKO NIPPON THOMPSON Ball Spline Applications Unlike ball bushings, the ball spline. • automation and packaging equipment. A ball spline is constructed with 3 basic components: A grooved shaft, a spline nut, and ball bearings. • oil, gas, and water exploration. Splines are vital in mechanical design, enabling efficient torque transmission across industries. They are used in systems. In this example, ball splines are used in. Ball Spline Applications.

From www.youtube.com

HIWIN Technologies Ball Splines YouTube Ball Spline Applications • automation and packaging equipment. The ball spline has larger load ratings compared to ball bush. A grooved shaft, a spline nut, and ball bearings. Unlike ball bushings, the ball spline. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or.. Ball Spline Applications.

From www.powertransmission.com

Beyond Bearings Unleashing the Potential of Ball Splines in Robotic Designs Power Ball Spline Applications Also, the ball spline can sustain radial load, moment (bending moment) and torque. A ball spline is constructed with 3 basic components: Common ball spline applications include: The ball spline has larger load ratings compared to ball bush. A grooved shaft, a spline nut, and ball bearings. In this example, ball splines are used in a paper manufacturing application. •. Ball Spline Applications.

From www.nbcorporation.com

Rotary Ball Splines NB Rotary Ball Spline SPB Nippon Bearing Ball Spline Applications Splines are vital in mechanical design, enabling efficient torque transmission across industries. • oil, gas, and water exploration. Common ball spline applications include: The ball spline has larger load ratings compared to ball bush. Also, the ball spline can sustain radial load, moment (bending moment) and torque. The path of the bearing balls is straight, not helical, which allows for. Ball Spline Applications.

From tu.tv

8 Things You Need To Know About Linear Ball Spline Systems Ball Spline Applications A grooved shaft, a spline nut, and ball bearings. Unlike ball bushings, the ball spline. In this example, ball splines are used in a paper manufacturing application. Splines are vital in mechanical design, enabling efficient torque transmission across industries. The ball spline has larger load ratings compared to ball bush. They are used in systems. Common ball spline applications include:. Ball Spline Applications.

From www.thomsonlinear.com

Why are Designers Rediscovering Ball Splines for MultiAxis Motion? Why are Designers Ball Spline Applications • automation and packaging equipment. The path of the bearing balls is straight, not helical, which allows for a very. Unlike ball bushings, the ball spline. A grooved shaft, a spline nut, and ball bearings. • oil, gas, and water exploration. In this example, ball splines are used in a paper manufacturing application. Common ball spline applications include: Splines are. Ball Spline Applications.

From www.thaisupport.co.th

Linear ball splines Rotary type (FSR type) Ball Spline Applications Unlike ball bushings, the ball spline. The path of the bearing balls is straight, not helical, which allows for a very. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. The ball spline has larger load ratings compared to ball. Ball Spline Applications.

From www.thomsonlinear.com

Thomson introduces precision ball splines that deliver robust rotary and linear motion Ball Spline Applications A grooved shaft, a spline nut, and ball bearings. Also, the ball spline can sustain radial load, moment (bending moment) and torque. In this example, ball splines are used in a paper manufacturing application. The path of the bearing balls is straight, not helical, which allows for a very. Common ball spline applications include: Unlike ball bushings, the ball spline.. Ball Spline Applications.

From www.nipponbearing.com

BALL SPLINE|NIPPON BEARING CO.,LTD Ball Spline Applications They are used in systems. In this example, ball splines are used in a paper manufacturing application. A grooved shaft, a spline nut, and ball bearings. The ball spline has larger load ratings compared to ball bush. Common ball spline applications include: • automation and packaging equipment. Machine designers should consider ball splines for any application requiring both rotary and. Ball Spline Applications.

From hiwin.com

Ball Splines HIWIN Ball Spline Applications Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Splines are vital in mechanical design, enabling efficient torque transmission across industries. The ball spline has larger load ratings compared to ball bush. Unlike ball bushings, the ball spline. • automation and packaging equipment. In this example,. Ball Spline Applications.

From www.thk.com

DSP Ball Spline with Integrated Ball Screw|Ball Screw|Product Information|THK Official Site Ball Spline Applications The path of the bearing balls is straight, not helical, which allows for a very. A ball spline is constructed with 3 basic components: • automation and packaging equipment. • oil, gas, and water exploration. Splines are vital in mechanical design, enabling efficient torque transmission across industries. Both standard and rotary ball splines are offered with a hollow spline shaft,. Ball Spline Applications.

From www.todaysmedicaldevelopments.com

Medical Motion Rotary Ball Spline Technologies Today's Medical Developments Ball Spline Applications A ball spline is constructed with 3 basic components: The ball spline has larger load ratings compared to ball bush. In this example, ball splines are used in a paper manufacturing application. Common ball spline applications include: The path of the bearing balls is straight, not helical, which allows for a very. Splines are vital in mechanical design, enabling efficient. Ball Spline Applications.

From www.directindustry.com

Ball spline shaft Thomson Industries, Inc. precision Ball Spline Applications Also, the ball spline can sustain radial load, moment (bending moment) and torque. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. The ball spline has larger load ratings compared to ball bush. • oil, gas, and water exploration. Unlike. Ball Spline Applications.

From www.linearmotiontips.com

When should you use a ball spline? Ball Spline Applications They are used in systems. A ball spline is constructed with 3 basic components: Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. A grooved shaft, a spline nut, and ball bearings. Unlike ball bushings, the ball spline. The ball. Ball Spline Applications.

From www.thaisupport.co.th

Linear ball splines Rotary type (FSR type) Ball Spline Applications • automation and packaging equipment. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. The path of the bearing balls is straight, not helical, which allows for a very. A ball spline is constructed with 3 basic components: • oil,. Ball Spline Applications.

From news.thomasnet.com

THK'S New Types SLS/SLF Ball Splines Feature Caged Technology for Even Smoother Motion Ball Spline Applications In this example, ball splines are used in a paper manufacturing application. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. Splines are vital in mechanical design, enabling efficient torque transmission across industries. The path of the bearing balls is. Ball Spline Applications.

From www.machinedesign.com

Top Tips Select the Right Ball Splines for Rotation or Linear Motion Machine Design Ball Spline Applications Unlike ball bushings, the ball spline. • oil, gas, and water exploration. The ball spline has larger load ratings compared to ball bush. Also, the ball spline can sustain radial load, moment (bending moment) and torque. In this example, ball splines are used in a paper manufacturing application. A grooved shaft, a spline nut, and ball bearings. • automation and. Ball Spline Applications.

From www.gforgames.com

When are Ball Splines Used 2024 Guide G For Games Ball Spline Applications Common ball spline applications include: Also, the ball spline can sustain radial load, moment (bending moment) and torque. The ball spline has larger load ratings compared to ball bush. A grooved shaft, a spline nut, and ball bearings. • automation and packaging equipment. They are used in systems. Splines are vital in mechanical design, enabling efficient torque transmission across industries.. Ball Spline Applications.

From hvhindustrial.com

Block Type Linear Ball Spline LSB guides IKO Ball Spline Applications The path of the bearing balls is straight, not helical, which allows for a very. Common ball spline applications include: Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. Splines are vital in mechanical design, enabling efficient torque transmission across. Ball Spline Applications.

From ikont.com

Ball Spline Rolling Guides IKO International Ball Spline Applications Splines are vital in mechanical design, enabling efficient torque transmission across industries. In this example, ball splines are used in a paper manufacturing application. Unlike ball bushings, the ball spline. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. Common. Ball Spline Applications.

From www.linearmotiontips.com

Rediscovering ball splines for robust linear and rotary motion Ball Spline Applications Common ball spline applications include: Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. A ball spline is constructed with 3 basic components: They are used in systems. A grooved shaft, a spline nut, and ball bearings. The ball spline. Ball Spline Applications.

From www.alibaba.com

High Speed Spline Shaft Flange Type Cylindrical Type Ball Spline Block Type Rotary Hollow Solid Ball Spline Applications • oil, gas, and water exploration. In this example, ball splines are used in a paper manufacturing application. Unlike ball bushings, the ball spline. Also, the ball spline can sustain radial load, moment (bending moment) and torque. The path of the bearing balls is straight, not helical, which allows for a very. Common ball spline applications include: Splines are vital. Ball Spline Applications.

From www.directindustry.com

Ball spline shaft Thomson Industries, Inc. for heavyduty applications Ball Spline Applications They are used in systems. Common ball spline applications include: A ball spline is constructed with 3 basic components: Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. • automation and packaging equipment. The path of the bearing balls is. Ball Spline Applications.

From www.thk.com

Ball Spline|Product Information|THK Official Site Ball Spline Applications Common ball spline applications include: Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Also, the ball spline can sustain radial load, moment (bending moment) and torque. A ball spline is constructed with 3 basic components: • automation and packaging equipment. The ball spline has larger. Ball Spline Applications.

From www.machinedesign.com

Demystifying Ball Spline Specs Machine Design Ball Spline Applications Common ball spline applications include: Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. They are used in systems. • automation and packaging equipment. Splines are vital in mechanical design, enabling efficient torque transmission across industries. Unlike ball bushings, the. Ball Spline Applications.

From www.machinedesign.com

Basics of Design How to Specify Ball Splines Machine Design Ball Spline Applications Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Unlike ball bushings, the ball spline. A ball spline is constructed with 3 basic components: • automation and packaging equipment. Common ball spline applications include: In this example, ball splines are used in a paper manufacturing application.. Ball Spline Applications.

From www.transdev.co.uk

IKO Ball Splines for linear motion TransDev Ball Spline Applications Also, the ball spline can sustain radial load, moment (bending moment) and torque. In this example, ball splines are used in a paper manufacturing application. The ball spline has larger load ratings compared to ball bush. Unlike ball bushings, the ball spline. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space. Ball Spline Applications.

From www.linearmotiontips.com

What's the difference between stroke ball splines and standard ball splines Ball Spline Applications Splines are vital in mechanical design, enabling efficient torque transmission across industries. A grooved shaft, a spline nut, and ball bearings. Unlike ball bushings, the ball spline. The path of the bearing balls is straight, not helical, which allows for a very. The ball spline has larger load ratings compared to ball bush. They are used in systems. A ball. Ball Spline Applications.

From www.todaysmedicaldevelopments.com

Tech Tips from NB Corp Today's Medical Developments Ball Spline Applications Splines are vital in mechanical design, enabling efficient torque transmission across industries. Also, the ball spline can sustain radial load, moment (bending moment) and torque. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability, or. Unlike ball bushings, the ball spline.. Ball Spline Applications.

From www.linearmotiontips.com

Ball spline preload How, why, and when it's applied Ball Spline Applications A grooved shaft, a spline nut, and ball bearings. Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Machine designers should consider ball splines for any application requiring both rotary and linear motion, especially if space is at a premium and stroke, load, high speed, reliability,. Ball Spline Applications.

From www.machinedesign.com

Basics of Design How to Specify Ball Splines Machine Design Ball Spline Applications Also, the ball spline can sustain radial load, moment (bending moment) and torque. Splines are vital in mechanical design, enabling efficient torque transmission across industries. Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Machine designers should consider ball splines for any application requiring both rotary. Ball Spline Applications.

From hvhindustrial.com

Ball Splines Distributor/Supplier Ball Screw, Rotary Ball Ball Spline Applications Both standard and rotary ball splines are offered with a hollow spline shaft, which helps with integration into systems such as scara robots,. Common ball spline applications include: Also, the ball spline can sustain radial load, moment (bending moment) and torque. In this example, ball splines are used in a paper manufacturing application. Unlike ball bushings, the ball spline. A. Ball Spline Applications.