Vacuum Quenching Process . vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached.

from www.prague-mint.eu

processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of.

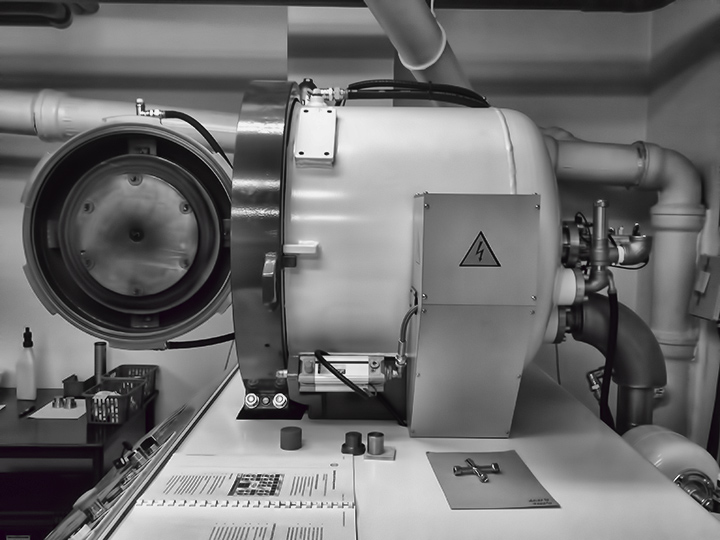

Vacuum Quenching (Coin dies hardness obtained by quenching in vacuo

Vacuum Quenching Process processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of.

From www.vacfurnace.com

Tungsten Carbide Gas Quenching Furnace Vacuum Quenching Process The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. the. Vacuum Quenching Process.

From www.sst.net

Annealing Process in Heat Treatment and More SST Vacuum Quenching Process vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is an improvement over conventional hardening in that the. Vacuum Quenching Process.

From sybzzk.en.made-in-china.com

Series Vacuum High Pressure Gas Quenching Furnace High Quality Alloy Vacuum Quenching Process processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. . Vacuum Quenching Process.

From www.furnace-vac.com

Heat Treatment Vacuum Sintering Furnace Process High Pressure Gas Vacuum Quenching Process vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum hardening is an improvement over conventional hardening. Vacuum Quenching Process.

From www.science.org

A vacuum flashassisted solution process for highefficiency largearea Vacuum Quenching Process processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. . Vacuum Quenching Process.

From www.tec-science.com

Overview of heat treatment of steel tecscience Vacuum Quenching Process processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up. Vacuum Quenching Process.

From www.secovacusa.com

Gas Quenching Vacuum Furnace w High Pressure Quench 2 to 25 Bar SECO Vacuum Quenching Process The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. the reason is that “vacuum quenching” insinuates that evaporation. Vacuum Quenching Process.

From www.dhioresearch.com

inar on Heat Treatment Simulation Process Modelling, Metallurgy Vacuum Quenching Process vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. processing of stainless. Vacuum Quenching Process.

From www.vacfurnace.com

Vacuum Quenching Process of 45 Steel and T10 Steel SIMUWU Vacuum Furnace Vacuum Quenching Process the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is. Vacuum Quenching Process.

From www.linkedin.com

Composition of vacuum quenching furnace Vacuum Quenching Process vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum oil quenching. Vacuum Quenching Process.

From www.cdoinduction.com

High Press Vacuum Gas /Oil Quenching FurnaceCooddo Vacuum Quenching Process processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. the reason is that “vacuum quenching” insinuates that. Vacuum Quenching Process.

From www.vacfurnace.com

Vacuum gas quenching furnace pellet die heat treatment process Vacuum Quenching Process vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. . Vacuum Quenching Process.

From www.vacfurnace.com

Die steel vacuum quenching process Vacuum Quenching Process this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. vacuum hardening is an improvement over conventional hardening. Vacuum Quenching Process.

From www.vacfurnace.com

Vacuum gas quenching process Vacuum Quenching Process The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c. Vacuum Quenching Process.

From www.npmplant.com

NPM has stateoftheart ring die manufacture and drilling factory Vacuum Quenching Process this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum oil quenching. Vacuum Quenching Process.

From www.tec-science.com

Quenching and tempering of steel tecscience Vacuum Quenching Process this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. The aim of this process variant is the creation. Vacuum Quenching Process.

From www.secovacusa.com

Gas Quenching Vacuum Furnace w High Pressure Quench 2 to 25 Bar SECO Vacuum Quenching Process The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. this paper reviews. Vacuum Quenching Process.

From www.diecastingcompany.com

The Heat Treatment Process Of 45 Steel Quenching And Tempering Minghe Vacuum Quenching Process The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from. Vacuum Quenching Process.

From www.cdoinduction.com

High Press Vacuum Gas /Oil Quenching FurnaceCooddo Vacuum Quenching Process vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. The aim of this process variant is the creation of bright. Vacuum Quenching Process.

From www.vacfurnace.com

Vacuum Quenching Process of 45 Steel and T10 Steel SIMUWU Vacuum Furnace Vacuum Quenching Process vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is a heat treatment process of metal. Vacuum Quenching Process.

From thermalprocessing.com

Intelligent Gas Carburizing with Super IQ ™ Thermal Processing Magazine Vacuum Quenching Process vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. this paper reviews the mechanisms, processes, equipment, and. Vacuum Quenching Process.

From www.secovacusa.com

Vacuum Quench Furnace for High Volume w Oil & Gas MultiChamber Vacuum Quenching Process vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. the reason is. Vacuum Quenching Process.

From www.vacfurnace.com

Vacuum Gas Quenching Furnace SIMUWU Vacuum Furnace Vacuum Quenching Process The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. the reason is that “vacuum quenching” insinuates that evaporation of solvent. Vacuum Quenching Process.

From www.vacfurnace.com

Vacuum Quenching Process of 45 Steel and T10 Steel SIMUWU Vacuum Furnace Vacuum Quenching Process the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. processing of stainless. Vacuum Quenching Process.

From www.vacfurnace.com

Accelerating quenching vacuum furnace Vacuum Quenching Process the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. . Vacuum Quenching Process.

From www.furnace-vac.com

Horizontal Internal Vacuum Quenching Furnace Process Gas Cooling Vacuum Quenching Process this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum. Vacuum Quenching Process.

From www.secovacusa.com

Vacuum Quench Furnace for High Volume w Oil & Gas MultiChamber Vacuum Quenching Process the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300. Vacuum Quenching Process.

From www.prague-mint.eu

Vacuum Quenching (Coin dies hardness obtained by quenching in vacuo Vacuum Quenching Process this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. the reason is. Vacuum Quenching Process.

From www.muffle-furnace.com

Fast Cooling Vacuum Gas Quench Furnace, Vacuum Quench Furnace up to 1320°C Vacuum Quenching Process vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is an improvement over conventional hardening in that the. Vacuum Quenching Process.

From thermalprocessing.com

A technical guide to quenching Thermal Processing Magazine Vacuum Quenching Process The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. processing of stainless. Vacuum Quenching Process.

From thermalprocessing.com

Vacuum Carburizing Large Gears Thermal Processing Magazine Vacuum Quenching Process vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. The aim of this process variant is the creation of bright metallic workpiece surfaces which render further mechanical processing unnecessary. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which. Vacuum Quenching Process.

From vacaero.com

Overview of a Vertical Gas Quenching Vacuum Furnace Vacuum Quenching Process this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. vacuum hardening is an improvement over conventional hardening in that the component surface is protected from possible negative effects of. vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. vacuum hardening is a heat treatment process of. Vacuum Quenching Process.

From vacaero.com

Overview of a Vertical Gas Quenching Vacuum Furnace Vacuum Quenching Process the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. vacuum hardening is an improvement over conventional hardening in that. Vacuum Quenching Process.

From www.nitrex.com

QUANTUM QUENCH VACUUM Nitrex Vacuum Quenching Process vacuum hardening is a heat treatment process of metal components carried out under controlled partial pressure, during which temperatures of up to 1,300 °c can be reached. processing of stainless steel components in vacuum furnaces is often specifi ed not only because of the cleanliness of the fi n. vacuum hardening is an improvement over conventional hardening. Vacuum Quenching Process.

From www.vacfurnace.com

Vacuum Heat Treatment And Quenching Advantages SIMUWU Vacuum Furnace Vacuum Quenching Process vacuum oil quenching and vacuum gas quenching are two commonly used vacuum quenching processes. this paper reviews the mechanisms, processes, equipment, and simulations of the vacuum gas quenching. the reason is that “vacuum quenching” insinuates that evaporation of solvent into a (near) vacuum, which is in essence boiling. The aim of this process variant is the creation. Vacuum Quenching Process.