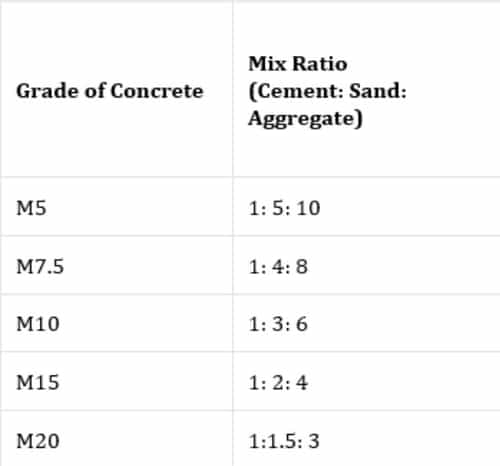

Concrete Mix Design Of M20 . So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). (i) concrete mix design provision. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. (ii) laboratory test data of material. The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. Procedure for concrete mix design of m25 concrete. The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement :

from byjusexamprep.com

Procedure for concrete mix design of m25 concrete. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. (ii) laboratory test data of material. Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: (i) concrete mix design provision. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement :

Concrete Mix Design Ratio, IS Code, Classifications

Concrete Mix Design Of M20 (i) concrete mix design provision. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). (i) concrete mix design provision. The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. Procedure for concrete mix design of m25 concrete. (ii) laboratory test data of material. Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures.

From www.youtube.com

M20 grade of concrete Design mix proportion of concrete Volume Concrete Mix Design Of M20 The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. (ii) laboratory test data of material. Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve. Concrete Mix Design Of M20.

From civilmint.com

Concrete Mix Design Calculation for M20, M25, M30 Concrete Concrete Mix Design Of M20 The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : Procedure for concrete mix design of m25 concrete. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: Concrete mix design for m20, m25, m30, and higher grades of concrete can be. Concrete Mix Design Of M20.

From www.youtube.com

is 10262 concrete mix design 2009 mix design calculation for m20 grade Concrete Mix Design Of M20 Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. (i) concrete mix design provision. So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20. Concrete Mix Design Of M20.

From www.youtube.com

Concrete mix ratio Various grades of concrete Concrete mix design Concrete Mix Design Of M20 Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. (ii) laboratory test data of material. Procedure for concrete mix design of m25 concrete. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: The design mix of m20 concrete is a specific. Concrete Mix Design Of M20.

From www.vrogue.co

Mix Design Of M20 Grade Concrete As Per Is 10262 Code vrogue.co Concrete Mix Design Of M20 The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. (ii) laboratory test data of material. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate. Concrete Mix Design Of M20.

From civilengghub.blogspot.com

DESIGN MIX FOR M20 CONCRETE CIVIL ENGINEERING HUB Concrete Mix Design Of M20 Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. The m20. Concrete Mix Design Of M20.

From www.youtube.com

M20 mix design ratio procedure by NEW IS code 10262 2019concrete grade Concrete Mix Design Of M20 The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. (ii) laboratory test data of material. The m20 concrete mix ratio typically. Concrete Mix Design Of M20.

From happho.com

Concrete Mix Design Illustrative Example M30 Grade (M20, M25, M40) Concrete Mix Design Of M20 The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. (ii) laboratory test data of material. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). The concrete mix design involves various steps, calculations and laboratory testing to find right mix. Concrete Mix Design Of M20.

From www.onlinecivilforum.com

Concrete Mix Design M20 Online Civil Concrete Mix Design Of M20 The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. The design mix. Concrete Mix Design Of M20.

From www.vrogue.co

Mix Design Of M20 Grade Concrete As Per Is 10262 Code vrogue.co Concrete Mix Design Of M20 The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. (i) concrete mix design. Concrete Mix Design Of M20.

From www.youtube.com

What is the M20 Concrete Grade?/M20 Concrete Mix Design/M20 Concrete Concrete Mix Design Of M20 Procedure for concrete mix design of m25 concrete. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). (ii) laboratory test data of material. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to. Concrete Mix Design Of M20.

From www.indiamart.com

Design Mix M25, M30, M20 Testing Services at Rs 8000 in Ghaziabad Concrete Mix Design Of M20 The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. The common concrete mix ratio to create m25. Concrete Mix Design Of M20.

From civilsir.com

How much cement sand & aggregate required for M20 concrete Civil Sir Concrete Mix Design Of M20 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. The m20 concrete. Concrete Mix Design Of M20.

From happho.com

Concrete Mix Design Illustrative Example M30 Grade (M20, M25, M40 Concrete Mix Design Of M20 The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. (ii) laboratory test data of material. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : (i) concrete mix design provision. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate. Concrete Mix Design Of M20.

From byjusexamprep.com

Concrete Mix Design Ratio, IS Code, Classifications Concrete Mix Design Of M20 Procedure for concrete mix design of m25 concrete. (i) concrete mix design provision. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. The design mix of m20 concrete is a specific ratio of materials used. Concrete Mix Design Of M20.

From www.constructiongo.in

1 INTRODUCTION Concrete Mix Design Of M20 Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. (i) concrete mix design provision. (ii) laboratory test data of material. Procedure for concrete mix design of m25 concrete. The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions.. Concrete Mix Design Of M20.

From www.semanticscholar.org

Table 2 from Comparative Study of M20 and M25 grades of Concrete by ACI Concrete Mix Design Of M20 (ii) laboratory test data of material. So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. The m20 concrete mix ratio typically. Concrete Mix Design Of M20.

From www.vrogue.co

Mix Design Of M20 Grade Concrete As Per Is 10262 Code vrogue.co Concrete Mix Design Of M20 Procedure for concrete mix design of m25 concrete. Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: Requirements a) specified minimum strength =. Concrete Mix Design Of M20.

From www.vrogue.co

M20 Concrete Material Calculation M20 Concrete Mix De vrogue.co Concrete Mix Design Of M20 The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. Procedure for concrete mix design of m25 concrete. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : Requirements a) specified. Concrete Mix Design Of M20.

From www.pinterest.com

Quantity of Cement in 1m3 of concrete Grade of concrete, Concrete mix Concrete Mix Design Of M20 Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). (ii) laboratory test data of material. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. Concrete mix design for m20,. Concrete Mix Design Of M20.

From www.youtube.com

Concrete Mix Design steps by IS 456 2000 M20, M25, M30 concrete Grade Concrete Mix Design Of M20 The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement. Concrete Mix Design Of M20.

From www.pinterest.com

How much cement, sand & aggregate required for M25,M20,M15,M10 & M7.5 Concrete Mix Design Of M20 The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: (ii) laboratory test data of material. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis.. Concrete Mix Design Of M20.

From civilsir.com

How much cement, sand & aggregate required for M25,M20,M15,M10 & M7.5 Concrete Mix Design Of M20 The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. (i) concrete mix design provision. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : Concrete. Concrete Mix Design Of M20.

From happho.com

Concrete Mix Design Illustrative Example M30 Grade (M20, M25, M40 Concrete Mix Design Of M20 So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. (i) concrete mix design provision. Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. (ii) laboratory test data of material. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement:. Concrete Mix Design Of M20.

From www.vrogue.co

Mix Design Of M20 Grade Concrete As Per Is 10262 Code vrogue.co Concrete Mix Design Of M20 The concrete mix design involves various steps, calculations and laboratory testing to find right mix proportions. (ii) laboratory test data of material. Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. (i) concrete mix design provision. So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. 1:2:4,. Concrete Mix Design Of M20.

From www.vrogue.co

Mix Design Of M20 Grade Concrete As Per Is 10262 Code vrogue.co Concrete Mix Design Of M20 Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. Procedure for concrete mix design of m25 concrete. The design mix of m20 concrete is a specific ratio of materials. Concrete Mix Design Of M20.

From stacieintogo.blogspot.com

pervious concrete mix design calculator stacieintogo Concrete Mix Design Of M20 The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. (ii) laboratory test data of material. Requirements a) specified minimum strength = 20 n/sq mm b) durability. Concrete Mix Design Of M20.

From v9306.1blu.de

How To Calculate Cement, Sand, And Aggregate For M20 Concrete Mix Design Of M20 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. (i) concrete mix design provision. (ii) laboratory test data of material. The typical concrete mix ratio for making m15,. Concrete Mix Design Of M20.

From www.pinterest.com

Q/A 39 DIFFERENT TYPES OF CONCRETE GRADES AND ITS STRENGTH Grade of Concrete Mix Design Of M20 Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given below. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. Requirements a) specified minimum strength. Concrete Mix Design Of M20.

From in.pinterest.com

How much cement, sand & aggregate required for M25,M20,M15,M10 & M7.5 Concrete Mix Design Of M20 Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). So, concrete mix design can be stated as concrete mix = cement:sand:aggregates. 1:2:4, 1:1.5:3 and 1:1:2 respectively according to volumetric analysis. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: (i) concrete mix design provision. The m20 concrete mix ratio typically consists. Concrete Mix Design Of M20.

From civilxperts.com

Procedure to the M20 Grade Mix Design of Concrete Concrete Mix Design Of M20 The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). The concrete mix design involves various steps, calculations and laboratory testing to. Concrete Mix Design Of M20.

From www.fantasticeng.com

Concrete mix ratio Concrete mix design FantasticEng Concrete Mix Design Of M20 The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. (i) concrete mix design provision. The typical concrete mix ratio for making m15, m20 and m25 concrete is (cement : (ii) laboratory test data of material. The concrete mix design involves various steps, calculations and laboratory testing to find right. Concrete Mix Design Of M20.

From www.pinterest.com

TIPS 169 DESIGN MIX OF M20 Engineering notes, Concrete mix design Concrete Mix Design Of M20 The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. Requirements a) specified minimum strength = 20 n/sq mm b) durability requirements i). Concrete mix design is the process of finding right proportions of cement, sand and aggregates for concrete to achieve target strength in structures. The common concrete. Concrete Mix Design Of M20.

From design.udlvirtual.edu.pe

What Is The Difference Between M20 And M25 Concrete Design Talk Concrete Mix Design Of M20 The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume. Concrete mix design for m20, m25, m30, and higher grades of concrete can be calculated from the example given. Concrete Mix Design Of M20.

From www.onlinecivilforum.com

CONCRETE MIX DESIGN CALCULATION USING IS 102622019 Concrete Mix Design Of M20 The design mix of m20 concrete is a specific ratio of materials used to achieve a compressive strength of 20 mpa. (i) concrete mix design provision. The common concrete mix ratio to create m25 grade of concrete is 1:1:2 (cement: The m20 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts aggregate by volume.. Concrete Mix Design Of M20.