Immersion Plating Process . Immersion tin plating involves dipping a circuit board in a copper and tin ions solution. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. This is the first step in the plating process. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. The surface is again washed with. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion tin involves depositing a uniform and thin tin layer on. This comprehensive article delves into the immersion tin finish process used in surface treatment. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin.

from elcoats.com

Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. Immersion tin involves depositing a uniform and thin tin layer on. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. This comprehensive article delves into the immersion tin finish process used in surface treatment. Immersion tin plating involves dipping a circuit board in a copper and tin ions solution. This is the first step in the plating process. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. The surface is again washed with.

Types of Metal Plating Elcoats Allied Industries

Immersion Plating Process This comprehensive article delves into the immersion tin finish process used in surface treatment. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Immersion tin plating involves dipping a circuit board in a copper and tin ions solution. The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. The surface is again washed with. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This is the first step in the plating process. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion tin involves depositing a uniform and thin tin layer on. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. This comprehensive article delves into the immersion tin finish process used in surface treatment.

From www.researchgate.net

Schematic images indicating stages of Ag immersion plating. Download Immersion Plating Process The surface is again washed with. This is the first step in the plating process. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Immersion. Immersion Plating Process.

From www.mdpi.com

Materials Free FullText Tin Whiskers’ Behavior under Stress Load Immersion Plating Process The surface is again washed with. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping. Immersion Plating Process.

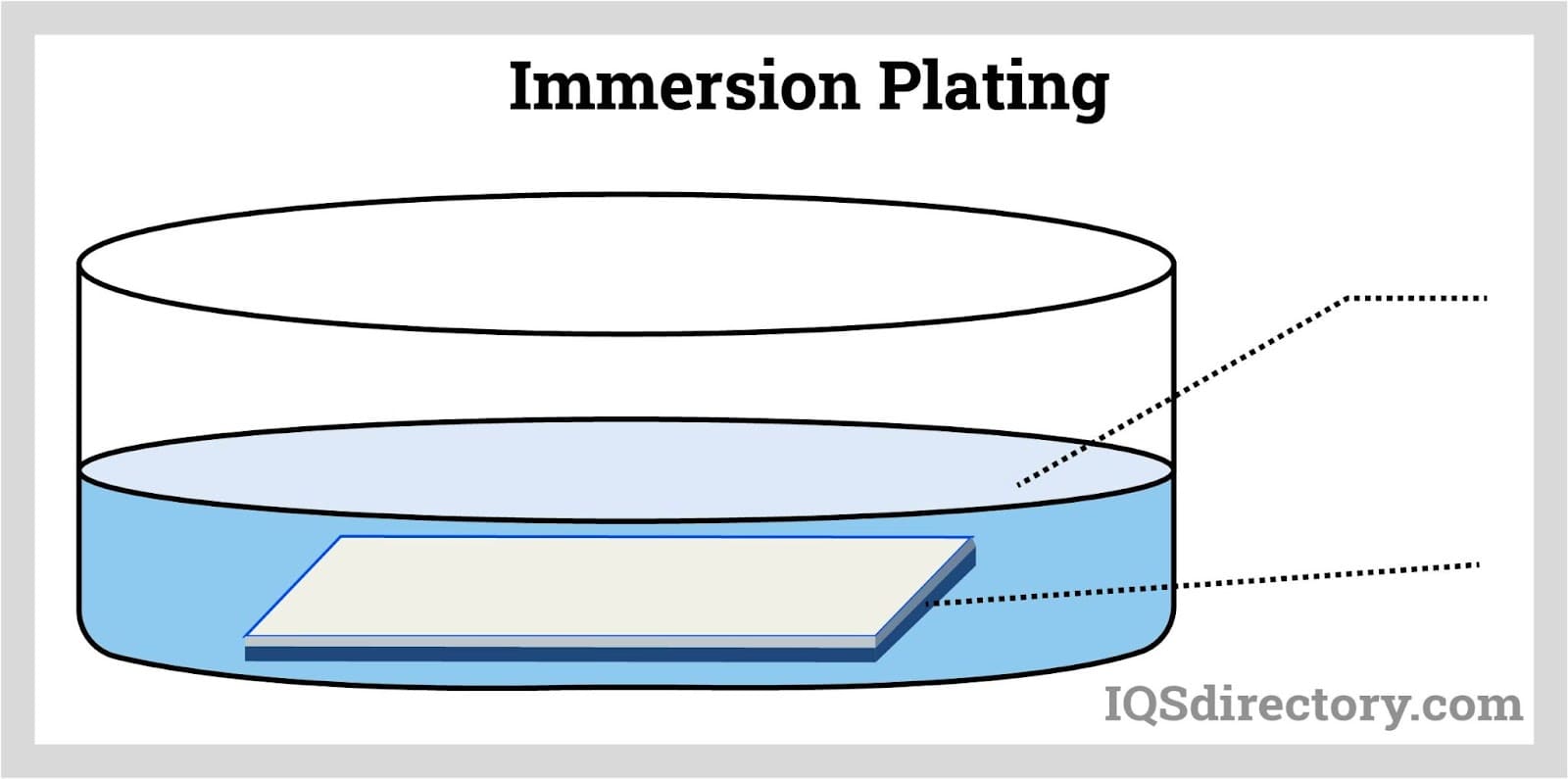

From www.iqsdirectory.com

Electroless Nickel Plating Variations, Types, Applications, and Benefits Immersion Plating Process Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion tin plating involves dipping a circuit board in a copper and tin ions solution. Immersion tin involves depositing a uniform and thin tin layer on. This step speeds up the electroless reduction process, where there is formation of a thin. Immersion Plating Process.

From www.youtube.com

Automated Electroless Nickel Electroless Palladium Immersion Gold Immersion Plating Process The surface is again washed with. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Several types of metal plating techniques are utilized across various sectors, especially. Immersion Plating Process.

From www.dupont.com

Copper pillar electroplating tutorial Immersion Plating Process This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. Immersion. Immersion Plating Process.

From www.youtube.com

Immersion copper plating YouTube Immersion Plating Process Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. This comprehensive article delves into the immersion tin finish process used in surface treatment. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Immersion plating is the process. Immersion Plating Process.

From www.electroplatingtank.com

PFA / PTFE Immersion Tank Heater For Chemical Plating Processing Immersion Plating Process Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. This is the first step in the plating process. This comprehensive article delves into the immersion tin finish process used. Immersion Plating Process.

From www.protoexpress.com

Immersion Tin Surface Finish Sierra Circuits Immersion Plating Process Immersion tin involves depositing a uniform and thin tin layer on. This is the first step in the plating process. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. This step speeds up the electroless reduction process, where there is formation of a thin layer of. Immersion Plating Process.

From www.youtube.com

Gold Plating What is Brush Plating? Brush vs. Immersion Immersion Plating Process This comprehensive article delves into the immersion tin finish process used in surface treatment. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Immersion tin plating involves dipping a circuit board in. Immersion Plating Process.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Immersion Plating Process The surface is again washed with. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by. Immersion Plating Process.

From www.imo-gmbh.com

Galvanic surface finishing with immersion technology IMO Immersion Plating Process Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This is the first step in the plating process. The circuit board is dipped in an acid solution to. Immersion Plating Process.

From www.researchgate.net

Schematic illustration of the gold, silver, and electrum electroless Immersion Plating Process Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. This comprehensive article delves into the immersion tin finish process used in surface treatment. Immersion tin involves depositing a uniform and. Immersion Plating Process.

From www.youtube.com

ElectroplatingVacuum coating equipmentImmersion platingEvaporation Immersion Plating Process The surface is again washed with. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. The circuit board is dipped in an acid solution to remove oil, grease, and. Immersion Plating Process.

From www.venture-mfg.com

Premier Manufacturer of Immersion Tin PCB Venture Electronics Immersion Plating Process This is the first step in the plating process. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. Immersion tin plating involves dipping a circuit board in a copper and tin ions solution. Immersion. Immersion Plating Process.

From www.soseng.com

A Beginner's Guide to Understanding the Selective Plating Process Immersion Plating Process Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. This is the first step in the plating process. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion tin involves depositing a uniform and thin tin layer on.. Immersion Plating Process.

From www.youtube.com

Gold Plating Kit, Immersion Electroplating with 59.00 Plating Kit Immersion Plating Process The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. This is the first step in the plating process. Immersion plating is the process of applying adhering layers of nobler metals to another metal's. Immersion Plating Process.

From www.researchgate.net

Schematic diagram of the immersion solder bumping process. Download Immersion Plating Process Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. This is the first step in the plating process. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper. Immersion Plating Process.

From www.nwengineeringllc.com

PCB Surface Plating Materials and Their Advantages NWES Blog Immersion Plating Process Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Immersion tin involves depositing a uniform and thin tin layer on. The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. Several types of metal plating techniques are utilized across. Immersion Plating Process.

From www.researchgate.net

Schematic showing the immersion plating arrangement Download Immersion Plating Process Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This comprehensive article delves into the immersion tin finish process used in surface treatment. Immersion tin involves depositing a uniform and thin tin layer on. This is the first step in the plating process. Immersion plating is the process of applying adhering. Immersion Plating Process.

From www.tanabe.co.th

Immersion Tin Plating TANABE (Thailand) Immersion Plating Process The surface is again washed with. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. This comprehensive article delves into the immersion tin finish process used in. Immersion Plating Process.

From thermalprocessing.com

Why is modeling the immersion process so important? Thermal Immersion Plating Process Immersion tin involves depositing a uniform and thin tin layer on. This is the first step in the plating process. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by. Immersion Plating Process.

From www.youtube.com

Immersion Plating Production Technology Diehl YouTube Immersion Plating Process Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. The surface is again washed with. Immersion tin plating involves dipping a circuit board in a copper and. Immersion Plating Process.

From pdfslide.net

(PDF) Electroless and Immersion Plating Process towards Immersion Plating Process Immersion tin plating involves dipping a circuit board in a copper and tin ions solution. This comprehensive article delves into the immersion tin finish process used in surface treatment. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. The circuit board is dipped in an acid solution to remove oil, grease,. Immersion Plating Process.

From www.beckerindustries.com

immersion plating solutions Bath Plating Immersion Plating Process The surface is again washed with. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. The circuit board is dipped in an acid solution to remove oil, grease, and other. Immersion Plating Process.

From incertec.com

Electroless Nickel Immersion Gold (ENIG) Plating INCERTEC Immersion Plating Process The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. Immersion tin involves depositing a uniform and thin tin layer on. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. Immersion tin plating is a direct electroless tin plating process used. Immersion Plating Process.

From www.slideserve.com

PPT Black Pad Defect PowerPoint Presentation, free download ID1318649 Immersion Plating Process Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This comprehensive article delves into the immersion tin finish process used in surface treatment. Immersion tin plating involves dipping a circuit. Immersion Plating Process.

From elcoats.com

Types of Metal Plating Elcoats Allied Industries Immersion Plating Process This comprehensive article delves into the immersion tin finish process used in surface treatment. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Immersion tin plating involves dipping a circuit board in a. Immersion Plating Process.

From www.uskoreahotlink.com

Automated Electroplating Equipment for Surface Finishing Immersion Plating Process Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a nobler. The surface is again washed with. Immersion tin is a direct electroless tin plating process where. Immersion Plating Process.

From www.researchgate.net

(PDF) Electroless and Immersion Plating Process towards Structures and Immersion Plating Process Immersion tin involves depositing a uniform and thin tin layer on. This is the first step in the plating process. The surface is again washed with. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace,. Immersion Plating Process.

From etchmachinery.com

Electroless nickel immersion gold (ENIG) plating machine for PCB,Manual Immersion Plating Process The surface is again washed with. Immersion tin plating involves dipping a circuit board in a copper and tin ions solution. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping in a. Immersion Plating Process.

From www.semanticscholar.org

Table 1 from Electroless and Immersion Plating Process towards Immersion Plating Process Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. This step speeds up the electroless reduction process, where there is formation of a thin layer of tin. Several types of metal plating techniques. Immersion Plating Process.

From www.youtube.com

Metal Plating Process A Complete Guide To Its Types And Technique Immersion Plating Process Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. The surface is again washed with. This step speeds up the electroless reduction process, where there is formation of a thin layer of. Immersion Plating Process.

From www.researchgate.net

a Schematic diagram of the electroless plating process of CuSnAg Immersion Plating Process Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. The circuit board is dipped in an acid solution to remove oil, grease, and other surface impurities. The surface is again washed with. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads,. Immersion Plating Process.

From www.mdpi.com

Electrochemical Migration Behavior of CopperClad Laminate and Immersion Plating Process This comprehensive article delves into the immersion tin finish process used in surface treatment. Several types of metal plating techniques are utilized across various sectors, especially in the aerospace, defense, and space. Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Immersion tin plating involves dipping. Immersion Plating Process.

From www.iqsdirectory.com

Industrial Coatings Types, Applications, Benefits, and Techniques Immersion Plating Process Immersion tin plating is a direct electroless tin plating process used to coat exposed copper traces, contact fingers, pads, and vias on pcbs. Immersion tin is a direct electroless tin plating process where boards are immersed in a heated aqueous tin solution. Immersion plating is the process of applying adhering layers of nobler metals to another metal's surface by dipping. Immersion Plating Process.