Cnc Machine Workholding . Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The basics of cnc workholding. Discover the best techniques and tools for securing your workpiece and optimizing cuts. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. Maximize your cnc router workholding with our total guide. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific.

from www.miteebite.com

Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Maximize your cnc router workholding with our total guide. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The basics of cnc workholding.

12/11/15 New Workholding Devices Enable 4th Axis Machining MiteeBite Products LLC.

Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The basics of cnc workholding. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. Maximize your cnc router workholding with our total guide.

From www.pinterest.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills in 2023 Cnc milling Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. Discover the best techniques and tools for securing your workpiece and optimizing cuts. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. There are various types of workholding devices available, each. Cnc Machine Workholding.

From www.pinterest.com

Pin on erowa system 3R workholding system Cnc Machine Workholding How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining. Cnc Machine Workholding.

From hyfore.shop

Collets Standard Workholding C Style Cnc Machine Workholding Discover the best techniques and tools for securing your workpiece and optimizing cuts. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. Maximize your cnc router. Cnc Machine Workholding.

From www.ame.com

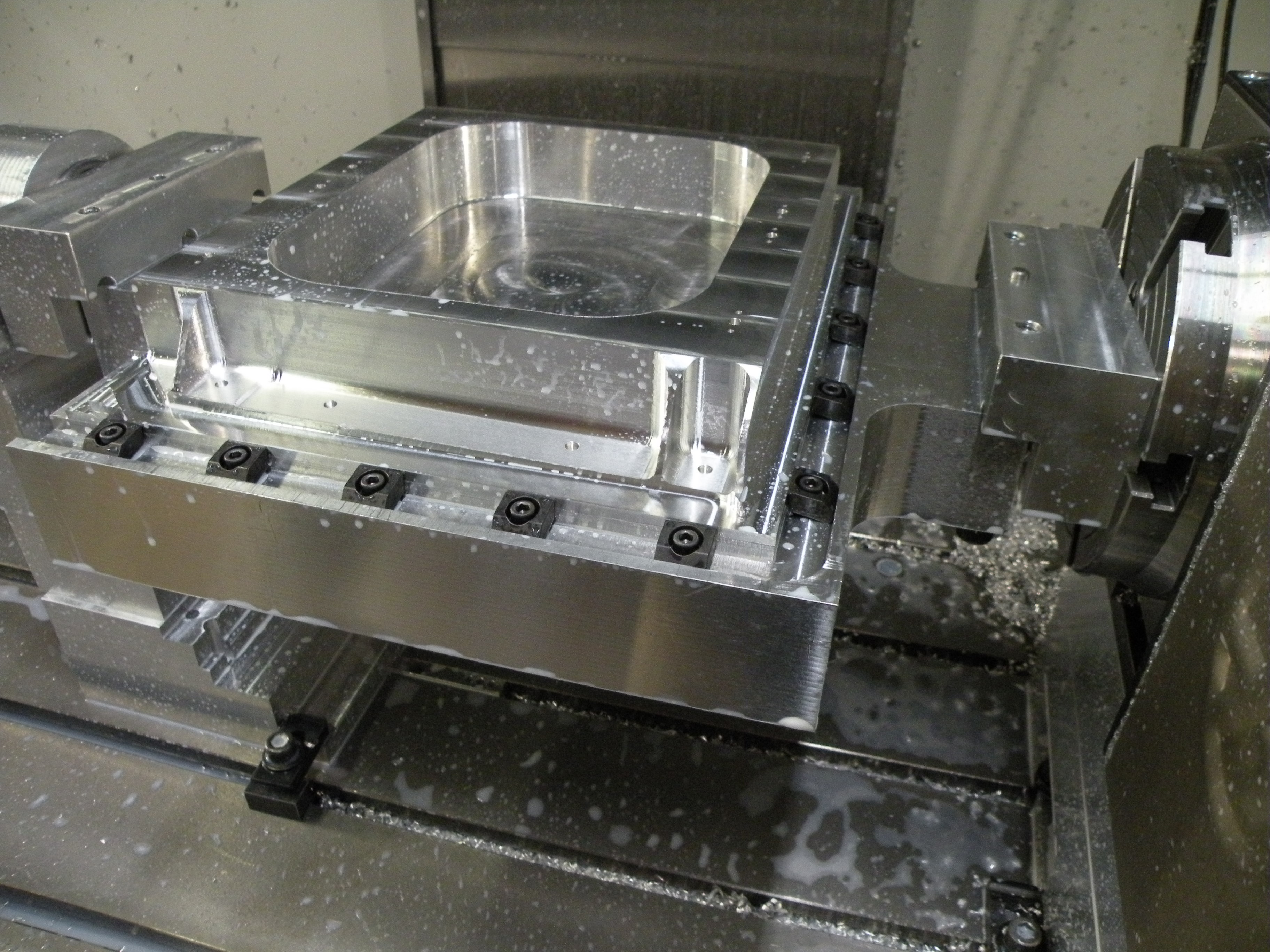

Modular Workholding for Vertical and Horizontal Machining Centers Advanced Machine and Cnc Machine Workholding Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. How. Cnc Machine Workholding.

From www.fictiv.com

Introduction to Workholding Options for CNC Machining Fictiv Cnc Machine Workholding The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The basics of cnc workholding. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Maximize your cnc router. Cnc Machine Workholding.

From lang-technik.co.uk

CNC Workholding Clamps & Machining Fixture Clamps & Devices Cnc Machine Workholding There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Discover the best techniques and tools for securing your workpiece and optimizing cuts. The basics of cnc workholding. Maximize your cnc router workholding with our total guide. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc. Cnc Machine Workholding.

From www.instructables.com

Free Online Autodesk Technology Center SF CNC Workholding Class Instructables Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The basics of cnc workholding. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture. Cnc Machine Workholding.

From hyfore.com

CNC Workholding Clamps & CNC Fixtures Hyfore Cnc Machine Workholding Discover the best techniques and tools for securing your workpiece and optimizing cuts. The basics of cnc workholding. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece. Cnc Machine Workholding.

From hyfore.com

Standard Workholding Hyfore Cnc Machine Workholding Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Maximize your cnc. Cnc Machine Workholding.

From lang-technik.co.uk

CNC Workholding Clamps & Machining Fixture Clamps & Devices Cnc Machine Workholding Discover the best techniques and tools for securing your workpiece and optimizing cuts. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The best workholding solution. Cnc Machine Workholding.

From www.cnccookbook.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills Cnc Machine Workholding The basics of cnc workholding. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. Workholding devices are. Cnc Machine Workholding.

From pawsworkholding.com

Fourth Axis Solutions PAWS Workholding Cnc Machine Workholding How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Maximize your cnc router workholding with our total guide. The choice of. Cnc Machine Workholding.

From www.fictiv.com

Introduction to Workholding Options for CNC Machining Fictiv Cnc Machine Workholding The basics of cnc workholding. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece. Cnc Machine Workholding.

From www.fictiv.com

Introduction to Workholding Options for CNC Machining Fictiv Cnc Machine Workholding The basics of cnc workholding. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. How a part is held can significantly affect a number of logistical factors, including. Cnc Machine Workholding.

From www.3erp.com

Find the best way to load your workpiece for CNC Machining Cnc Machine Workholding How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. The basics of cnc workholding. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Maximize your cnc. Cnc Machine Workholding.

From www.fastradius.com

Workholding for CNC Manufacturing Resources Fast Radius Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable. Cnc Machine Workholding.

From pawsworkholding.com

Multiple Part Workholding Fixtures PAWS Workholding Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The basics of cnc workholding. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools.. Cnc Machine Workholding.

From seisanzai-japan.com

Machining 08 What are work holding devices? Industry and Manufacturing News Archive Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. Maximize your cnc router workholding with our total guide. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The best workholding solution for a cnc machine depends on the type of material. Cnc Machine Workholding.

From makezine.com

Keep Your Project Secure with These CNC Workholding Techniques Make Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. Discover the best techniques and tools for securing your workpiece and optimizing cuts. Maximize. Cnc Machine Workholding.

From mungfali.com

CNC Workholding Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. How a part is held can significantly affect a number of logistical factors, including viable toolpaths,. Cnc Machine Workholding.

From www.fictiv.com

Introduction to Workholding Options for CNC Machining Fictiv Cnc Machine Workholding There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Discover the best techniques and tools for securing your workpiece and optimizing cuts. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. The choice of workholding solution can. Cnc Machine Workholding.

From toolstoday.com

Best CNC Workholding Methods for Woodworking Cnc Machine Workholding Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. Discover the best techniques and tools for securing your workpiece and optimizing cuts. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part,. Cnc Machine Workholding.

From www.fastradius.com

Workholding for CNC Manufacturing Resources Fast Radius Cnc Machine Workholding There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The basics of cnc workholding. How a part is held can significantly affect a number of logistical. Cnc Machine Workholding.

From www.fastradius.com

Workholding for CNC Manufacturing Resources Fast Radius Cnc Machine Workholding The basics of cnc workholding. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The best workholding solution for a cnc machine depends on the type. Cnc Machine Workholding.

From www.trunniontable.com

Custom CNC Workholding Martin Trunnion Tables Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. The basics of cnc workholding.. Cnc Machine Workholding.

From www.miteebite.com

12/11/15 New Workholding Devices Enable 4th Axis Machining MiteeBite Products LLC. Cnc Machine Workholding There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The basics of cnc workholding. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. Cnc workholding refers to the methods and devices used to securely hold. Cnc Machine Workholding.

From www.hvrmagnet.com

Workholding for Lathe/Grinding/Milling/CNC Machining Centers Cnc Machine Workholding Discover the best techniques and tools for securing your workpiece and optimizing cuts. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part,. Cnc Machine Workholding.

From sienci.com

Make your own CNC workholding with your LongMill Sienci Labs Cnc Machine Workholding The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. Maximize your cnc router workholding with our total guide. Cnc workholding refers to the methods and devices used to. Cnc Machine Workholding.

From lang-technik.co.uk

4th & 5th Axis Rotary Table For CNC Milling Machine & Workholding Clamp Cnc Machine Workholding Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining. Cnc Machine Workholding.

From www.fastradius.com

Workholding for CNC Manufacturing Resources Fast Radius Cnc Machine Workholding Cnc workholding refers to the methods and devices used to securely hold and stabilize a workpiece during the machining process. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific. There are various types of workholding devices available, each designed for specific workpieces, materials, and machining. Cnc Machine Workholding.

From www.3erp.com

Find the best way to load your workpiece for CNC Machining Cnc Machine Workholding The basics of cnc workholding. The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. Discover the best techniques and tools for securing your workpiece and optimizing cuts. The best workholding solution for a cnc machine depends on the type of material being machined, the complexity of the part, and the specific.. Cnc Machine Workholding.

From lang-technik.co.uk

4th & 5th Axis Rotary Table For CNC Milling Machine & Workholding Clamp Cnc Machine Workholding There are various types of workholding devices available, each designed for specific workpieces, materials, and machining operations. The basics of cnc workholding. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. Discover the best. Cnc Machine Workholding.

From www.cnccookbook.com

Total Guide to CNC Milling Machine Workholding Cnc Machine Workholding Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting. Cnc Machine Workholding.

From hyfore.com

CNC Workholding Equipment Hyfore Cnc Machine Workholding The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. The basics of cnc workholding. Workholding devices are essential tools used in cnc machining and other manufacturing processes to hold, clamp, or fixture a workpiece securely in place during machining operations. How a part is held can significantly affect a number of. Cnc Machine Workholding.

From www.cnccookbook.com

Total Guide to CNC Jigs, Fixtures, and Workholding Solutions for Mills Cnc Machine Workholding The choice of workholding solution can significantly impact the efficiency, precision, and safety of the cnc machining process. How a part is held can significantly affect a number of logistical factors, including viable toolpaths, which workpiece surfaces will be machinable without additional setups, and the allowable speed and force of the cutting tools. Discover the best techniques and tools for. Cnc Machine Workholding.