Steel Mold Casting . Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Metal mould casting, on the other hand, has weight and shape limitations. It is a casting process during which castings are made by pouring liquid metal into a metal mold. Metal casting is arguably the earliest and most influential industrial process in history. During metal casting, molten metal is transferred from a. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. This mold is generally cut from cast iron or steel (and historically stone or. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. The metal mold can be used hundreds to thousands of times before needing to be replaced.

from www.youtube.com

Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. Metal casting is arguably the earliest and most influential industrial process in history. This mold is generally cut from cast iron or steel (and historically stone or. The metal mold can be used hundreds to thousands of times before needing to be replaced. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. It is a casting process during which castings are made by pouring liquid metal into a metal mold. During metal casting, molten metal is transferred from a. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. Metal mould casting, on the other hand, has weight and shape limitations.

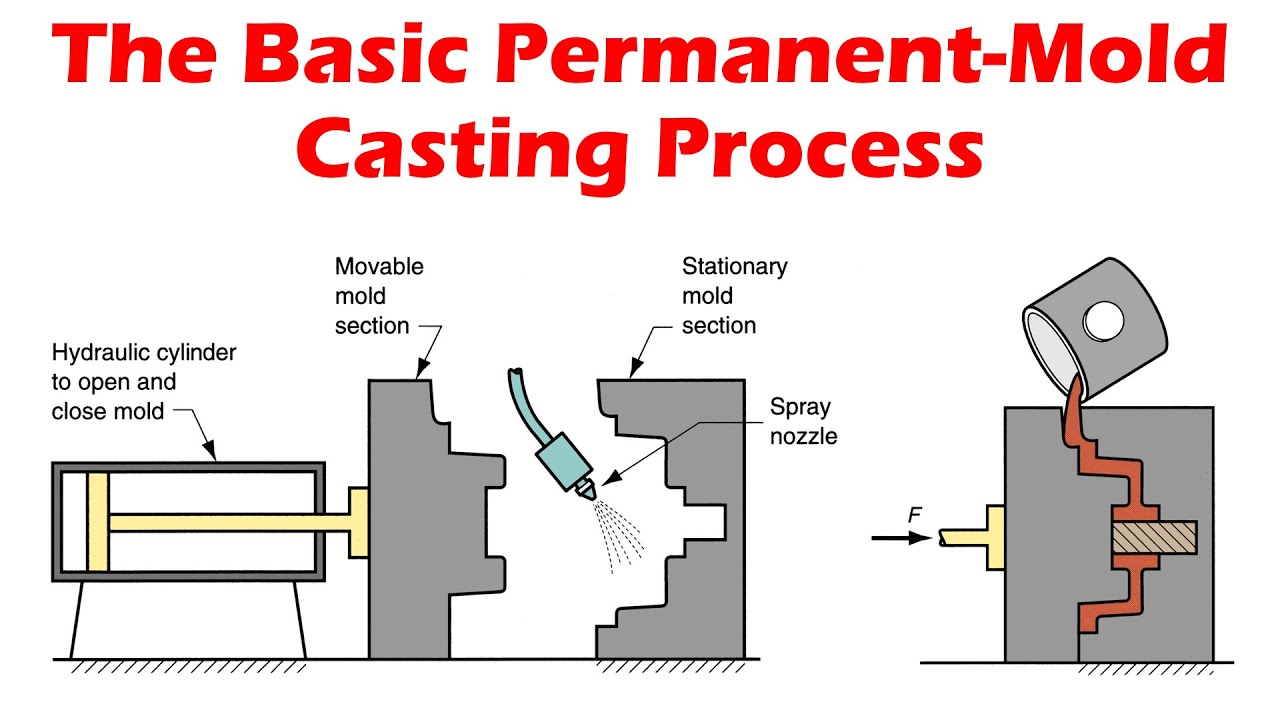

The Basic Permanent Mold Casting Process YouTube

Steel Mold Casting Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Metal mould casting, on the other hand, has weight and shape limitations. The metal mold can be used hundreds to thousands of times before needing to be replaced. Metal casting is arguably the earliest and most influential industrial process in history. During metal casting, molten metal is transferred from a. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. This mold is generally cut from cast iron or steel (and historically stone or. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. It is a casting process during which castings are made by pouring liquid metal into a metal mold. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components.

From centurymfg.com

metal casting mold Century Manufacturing Steel Mold Casting Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. It is a casting process during which castings are made by pouring liquid metal into a metal mold. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where. Steel Mold Casting.

From www.steel-foundry.com

Cast Carbon Steel Shell Mold Casting Steel Casting Factory Cast Steel Mold Casting Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. It is a casting process during which castings are made by. Steel Mold Casting.

From www.syalons.com

Continuous Steel Casting with Syalon Break Rings Steel Mold Casting In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. This mold is generally cut from cast iron or steel (and historically stone or. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. The metal mold can be. Steel Mold Casting.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Steel Mold Casting In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Metal casting is arguably the earliest and most influential industrial process in history. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a. Steel Mold Casting.

From aminds.com

3 POPULAR TYPES OF METAL CASTING AM Industries Vietnam Steel Mold Casting Metal mould casting, on the other hand, has weight and shape limitations. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. It is a casting process during which castings are made by pouring liquid metal into a metal mold. During metal casting, molten metal is transferred from a. The metal mold can be used hundreds. Steel Mold Casting.

From www.youtube.com

The Basic Permanent Mold Casting Process YouTube Steel Mold Casting This mold is generally cut from cast iron or steel (and historically stone or. The metal mold can be used hundreds to thousands of times before needing to be replaced. It is a casting process during which castings are made by pouring liquid metal into a metal mold. Though the process takes some time to learn, casting metal is incredibly. Steel Mold Casting.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Steel Mold Casting This mold is generally cut from cast iron or steel (and historically stone or. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. During metal casting, molten metal is transferred from a. It is a casting process during which castings are made by pouring liquid metal into. Steel Mold Casting.

From www.thelibraryofmanufacturing.com

Metal Casting Process Steel Mold Casting Metal mould casting, on the other hand, has weight and shape limitations. During metal casting, molten metal is transferred from a. It is a casting process during which castings are made by pouring liquid metal into a metal mold. This mold is generally cut from cast iron or steel (and historically stone or. Shell molding can achieve tight tolerances and. Steel Mold Casting.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Steel Mold Casting Metal mould casting, on the other hand, has weight and shape limitations. Metal casting is arguably the earliest and most influential industrial process in history. During metal casting, molten metal is transferred from a. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. The metal. Steel Mold Casting.

From veenaengicast.com

Metal Casting Guide for Beginners Veena Enterprise Steel Mold Casting Metal casting is arguably the earliest and most influential industrial process in history. This mold is generally cut from cast iron or steel (and historically stone or. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. Shell molding can achieve tight tolerances and excellent surface finishes in. Steel Mold Casting.

From www.dreamstime.com

Steel Molds for Casting Metal Parts Stock Photo Image of generated Steel Mold Casting In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Metal casting is arguably the earliest and most influential industrial process in history. It is a casting process during which castings are made by pouring liquid metal into a metal mold. Though the. Steel Mold Casting.

From www.3erp.com

Everything you need to know about metal casting Steel Mold Casting Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. This mold is generally cut from cast iron or steel (and historically stone or. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. It is a casting process during which castings. Steel Mold Casting.

From www.leclairemfg.com

What Is Metal Mold Casting? LeClaire Manufacturing Co. Steel Mold Casting During metal casting, molten metal is transferred from a. Metal mould casting, on the other hand, has weight and shape limitations. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. The metal mold can be used hundreds to thousands of times before needing to be replaced. This. Steel Mold Casting.

From www.thelibraryofmanufacturing.com

Metal Casting Process Steel Mold Casting It is a casting process during which castings are made by pouring liquid metal into a metal mold. Metal casting is arguably the earliest and most influential industrial process in history. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Metal casting. Steel Mold Casting.

From www.alamy.com

Metal casting process in foundry, liquid metal pouring from container Steel Mold Casting Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. Metal casting is arguably the earliest and most influential industrial process in history. This mold is generally cut from cast iron or steel (and historically stone or. Metal casting is an ancient crafting process where you pour molten. Steel Mold Casting.

From riversofsteel.com

Aluminum Casting Session — Rivers of Steel Steel Mold Casting This mold is generally cut from cast iron or steel (and historically stone or. The metal mold can be used hundreds to thousands of times before needing to be replaced. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. During metal casting, molten metal is transferred from a. Metal casting is arguably the earliest and. Steel Mold Casting.

From marketsharegroup.com

7 Types of Metal Casting Market Share Group Steel Mold Casting During metal casting, molten metal is transferred from a. Metal mould casting, on the other hand, has weight and shape limitations. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. This mold is generally cut from cast iron or steel (and historically stone or. In the metal casting process, metal shapes are formed by pouring. Steel Mold Casting.

From www.ccmrolling.com

China Slab Continuous Casting Metal Mold Casting for Steel factory and Steel Mold Casting During metal casting, molten metal is transferred from a. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry.. Steel Mold Casting.

From www.thecrucible.org

Metal Casting 101 Learn To Cast Metal [Types & Processes] Steel Mold Casting It is a casting process during which castings are made by pouring liquid metal into a metal mold. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. During metal casting, molten metal is transferred from a. Metal casting is arguably the earliest and most influential industrial process. Steel Mold Casting.

From www.glasshousestore.com

12″ Casting Square Stainless Steel Mold Glass House Store Steel Mold Casting Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. It is a casting process during which castings are made by pouring liquid metal. Steel Mold Casting.

From www.leclairemfg.com

Ultimate Guide to the Permanent Mold Casting Process Steel Mold Casting The metal mold can be used hundreds to thousands of times before needing to be replaced. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. It is a casting process during which castings are made by pouring liquid metal into a metal mold. In the. Steel Mold Casting.

From www.dreamstime.com

Pouring Molten Metal To Casting Mold Stock Image Image of steel, cast Steel Mold Casting This mold is generally cut from cast iron or steel (and historically stone or. It is a casting process during which castings are made by pouring liquid metal into a metal mold. Metal casting is arguably the earliest and most influential industrial process in history. Metal casting is an ancient crafting process where you pour molten metal into a custom. Steel Mold Casting.

From www.ebay.com

Metal Silver Jewelry Cast Ingot Mould Casting Melting Mold Steel Groove Steel Mold Casting Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. This mold is generally cut from cast iron or. Steel Mold Casting.

From novastevensville.com

Molding Manufacturing Creating the World's Most Useful Products Steel Mold Casting Metal casting is arguably the earliest and most influential industrial process in history. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. During metal casting, molten metal is transferred from a. The metal mold can be used hundreds to thousands of times. Steel Mold Casting.

From buntyllc.com

Custom Metal Casting Molds Bunty LLC Steel Mold Casting Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. During metal casting, molten metal is transferred from a. This mold is generally cut from cast iron or steel (and historically stone or. Metal casting is arguably the earliest and most influential industrial process in history.. Steel Mold Casting.

From www.iqsdirectory.com

Permanent Mold Castings What Is It? How Does It Work? Advantages Steel Mold Casting It is a casting process during which castings are made by pouring liquid metal into a metal mold. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. The metal mold can be used hundreds to thousands of times before needing to be replaced. In the metal casting process, metal shapes are formed by pouring molten. Steel Mold Casting.

From www.mdpi.com

Materials Free FullText Modeling of Interfacial Tension and Steel Mold Casting Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. During metal casting, molten metal is transferred from a. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. It is a casting process during which castings are made by pouring liquid. Steel Mold Casting.

From www.glasshousestore.com

6″ Square Casting Stainless Steel Mold Glass House Store Steel Mold Casting Metal mould casting, on the other hand, has weight and shape limitations. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. During metal casting, molten metal is transferred from a. The metal mold can be used hundreds to thousands of times before needing to be replaced. In the metal casting process, metal shapes are formed. Steel Mold Casting.

From punchlistzero.com

Metal Casting Process, Techniques and Applications Steel Mold Casting Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry. Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and. Steel Mold Casting.

From theeventchronicle.com

Metal And Steel Casting Tips & Tricks for Beginners in 2024 The Event Steel Mold Casting Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. This mold is generally cut from cast iron or steel (and. Steel Mold Casting.

From blog.eaglegroupmanufacturers.com

Shell Mold Casting Glossary of Terms Steel Mold Casting Metal mould casting, on the other hand, has weight and shape limitations. The metal mold can be used hundreds to thousands of times before needing to be replaced. During metal casting, molten metal is transferred from a. Metal casting is arguably the earliest and most influential industrial process in history. It is a casting process during which castings are made. Steel Mold Casting.

From www.clinchrivercasting.com

Molding Clinch River Casting NoBake Casting Foundry Steel Mold Casting Shell molding can achieve tight tolerances and excellent surface finishes in alloy steel components. Metal mould casting, on the other hand, has weight and shape limitations. This mold is generally cut from cast iron or steel (and historically stone or. It is a casting process during which castings are made by pouring liquid metal into a metal mold. In the. Steel Mold Casting.

From www.apexesmachinery.com

Gravity Casting Foundry Steel Mold Casting Steel Mold Casting Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. During metal casting, molten metal is transferred from a. Metal casting is arguably the earliest and most influential industrial process in history. Metal mould casting, on the other hand, has weight and shape limitations. It is a casting. Steel Mold Casting.

From www.reliance-foundry.com

Cast Steel Production Metal Casting Blog Steel Mold Casting Though the process takes some time to learn, casting metal is incredibly rewarding and may even lead you to a lifelong hobby. This mold is generally cut from cast iron or steel (and historically stone or. Metal casting is an ancient crafting process where you pour molten metal into a custom mold to create objects like coins, swords, and jewelry.. Steel Mold Casting.

From www.youtube.com

Casting Metal Parts into 3D Printed Molds YouTube Steel Mold Casting This mold is generally cut from cast iron or steel (and historically stone or. In the metal casting process, metal shapes are formed by pouring molten metal into a mold cavity, where it is cooled and later extracted from the mold. Metal mould casting, on the other hand, has weight and shape limitations. Metal casting is an ancient crafting process. Steel Mold Casting.