Spray Dryer Energy Balance . The main reason for this is the need to supply the latent heat of evaporation to. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. They can also be used to improve dryer operations by answering various. In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : Performing mass and energy balances enables engineers to use information on. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. The feed mass flow rate (can be done thanks to a flowmeter) the. Mass and energy balances are not just for process and equipment design. Figure 2 is a schematic diagram of the energy flows around a spray dryer. 4) or calculated by the classical formula:

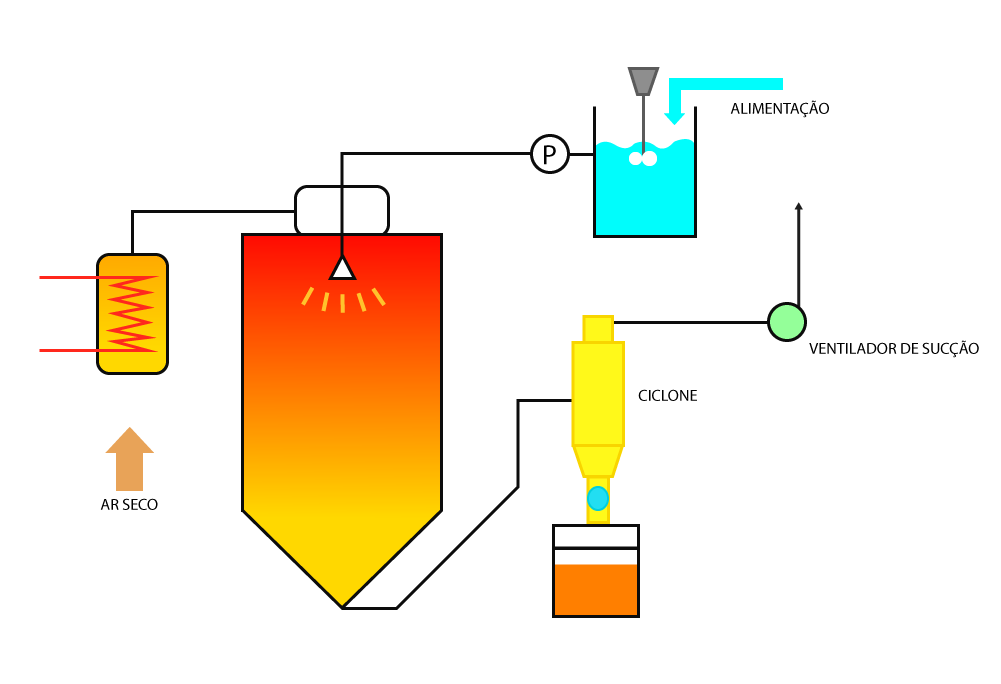

from blog.globesystems.com.br

In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. Performing mass and energy balances enables engineers to use information on. Mass and energy balances are not just for process and equipment design. The feed mass flow rate (can be done thanks to a flowmeter) the. 4) or calculated by the classical formula: Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Figure 2 is a schematic diagram of the energy flows around a spray dryer. The main reason for this is the need to supply the latent heat of evaporation to.

Entenda o que é spray dryer Globe Systems

Spray Dryer Energy Balance Performing mass and energy balances enables engineers to use information on. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. The feed mass flow rate (can be done thanks to a flowmeter) the. Figure 2 is a schematic diagram of the energy flows around a spray dryer. In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : Performing mass and energy balances enables engineers to use information on. Mass and energy balances are not just for process and equipment design. They can also be used to improve dryer operations by answering various. The main reason for this is the need to supply the latent heat of evaporation to. 4) or calculated by the classical formula: Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration.

From www.youtube.com

Dryer Design Heat and Mass Energy Balance YouTube Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. They can also be used to improve dryer operations by answering various. The feed mass flow rate (can be done thanks to a flowmeter) the. Spray drying is an efficient unit operation applied in food drying that demands a. Spray Dryer Energy Balance.

From www.mdpi.com

Energies Free FullText Superheated Steam Spray Drying as an Energy Spray Dryer Energy Balance 4) or calculated by the classical formula: They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. The main reason for this is the need to supply the latent heat of evaporation to. Figure 2 is a. Spray Dryer Energy Balance.

From www.mrclab.com

VACUUM SPRAY DRYER Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : Figure 2 is a schematic diagram of the energy. Spray Dryer Energy Balance.

From www.researchgate.net

(PDF) Thermodynamic Characterization of SingleStage SprayDryers Mass Spray Dryer Energy Balance The main reason for this is the need to supply the latent heat of evaporation to. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. Performing mass and energy balances enables engineers to use information on. 4) or calculated by the classical formula: In. Spray Dryer Energy Balance.

From fooddryingoven.com

Spray Dryer Machine/Spray Drying Machine for Fruit Powder Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Performing mass and energy balances enables engineers to use information on. The main reason for this is the need to supply the latent heat of evaporation to. Figure 2 is a schematic diagram of the energy flows around a. Spray Dryer Energy Balance.

From www.mdpi.com

Energies Free FullText Superheated Steam Spray Drying as an Energy Spray Dryer Energy Balance 4) or calculated by the classical formula: Mass and energy balances are not just for process and equipment design. The feed mass flow rate (can be done thanks to a flowmeter) the. The main reason for this is the need to supply the latent heat of evaporation to. In order to be able to complete the heat and mass balance. Spray Dryer Energy Balance.

From www.pharmamirror.com

Spray Drying Equipment to Account for of Industrial Dryer Spray Dryer Energy Balance Performing mass and energy balances enables engineers to use information on. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Figure 2 is a schematic diagram of the energy flows around a spray dryer. Spray drying is an efficient unit operation applied in food drying that demands a. Spray Dryer Energy Balance.

From electricalworkbook.com

What is Spray Dryer? Working Principle, Construction, Diagram Spray Dryer Energy Balance They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. The feed mass flow rate (can be done thanks to a flowmeter) the. Performing mass and energy balances enables engineers to use information on. Spray drying is. Spray Dryer Energy Balance.

From caloris.com

Scenes from a Caloris FlexMode® and Spray Dryer Installation Caloris Spray Dryer Energy Balance In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : Figure 2 is a schematic diagram of the energy flows around a spray dryer. Mass and energy balances are not just for process and equipment design. 4) or calculated by the classical formula: The. Spray Dryer Energy Balance.

From blog.globesystems.com.br

Entenda o que é spray dryer Globe Systems Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. 4) or calculated by the classical formula: In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : They can also be used to. Spray Dryer Energy Balance.

From www.ibu-tec.com

IBUtec Spray Dryer for Research and Development Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. The main reason for this is the need to supply the latent heat of evaporation to. Mass and energy balances are not just for process and equipment design. 4) or calculated by the classical formula:. Spray Dryer Energy Balance.

From www.researchgate.net

Different configuration of SHS spray dryers (a) standard SHS spray Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Figure 2 is a schematic diagram of the energy flows around a spray dryer. The feed mass flow rate (can be done thanks to a flowmeter) the. 4) or calculated by the classical formula: Mass and energy balances are. Spray Dryer Energy Balance.

From www.researchgate.net

Energy balance across the dryer Download Scientific Diagram Spray Dryer Energy Balance Mass and energy balances are not just for process and equipment design. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Performing mass and energy balances enables engineers to use information on. 4) or calculated by the classical formula: The main reason for this is the need to. Spray Dryer Energy Balance.

From www.researchgate.net

Energy balance across the dryer Download Scientific Diagram Spray Dryer Energy Balance In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation. Spray Dryer Energy Balance.

From pharmaguddu.com

Spray Dryer Principle, Construction, Working, Advantages, and Spray Dryer Energy Balance Mass and energy balances are not just for process and equipment design. Figure 2 is a schematic diagram of the energy flows around a spray dryer. They can also be used to improve dryer operations by answering various. 4) or calculated by the classical formula: In order to be able to complete the heat and mass balance of a spray. Spray Dryer Energy Balance.

From www.mdpi.com

Energies Free FullText Superheated Steam Spray Drying as an Energy Spray Dryer Energy Balance Mass and energy balances are not just for process and equipment design. In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. They. Spray Dryer Energy Balance.

From powderprocess.net

Spray dryer Heat and Mass Balance calculation Excel calculator Spray Dryer Energy Balance Performing mass and energy balances enables engineers to use information on. Mass and energy balances are not just for process and equipment design. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. They can also be used to improve dryer operations by answering various. In order to be. Spray Dryer Energy Balance.

From www.scribd.com

Thermodynamic Characterization of Single Stage Spray Dryers Mass and Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. They can also be used to improve dryer operations by answering various. Performing mass and energy balances enables engineers to use information on. In order to be able to complete the heat and mass balance. Spray Dryer Energy Balance.

From dxotscsix.blob.core.windows.net

Fluidized Bed Dryer Diagram at Daisy Flores blog Spray Dryer Energy Balance Performing mass and energy balances enables engineers to use information on. The main reason for this is the need to supply the latent heat of evaporation to. Mass and energy balances are not just for process and equipment design. Figure 2 is a schematic diagram of the energy flows around a spray dryer. They can also be used to improve. Spray Dryer Energy Balance.

From pharmacyscope.com

Spray Dryer Principle, Construction and Working Spray Dryer Energy Balance 4) or calculated by the classical formula: The feed mass flow rate (can be done thanks to a flowmeter) the. They can also be used to improve dryer operations by answering various. Performing mass and energy balances enables engineers to use information on. In order to be able to complete the heat and mass balance of a spray dryer, it. Spray Dryer Energy Balance.

From dedert.com

Spray Drying Dryer Types, Advantages and Applications Spray Dryer Energy Balance Figure 2 is a schematic diagram of the energy flows around a spray dryer. Mass and energy balances are not just for process and equipment design. The main reason for this is the need to supply the latent heat of evaporation to. The feed mass flow rate (can be done thanks to a flowmeter) the. They can also be used. Spray Dryer Energy Balance.

From www.semanticscholar.org

Figure 1 from Heat balance of a multistage spraydryer principles and Spray Dryer Energy Balance In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Performing. Spray Dryer Energy Balance.

From www.researchgate.net

Energy balance in the dryer. Download Scientific Diagram Spray Dryer Energy Balance The feed mass flow rate (can be done thanks to a flowmeter) the. They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. 4) or calculated by the classical formula: Spray drying is. Spray Dryer Energy Balance.

From powderprocess.net

Spray dryer Heat and Mass Balance calculation Excel calculator Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. Figure 2 is a schematic diagram of the energy flows around a spray dryer.. Spray Dryer Energy Balance.

From www.spraydryworks.com

Spray Dry Works (Rental) Drier Solutions Spray Dryer Energy Balance The main reason for this is the need to supply the latent heat of evaporation to. Performing mass and energy balances enables engineers to use information on. Mass and energy balances are not just for process and equipment design. They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in. Spray Dryer Energy Balance.

From printablefullhooey.z19.web.core.windows.net

Spray Record Sheet Excel Spray Dryer Energy Balance The main reason for this is the need to supply the latent heat of evaporation to. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Mass and energy balances are not just for process and equipment design. 4) or calculated by the classical formula: Spray drying is an. Spray Dryer Energy Balance.

From powderprocess.net

Spray dryer Heat and Mass Balance calculation Excel calculator Spray Dryer Energy Balance Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. 4) or calculated by the classical formula: They can also be used to improve dryer operations by answering various. Figure 2 is a schematic diagram of the energy flows around a spray dryer. Spray drying. Spray Dryer Energy Balance.

From www.mdpi.com

Processes Free FullText Encapsulation of Active Ingredients in Spray Dryer Energy Balance Mass and energy balances are not just for process and equipment design. 4) or calculated by the classical formula: Performing mass and energy balances enables engineers to use information on. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Figure 2 is a schematic diagram of the energy. Spray Dryer Energy Balance.

From www.youtube.com

Chapter 12 Dryer Energy Balance YouTube Spray Dryer Energy Balance The feed mass flow rate (can be done thanks to a flowmeter) the. They can also be used to improve dryer operations by answering various. In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : The main reason for this is the need to. Spray Dryer Energy Balance.

From www.alibaba.com

Lpg Industrial Spray Dryer (energy Saving,Customized Design) Buy Spray Dryer Energy Balance Mass and energy balances are not just for process and equipment design. 4) or calculated by the classical formula: The main reason for this is the need to supply the latent heat of evaporation to. In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically. Spray Dryer Energy Balance.

From www.researchgate.net

(PDF) Thermodynamic Characterization of SingleStage SprayDryers Mass Spray Dryer Energy Balance They can also be used to improve dryer operations by answering various. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. The main reason for this is the need to supply the latent heat of evaporation to. Figure 2 is a schematic diagram of the energy flows around. Spray Dryer Energy Balance.

From www.voegtlin.com

Digital Gas Flow Control for Spray Dryers offers Repeatability Spray Dryer Energy Balance Performing mass and energy balances enables engineers to use information on. 4) or calculated by the classical formula: The feed mass flow rate (can be done thanks to a flowmeter) the. Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum evaporation and membrane filtration. The main reason for. Spray Dryer Energy Balance.

From www.fluidairinc.com

Electrostatic Drying Fluid Air Spray Dryer Energy Balance Mass and energy balances are not just for process and equipment design. Performing mass and energy balances enables engineers to use information on. They can also be used to improve dryer operations by answering various. In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically. Spray Dryer Energy Balance.

From www.alaquainc.com

What is a Spray Dryer and How does a spray dryer work? Spray Dryer Energy Balance 4) or calculated by the classical formula: In order to be able to complete the heat and mass balance of a spray dryer, it is necessary to measure some process parameters, typically : Figure 2 is a schematic diagram of the energy flows around a spray dryer. They can also be used to improve dryer operations by answering various. Performing. Spray Dryer Energy Balance.

From www.laboao.com

New Energy Closedloop Organic Solvent Spray Dryer China New Energy Spray Dryer Energy Balance They can also be used to improve dryer operations by answering various. The feed mass flow rate (can be done thanks to a flowmeter) the. 4) or calculated by the classical formula: Spray drying is an efficient unit operation applied in food drying that demands a high amount of energy compared to vacuum. Spray drying is an efficient unit operation. Spray Dryer Energy Balance.