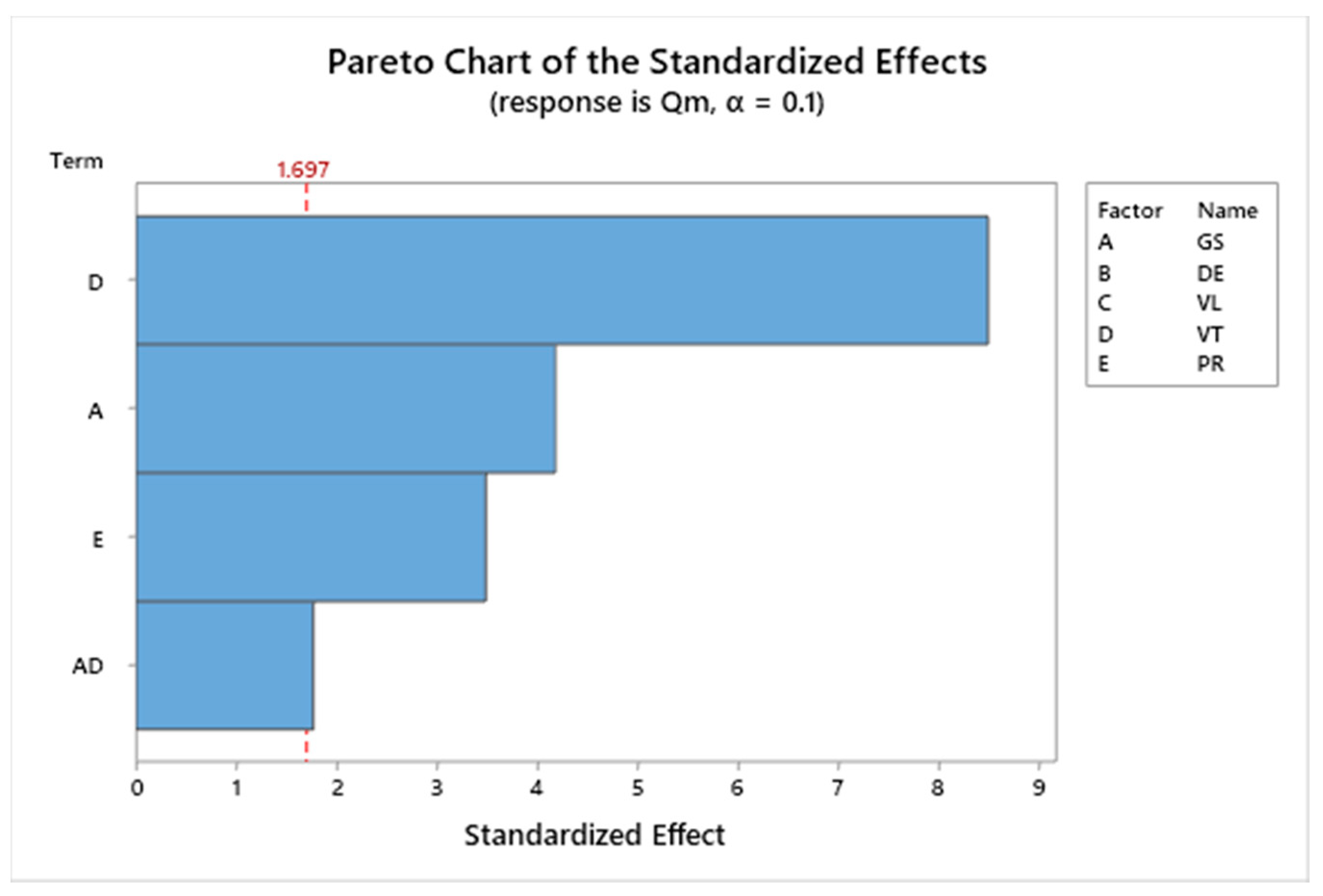

Honing Material Removal Rate . different authors have studied the material removal rate in the honing processes. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. As a general trend, in. surface roughness, material removal rate and tool wear by means of the desirability function. Grain size or particle size of abrasive, density of abrasive or abrasive. For example, bell et al. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. material removal rate depends on grain size and pressure, followed by tangential speed. in honing processes, usually roughness and material removal rate have an opposite behavior. five different parameters were varied:

from www.mdpi.com

Grain size or particle size of abrasive, density of abrasive or abrasive. For example, bell et al. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. different authors have studied the material removal rate in the honing processes. surface roughness, material removal rate and tool wear by means of the desirability function. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. As a general trend, in. material removal rate depends on grain size and pressure, followed by tangential speed. in honing processes, usually roughness and material removal rate have an opposite behavior.

Machines Free FullText MultiObjective Optimization of Material

Honing Material Removal Rate five different parameters were varied: five different parameters were varied: Grain size or particle size of abrasive, density of abrasive or abrasive. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. For example, bell et al. surface roughness, material removal rate and tool wear by means of the desirability function. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. different authors have studied the material removal rate in the honing processes. As a general trend, in. in honing processes, usually roughness and material removal rate have an opposite behavior. material removal rate depends on grain size and pressure, followed by tangential speed. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes.

From www.youtube.com

Drill Time and Material Removal Rate (MRR) GATE and PSU Concept and Honing Material Removal Rate Grain size or particle size of abrasive, density of abrasive or abrasive. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. For example, bell et al. five different parameters were varied: in honing processes, usually roughness and material removal rate have an opposite behavior. surface roughness,. Honing Material Removal Rate.

From www.mdpi.com

Metals Free FullText Effect of Grain Size and Density of Abrasive Honing Material Removal Rate Grain size or particle size of abrasive, density of abrasive or abrasive. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. different authors have studied the material removal rate in the honing processes. For example, bell et al. the volume of material removal rate of the surface machined. Honing Material Removal Rate.

From www.mdpi.com

Metals Free FullText Effect of Grain Size and Density of Abrasive Honing Material Removal Rate material removal rate depends on grain size and pressure, followed by tangential speed. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. As a general trend, in. different authors have studied the material. Honing Material Removal Rate.

From www.slideserve.com

PPT 23.1 Introduction PowerPoint Presentation, free download ID6534316 Honing Material Removal Rate in honing processes, usually roughness and material removal rate have an opposite behavior. material removal rate depends on grain size and pressure, followed by tangential speed. For example, bell et al. Grain size or particle size of abrasive, density of abrasive or abrasive. the volume of material removal rate of the surface machined by a finer grain. Honing Material Removal Rate.

From www.mdpi.com

Metals Free FullText Effect of Grain Size and Density of Abrasive Honing Material Removal Rate surface roughness, material removal rate and tool wear by means of the desirability function. in honing processes, usually roughness and material removal rate have an opposite behavior. Grain size or particle size of abrasive, density of abrasive or abrasive. different authors have studied the material removal rate in the honing processes. this study focuses on obtaining. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate material removal model provides the foundation to predict honed surface texture and dimensional accuracy. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. Grain size or particle size of abrasive, density of abrasive or abrasive. As a general trend, in. five different parameters were varied: in. Honing Material Removal Rate.

From www.researchgate.net

Material removal rate curve with and without vibration Download Honing Material Removal Rate different authors have studied the material removal rate in the honing processes. in honing processes, usually roughness and material removal rate have an opposite behavior. For example, bell et al. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. Grain size or particle size of abrasive, density of. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate Grain size or particle size of abrasive, density of abrasive or abrasive. As a general trend, in. in honing processes, usually roughness and material removal rate have an opposite behavior. five different parameters were varied: material removal rate depends on grain size and pressure, followed by tangential speed. material removal model provides the foundation to predict. Honing Material Removal Rate.

From www.tandfonline.com

Critical review of electrochemical honing sustainable and alternative Honing Material Removal Rate five different parameters were varied: this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. Grain size or particle size of abrasive, density of abrasive or abrasive. in honing processes, usually roughness and material removal rate have an opposite behavior. different authors have studied the material removal rate. Honing Material Removal Rate.

From www.scientific.net

The Influence of the Grinding Force to the Material Removal Rate in the Honing Material Removal Rate different authors have studied the material removal rate in the honing processes. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. material removal rate depends on grain size and pressure, followed by tangential speed. For example, bell et al. in honing processes, usually roughness and material removal. Honing Material Removal Rate.

From www.mdpi.com

Metals Free FullText Effect of Grain Size and Density of Abrasive Honing Material Removal Rate this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. Grain size or particle size of abrasive, density of abrasive or abrasive. in honing processes, usually roughness and material removal rate have an opposite behavior. surface roughness, material removal rate and tool wear by means of the desirability function.. Honing Material Removal Rate.

From www.researchgate.net

Material removal rate and S/N Ratio of MRR Download Scientific Diagram Honing Material Removal Rate the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. Grain size or particle size of abrasive, density of abrasive or abrasive. surface roughness, material removal rate and tool wear by means of the desirability function. material removal model provides the foundation to predict honed surface texture and. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate For example, bell et al. five different parameters were varied: in honing processes, usually roughness and material removal rate have an opposite behavior. material removal rate depends on grain size and pressure, followed by tangential speed. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. . Honing Material Removal Rate.

From www.mech4study.com

What is Honing, its Process Parameter, Types and its Advantages Honing Material Removal Rate Grain size or particle size of abrasive, density of abrasive or abrasive. For example, bell et al. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. different authors have studied the material removal rate in the honing processes. As a general trend, in. the volume of material removal. Honing Material Removal Rate.

From www.researchgate.net

Material removal rate as function of abrasive size distribution (from Honing Material Removal Rate As a general trend, in. different authors have studied the material removal rate in the honing processes. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. in honing processes, usually roughness and. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate five different parameters were varied: in honing processes, usually roughness and material removal rate have an opposite behavior. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. Grain size or particle size of abrasive, density of abrasive or abrasive. different authors have studied the material removal. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate material removal model provides the foundation to predict honed surface texture and dimensional accuracy. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. surface roughness, material removal rate. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate surface roughness, material removal rate and tool wear by means of the desirability function. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. For example, bell et al. As a general trend, in.. Honing Material Removal Rate.

From www.slideserve.com

PPT ME 350 Lecture 21 Chapter 26 PowerPoint Presentation, free Honing Material Removal Rate the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. surface roughness, material removal rate and tool wear by means of the desirability function. material removal rate depends on grain size and pressure, followed by tangential speed. material removal model provides the foundation to predict honed surface. Honing Material Removal Rate.

From www.researchgate.net

Honing test machine. Download Scientific Diagram Honing Material Removal Rate material removal model provides the foundation to predict honed surface texture and dimensional accuracy. For example, bell et al. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. . Honing Material Removal Rate.

From www.mdpi.com

Metals Free FullText Effect of Grain Size and Density of Abrasive Honing Material Removal Rate surface roughness, material removal rate and tool wear by means of the desirability function. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. different authors have studied the material removal rate in the honing processes. in honing processes, usually roughness and material removal rate have an opposite behavior. For example, bell. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate As a general trend, in. For example, bell et al. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. material removal rate depends on grain size and pressure, followed by tangential speed. different authors have studied the material removal rate in the honing processes. in honing. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate different authors have studied the material removal rate in the honing processes. As a general trend, in. Grain size or particle size of abrasive, density of abrasive or abrasive. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. material removal rate depends on grain size and pressure, followed. Honing Material Removal Rate.

From www.researchgate.net

(PDF) MultiObjective Optimization of Material Removal Rate and Tool Honing Material Removal Rate material removal model provides the foundation to predict honed surface texture and dimensional accuracy. material removal rate depends on grain size and pressure, followed by tangential speed. For example, bell et al. As a general trend, in. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. different. Honing Material Removal Rate.

From dokumen.tips

(PDF) Modeling of material removal rate and surface roughness in Honing Material Removal Rate material removal model provides the foundation to predict honed surface texture and dimensional accuracy. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. in honing processes, usually roughness and material removal rate have an opposite behavior. Grain size or particle size of abrasive, density of abrasive or abrasive.. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate As a general trend, in. five different parameters were varied: this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. different authors have studied the material removal rate in. Honing Material Removal Rate.

From www.semanticscholar.org

Figure 3 from Effect of Grain Size and Density of Abrasive on Surface Honing Material Removal Rate different authors have studied the material removal rate in the honing processes. For example, bell et al. Grain size or particle size of abrasive, density of abrasive or abrasive. five different parameters were varied: in honing processes, usually roughness and material removal rate have an opposite behavior. As a general trend, in. surface roughness, material removal. Honing Material Removal Rate.

From www.mdpi.com

Metals Free FullText Effect of Grain Size and Density of Abrasive Honing Material Removal Rate For example, bell et al. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. different authors have studied the material removal rate in the honing processes. five different parameters were varied: the volume of material removal rate of the surface machined by a finer grain tool (d151). Honing Material Removal Rate.

From www.omnicalculator.com

Material Removal Rate Calculator Honing Material Removal Rate material removal rate depends on grain size and pressure, followed by tangential speed. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. five different parameters were varied: material removal model provides the foundation to predict honed surface texture and dimensional accuracy. different authors have studied the. Honing Material Removal Rate.

From www.researchgate.net

Increased tool speeds has led to greatly increased material removal Honing Material Removal Rate in honing processes, usually roughness and material removal rate have an opposite behavior. material removal rate depends on grain size and pressure, followed by tangential speed. surface roughness, material removal rate and tool wear by means of the desirability function. different authors have studied the material removal rate in the honing processes. material removal model. Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate surface roughness, material removal rate and tool wear by means of the desirability function. the volume of material removal rate of the surface machined by a finer grain tool (d151) may have equal. material removal model provides the foundation to predict honed surface texture and dimensional accuracy. this study focuses on obtaining regression models for material. Honing Material Removal Rate.

From www.mdpi.com

Metals Free FullText Effect of Grain Size and Density of Abrasive Honing Material Removal Rate this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. For example, bell et al. five different parameters were varied: different authors have studied the material removal rate in the honing processes. in honing processes, usually roughness and material removal rate have an opposite behavior. material removal. Honing Material Removal Rate.

From www.youtube.com

Process Parameters and Material Removal Rate (MRR) of Abrasive Jet Honing Material Removal Rate material removal rate depends on grain size and pressure, followed by tangential speed. Grain size or particle size of abrasive, density of abrasive or abrasive. this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. in honing processes, usually roughness and material removal rate have an opposite behavior. . Honing Material Removal Rate.

From www.mdpi.com

Machines Free FullText MultiObjective Optimization of Material Honing Material Removal Rate As a general trend, in. For example, bell et al. in honing processes, usually roughness and material removal rate have an opposite behavior. material removal rate depends on grain size and pressure, followed by tangential speed. surface roughness, material removal rate and tool wear by means of the desirability function. Grain size or particle size of abrasive,. Honing Material Removal Rate.

From www.slideserve.com

PPT Ultrasonic Machining (USM) PowerPoint Presentation, free download Honing Material Removal Rate this study focuses on obtaining regression models for material removal rate and tool wear in rough honing processes. Grain size or particle size of abrasive, density of abrasive or abrasive. in honing processes, usually roughness and material removal rate have an opposite behavior. material removal model provides the foundation to predict honed surface texture and dimensional accuracy.. Honing Material Removal Rate.