Push Or Pull Process . A pull system, however, uses current customer. In push manufacturing, businesses produce products based on demand planning. This allows for a much more granular approach than push systems. For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). What else sets push and pull systems apart is the amount of wip inventory. For a turn item however, you can use a more sophisticated min. Differences between push and pull manufacturing strategies. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. Production is pushed out to meet customer forecasted demands, even if those customers have not yet placed orders. The terms “push” and “pull” come from the supply chain management (scm) world. It dictates when and how much to produce. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. A company using the push system will forecast demand and employ. A push system relies on market demand and forecasting to dictate production levels.

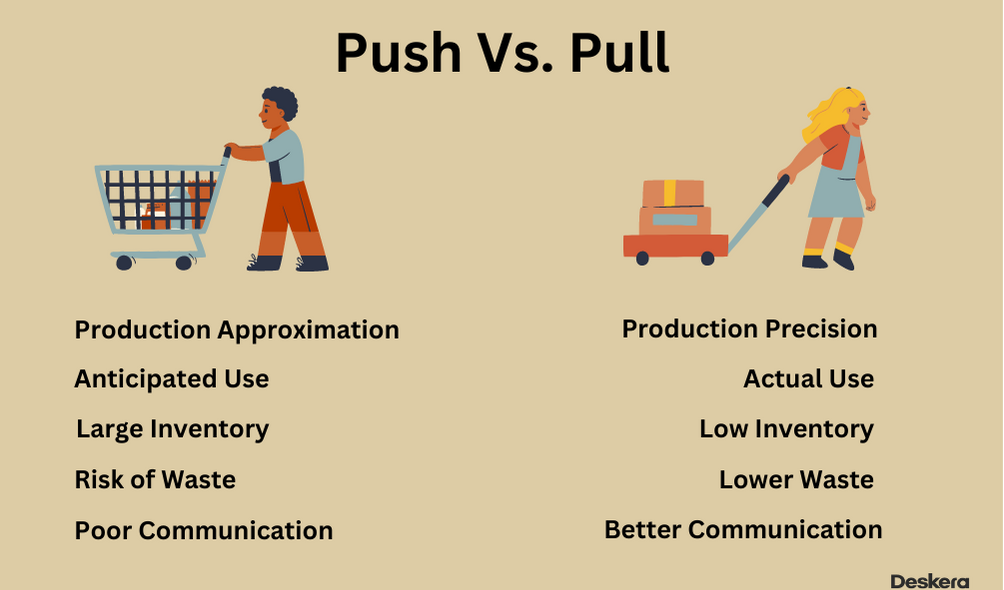

from www.deskera.com

What else sets push and pull systems apart is the amount of wip inventory. A pull production supposedly produces only if. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. In push manufacturing, businesses produce products based on demand planning. For a turn item however, you can use a more sophisticated min. This allows for a much more granular approach than push systems. It dictates when and how much to produce. Production is pushed out to meet customer forecasted demands, even if those customers have not yet placed orders. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. Differences between push and pull manufacturing strategies.

Push System vs. Pull System in Manufacturing Management

Push Or Pull Process The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. What else sets push and pull systems apart is the amount of wip inventory. A pull system, however, uses current customer. It dictates when and how much to produce. A company using the push system will forecast demand and employ. For a turn item however, you can use a more sophisticated min. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. This allows for a much more granular approach than push systems. The terms “push” and “pull” come from the supply chain management (scm) world. A pull production supposedly produces only if. In push manufacturing, businesses produce products based on demand planning. For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). A push system relies on market demand and forecasting to dictate production levels. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. In pull manufacturing, production is based on actual customer orders. Differences between push and pull manufacturing strategies.

From www.slideserve.com

PPT Push vs. Pull Process Control PowerPoint Presentation, free Push Or Pull Process For a turn item however, you can use a more sophisticated min. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. The disparities between push and pull manufacturing strategies go beyond. Push Or Pull Process.

From www.inflowinventory.com

Push vs Pull System Manufacturing An InDepth Analysis Push Or Pull Process A pull system, however, uses current customer. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. In pull. Push Or Pull Process.

From www.slideserve.com

PPT Supply Chain Management PowerPoint Presentation, free download Push Or Pull Process For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). For a turn item however, you can use a more sophisticated min. It dictates when and how much to produce. A push system relies on market demand and forecasting to dictate production levels. A pull system, however, uses current customer. A company using the. Push Or Pull Process.

From slidetodoc.com

Supply Chain Management Chapter 1 Understanding the Supply Push Or Pull Process For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. A company using the push system will forecast demand and employ. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. In pull. Push Or Pull Process.

From www.slideserve.com

PPT Push and Pull Production Systems PowerPoint Presentation ID385010 Push Or Pull Process For a turn item however, you can use a more sophisticated min. A pull production supposedly produces only if. It dictates when and how much to produce. In pull manufacturing, production is based on actual customer orders. This allows for a much more granular approach than push systems. For example, a pull network supports multiple replenishment policies based on the. Push Or Pull Process.

From www.slideserve.com

PPT Original course by Smart Lectures by Steve Sheard Push Or Pull Process The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. What else sets push and pull systems apart is the amount of wip inventory. In pull manufacturing, production is based on actual customer orders. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. A pull system, however, uses. Push Or Pull Process.

From www.fool.com

A Beginner's Guide to Push vs. Pull Marketing The Blueprint Push Or Pull Process For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). It dictates when and how much to produce. This allows for a much more granular approach than push systems. A company using the push system will forecast demand and employ. The main difference between push and pull manufacturing is that in a push system,. Push Or Pull Process.

From www.slideserve.com

PPT Supply Chain Management PowerPoint Presentation, free download Push Or Pull Process Differences between push and pull manufacturing strategies. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. The terms “push” and “pull” come from the supply chain management (scm) world. In push manufacturing, businesses produce products based on demand planning. It dictates when and how much to produce. For a “slow mover” you can manage by a. Push Or Pull Process.

From studylib.net

Push vs. Pull Process Control Push Or Pull Process A pull system, however, uses current customer. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. Production is pushed out to meet customer forecasted demands, even if those customers have not yet placed orders. This allows for a much more granular approach than push systems. Differences between push and pull manufacturing strategies. A pull production supposedly. Push Or Pull Process.

From gomingo.io

Push vs. Pull System Mingo Manufacturing Productivity Push Or Pull Process For a turn item however, you can use a more sophisticated min. A company using the push system will forecast demand and employ. A pull production supposedly produces only if. It dictates when and how much to produce. What else sets push and pull systems apart is the amount of wip inventory. For a “slow mover” you can manage by. Push Or Pull Process.

From blog.megaventory.com

Push vs Pull Inventory Management Which One Is Better For You Push Or Pull Process It dictates when and how much to produce. Production is pushed out to meet customer forecasted demands, even if those customers have not yet placed orders. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand. Push Or Pull Process.

From www.mudamasters.com

Pull connections The 3 strategies MudaMasters Push Or Pull Process For a turn item however, you can use a more sophisticated min. A push system relies on market demand and forecasting to dictate production levels. A pull system, however, uses current customer. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. In pull manufacturing, production is based on actual customer orders. For a “slow mover” you. Push Or Pull Process.

From marketinchoices.blogspot.com

Push Pull Strategy In Marketing Marketing Choices Push Or Pull Process In push manufacturing, businesses produce products based on demand planning. A pull system, however, uses current customer. It dictates when and how much to produce. In pull manufacturing, production is based on actual customer orders. For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). This allows for a much more granular approach than. Push Or Pull Process.

From www.retaildogma.com

Push & Pull Strategy Explained With RealLife Example Push Or Pull Process A push system relies on market demand and forecasting to dictate production levels. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. For a “slow mover” you can manage by a simple reorder point (sell one, replenish one).. Push Or Pull Process.

From 101blockchains.com

Push and Pull Strategy in Supply Chain Management A Comprehensive Guide Push Or Pull Process It dictates when and how much to produce. A pull system, however, uses current customer. For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in. Push Or Pull Process.

From www.deskera.com

Push System vs. Pull System in Manufacturing Management Push Or Pull Process In pull manufacturing, production is based on actual customer orders. A push system relies on market demand and forecasting to dictate production levels. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. What else sets push and pull systems apart is the amount of wip inventory. Differences between push and pull. Push Or Pull Process.

From slidemodel.com

Manufacturing Pull vs Push PowerPoint Template SlideModel Push Or Pull Process In pull manufacturing, production is based on actual customer orders. It dictates when and how much to produce. What else sets push and pull systems apart is the amount of wip inventory. The terms “push” and “pull” come from the supply chain management (scm) world. A company using the push system will forecast demand and employ. In push manufacturing, businesses. Push Or Pull Process.

From operationsinsider.com

Push vs Pull — Operations Insider Push Or Pull Process This allows for a much more granular approach than push systems. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. The terms “push” and “pull” come from the supply chain management. Push Or Pull Process.

From dev.powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push Or Pull Process For a turn item however, you can use a more sophisticated min. What else sets push and pull systems apart is the amount of wip inventory. It dictates when and how much to produce. A company using the push system will forecast demand and employ. A push system relies on market demand and forecasting to dictate production levels. A pull. Push Or Pull Process.

From businessmap.io

What Is a Pull System? A Practical Guide to Increasing Process Efficiency Push Or Pull Process Production is pushed out to meet customer forecasted demands, even if those customers have not yet placed orders. It dictates when and how much to produce. The terms “push” and “pull” come from the supply chain management (scm) world. Differences between push and pull manufacturing strategies. In pull manufacturing, production is based on actual customer orders. What else sets push. Push Or Pull Process.

From www.pinterest.com

Push vs. Pull Lean manufacturing, Operations management, Business Push Or Pull Process What else sets push and pull systems apart is the amount of wip inventory. This allows for a much more granular approach than push systems. The terms “push” and “pull” come from the supply chain management (scm) world. In push manufacturing, businesses produce products based on demand planning. For example, a pull network supports multiple replenishment policies based on the. Push Or Pull Process.

From study.com

Push & Pull Forces Lesson for Kids Definition & Examples Lesson Push Or Pull Process The terms “push” and “pull” come from the supply chain management (scm) world. For a turn item however, you can use a more sophisticated min. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. What else sets push and pull systems apart is the amount of wip inventory. A company using. Push Or Pull Process.

From www.youtube.com

SCM Topic 1 5. Cycle View and Push/Pull View of Supply Chain YouTube Push Or Pull Process Production is pushed out to meet customer forecasted demands, even if those customers have not yet placed orders. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. For a turn item. Push Or Pull Process.

From www.sketchbubble.com

Push and Pull Strategy PowerPoint Template SketchBubble Push Or Pull Process A pull production supposedly produces only if. What else sets push and pull systems apart is the amount of wip inventory. In pull manufacturing, production is based on actual customer orders. Differences between push and pull manufacturing strategies. This allows for a much more granular approach than push systems. It dictates when and how much to produce. For a “slow. Push Or Pull Process.

From slidemodel.com

Manufacturing Pull vs Push PowerPoint Template SlideModel Push Or Pull Process The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. The terms “push” and “pull” come from the supply chain management (scm) world. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand. Push Or Pull Process.

From www.allaboutlean.com

The (true) Difference between Push and Pull Push Or Pull Process A company using the push system will forecast demand and employ. For a turn item however, you can use a more sophisticated min. It dictates when and how much to produce. A push system relies on market demand and forecasting to dictate production levels. The main difference between push and pull manufacturing is that in a push system, production dictates. Push Or Pull Process.

From www.slideshare.net

Supply chain management ii mft Push Or Pull Process A push system relies on market demand and forecasting to dictate production levels. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. The terms “push” and “pull” come from the supply chain management (scm) world. A pull production supposedly produces only if. Production is pushed out to meet customer forecasted demands,. Push Or Pull Process.

From www.dozuki.com

Push vs. Pull System in Manufacturing A Complete Overview for Push Or Pull Process A pull production supposedly produces only if. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. In pull manufacturing, production is based on actual customer orders. A company using the push system will forecast demand and employ. The. Push Or Pull Process.

From fashioncoached.com

Learning Push & Pull System with their Advantage, Disadvantage & the Push Or Pull Process It dictates when and how much to produce. In push manufacturing, businesses produce products based on demand planning. The main difference between push and pull manufacturing is that in a push system, production dictates how much of the product will be “pushed” to the market while in a pull system, current demand “pulls” the goods, i.e. A pull system, however,. Push Or Pull Process.

From wiringlibrarychavez.z13.web.core.windows.net

Push And Pull Process Push Or Pull Process For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. The terms “push” and “pull” come from the supply chain management (scm) world. The disparities between push and pull manufacturing strategies go beyond their underlying philosophy. What else sets push and pull systems apart is the amount of wip inventory. Differences between. Push Or Pull Process.

From www.allaboutlean.com

The (true) Difference between Push and Pull Push Or Pull Process A pull system, however, uses current customer. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. Differences between push and pull manufacturing strategies. A pull production supposedly produces only if. What else sets push and pull systems apart is the amount of wip inventory. The terms “push” and “pull” come from. Push Or Pull Process.

From www.blockchain-council.org

What is Push and Pull Strategy in Supply Chain Management? Push Or Pull Process The terms “push” and “pull” come from the supply chain management (scm) world. Differences between push and pull manufacturing strategies. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. What else sets push and pull systems apart is the amount of wip inventory. A company using the push system will forecast. Push Or Pull Process.

From www.slideserve.com

PPT Introduction to Lean Manufacturing PowerPoint Presentation, free Push Or Pull Process For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. It dictates when and how much to produce. A pull production supposedly produces only if. The terms “push” and “pull” come from the supply chain management. Push Or Pull Process.

From www.blockchain-council.org

What is Push and Pull Strategy in Supply Chain Management? Push Or Pull Process The terms “push” and “pull” come from the supply chain management (scm) world. This allows for a much more granular approach than push systems. What else sets push and pull systems apart is the amount of wip inventory. For example, a pull network supports multiple replenishment policies based on the individual demand profile of the product. In pull manufacturing, production. Push Or Pull Process.

From powerslides.com

Push vs Pull Strategy 7,000+ Templates PowerSlides™ Push Or Pull Process For a turn item however, you can use a more sophisticated min. What else sets push and pull systems apart is the amount of wip inventory. For a “slow mover” you can manage by a simple reorder point (sell one, replenish one). A pull system, however, uses current customer. The main difference between push and pull manufacturing is that in. Push Or Pull Process.