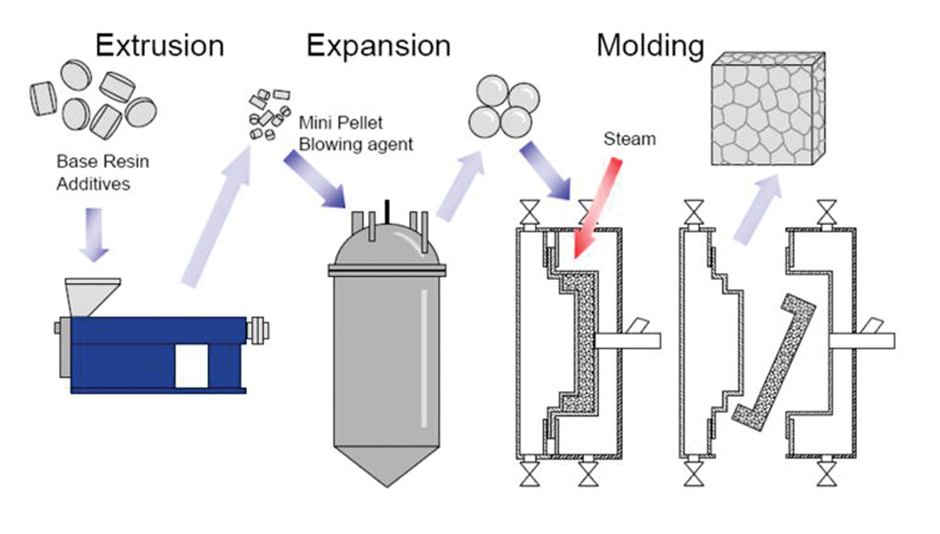

Eps Foam Process . Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. Expanded polystyrene (eps) is a lightweight and rigid foam material. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. The production of eps begins with the polymerization of styrene monomer. It is a material of choice for the packaging and construction industry. The raw materials used in the production of eps include: Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. The process of converting eps resins into expanded polystyrene foam articles requires three main stages: Dive into the manufacturing process of eps, its unique cell. Styrene is derived from petroleum and is. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder.

from read.nxtbook.com

Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. Dive into the manufacturing process of eps, its unique cell. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Styrene is derived from petroleum and is. Expanded polystyrene (eps) is a lightweight and rigid foam material. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. It is a material of choice for the packaging and construction industry. The process of converting eps resins into expanded polystyrene foam articles requires three main stages:

Foamcore BlowMolded Structural Components for Transportation Applications

Eps Foam Process Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. Expanded polystyrene (eps) is a lightweight and rigid foam material. The raw materials used in the production of eps include: Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. The process of converting eps resins into expanded polystyrene foam articles requires three main stages: The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. The production of eps begins with the polymerization of styrene monomer. Styrene is derived from petroleum and is. Dive into the manufacturing process of eps, its unique cell. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. It is a material of choice for the packaging and construction industry.

From www.diytrade.com

EPS foam box making machine HSYF1750 HUASHENG (China Manufacturer Eps Foam Process Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. Dive into the manufacturing process of eps, its unique cell. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. The process of converting eps resins into expanded polystyrene foam articles requires three main stages: The. Eps Foam Process.

From read.nxtbook.com

Foamcore BlowMolded Structural Components for Transportation Applications Eps Foam Process The raw materials used in the production of eps include: Styrene is derived from petroleum and is. Dive into the manufacturing process of eps, its unique cell. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. The production of eps begins with the polymerization of styrene monomer. Its manufacturing process. Eps Foam Process.

From www.jmt.in

What Is Expandable Polystyrene EPS Eps Foam Process Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. Styrene is derived from petroleum and is. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Expanded polystyrene (eps) is a lightweight and rigid foam material. It is a. Eps Foam Process.

From www.youtube.com

The expanded polystyrene casting process Expandable Mold Casting Eps Foam Process Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. The process of converting eps resins into expanded polystyrene foam articles requires three main stages: Styrene is derived from petroleum and is. Dive into the. Eps Foam Process.

From culturaverde.org

The Role of EPS Form in the Future of Sustainable Packaging Solutions Eps Foam Process The production of eps begins with the polymerization of styrene monomer. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. This plank foam is produced through a continuous molding process that the polystyrene is. Eps Foam Process.

From www.epsmachinechina.com

EPS Production Line, EPS Manufacturing Plant, Production Process Eps Foam Process Expanded polystyrene (eps) is a lightweight and rigid foam material. It is a material of choice for the packaging and construction industry. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. Expanded polystyrene (eps) is a lightweight,. Eps Foam Process.

From sk-machine.en.made-in-china.com

EPS Foam Underwater Plastic Pellet Process Production Line China PVC Eps Foam Process It is a material of choice for the packaging and construction industry. Styrene is derived from petroleum and is. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives. Eps Foam Process.

From www.alibaba.com

Automatic Expandable Polystyrene Light Weight Eps Foam Plate Sheet Eps Foam Process This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. The raw materials used in the production of eps include: Expanded polystyrene (eps) is a lightweight and rigid foam material. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam. Eps Foam Process.

From estechtic.net

EPS foam processing machines EPS foam processing machines Eps Foam Process Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. Expanded polystyrene (eps) is a lightweight and rigid foam material. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. The production of eps begins with the polymerization of styrene monomer. It is a material of choice for. Eps Foam Process.

From www.welleps.com

News What is EPS lost foam casting process? Eps Foam Process It is a material of choice for the packaging and construction industry. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. Styrene is derived from petroleum and is. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives. Eps Foam Process.

From www.alibaba.com

Powder Type Eps Foam Coating For Lost Foam Precision Casting Process Eps Foam Process Expanded polystyrene (eps) is a lightweight and rigid foam material. The production of eps begins with the polymerization of styrene monomer. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction.. Eps Foam Process.

From www.plasticgranularmachine.com

Foam Crushing Machine EPS Foam Crusher Eps Foam Process Expanded polystyrene (eps) is a lightweight and rigid foam material. The raw materials used in the production of eps include: The production of eps begins with the polymerization of styrene monomer. Styrene is derived from petroleum and is. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. It is a material of. Eps Foam Process.

From onlinelibrary.wiley.com

Journal of Applied Polymer Science Wiley Online Library Eps Foam Process The raw materials used in the production of eps include: The production of eps begins with the polymerization of styrene monomer. Expanded polystyrene (eps) is a lightweight and rigid foam material. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. Learn how expanded polystyrene (eps) is made, from styrene monomer production to. Eps Foam Process.

From www.indiamart.com

White EPS beads for Light Weight Concrete, Packaging Type Bag Eps Foam Process The process of converting eps resins into expanded polystyrene foam articles requires three main stages: Styrene is derived from petroleum and is. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Expanded polystyrene (eps) is a lightweight and rigid foam material. It is a material of choice for the. Eps Foam Process.

From www.recycle-plant.com

EPS foam cold pressing styrofoam densifier sent to Malaysia Eps Foam Process This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. It is a material of choice for the packaging and construction industry. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. The raw materials. Eps Foam Process.

From www.epsmachinechina.com

EPS Foam Making Machine, EPS Shape Moulding Machine Eps Foam Process Styrene is derived from petroleum and is. The process of converting eps resins into expanded polystyrene foam articles requires three main stages: The raw materials used in the production of eps include: This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Dive into the. Eps Foam Process.

From www.alibaba.com

Automatic Eps Decoration Eps Foam Shape Moulding Machine Buy Eps Foam Eps Foam Process Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. The raw materials used in the production of eps include: Styrene is derived from petroleum and is. The. Eps Foam Process.

From insulationcorp.com

What is Expanded Polystyrene (EPS) foam? The possibilities are endless! Eps Foam Process This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Styrene is derived from petroleum and is. Expanded polystyrene (eps) is a lightweight and rigid foam material. The production of eps begins with the polymerization of styrene monomer. The raw materials used in the production. Eps Foam Process.

From www.s-cellfoam.com

S&S Patarachard Co., Ltd. Eps Foam Process It is a material of choice for the packaging and construction industry. Expanded polystyrene (eps) is a lightweight and rigid foam material. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. The process of converting eps resins into expanded polystyrene foam articles requires three main stages: Styrene is derived from petroleum and is. Its. Eps Foam Process.

From www.researchgate.net

Description of the modification process of waste EPS foams. Download Eps Foam Process Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. Styrene is derived from petroleum and is. Expanded polystyrene (eps) is a lightweight and rigid foam material. Its manufacturing process involves the expansion of polystyrene resin. Eps Foam Process.

From www.researchgate.net

CTscan images of EPS foam before and after dynamic compression test Eps Foam Process Styrene is derived from petroleum and is. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. It is a material of choice for the packaging and construction industry. The raw materials used in the production of eps include: The production of eps begins with. Eps Foam Process.

From insulationcorp.com

What is Expanded Polystyrene (EPS) foam? The possibilities are endless! Eps Foam Process Dive into the manufacturing process of eps, its unique cell. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. Styrene is derived from petroleum and is. The raw materials used in the production of eps include: Expanded polystyrene (eps) is a lightweight and rigid foam material. It is a material of choice. Eps Foam Process.

From www.youtube.com

Foam Difference EPS (Styrofoam foam) ; EPP; Polyurethane. YouTube Eps Foam Process The production of eps begins with the polymerization of styrene monomer. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. The process of converting eps resins into expanded polystyrene foam articles requires three main stages: Dive into the manufacturing process of eps, its unique cell. Its manufacturing process involves. Eps Foam Process.

From www.atcon.co.th

โฟมอีพีเอส คืออะไร? โรงงานโฟม ผู้ผลิตโฟม โฟมอีพีเอส โฟมก้อน โฟมเเผ่น Eps Foam Process Styrene is derived from petroleum and is. The production of eps begins with the polymerization of styrene monomer. Dive into the manufacturing process of eps, its unique cell. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. Expanded polystyrene (eps) is a lightweight and rigid foam material. Expanded polystyrene (eps) is a lightweight, rigid,. Eps Foam Process.

From www.eps-mould.com

EPS Foam Cement Coating Machine Green Building EPS Machine Eps Foam Process It is a material of choice for the packaging and construction industry. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. Styrene is derived from petroleum and is. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Expanded. Eps Foam Process.

From www.making.unsw.edu.au

Working with XPS Foam UNSW Making Eps Foam Process Dive into the manufacturing process of eps, its unique cell. The raw materials used in the production of eps include: It is a material of choice for the packaging and construction industry. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. The production of eps begins with the polymerization of. Eps Foam Process.

From www.shuliy.com

EPS Foam Granulating Line EPE Styrofoam Pelletizing Machine Shuliy Eps Foam Process The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Styrene is derived from petroleum and is. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Expanded polystyrene (eps) is a lightweight, rigid, and. Eps Foam Process.

From www.constguide.com

Constguide EPS Foam Eps Foam Process The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. The production of eps begins with the polymerization of styrene monomer. The raw materials used in the production of eps include:. Eps Foam Process.

From estechtic.net

EPS foam processing machines EPS foam processing machines Eps Foam Process Dive into the manufacturing process of eps, its unique cell. The production of eps begins with the polymerization of styrene monomer. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Styrene is derived from petroleum and is. The process of converting eps resins into. Eps Foam Process.

From www.youtube.com

All about EPS ( Expanded PolyStyrene ) Foam YouTube Eps Foam Process This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. It is a material of choice for the packaging and construction industry. The production of eps begins with the polymerization of styrene monomer. Learn how expanded polystyrene (eps) is made, from styrene monomer production to. Eps Foam Process.

From usstuccosupply.com

Custom EPS Foam Shapes Eps Foam Process Styrene is derived from petroleum and is. This plank foam is produced through a continuous molding process that the polystyrene is melted and mixed with blowing agents and additives in the extruder. Dive into the manufacturing process of eps, its unique cell. The raw materials used in the production of eps include: The process of converting eps resins into expanded. Eps Foam Process.

From www.moldingmachinetepai.com

EPS Foam Pre Expander Eps Foam Process It is a material of choice for the packaging and construction industry. Styrene is derived from petroleum and is. The raw materials used in the production of eps include: Dive into the manufacturing process of eps, its unique cell. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. Expanded. Eps Foam Process.

From www.epsmachinechina.com

EPS Foam Machine, EPS Foam Moulding Machine Eps Foam Process Dive into the manufacturing process of eps, its unique cell. The production of eps begins with the polymerization of styrene monomer. The wire is heated to extreme temperatures and “cuts” the eps by vaporizing the foam as it passes through it. The raw materials used in the production of eps include: This plank foam is produced through a continuous molding. Eps Foam Process.

From www.youtube.com

Designing of Plastic Products for Injection Moulding EPS Animation Eps Foam Process The process of converting eps resins into expanded polystyrene foam articles requires three main stages: Expanded polystyrene (eps) is a lightweight, rigid, and versatile plastic foam material widely used in packaging, insulation, and construction. Dive into the manufacturing process of eps, its unique cell. This plank foam is produced through a continuous molding process that the polystyrene is melted and. Eps Foam Process.

From recyclingequipinc.com

EPS EPE Foam Plastic Melting Machine Startup Process Eps Foam Process Styrene is derived from petroleum and is. Its manufacturing process involves the expansion of polystyrene resin beads using heat and steam, resulting with exceptional. Dive into the manufacturing process of eps, its unique cell. Learn how expanded polystyrene (eps) is made, from styrene monomer production to shaping and cutting. The wire is heated to extreme temperatures and “cuts” the eps. Eps Foam Process.