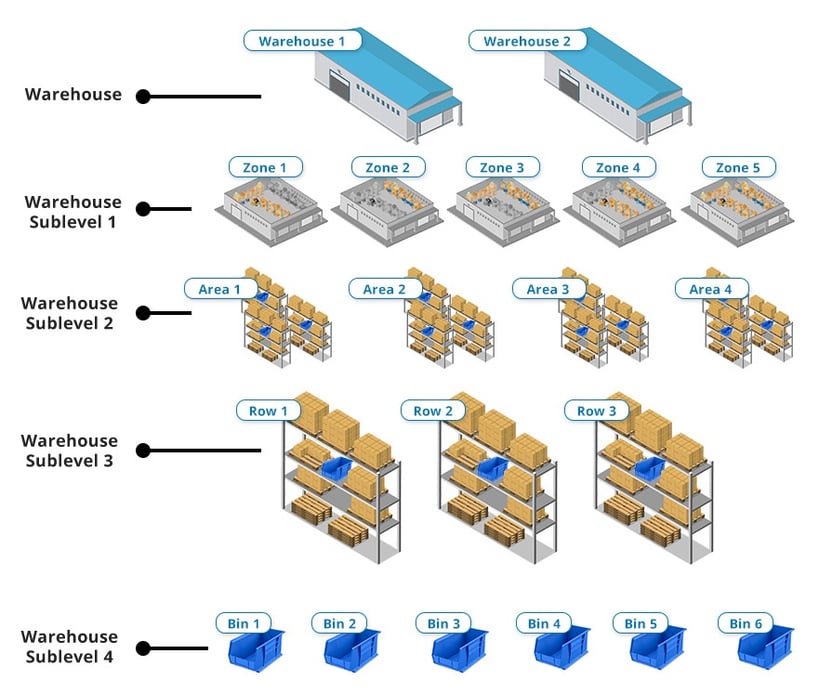

What Is Bin Number In Inventory Management . In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. It creates a structured, repeatable process for. An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Designing a bin numbering system is integral to an effective bin location strategy. It is used to keep a running record of the quantity of items in stock, as. Typically only a single sku is stored in each bin. Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock levels. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin.

from blog.vision33.co.uk

An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. Designing a bin numbering system is integral to an effective bin location strategy. Typically only a single sku is stored in each bin. It creates a structured, repeatable process for. It is used to keep a running record of the quantity of items in stock, as. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction.

How to Create Bin Locations in SAP Business One for an Efficient Warehouse

What Is Bin Number In Inventory Management Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. It is used to keep a running record of the quantity of items in stock, as. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock levels. Designing a bin numbering system is integral to an effective bin location strategy. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. It creates a structured, repeatable process for. Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Typically only a single sku is stored in each bin.

From www.youtube.com

How to Setup Bin Locations YouTube What Is Bin Number In Inventory Management An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. It creates a structured, repeatable process for. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. An organized system of zones, aisles, rows, bays, and bins. What Is Bin Number In Inventory Management.

From www.pinterest.com

How To Create Inventory Monitoring System For Stock Cards Youtube In What Is Bin Number In Inventory Management It creates a structured, repeatable process for. An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. It is used to keep a running record of the quantity of items in stock,. What Is Bin Number In Inventory Management.

From joiodqdur.blob.core.windows.net

Best Bin Numbers at Robert Fix blog What Is Bin Number In Inventory Management A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Designing a bin numbering system is integral to an effective bin location strategy. Bin level inventory is when. What Is Bin Number In Inventory Management.

From www.top-sage-resellers.com

Introducing Sage 100 MultiBin Inventory Management What Is Bin Number In Inventory Management Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. Typically only a single sku is stored in each bin. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Designing. What Is Bin Number In Inventory Management.

From redstagfulfillment.com

Inventory Control 101 The What, Why, and How Red Stag Fulfillment What Is Bin Number In Inventory Management Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock levels. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. Typically. What Is Bin Number In Inventory Management.

From www.magestore.com

Bin location effective method to manage warehouse in 2023 What Is Bin Number In Inventory Management Designing a bin numbering system is integral to an effective bin location strategy. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. Typically only a single sku is stored in each bin. A bin location system is a solution that assigns codes and barcodes. What Is Bin Number In Inventory Management.

From adsy.me

What are the advantages of using a bin system for inventory management? What Is Bin Number In Inventory Management An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. It creates a structured, repeatable process for. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. Designing a bin numbering system is integral to an effective. What Is Bin Number In Inventory Management.

From www.examples.com

Inventory List 14+ Examples, Format, Word, Google Docs, Google Sheets What Is Bin Number In Inventory Management In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. It creates a structured, repeatable process for. It is used to keep a running record of the quantity of items in stock, as. An inventory bin card is a document that tracks the inventory levels. What Is Bin Number In Inventory Management.

From exorlooes.blob.core.windows.net

Storage Bin Location Example at Daniel Shields blog What Is Bin Number In Inventory Management Designing a bin numbering system is integral to an effective bin location strategy. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Inventory bin cards, also known as stock. What Is Bin Number In Inventory Management.

From www.investopedia.com

TwoBin Inventory Control Definition, How It Works, and Example What Is Bin Number In Inventory Management In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock. What Is Bin Number In Inventory Management.

From www.azurecurve.co.uk

In Microsoft Dynamics 365 Business Central (Inventory and Warehouse What Is Bin Number In Inventory Management An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. Typically only a single sku is stored in each bin. Designing. What Is Bin Number In Inventory Management.

From www.superfastcpa.com

What is TwoBin Inventory Control? What Is Bin Number In Inventory Management Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of. What Is Bin Number In Inventory Management.

From www.finaleinventory.com

Inventory Management Multiple Locations & Sublocations What Is Bin Number In Inventory Management Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. A bin location system is a solution that assigns codes and barcodes to bins in your. What Is Bin Number In Inventory Management.

From fundamentalsofaccounting.org

What is Bin Card in Cost Accounting? Fundamentals of Accounting What Is Bin Number In Inventory Management An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. It is used to keep a running record of the quantity of items in stock, as. Bin. What Is Bin Number In Inventory Management.

From www.erp-information.com

What is the Days of Inventory Formula? (Importance and Example) What Is Bin Number In Inventory Management An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. It is used to keep a running record of the quantity of items in stock, as. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction.. What Is Bin Number In Inventory Management.

From www.magestore.com

Use Bin Location to Manage Warehouse Retail Operation Magestore POS What Is Bin Number In Inventory Management In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. It is used to keep a running record of the quantity of items in stock, as.. What Is Bin Number In Inventory Management.

From labelworks.epson.com

Label Printers + Makers for Warehouse + Inventory Management What Is Bin Number In Inventory Management An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. An inventory bin card is a document. What Is Bin Number In Inventory Management.

From scanningsolutions.com

Item Inventory Report Shows inventory count of every individual item What Is Bin Number In Inventory Management It creates a structured, repeatable process for. An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. Typically only a single sku is stored in each bin. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer. What Is Bin Number In Inventory Management.

From www.magestore.com

Bin location effective method to manage warehouse in 2023 What Is Bin Number In Inventory Management Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. An inventory bin card is a document that tracks the inventory levels of a specific item in a. What Is Bin Number In Inventory Management.

From www.cin7.com

Best CloudBased Inventory Management Software Cin7 What Is Bin Number In Inventory Management An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. An inventory bin card is a document that tracks the inventory levels of a specific item. What Is Bin Number In Inventory Management.

From exyabujas.blob.core.windows.net

What Is The Bin Directory Used For at Ines Powell blog What Is Bin Number In Inventory Management Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock levels. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. It is used. What Is Bin Number In Inventory Management.

From fabalabse.com

What does a BIN number look like? Leia aqui How many digits is a BIN What Is Bin Number In Inventory Management An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. Designing a bin numbering system is integral to an effective. What Is Bin Number In Inventory Management.

From eam.calemeam.com

How to Search Inventory by Serial Numbers Clay's Blog Scalable CMMS What Is Bin Number In Inventory Management Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. It creates a structured, repeatable process for. Typically only a single sku is stored in each bin. An organized system of zones, aisles, rows, bays, and. What Is Bin Number In Inventory Management.

From www.nimblefreelancer.com

Two Bin System in Inventory Management Nimble Freelancer What Is Bin Number In Inventory Management Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Typically only a single sku is stored in each bin. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. Designing a bin numbering system is integral to an effective bin location strategy. A bin. What Is Bin Number In Inventory Management.

From 2-b.io

Effective inventory management experience when doing business on What Is Bin Number In Inventory Management Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock levels. Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. A bin location system is a solution that assigns codes and barcodes to. What Is Bin Number In Inventory Management.

From www.speedrackwest.com

Bin Shelving System Plastic Storage Bin Speedrack West What Is Bin Number In Inventory Management Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Typically only a single sku is stored in each bin. A bin location system is a solution that assigns codes and barcodes to bins in your. What Is Bin Number In Inventory Management.

From cashflowinventory.com

TwoBin Inventory Control A Simple Yet Effective Way to Manage Your Stock What Is Bin Number In Inventory Management It creates a structured, repeatable process for. Typically only a single sku is stored in each bin. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Bin cards play a. What Is Bin Number In Inventory Management.

From www.laceupsolutions.com

Bin inventory replenishment What it is and why is important What Is Bin Number In Inventory Management A bin location system is a solution that assigns codes and barcodes to bins in your warehouse to make them easier to locate. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock levels.. What Is Bin Number In Inventory Management.

From support.ordoro.com

Ordoro How do I create an inventory log for my kit parents and What Is Bin Number In Inventory Management Bin locations in inventory including bin locations in inventory transactions like picklists, move orders and transfer orders helps improve. Designing a bin numbering system is integral to an effective bin location strategy. In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. Typically only a. What Is Bin Number In Inventory Management.

From blog.vision33.co.uk

How to Create Bin Locations in SAP Business One for an Efficient Warehouse What Is Bin Number In Inventory Management Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. It creates a structured, repeatable process for. Designing a bin numbering system is integral to an effective bin location strategy. It is used to keep a running record of the. What Is Bin Number In Inventory Management.

From timly.com

What Is an Inventory Number? What Is Bin Number In Inventory Management In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. It is used to keep a running record of the quantity of items in stock, as. Bin cards play a crucial role in inventory management, ensuring efficient tracking and control of stock levels. Bin level. What Is Bin Number In Inventory Management.

From www.abr.com

Warehouse Inventory Management System AB&R® What Is Bin Number In Inventory Management Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. An organized system of zones, aisles, rows, bays, and bins. What Is Bin Number In Inventory Management.

From www.kennedygrp.com

HowToGuide for Placement of Bin and Rack ID Labels Labeling What Is Bin Number In Inventory Management An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. It is used to keep a running record of the quantity of items in stock, as. Bin cards play a crucial. What Is Bin Number In Inventory Management.

From www.hechtgroup.com

Hecht Group The Different Types Of Warehouse Bin Locations What Is Bin Number In Inventory Management Inventory bin cards, also known as stock cards or bin tags, are physical or digital records used to track the movement of inventory items within a warehouse or storage facility. Designing a bin numbering system is integral to an effective bin location strategy. Typically only a single sku is stored in each bin. A bin location system is a solution. What Is Bin Number In Inventory Management.

From www.slideserve.com

PPT O peration M anagement INVENTORY MANAGEMENT PowerPoint What Is Bin Number In Inventory Management It is used to keep a running record of the quantity of items in stock, as. It creates a structured, repeatable process for. An inventory bin card is a document that tracks the inventory levels of a specific item in a specific bin. Bin level inventory is when each individual aisle, rack, shelf, and bin is tracked independently. An organized. What Is Bin Number In Inventory Management.