Lubrication System Faults . Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. According to a study, 34.4% of bearings fail due to inadequate lubrication. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. Lubrication failure is a critical issue in machinery and engines. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. It involves selecting the right type of.

from innovationdiscoveries.space

By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. Lubrication failure is a critical issue in machinery and engines. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. It involves selecting the right type of. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. According to a study, 34.4% of bearings fail due to inadequate lubrication. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”.

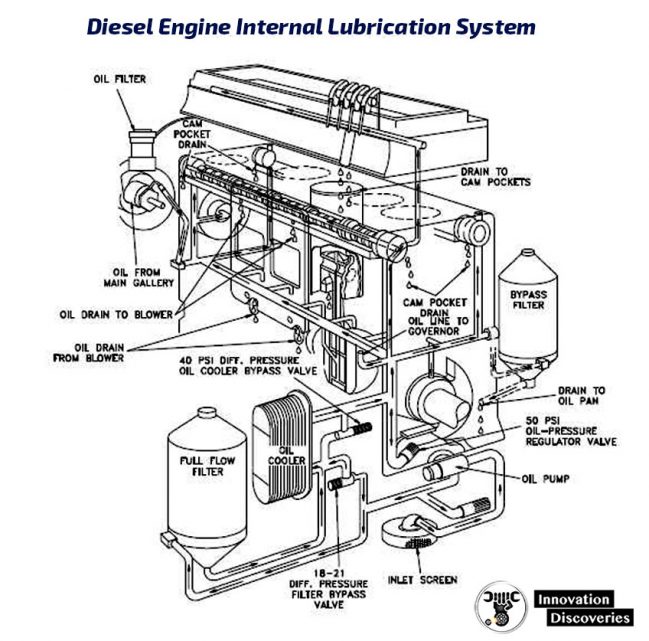

Diesel engine lubrication system components and operation

Lubrication System Faults According to a study, 34.4% of bearings fail due to inadequate lubrication. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Lubrication failure is a critical issue in machinery and engines. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. According to a study, 34.4% of bearings fail due to inadequate lubrication. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. It involves selecting the right type of. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently.

From blog.softinway.com

[en]Gas Turbine Lubrication Systems[] Turbomachinery blog Lubrication System Faults By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. It involves selecting the right type of. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Precision lubrication doesn’t mean using more expensive lubricants or lubricating. Lubrication System Faults.

From www.machinerylubrication.com

Centralized Grease Lubrication Systems Explained Lubrication System Faults According to a study, 34.4% of bearings fail due to inadequate lubrication. It involves selecting the right type of. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Lubrication failure is a critical issue in machinery and engines. By understanding the. Lubrication System Faults.

From www.machinerylubrication.com

Determining the Reliability of Automatic Grease Lubrication Systems Lubrication System Faults It involves selecting the right type of. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a. Lubrication System Faults.

From innovationdiscoveries.space

What is a lubrication system? Types of lubrication systems. Lubrication System Faults It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. Lubrication failure is a critical issue in machinery and engines. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump,. Lubrication System Faults.

From www.youtube.com

Engine Oil Lubrication System How does Engine Lubrication System Work Lubrication System Faults According to a study, 34.4% of bearings fail due to inadequate lubrication. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. It involves selecting the right type of. The. Lubrication System Faults.

From www.youtube.com

How a dry sump lubrication system work how dry sump engine works Lubrication System Faults Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. It involves selecting the right type of. According to a study, 34.4% of bearings fail due to inadequate lubrication. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Lubrication. Lubrication System Faults.

From innovationdiscoveries.space

What is a lubrication system? Types of lubrication systems. Lubrication System Faults The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. Lubrication failure is a critical issue in machinery and engines. It occurs when the lubrication supply system, responsible for. Lubrication System Faults.

From www.efficientplantmag.com

Crack the Code on Lube Faults, Failures Efficient Plant Lubrication System Faults It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. The most common result is an. Lubrication System Faults.

From innovationdiscoveries.space

What is a lubrication system? Types of lubrication systems. Lubrication System Faults The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. According to a study, 34.4% of bearings fail due to inadequate lubrication. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Lubrication failure is a critical issue in. Lubrication System Faults.

From innovationdiscoveries.space

Diesel engine lubrication system components and operation Lubrication System Faults It involves selecting the right type of. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Lubrication failure is a critical issue in machinery and engines. According. Lubrication System Faults.

From mtsolutionkenya.com

automatic lubrication systems Maschine Tecnique Solutions Ltd Lubrication System Faults However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. It involves selecting. Lubrication System Faults.

From www.pinterest.com

ENGINE LUBRICATION SYSTEM, the engine lubrication system is provide the Lubrication System Faults However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. According to a study, 34.4% of bearings fail due to inadequate lubrication. It involves selecting the right type of. The most common result is an engine ruined by excess accumulations of varnish and. Lubrication System Faults.

From www.researchgate.net

The structure principle of centralized lubrication system. Download Lubrication System Faults Lubrication failure is a critical issue in machinery and engines. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Low oil levels or low oil. Lubrication System Faults.

From www.recyclingproductnews.com

Automated lubrication the next logical step for preventative maintenance Lubrication System Faults It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. It involves selecting the right type of. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the. Lubrication System Faults.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Lubrication System Faults The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. It involves selecting the right type of. Lubrication failure is a critical issue in machinery and. Lubrication System Faults.

From www.iqsdirectory.com

Lubricating System Types, Uses, Features and Benefits Lubrication System Faults By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. Lubrication failure is a critical issue in machinery and engines. It involves selecting the right type of.. Lubrication System Faults.

From www.heritagepartscentre.com

Lessons in lubrication Engine Oil Explained Lubrication System Faults Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. According to a study, 34.4% of bearings fail due to inadequate lubrication. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Low oil levels or low oil. Lubrication System Faults.

From isohitech.com

Understanding the 100 items Dual Line Lubrication Systems A Lubrication System Faults It involves selecting the right type of. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. It occurs when the lubrication supply system, responsible for reducing friction and wear,. Lubrication System Faults.

From innovationdiscoveries.space

Parts and working principles of Lubrication System EFI Engine Lubrication System Faults By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. According to a study, 34.4% of bearings fail due to inadequate lubrication. Lubrication failure is a critical issue in machinery and engines. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are. Lubrication System Faults.

From www.slideserve.com

PPT CHAPTER 16 LUBRICATION SYSTEM OPERATION AND DIAGNOSIS PowerPoint Lubrication System Faults According to a study, 34.4% of bearings fail due to inadequate lubrication. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. It involves selecting the right type of. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. Low. Lubrication System Faults.

From www.shutterstock.com

Vehicle Lubrication System Infographic Diagram Showing Stock Lubrication System Faults It involves selecting the right type of. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. According to a study, 34.4% of bearings fail due to inadequate lubrication. Lubrication failure is a critical issue in machinery and engines. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Precision lubrication doesn’t mean. Lubrication System Faults.

From blog.softinway.com

[en]Gas Turbine Lubrication Systems[] Turbomachinery blog Lubrication System Faults It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Precision lubrication doesn’t mean using. Lubrication System Faults.

From www.theengineerspost.com

8 Different Parts of Lubrication System with [Diagrams & PDF] Lubrication System Faults By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such. Lubrication System Faults.

From www.knowledgepeoplecreators.com

what is lubrication system in engine and why we use lubrication oil K P C Lubrication System Faults According to a study, 34.4% of bearings fail due to inadequate lubrication. Lubrication failure is a critical issue in machinery and engines. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Precision lubrication doesn’t mean using more expensive lubricants or lubricating. Lubrication System Faults.

From www.stle.org

Lubrication Fundamentals Lubrication System Faults Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. According to a study, 34.4% of bearings fail due to inadequate lubrication. The most common result is an. Lubrication System Faults.

From www.youtube.com

How is an Aircraft Engine Lubricated? Engine Oil System in 3 minutes Lubrication System Faults Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. Lubrication failure is a critical issue in machinery and engines. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Low oil levels or low oil pressure. Lubrication System Faults.

From www.alamy.com

Typical gasoline engine lubrication system Stock Photo Alamy Lubrication System Faults Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. According to a study, 34.4% of. Lubrication System Faults.

From www.studypool.com

SOLUTION IC Engine Lubrication System Studypool Lubrication System Faults It involves selecting the right type of. Lubrication failure is a critical issue in machinery and engines. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. According to a study, 34.4% of bearings fail due to inadequate lubrication. The most. Lubrication System Faults.

From www.youtube.com

SKF singleline lubrication systems YouTube Lubrication System Faults The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. It involves selecting the right type of. Lubrication failure is a critical issue in machinery and engines. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. It occurs. Lubrication System Faults.

From www.youtube.com

Lubrication System Troubleshooting Haas Automation Service Tip YouTube Lubrication System Faults The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Precision lubrication doesn’t mean using more expensive lubricants or lubricating machines more frequently. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. It occurs when the lubrication supply. Lubrication System Faults.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Lubrication System Faults According to a study, 34.4% of bearings fail due to inadequate lubrication. By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. Lubrication failure is a critical issue in machinery and engines. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil. Lubrication System Faults.

From www.slideserve.com

PPT Engine Lubrication System PowerPoint Presentation, free download Lubrication System Faults By understanding the technical details of lubrication system failures and implementing a comprehensive preventive maintenance and. It involves selecting the right type of. Lubrication failure is a critical issue in machinery and engines. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil.. Lubrication System Faults.

From www.studypool.com

SOLUTION IC Engine Lubrication System Studypool Lubrication System Faults However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. It occurs when the lubrication supply system, responsible for reducing friction and wear, falters. According to a study, 34.4% of. Lubrication System Faults.

From www.pinterest.com

The working & function of Lubrication system. The Lubrications system Lubrication System Faults Low oil levels or low oil pressure can indicate a problem with the lubrication system, such as a leak, a faulty oil pump, or a clogged oil. It involves selecting the right type of. According to a study, 34.4% of bearings fail due to inadequate lubrication. However, to some extent, every lubricant is contaminated with solid particulates called “asperities.”. The. Lubrication System Faults.

From www.marineengineersknowledge.com

Lets understand about main engine lubrication system Marine engineers Lubrication System Faults It involves selecting the right type of. The most common result is an engine ruined by excess accumulations of varnish and sludge due to using motor oils that are not approved by the engine manufacturer. Lubrication failure is a critical issue in machinery and engines. Low oil levels or low oil pressure can indicate a problem with the lubrication system,. Lubrication System Faults.