Diaphragm Pump Suction Strainer . a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. The design of pump suction / inlet piping. Unless the suction system contains a permanent filter, a temporary conical. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. system designers frequently place strainers on the suction side of a pump. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms.

from www.grainger.com

This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. The design of pump suction / inlet piping. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. Unless the suction system contains a permanent filter, a temporary conical. system designers frequently place strainers on the suction side of a pump.

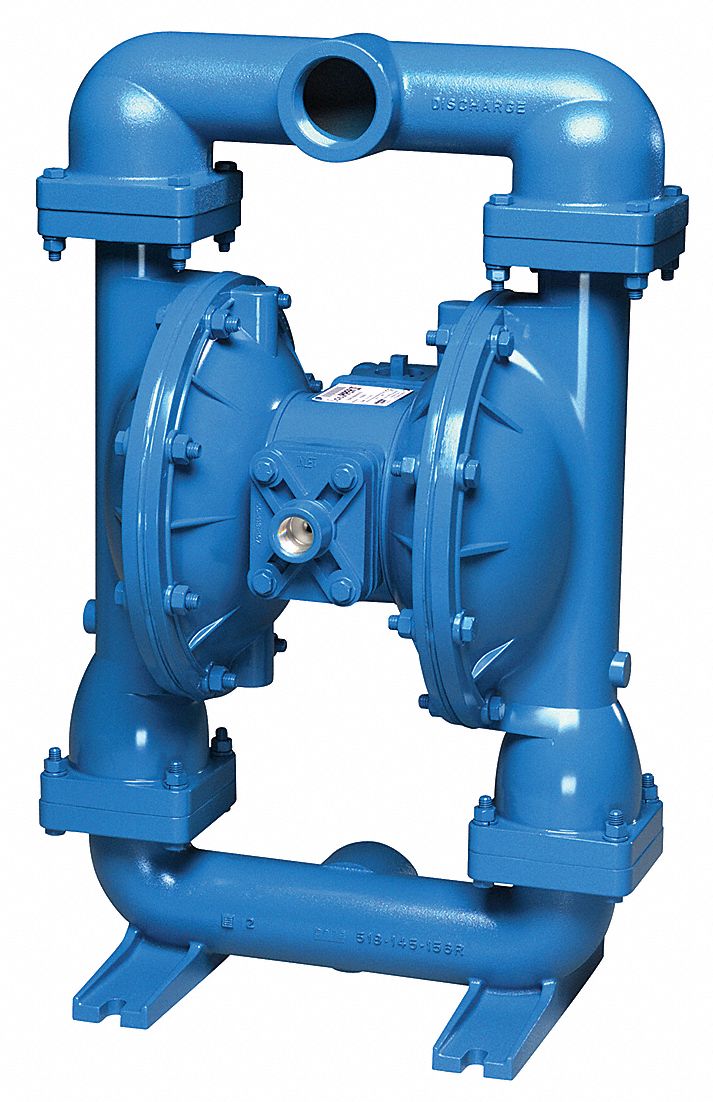

SANDPIPER Double Diaphragm Pump, 150 gpm Max. Flow, PTFE Santoprene(R

Diaphragm Pump Suction Strainer Unless the suction system contains a permanent filter, a temporary conical. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. system designers frequently place strainers on the suction side of a pump. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. The design of pump suction / inlet piping. Unless the suction system contains a permanent filter, a temporary conical. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a.

From www.yamadapump.com

SolidPRO Solids Diaphragm Pump Yamada Pump Diaphragm Pump Suction Strainer This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms.. Diaphragm Pump Suction Strainer.

From process-eng.blogspot.com

Process Engineer Pump Suction Strainer Diaphragm Pump Suction Strainer while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha). Diaphragm Pump Suction Strainer.

From www.ttpumps.com

Pump Accessories Suction Strainer TT Pumps Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. The design of pump suction / inlet piping. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available. Diaphragm Pump Suction Strainer.

From sanctuarylounge.com.au

110V AC Water Pressure Diaphragm Pump 4.99GPM 55 PSI Caravan/Marine w Diaphragm Pump Suction Strainer while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. Unless the suction system contains a permanent filter, a temporary conical. system designers frequently place strainers on the suction side of a pump. “starved” suction due to a clogged strainer or a closed. Diaphragm Pump Suction Strainer.

From www.pipingengineer.org

Strainer in Pump Suction The Piping Engineering World Diaphragm Pump Suction Strainer The design of pump suction / inlet piping. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. system designers frequently place strainers on the suction side of a pump. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms.. Diaphragm Pump Suction Strainer.

From aquatechnika.com.pl

Suction strainer DN100 for pump suction hoses Diaphragm Pump Suction Strainer while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. Unless the suction system contains a permanent filter, a temporary conical. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. The design of pump suction /. Diaphragm Pump Suction Strainer.

From cegqhrfa.blob.core.windows.net

Diaphragm Pump Uses at Herman Drexler blog Diaphragm Pump Suction Strainer Unless the suction system contains a permanent filter, a temporary conical. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. The design of pump suction / inlet piping. system. Diaphragm Pump Suction Strainer.

From www.linquip.com

Strainer Valve a basic guide to know it better Industrial Diaphragm Pump Suction Strainer The design of pump suction / inlet piping. system designers frequently place strainers on the suction side of a pump. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms.. Diaphragm Pump Suction Strainer.

From www.youtube.com

What is the Pump Suction Strainer? Pump strainer kya hai Where is Diaphragm Pump Suction Strainer The design of pump suction / inlet piping. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available. Diaphragm Pump Suction Strainer.

From www.seaflomarinerv.com

seaflomarinerv 55 Series Automatic Demand Diaphragm Pump Diaphragm Pump Suction Strainer system designers frequently place strainers on the suction side of a pump. Unless the suction system contains a permanent filter, a temporary conical. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. The design of pump suction / inlet piping. “starved” suction due to a clogged strainer or a. Diaphragm Pump Suction Strainer.

From www.youtube.com

2 Inch Diaphragm Pump and Reflex Strainer YouTube Diaphragm Pump Suction Strainer while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues. Diaphragm Pump Suction Strainer.

From www.amazon.com

Pipe King 4" Suction and Lay Flat Round Hole Steel Strainer and Diaphragm Pump Suction Strainer Unless the suction system contains a permanent filter, a temporary conical. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. This practice, ostensibly based on good. Diaphragm Pump Suction Strainer.

From sanctuarylounge.com.au

110V AC Water Pressure Diaphragm Pump 4.99GPM 55 PSI Caravan/Marine w Diaphragm Pump Suction Strainer “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. The design of pump suction / inlet piping. Unless the suction system contains a permanent filter, a temporary conical. system. Diaphragm Pump Suction Strainer.

From exoytpvym.blob.core.windows.net

Pump Suction Strainer Types at Jeffry Cason blog Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. The design of. Diaphragm Pump Suction Strainer.

From firefighting-phhp.com

Suction strainer PH B75 with a nonreturn valve Diaphragm Pump Suction Strainer while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha). Diaphragm Pump Suction Strainer.

From www.ricitepump.com

1/4" 1/2" Self Priming Air Diaphragm Pump Suction Lift 6m Electrical Diaphragm Pump Suction Strainer system designers frequently place strainers on the suction side of a pump. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. The design of pump suction / inlet piping. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from. Diaphragm Pump Suction Strainer.

From www.researchgate.net

a. Diaphragm pumpsuction stroke. Download Scientific Diagram Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. system designers frequently place strainers on the suction side of a pump. “starved” suction due. Diaphragm Pump Suction Strainer.

From www.pumpahead.com

Suction Strainer with Backflow Prevention 1.5" Diaphragm Pump Suction Strainer Unless the suction system contains a permanent filter, a temporary conical. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. This practice, ostensibly based on good. Diaphragm Pump Suction Strainer.

From exoytpvym.blob.core.windows.net

Pump Suction Strainer Types at Jeffry Cason blog Diaphragm Pump Suction Strainer This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. The design of pump suction / inlet piping. “starved” suction due to a clogged strainer or a closed suction valve. Diaphragm Pump Suction Strainer.

From www.vanislewater.com

1 1/2" FIPT Plastic Suction Strainer Diaphragm Pump Suction Strainer while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. Unless the suction system contains a permanent filter, a temporary conical. This practice, ostensibly. Diaphragm Pump Suction Strainer.

From firefighting-phhp.com

Suction strainer PH B75 with a nonreturn valve Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. “starved” suction. Diaphragm Pump Suction Strainer.

From www.tapflo.com

Diaphragm pumps PE & PTFE, sanitary, metal, pharmaceutical, EHEDG Diaphragm Pump Suction Strainer while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. The design of pump suction / inlet piping. This practice, ostensibly based on good. Diaphragm Pump Suction Strainer.

From www.blue-white.com

Diaphragm Pumps BlueWhite Industries Diaphragm Pump Suction Strainer “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow.. Diaphragm Pump Suction Strainer.

From exoytpvym.blob.core.windows.net

Pump Suction Strainer Types at Jeffry Cason blog Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. system designers frequently place strainers on the suction side of a pump. Unless the suction system contains a permanent filter, a temporary conical. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for. Diaphragm Pump Suction Strainer.

From www.usplastic.com

2" MNPT x 20 Mesh x 4.2" Dia. Nylon/Stainless Steel Suction Strainer Diaphragm Pump Suction Strainer system designers frequently place strainers on the suction side of a pump. The design of pump suction / inlet piping. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow.. Diaphragm Pump Suction Strainer.

From www.linquip.com

Diaphragm Pump Working Principles, Function & Diagram Linquip Diaphragm Pump Suction Strainer system designers frequently place strainers on the suction side of a pump. Unless the suction system contains a permanent filter, a temporary conical. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. The design of pump suction / inlet piping. This practice, ostensibly based on good intentions, is rarely a. Diaphragm Pump Suction Strainer.

From www.vevor.ca

VEVOR AirOperated Double Diaphragm Pump, 12 GPM, Max 115 PSI With 1/2 Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the. Diaphragm Pump Suction Strainer.

From www.ysenmed.com

Mobile diaphragm suction unit YS23C2,Suction Units Diaphragm Pump Suction Strainer The design of pump suction / inlet piping. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. while a strainer is a simple addition to any type of pump,. Diaphragm Pump Suction Strainer.

From www.grainger.com

SANDPIPER Double Diaphragm Pump, 150 gpm Max. Flow, PTFE Santoprene(R Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. system designers. Diaphragm Pump Suction Strainer.

From www.grainger.com

GRAINGER APPROVED Hydraulic Suction Strainer 1 in NPT Thread Size, 10 Diaphragm Pump Suction Strainer a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. The design of pump suction / inlet piping. Unless the suction system contains a permanent filter, a. Diaphragm Pump Suction Strainer.

From www.youtube.com

Pump Strainer Why strainer is used at suction side of the Centrifugal Diaphragm Pump Suction Strainer The design of pump suction / inlet piping. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. system designers frequently place strainers on the suction side of a pump. This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from. Diaphragm Pump Suction Strainer.

From firefighting-phhp.com

Suction strainer PH B75 with a nonreturn valve Diaphragm Pump Suction Strainer This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. system designers frequently place strainers on the suction side of a pump. “starved” suction due to a clogged strainer. Diaphragm Pump Suction Strainer.

From exoytpvym.blob.core.windows.net

Pump Suction Strainer Types at Jeffry Cason blog Diaphragm Pump Suction Strainer The design of pump suction / inlet piping. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. “starved” suction due to a clogged strainer or. Diaphragm Pump Suction Strainer.

From process-eng.blogspot.com

Process Engineer Pump Suction Strainer Diaphragm Pump Suction Strainer “starved” suction due to a clogged strainer or a closed suction valve will cause premature failure of the pump diaphragms. system designers frequently place strainers on the suction side of a pump. while a strainer is a simple addition to any type of pump, it is an essential component that keeps the whole system running smoothly. . Diaphragm Pump Suction Strainer.

From www.seawaterroplant.com

Stainless steel pneumatic diaphragm pump for chemical injection process Diaphragm Pump Suction Strainer This practice, ostensibly based on good intentions, is rarely a good idea and will create serious issues for the pump from the aspect of reduced and turbulent flow, inadequate net positive suction head available (npsha) and eventually blocked flow. a diaphragm pump, also known as a membrane pump, is a positive displacement pump that uses a. Unless the suction. Diaphragm Pump Suction Strainer.