Laser Beam Oscillation . Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld.

from www.mdpi.com

The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Laser welds made with beam oscillation had a greater fz area than conventional laser welds.

Applied Sciences Free FullText Microstructure and Mechanical

Laser Beam Oscillation Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Laser welds made with beam oscillation had a greater fz area than conventional laser welds.

From www.thefabricator.com

Shaping the laser beam for the best cut Laser Beam Oscillation The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Laser welds made. Laser Beam Oscillation.

From www.researchgate.net

(PDF) A study of high frequency laser beam oscillation induced keyhole Laser Beam Oscillation Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. Laser welds made with beam oscillation. Laser Beam Oscillation.

From www.researchgate.net

Circular and infiniteshaped laser oscillation beam patterns at a Laser Beam Oscillation The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. In this study, the. Laser Beam Oscillation.

From www.researchgate.net

(PDF) Fast Beam Oscillations Improve Laser Cutting of Thick Materials Laser Beam Oscillation Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The welding was performed by applying a laser beam. Laser Beam Oscillation.

From www.slideshare.net

Laser Basics Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. Laser welds. Laser Beam Oscillation.

From www.mdpi.com

Applied Sciences Free FullText Understanding the Changed Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The welding was performed. Laser Beam Oscillation.

From www.researchgate.net

Interface homogenization and its relationship with tensile properties Laser Beam Oscillation Laser welds made with beam oscillation had a greater fz area than conventional laser welds. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation in the laser welding process has demonstrated numerous. Laser Beam Oscillation.

From www.mdpi.com

Applied Sciences Free FullText Improvement of Laser Beam Fusion Laser Beam Oscillation Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The welding was performed by applying a laser beam. Laser Beam Oscillation.

From www.researchgate.net

(PDF) Measurements of weld quality with OCT during laser beam Laser Beam Oscillation Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The welding was performed by applying a laser beam oscillation technique in which. Laser Beam Oscillation.

From www.researchgate.net

Weld seam pictures of laser beam oscillation amplitude (2As) variation Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The influence of. Laser Beam Oscillation.

From www.mdpi.com

Materials Free FullText Effect of Laser Beam Oscillation on Laser Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The. Laser Beam Oscillation.

From weldlogic.com

Laser Seam Welder with Beam Oscillation Weldlogic Inc. Laser Beam Oscillation Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. In this study, the laser beam oscillation welding using. Laser Beam Oscillation.

From www.mdpi.com

Effect of Laser Beam Oscillation on Laser WeldingBrazing of Ti/Al Laser Beam Oscillation The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation in the laser welding. Laser Beam Oscillation.

From www.researchgate.net

Circular and infiniteshaped laser oscillation beam patterns at a Laser Beam Oscillation The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Beam oscillation in. Laser Beam Oscillation.

From www.mdpi.com

Micromachines Free FullText QuasiContinuous Wave Pulsed Laser Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has. Laser Beam Oscillation.

From weldlogic.com

Laser Seam Welder with Beam Oscillation Weldlogic Inc. Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The influence of the laser beam oscillation on. Laser Beam Oscillation.

From weldlogic.com

Laser Seam Welder with Beam Oscillation Weldlogic Inc. Laser Beam Oscillation Laser welds made with beam oscillation had a greater fz area than conventional laser welds. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation during laser welding generally decreases the. Laser Beam Oscillation.

From www.semanticscholar.org

Figure 2 from Investigation of the influence of beam oscillation on the Laser Beam Oscillation Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Laser welds made with beam oscillation. Laser Beam Oscillation.

From www.photonics.com

Dynamic Beam Shaping Improves Laser Cutting of Thick Steel Plates May Laser Beam Oscillation Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Laser welds made with beam oscillation. Laser Beam Oscillation.

From www.semanticscholar.org

Figure 3 from Improvement of Laser Beam Fusion Cutting of Mild and Laser Beam Oscillation Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Laser welds made with beam oscillation. Laser Beam Oscillation.

From www.mdpi.com

JMMP Free FullText Process Stability during Laser Beam Welding Laser Beam Oscillation The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. Beam oscillation during. Laser Beam Oscillation.

From www.mdpi.com

LaserArc Hybrid Cladding of AlMg Alloy Coating on AZ80 Mg Alloy Laser Beam Oscillation The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. In this study, the laser beam oscillation welding using. Laser Beam Oscillation.

From www.researchgate.net

(PDF) Laser welding of AZ31B magnesium alloy with beam oscillation Laser Beam Oscillation Laser welds made with beam oscillation had a greater fz area than conventional laser welds. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. In this study, the laser beam oscillation welding using the modulated. Laser Beam Oscillation.

From www.mdpi.com

Applied Sciences Free FullText Improvement of Laser Beam Fusion Laser Beam Oscillation The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. In this study, the laser beam oscillation welding using. Laser Beam Oscillation.

From www.mdpi.com

Applied Sciences Free FullText Microstructure and Mechanical Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. The influence of. Laser Beam Oscillation.

From www.mdpi.com

Applied Sciences Free FullText Microstructure and Mechanical Laser Beam Oscillation Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The influence of the laser beam oscillation on. Laser Beam Oscillation.

From www.mdpi.com

JMMP Free FullText Process Stability during Laser Beam Welding Laser Beam Oscillation Laser welds made with beam oscillation had a greater fz area than conventional laser welds. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The influence of the laser beam. Laser Beam Oscillation.

From www.mdpi.com

Micromachines Free FullText QuasiContinuous Wave Pulsed Laser Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. The welding was performed. Laser Beam Oscillation.

From weldlogic.com

Laser Seam Welder with Beam Oscillation Weldlogic Inc. Laser Beam Oscillation In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a. Laser Beam Oscillation.

From www.mdpi.com

Photonics Free FullText Towards Ultimate HighPower Scaling Laser Beam Oscillation Laser welds made with beam oscillation had a greater fz area than conventional laser welds. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. In this study, the laser beam oscillation welding using the modulated. Laser Beam Oscillation.

From www.mdpi.com

Effect of Laser Beam Oscillation on Laser WeldingBrazing of Ti/Al Laser Beam Oscillation The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The influence of the laser beam oscillation on. Laser Beam Oscillation.

From weldlogic.com

Laser Seam Welder with Beam Oscillation Weldlogic Inc. Laser Beam Oscillation Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The influence of the laser beam oscillation on. Laser Beam Oscillation.

From weldlogic.com

Laser Seam Welder with Beam Oscillation Weldlogic Inc. Laser Beam Oscillation Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. In this study, the laser beam oscillation welding using the modulated beams by doe was carried out for aa5052, and the weld. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The welding was performed by applying. Laser Beam Oscillation.

From www.researchgate.net

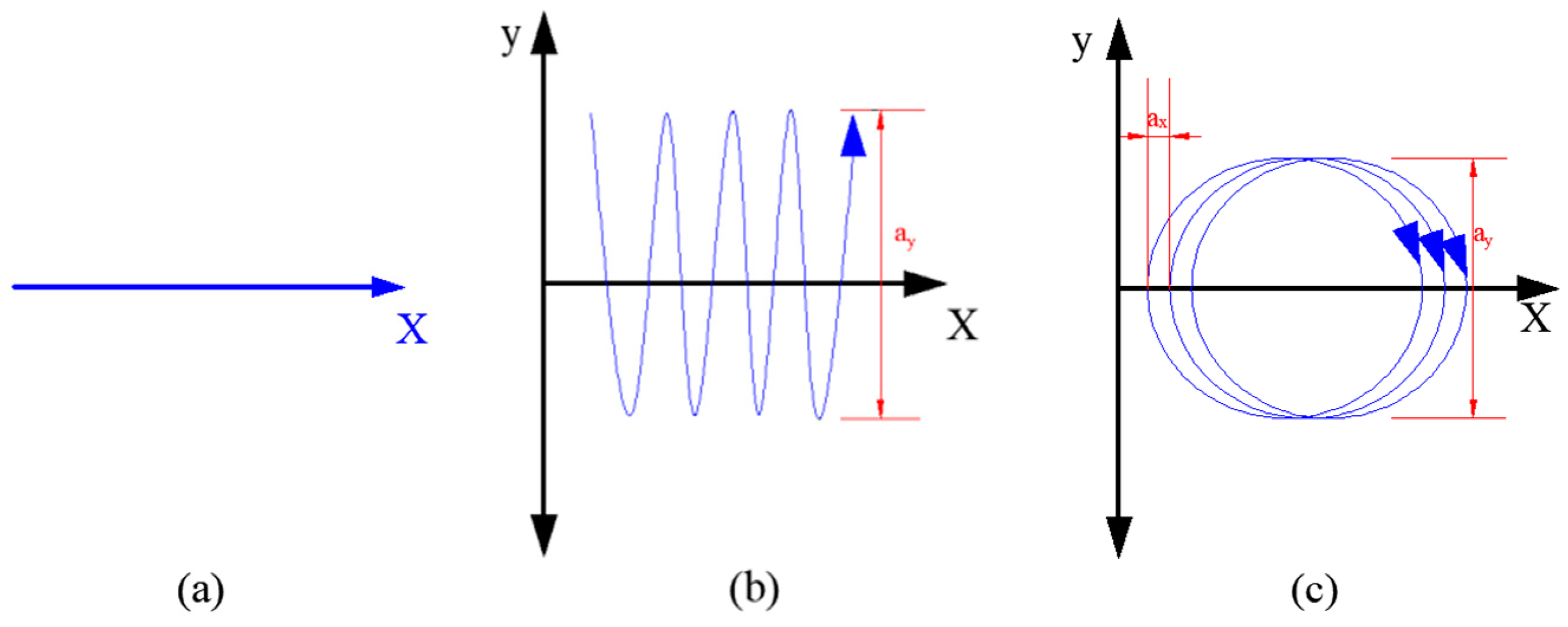

Laser beam oscillation path. Download Scientific Diagram Laser Beam Oscillation Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. Beam oscillation in the laser welding process has demonstrated numerous advantages in suppressing spatters, eliminating pores, and. The welding was performed by applying a laser beam. Laser Beam Oscillation.

From www.mdpi.com

Metals Free FullText Laser Beam and LaserArc Hybrid Welding of Laser Beam Oscillation The influence of the laser beam oscillation on the temperature field in laser brazing with keyhole formation has been. The welding was performed by applying a laser beam oscillation technique in which weld seam is generated by a spiral. Beam oscillation during laser welding generally decreases the penetration depth compared to conventional laser welding. Laser welds made with beam oscillation. Laser Beam Oscillation.