Equipment Rack Bonding . Top of rack switches), use bonding. What are the server rack grounding requirements? tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. Illustration of acceptable and unacceptable equipment bonding. three methods to bond equipment & racks to ground. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges.

from www.iqsdirectory.com

tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. three methods to bond equipment & racks to ground. What are the server rack grounding requirements? bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. Top of rack switches), use bonding. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. Illustration of acceptable and unacceptable equipment bonding.

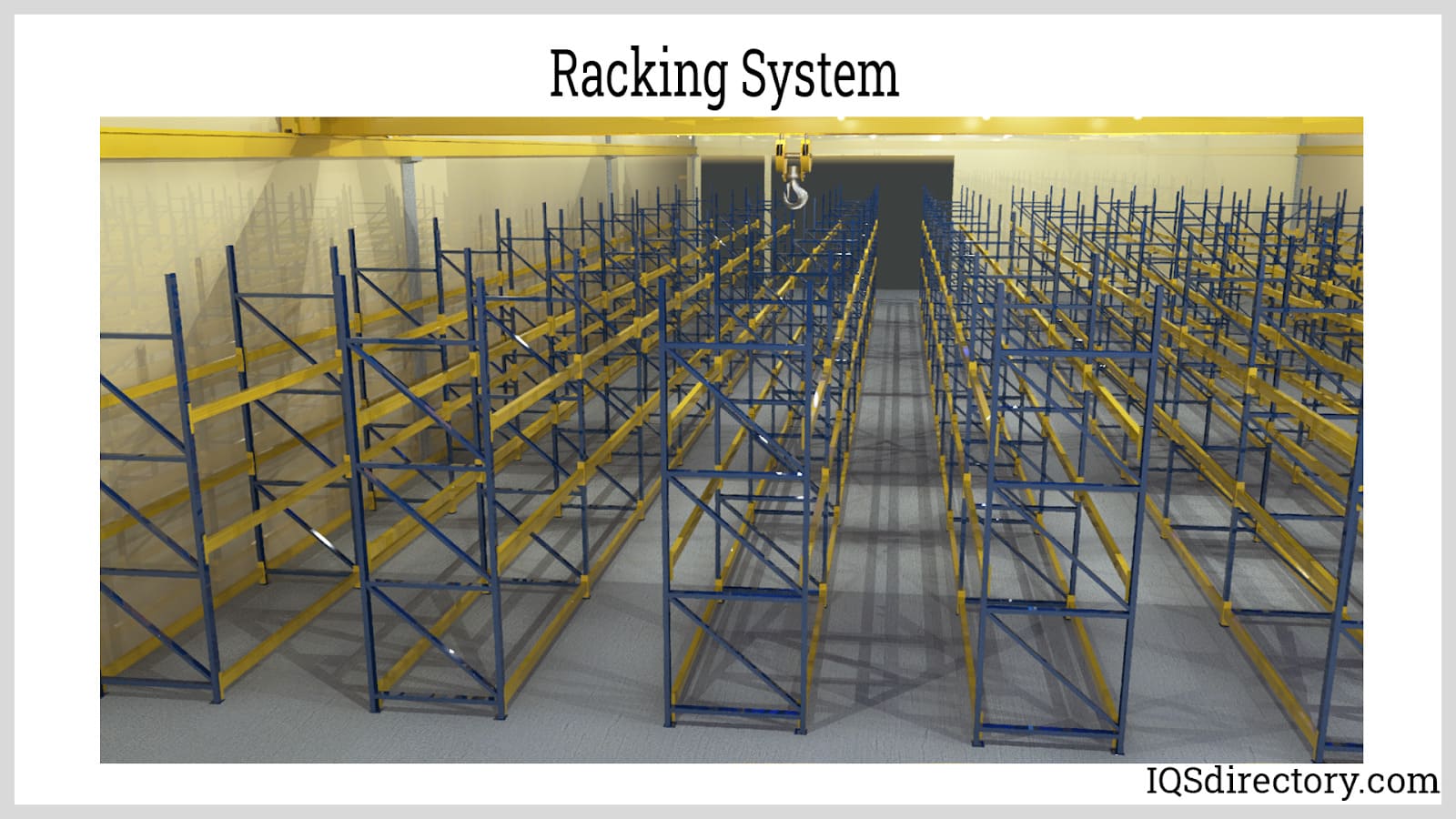

Warehouse Racking What Is It? How Is It Made? Types Of

Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. three methods to bond equipment & racks to ground. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. Top of rack switches), use bonding. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. Illustration of acceptable and unacceptable equipment bonding. What are the server rack grounding requirements?

From studylib.net

grounding and bonding application Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. Top of rack switches), use. Equipment Rack Bonding.

From mirapath.com

Are Your Racks and Equipment Properly Grounded and Bonded? Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. three methods to bond equipment & racks to ground. in. Equipment Rack Bonding.

From www.pducables.com

Vertical Rack Bonding Busbar Kit SurgGuard PDU Cables Equipment Rack Bonding for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. three methods to bond equipment & racks to ground. for racks and cabinets, use. Equipment Rack Bonding.

From www.cablinginstall.com

Updated bonding standard on shaky ground Cabling Installation Equipment Rack Bonding tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. Top of rack switches), use bonding. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. Illustration of acceptable and unacceptable equipment bonding. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. bonding (or grounding) is a system. Equipment Rack Bonding.

From www.fsbondtec.at

The perfect entrylevel machines for wire bonding and testing Equipment Rack Bonding What are the server rack grounding requirements? Illustration of acceptable and unacceptable equipment bonding. Top of rack switches), use bonding. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. . Equipment Rack Bonding.

From www.bhphotovideo.com

Middle Atlantic BONDG24 Rack Bonding / Ganging Hardware Equipment Rack Bonding rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. bonding. Equipment Rack Bonding.

From www.pducables.com

Equipment Rack Ground Bonding SurgGuard PDU Cables Equipment Rack Bonding Top of rack switches), use bonding. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. three methods to bond equipment & racks to ground. in most cases, bonding your server racks. Equipment Rack Bonding.

From www.pducables.com

Equipment Rack Ground Bonding SurgGuard PDU Cables Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. What are the server rack grounding requirements? bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. Top of rack switches), use bonding. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. three methods to bond equipment. Equipment Rack Bonding.

From nassaunationalcable.com

40172001_1200x1200.jpg?v=1665569462 Equipment Rack Bonding for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design. Equipment Rack Bonding.

From www.pducables.com

Equipment Rack Ground Bonding SurgGuard PDU Cables Equipment Rack Bonding bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. three methods to bond equipment & racks to ground. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. for racks and cabinets, use a rack bonding busbar (rbb) to provide an. Equipment Rack Bonding.

From www.electricianinformationresource.com

Electrical Bonding and Grounding Explained Equipment Rack Bonding rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. Illustration of acceptable and unacceptable equipment bonding. for racks and cabinets, use a rack bonding. Equipment Rack Bonding.

From www.chatsworth.com

Rack Bonding Jumper Kit Chatsworth Products Equipment Rack Bonding for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. three methods to bond equipment & racks to ground. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. Top. Equipment Rack Bonding.

From www.evgroup.com

BONDSCALE® Production Fusion Bonding System Equipment Rack Bonding in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. What are. Equipment Rack Bonding.

From www.okestorage.com

Drivein Rack, Drive In Rack System, Drive Through Racking OKE Storage Equipment Rack Bonding Top of rack switches), use bonding. Illustration of acceptable and unacceptable equipment bonding. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding. Equipment Rack Bonding.

From www.racksolutions.com

Equipment needed for server rack cable management RackSolutions Equipment Rack Bonding bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. rack bonding conductor (rbc) bonds the rack. Equipment Rack Bonding.

From www.resnooze.com

Grounding Data Center Equipment Rack Bonding in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. Top of rack switches), use bonding. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. Illustration of acceptable and unacceptable equipment bonding. for racks and cabinets,. Equipment Rack Bonding.

From iaeimagazine.org

Sizing of Conductors Related to Grounding & Bonding IAEI Magazine Equipment Rack Bonding for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. Top of rack switches), use bonding. three methods to bond equipment & racks to ground. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. in most cases,. Equipment Rack Bonding.

From www.reddit.com

Data rack and cabling. Service loops are above the ceiling tiles. r Equipment Rack Bonding three methods to bond equipment & racks to ground. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. Illustration of acceptable and unacceptable equipment bonding. for racks and cabinets, use a rack bonding busbar (rbb) to provide. Equipment Rack Bonding.

From www.pducables.com

Equipment Rack Ground Bonding SurgGuard PDU Cables Equipment Rack Bonding rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. Top of rack switches), use bonding. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. What are the server. Equipment Rack Bonding.

From www.pducables.com

Equipment Bonding Conductor Kit (TEBC) SurgGuard Equipment Rack Bonding for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. three methods to bond equipment & racks to ground. in most cases, bonding your server racks and cabinets to. Equipment Rack Bonding.

From www.eigenengineering.com

Rack Barrel Plating Services Transform Your Components with Precision Equipment Rack Bonding What are the server rack grounding requirements? tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due. Equipment Rack Bonding.

From tlctelecom.net

GROUNDING & TLC Equipment Rack Bonding for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. What are the server rack grounding requirements? Illustration of acceptable and unacceptable equipment bonding. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. three methods to bond equipment. Equipment Rack Bonding.

From www.pinterest.com

Our Rack Team's work Data center design, Computer network, Structured Equipment Rack Bonding What are the server rack grounding requirements? in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. for racks and cabinets, use a rack bonding. Equipment Rack Bonding.

From www.pducables.com

Rack Bonding Conductor Kit SurgGuard PDU Cables Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. three methods to bond equipment & racks to ground. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. What are the server rack grounding requirements? rack. Equipment Rack Bonding.

From www.pducables.com

Equipment Rack Ground Bonding SurgGuard PDU Cables Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. What are the server rack grounding requirements? for. Equipment Rack Bonding.

From ar.inspiredpencil.com

Data Center Rack Grounding Equipment Rack Bonding rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching. Equipment Rack Bonding.

From www.electricalsafetypub.com

How Understanding Bonding & Grounding Saves Lives and Equipment Equipment Rack Bonding Top of rack switches), use bonding. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. tebc (telecommunications equipment bonding. Equipment Rack Bonding.

From www.iqsdirectory.com

Warehouse Racking What Is It? How Is It Made? Types Of Equipment Rack Bonding bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. for racks and cabinets, use a rack bonding busbar (rbb) to. Equipment Rack Bonding.

From jadelearning.com

Article 100. Bonding Jumper, Equipment. Equipment Rack Bonding What are the server rack grounding requirements? for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. Top of rack. Equipment Rack Bonding.

From www.youtube.com

CPI Standard TwoPost Rack Integrated Grounding Features YouTube Equipment Rack Bonding bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. Top of rack switches), use bonding. three methods to bond equipment & racks to ground. Illustration of acceptable and unacceptable equipment bonding. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential. Equipment Rack Bonding.

From risingracks.com

Beginners Guide to Server Racks Raising Electronics Equipment Rack Bonding What are the server rack grounding requirements? three methods to bond equipment & racks to ground. Illustration of acceptable and unacceptable equipment bonding. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. for racks and cabinets, use a rack bonding busbar. Equipment Rack Bonding.

From bonding-machine.com

Bonding Machines Professional in ACF bonding machine,ACF bonder, Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of. three methods to bond equipment & racks to ground. Top of rack switches), use bonding. in most cases, bonding your server racks and cabinets to a proper grounding system. Equipment Rack Bonding.

From www.pducables.com

Equipment Rack Ground Bonding SurgGuard PDU Cables Equipment Rack Bonding in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk of equipment damage and downtime due to electrical surges. rack bonding conductor (rbc) bonds the rack or cabinet to the grounding busbar. Top of rack switches), use bonding. three methods to bond equipment & racks to ground.. Equipment Rack Bonding.

From www.youtube.com

Ground and Bonding YouTube Equipment Rack Bonding for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. in most cases, bonding your server racks and cabinets to a proper grounding system is beneficial for reducing the risk. Equipment Rack Bonding.

From www.cablinginstall.com

Make the right connection Bonding a shielded system Cabling Equipment Rack Bonding Illustration of acceptable and unacceptable equipment bonding. for equipment that bonds through its mounting fl anges (no grounding pad) (e.g. tebc (telecommunications equipment bonding conductor) ubc (unit bonding conductor) design requirements. for racks and cabinets, use a rack bonding busbar (rbb) to provide an equipotential plane to protect equipment and patch panels that require bonding to the.. Equipment Rack Bonding.