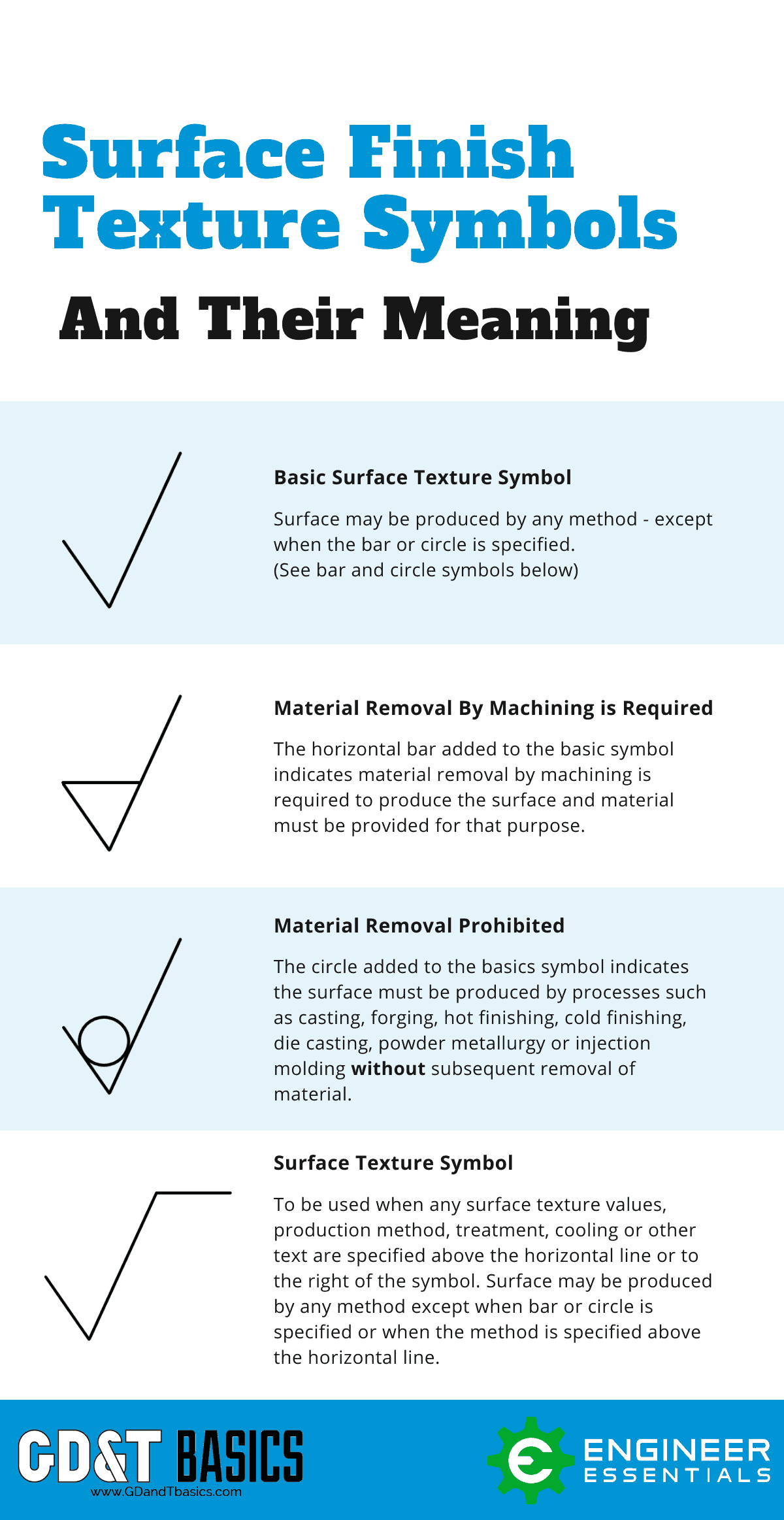

Surface Finish Marks Standards . by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. How surface finish is measured. the finish of a product indicates the performance of its components. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. Also, the level of roughness may affect the. in the united states, surface finish is usually specified using the asme y14.36m standard. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. The rest of the world commonly. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality.

from www.gdandtbasics.com

surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. the finish of a product indicates the performance of its components. How surface finish is measured. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. in the united states, surface finish is usually specified using the asme y14.36m standard. The rest of the world commonly. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. Also, the level of roughness may affect the.

The Basics of Surface Finish GD&T Basics

Surface Finish Marks Standards surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. Also, the level of roughness may affect the. the finish of a product indicates the performance of its components. The rest of the world commonly. How surface finish is measured. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. in the united states, surface finish is usually specified using the asme y14.36m standard. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,.

From mavink.com

Engineering Surface Finish Symbols Surface Finish Marks Standards surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. the finish of a product indicates the performance of its components. in the united states, surface finish is usually specified using the asme y14.36m standard. Also, the level of roughness may affect the. most notably, there is roughness average,. Surface Finish Marks Standards.

From quoteimg.com

surface finish symbols Surface Finish Marks Standards The rest of the world commonly. Also, the level of roughness may affect the. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. How surface finish is measured. surface finishes are arranged according to a standardize way, which also helps in maintain the. Surface Finish Marks Standards.

From mechheart.com

Surface Finish Symbols for Engineering Drawings MECHHEART Surface Finish Marks Standards in the united states, surface finish is usually specified using the asme y14.36m standard. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and.. Surface Finish Marks Standards.

From celfekqs.blob.core.windows.net

Convert Surface Finish Metric To English at Camille Gustafson blog Surface Finish Marks Standards in the united states, surface finish is usually specified using the asme y14.36m standard. The rest of the world commonly. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. How surface finish is measured. the american society of mechanical engineers (asme) defines. Surface Finish Marks Standards.

From mechutopia.com

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA Surface Finish Marks Standards the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. The rest. Surface Finish Marks Standards.

From exocmwfhy.blob.core.windows.net

Finish Quality at Stephanie Draper blog Surface Finish Marks Standards How surface finish is measured. the finish of a product indicates the performance of its components. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. by better. Surface Finish Marks Standards.

From www.usatco.com

SPI® Surface Roughness Standards Sets WEB 306951 Surface Finish Marks Standards in the united states, surface finish is usually specified using the asme y14.36m standard. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. How surface finish is measured. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface.. Surface Finish Marks Standards.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart Surface Finish Marks Standards The rest of the world commonly. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. most notably, there is roughness average, ra, but numerous other essential values are outlined in. Surface Finish Marks Standards.

From www.pcbcart.com

The Most Comprehensive Guidelines for Surface Finish Selection PCBCart Surface Finish Marks Standards most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. The rest of the world commonly. in the united states, surface finish is usually specified using the asme y14.36m standard. Also, the level of roughness may affect the. by better understanding the different. Surface Finish Marks Standards.

From www.engineeringchoice.com

What is Surface Finish? Units, Symbols & Chart Surface Finish Marks Standards most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. in the united states, surface finish is usually specified using the asme y14.36m standard. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. How surface. Surface Finish Marks Standards.

From cncpartsxtj.com

Know The Different Types Of Surface Finishing Symbols And Their Surface Finish Marks Standards How surface finish is measured. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the american society of mechanical engineers (asme) defines surface. Surface Finish Marks Standards.

From jiga.io

Surface Finish Standards, Techniques, Applications, and More Surface Finish Marks Standards the finish of a product indicates the performance of its components. in the united states, surface finish is usually specified using the asme y14.36m standard. Also, the level of roughness may affect the. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. How surface finish is measured.. Surface Finish Marks Standards.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Marks Standards most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. How surface finish is measured. Also, the level of roughness may affect the. in the united states, surface finish is usually specified using the asme y14.36m standard. the basic surface finish symbol is. Surface Finish Marks Standards.

From aronness.blogspot.com

machining surface finish symbols triangle Aron Ness Surface Finish Marks Standards The rest of the world commonly. Also, the level of roughness may affect the. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. in the. Surface Finish Marks Standards.

From www.scribd.com

Surface Finish Charts Surface Finish Marks Standards surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. How surface finish is measured. in the united states, surface finish is usually specified using the asme y14.36m standard. Also, the level of roughness may affect the. the basic surface finish symbol is a check mark with the point resting. Surface Finish Marks Standards.

From www.youtube.com

Different surface finish symbol on drawing and Surface finish of Surface Finish Marks Standards most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. the finish of a product indicates the performance of its components. Also, the level. Surface Finish Marks Standards.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Marks Standards The rest of the world commonly. the finish of a product indicates the performance of its components. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. in the united states, surface finish is usually specified using the asme y14.36m standard. the basic surface finish symbol is a check. Surface Finish Marks Standards.

From www.youtube.com

Surface Roughness & Finishing Symbols YouTube Surface Finish Marks Standards Also, the level of roughness may affect the. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. How surface finish is measured. in the united states, surface finish is usually specified using the asme y14.36m standard. surface finishes are arranged according to. Surface Finish Marks Standards.

From mechutopia.com

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA Surface Finish Marks Standards the basic surface finish symbol is a check mark with the point resting on the surface to be specified. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. the american society of mechanical engineers (asme) defines surface finish specifications in standards such. Surface Finish Marks Standards.

From mechutopia.com

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA Surface Finish Marks Standards The rest of the world commonly. in the united states, surface finish is usually specified using the asme y14.36m standard. the finish of a product indicates the performance of its components. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. How surface finish is measured. the basic surface. Surface Finish Marks Standards.

From www.tpsearchtool.com

Complete Surface Finish Chart Symbols Roughness Conversion Tables Images Surface Finish Marks Standards the basic surface finish symbol is a check mark with the point resting on the surface to be specified. the finish of a product indicates the performance of its components. in the united states, surface finish is usually specified using the asme y14.36m standard. The rest of the world commonly. the american society of mechanical engineers. Surface Finish Marks Standards.

From china-maching.com

Surface Finishing Symbols Understanding Surface Roughness ETCN Surface Finish Marks Standards The rest of the world commonly. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. Also, the level of roughness may affect the. the finish of a product indicates the performance of its components. in the united states, surface finish is usually specified using the asme y14.36m. Surface Finish Marks Standards.

From mavink.com

Iso Surface Finish Chart Surface Finish Marks Standards surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. in the united states, surface finish is usually specified using the asme y14.36m standard. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the. Surface Finish Marks Standards.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish Marks Standards the basic surface finish symbol is a check mark with the point resting on the surface to be specified. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. most notably, there is roughness average, ra, but numerous other essential values are outlined. Surface Finish Marks Standards.

From www.vrogue.co

Surface Finish Chart vrogue.co Surface Finish Marks Standards The rest of the world commonly. in the united states, surface finish is usually specified using the asme y14.36m standard. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. . Surface Finish Marks Standards.

From www.cnccookbook.com

Complete Surface Finish Chart, Symbols & Roughness Conversion Tables Surface Finish Marks Standards by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. Also, the level of roughness may affect the. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the. Surface Finish Marks Standards.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish Marks Standards by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. The rest of the world commonly. in the united states, surface finish is usually specified using the asme y14.36m standard. most notably, there is roughness average, ra, but numerous other essential values are. Surface Finish Marks Standards.

From www.slideshare.net

Surface roughness 200708 Surface Finish Marks Standards How surface finish is measured. the finish of a product indicates the performance of its components. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality.. Surface Finish Marks Standards.

From edmontonrealestateinvestmentblog.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish Marks Standards most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. How surface finish is measured. Also, the level of roughness may affect the. The rest. Surface Finish Marks Standards.

From cemspppu.blob.core.windows.net

Surface Finish Inch Metric Chart at Marie Champlin blog Surface Finish Marks Standards the finish of a product indicates the performance of its components. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. Also, the level. Surface Finish Marks Standards.

From www.flexbar.com

Surface Roughness Standards Set 30 Specimens — Flexbar Machine Surface Finish Marks Standards the basic surface finish symbol is a check mark with the point resting on the surface to be specified. the american society of mechanical engineers (asme) defines surface finish specifications in standards such as y14.36m, which outlines surface. How surface finish is measured. the finish of a product indicates the performance of its components. Also, the level. Surface Finish Marks Standards.

From www.scribd.com

Surface Finish Chart Surface Finish Marks Standards How surface finish is measured. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. in the united states, surface finish is usually specified using the asme y14.36m standard. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root. Surface Finish Marks Standards.

From www.gdandtbasics.com

SurfaceFinishSymbolsChart GD&T Basics Surface Finish Marks Standards most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root mean square (rms) roughness rq,. the finish of a product indicates the performance of its components. Also, the level of roughness may affect the. the american society of mechanical engineers (asme) defines surface finish specifications in standards such. Surface Finish Marks Standards.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Surface Finish Marks Standards in the united states, surface finish is usually specified using the asme y14.36m standard. by better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and. most notably, there is roughness average, ra, but numerous other essential values are outlined in this standard, including root. Surface Finish Marks Standards.

From mungfali.com

Surface Finish Symbols Surface Finish Marks Standards The rest of the world commonly. the basic surface finish symbol is a check mark with the point resting on the surface to be specified. in the united states, surface finish is usually specified using the asme y14.36m standard. surface finishes are arranged according to a standardize way, which also helps in maintain the product quality. . Surface Finish Marks Standards.