Gear Motor Maintenance . the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. An increase in vibration is a sure sign of impending problems. the gear head and motor should be handled, installed and maintained by trained technicians. monitor vibration of the bearings and internal gears. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. Typical things to look out for include: the gear head and motor should be handled, installed and maintained by trained technicians. routine maintenance differs depending on the type of gear motor. Identify asset failures and receive accurate reports on how to act.

from www.plantservices.com

Typical things to look out for include: routine maintenance differs depending on the type of gear motor. An increase in vibration is a sure sign of impending problems. monitor vibration of the bearings and internal gears. the gear head and motor should be handled, installed and maintained by trained technicians. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. the gear head and motor should be handled, installed and maintained by trained technicians. Identify asset failures and receive accurate reports on how to act. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s.

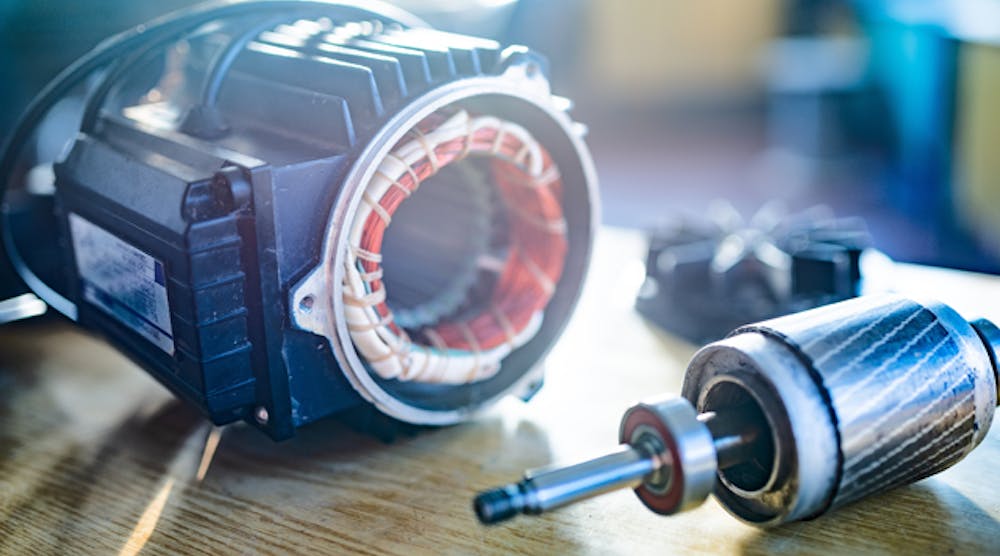

Electric motor maintenance best practices Plant Services

Gear Motor Maintenance to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. monitor vibration of the bearings and internal gears. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. the gear head and motor should be handled, installed and maintained by trained technicians. the gear head and motor should be handled, installed and maintained by trained technicians. Typical things to look out for include: An increase in vibration is a sure sign of impending problems. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. Identify asset failures and receive accurate reports on how to act. routine maintenance differs depending on the type of gear motor.

From www.dreamstime.com

Hand Oiling Gear and during Maintenance Work of Electric Motor Stock Gear Motor Maintenance by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. routine maintenance differs depending on the type of gear motor. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. Typical things to look out for include: to prolong the. Gear Motor Maintenance.

From www.dreamstime.com

Hand Oiling Gear and during Maintenance Work of Electric Motor Stock Gear Motor Maintenance by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. the gear head and motor should be handled, installed and maintained by trained technicians. routine maintenance differs depending on the. Gear Motor Maintenance.

From www.reductionmotor.com

Efficient Operation Use and Maintenance of Geared Motors Gear Gear Motor Maintenance by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. Typical things to look out for include: to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is. Gear Motor Maintenance.

From www.alamy.com

Changing Gear Oil or Engine or Motor OIL in Car Service with auto on Gear Motor Maintenance Identify asset failures and receive accurate reports on how to act. routine maintenance differs depending on the type of gear motor. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. An increase in vibration is a sure sign of impending problems. the gear head and motor should be handled,. Gear Motor Maintenance.

From www.dreamstime.com

Refueling and Pouring Oil Quality into the Engine Motor Car Gear Motor Maintenance Identify asset failures and receive accurate reports on how to act. monitor vibration of the bearings and internal gears. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. An increase in vibration is a sure sign of impending problems. the gear head and motor should be handled, installed and maintained by. Gear Motor Maintenance.

From www.plantservices.com

Electric motor maintenance best practices Plant Services Gear Motor Maintenance monitor vibration of the bearings and internal gears. Identify asset failures and receive accurate reports on how to act. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. routine maintenance differs depending on the type of gear motor. the gear head and motor should be handled, installed and. Gear Motor Maintenance.

From www.dreamstime.com

Car Mechanic Checking Oil Quality the Engine Motor Car Transmission and Gear Motor Maintenance An increase in vibration is a sure sign of impending problems. the gear head and motor should be handled, installed and maintained by trained technicians. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. monitor vibration of the bearings and internal gears. routine maintenance differs depending. Gear Motor Maintenance.

From circuitwiringflexed55.z13.web.core.windows.net

Gears For Electric Motors Gear Motor Maintenance to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Identify asset failures and receive accurate reports on how to act. Typical things to look out for include: monitor vibration of the bearings and internal gears. routine maintenance differs depending on the type of gear motor. the gear head and motor. Gear Motor Maintenance.

From exostlbnw.blob.core.windows.net

Gear Motor Motor Electric at Jacob Edwards blog Gear Motor Maintenance the gear head and motor should be handled, installed and maintained by trained technicians. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. An increase in vibration is a sure sign of impending problems. routine maintenance differs depending on the type of gear motor. monitor vibration of the. Gear Motor Maintenance.

From www.maintenance-dortmund.de

Gear Boxes and Geared Motor Maintenance Dortmund Gear Motor Maintenance monitor vibration of the bearings and internal gears. An increase in vibration is a sure sign of impending problems. the gear head and motor should be handled, installed and maintained by trained technicians. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. the maintenance and inspection stage in gearmotors is. Gear Motor Maintenance.

From www.youtube.com

Gearbox Maintenance Gearbox Maintenance Procedure YouTube Gear Motor Maintenance the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. Identify asset failures and receive accurate reports on how to act. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. routine maintenance differs depending on the type of gear motor.. Gear Motor Maintenance.

From www.lazada.com.ph

DC Gear Motor, Worm Gear Motor Easy To Maintain DC24V 30RPM for Small Gear Motor Maintenance An increase in vibration is a sure sign of impending problems. Typical things to look out for include: to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. monitor vibration of the bearings and internal gears. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor. Gear Motor Maintenance.

From www.dreamstime.com

Repair of a Bicycle Electric Motor. the Disassembled Motor is Installed Gear Motor Maintenance Typical things to look out for include: monitor vibration of the bearings and internal gears. routine maintenance differs depending on the type of gear motor. the gear head and motor should be handled, installed and maintained by trained technicians. Identify asset failures and receive accurate reports on how to act. the maintenance and inspection stage in. Gear Motor Maintenance.

From www.dreamstime.com

Hand Oiling Gear and during Maintenance Work of Electric Motor Stock Gear Motor Maintenance by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Identify asset failures and receive accurate reports on how to act. monitor vibration of the bearings and internal gears. the gear head and motor. Gear Motor Maintenance.

From www.arnoldengineering.co.uk

Motor Maintenance Service Arnold Engineering Arnold Engineering Gear Motor Maintenance routine maintenance differs depending on the type of gear motor. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. Typical things to look out for include: An increase in vibration is a sure sign. Gear Motor Maintenance.

From www.dreamstime.com

Repair of a Bicycle Electric Motor. the Disassembled Motor is Installed Gear Motor Maintenance the gear head and motor should be handled, installed and maintained by trained technicians. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. An increase in vibration is a sure. Gear Motor Maintenance.

From www.clutchengineering.com

Gearmotors Clutch Engineering Gear Motor Maintenance routine maintenance differs depending on the type of gear motor. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. An increase in vibration is a sure sign of impending problems. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives.. Gear Motor Maintenance.

From www.sogears.com

Belt Conveyor gearmotors Gear Motor Maintenance the gear head and motor should be handled, installed and maintained by trained technicians. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. monitor vibration of the bearings and internal gears. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear. Gear Motor Maintenance.

From www.dreamstime.com

Hand Oiling Gear and during Maintenance Work of Electric Motor Stock Gear Motor Maintenance the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. the gear head and motor should be handled, installed and maintained by trained technicians. monitor vibration of the bearings and internal gears. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear. Gear Motor Maintenance.

From dacworldwide.com

Pump Maintenance with Alignment Trainer HandsOn Industrial Training Gear Motor Maintenance Identify asset failures and receive accurate reports on how to act. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. the gear head and motor should be handled, installed and maintained by trained technicians. Typical things to look out for include: the gear head and motor should. Gear Motor Maintenance.

From instrumentationtools.com

Motor Maintenance, Troubles, Regular Checks, Performance Gear Motor Maintenance the gear head and motor should be handled, installed and maintained by trained technicians. routine maintenance differs depending on the type of gear motor. the gear head and motor should be handled, installed and maintained by trained technicians. Identify asset failures and receive accurate reports on how to act. Typical things to look out for include: . Gear Motor Maintenance.

From rotamec.com

How to maintain your servo motor Gear Motor Maintenance Typical things to look out for include: the gear head and motor should be handled, installed and maintained by trained technicians. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. An increase in vibration is a sure sign of impending problems. Identify asset failures and receive accurate reports. Gear Motor Maintenance.

From www.alamy.com

Refueling and pouring oil into the engine motor car. Maintenance and Gear Motor Maintenance monitor vibration of the bearings and internal gears. An increase in vibration is a sure sign of impending problems. the gear head and motor should be handled, installed and maintained by trained technicians. Typical things to look out for include: by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives.. Gear Motor Maintenance.

From www.alamy.com

Auto spare parts, car service, repair and maintenance retro vector Gear Motor Maintenance to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. the gear head and motor should be handled, installed and maintained by trained technicians. monitor vibration of the bearings and internal gears. the gear head and motor should be handled, installed and maintained by trained technicians. the maintenance and inspection. Gear Motor Maintenance.

From premium-transmission.com

Various Types of Geared Motors & Their Applications Premium Transmission Gear Motor Maintenance monitor vibration of the bearings and internal gears. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. An increase in vibration is a sure sign of impending problems. Typical things to look out for include: the gear head and motor should be handled, installed and maintained by trained technicians. the. Gear Motor Maintenance.

From www.pngegg.com

Free download Car Transmission Automobile repair shop Motor Vehicle Gear Motor Maintenance monitor vibration of the bearings and internal gears. An increase in vibration is a sure sign of impending problems. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. Identify asset failures and receive accurate reports on how to act. the maintenance and inspection stage in gearmotors is important and crucial, as. Gear Motor Maintenance.

From ksbanglimotors.en.made-in-china.com

Factory Price Maintenance Free 100W 200W 400W 750W 1.5kw Vertical AC Gear Motor Maintenance routine maintenance differs depending on the type of gear motor. An increase in vibration is a sure sign of impending problems. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. the gear head. Gear Motor Maintenance.

From www.nord.cn

Geared Motors NORD Gear Motor Maintenance Identify asset failures and receive accurate reports on how to act. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. the gear head and motor should be handled, installed and maintained by trained technicians. An increase in vibration is a sure sign of impending problems. routine maintenance differs depending. Gear Motor Maintenance.

From www.dreamstime.com

Repair of a Bicycle Electric Motor. the Disassembled Motor is Installed Gear Motor Maintenance by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. monitor vibration of the bearings and internal gears. Typical things to look out for include: An increase in vibration is a sure sign of impending problems. routine maintenance differs depending on the type of gear motor. the gear head. Gear Motor Maintenance.

From www.gearedmotor-india.com

Geared Motor Gear Motor Gear motor india Geared motor india Gear Motor Maintenance Identify asset failures and receive accurate reports on how to act. An increase in vibration is a sure sign of impending problems. monitor vibration of the bearings and internal gears. Typical things to look out for include: routine maintenance differs depending on the type of gear motor. the maintenance and inspection stage in gearmotors is important and. Gear Motor Maintenance.

From www.bauermld.com

Gear Motor Maintenance Gear Motor Maintenance the gear head and motor should be handled, installed and maintained by trained technicians. Typical things to look out for include: the gear head and motor should be handled, installed and maintained by trained technicians. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. to prolong the operational. Gear Motor Maintenance.

From www.dreamstime.com

Refueling and Pouring Oil Quality into the Engine Motor Car Gear Motor Maintenance the gear head and motor should be handled, installed and maintained by trained technicians. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. by incorporating advanced maintenance techniques, you can maximize the reliability and lifespan of your gear motor drives. routine maintenance differs depending on the. Gear Motor Maintenance.

From tractian.com

Gearmotor Maintenance Advanced Techniques Gear Motor Maintenance the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. routine maintenance differs depending on the type of gear motor. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. the gear head and motor should be handled, installed and maintained by. Gear Motor Maintenance.

From www.indiamart.com

Geared Motors Maintenance in Shobana Colony, Hyderabad ID 9957290348 Gear Motor Maintenance to prolong the operational life of your industrial gearboxes, regular inspections and maintenance is essential. routine maintenance differs depending on the type of gear motor. Identify asset failures and receive accurate reports on how to act. Typical things to look out for include: the maintenance and inspection stage in gearmotors is important and crucial, as good practices. Gear Motor Maintenance.

From www.electricmotorshop.com

Maximize Efficiency Predictive Maintenance For Electric Motors Gear Motor Maintenance the gear head and motor should be handled, installed and maintained by trained technicians. An increase in vibration is a sure sign of impending problems. the maintenance and inspection stage in gearmotors is important and crucial, as good practices contribute to prolonging the asset’s. to prolong the operational life of your industrial gearboxes, regular inspections and maintenance. Gear Motor Maintenance.