Hydraulic Cylinder Not Extending Fully . With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. Incorrect connections can cause movement and jamming. The pump is working fine and the lift is always to the same height when the. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. Verify that the connection between the hydraulic cylinder and the load is correct.

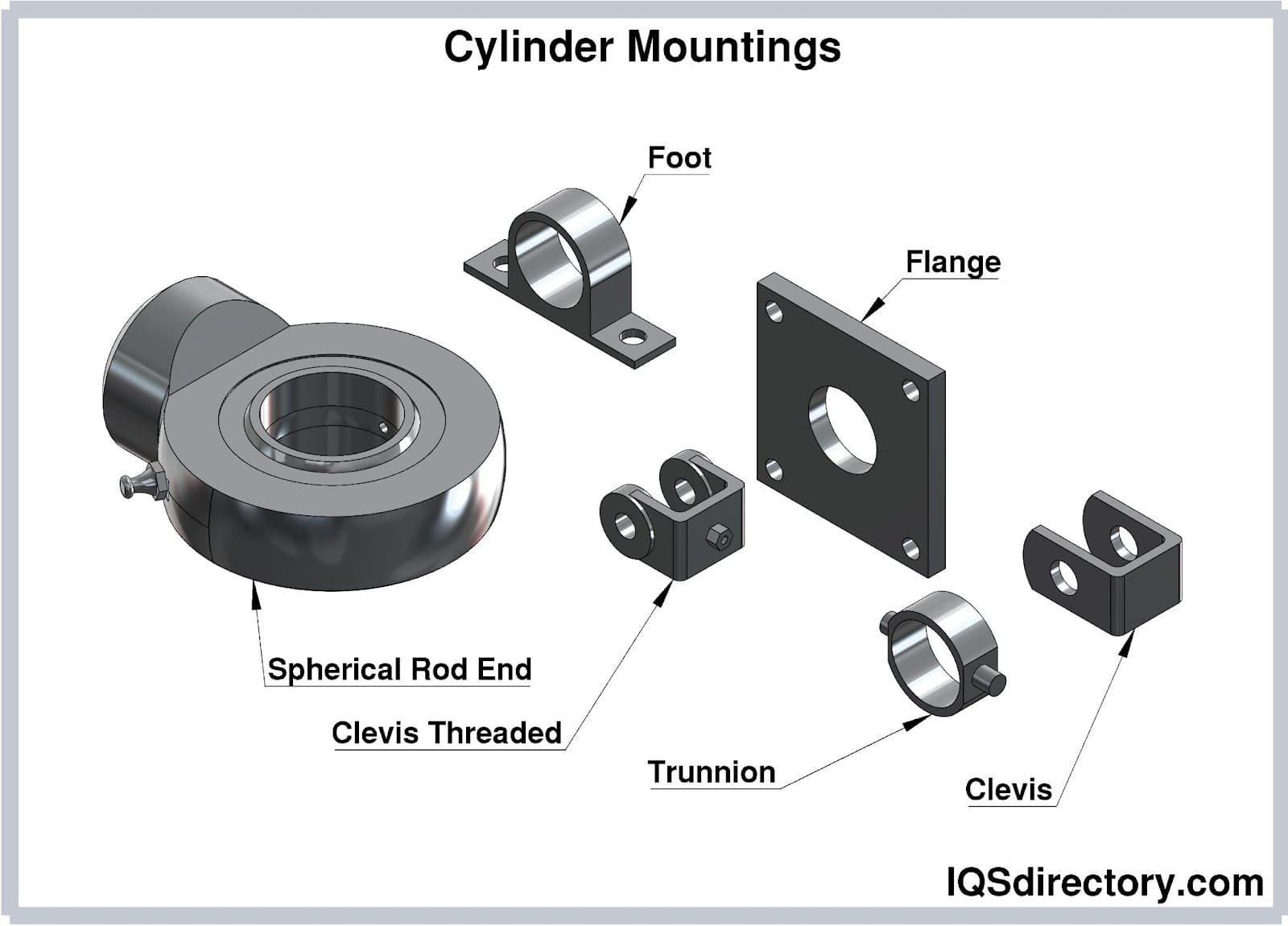

from www.iqsdirectory.com

Verify that the connection between the hydraulic cylinder and the load is correct. Incorrect connections can cause movement and jamming. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. The pump is working fine and the lift is always to the same height when the. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting.

Hydraulic Cylinders Types, Configurations & Applications

Hydraulic Cylinder Not Extending Fully The pump is working fine and the lift is always to the same height when the. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. Incorrect connections can cause movement and jamming. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The pump is working fine and the lift is always to the same height when the. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. Verify that the connection between the hydraulic cylinder and the load is correct.

From www.chegg.com

Solved If the hydraulic cylinder AB is extending at a Hydraulic Cylinder Not Extending Fully Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. Incorrect connections can cause movement and. Hydraulic Cylinder Not Extending Fully.

From www.chegg.com

Solved At the instant under consideration, the rod of the Hydraulic Cylinder Not Extending Fully With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The pump is working fine. Hydraulic Cylinder Not Extending Fully.

From giodecpdi.blob.core.windows.net

Extending Hydraulic Cylinder at Leona Ferguson blog Hydraulic Cylinder Not Extending Fully With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Incorrect connections can cause movement and jamming. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a. Hydraulic Cylinder Not Extending Fully.

From www.youtube.com

Rebuilding Broken Hydraulic Cylinder Shaft How To Repair Broken Hydraulic Cylinder Not Extending Fully Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. The pump is working fine and the lift is always to the same height when the. Incorrect connections can cause movement and jamming. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage. Hydraulic Cylinder Not Extending Fully.

From www.toparts.cc

What happens when the hydraulic cylinder works malfunction? Hydraulic Cylinder Not Extending Fully With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. The pump is working fine and the lift is always to the same height when the. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. One of the most common reasons for hydraulic. Hydraulic Cylinder Not Extending Fully.

From blog.berendsen.com.au

Are Your Hydraulic Cylinders Failing To Meet Running Hour Requirements? Hydraulic Cylinder Not Extending Fully Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. Verify that the connection between the hydraulic cylinder and the load is correct. Incorrect connections can cause movement and jamming. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The most common causes include a lack. Hydraulic Cylinder Not Extending Fully.

From diyquickly.com

How to Rebuild Hydraulic Cylinders 14 Effective Steps (2024) Hydraulic Cylinder Not Extending Fully The pump is working fine and the lift is always to the same height when the. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. Incorrect connections can cause movement and jamming. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. Verify. Hydraulic Cylinder Not Extending Fully.

From www.powermotiontech.com

Understanding Buckling Strength of Hydraulic Cylinders Power & Motion Hydraulic Cylinder Not Extending Fully Incorrect connections can cause movement and jamming. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. The most common causes include a lack. Hydraulic Cylinder Not Extending Fully.

From www.hyroconnect.de

Hydraulic cylinders The heroes of every construction site Hydraulic Cylinder Not Extending Fully When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Verify that the connection between the hydraulic cylinder and the load is correct. The most common causes include a lack of hydraulic fluid, a. Hydraulic Cylinder Not Extending Fully.

From theenterpriseworld.com

A Guide to Hydraulic Cylinder Maintenance and Repair in 2023 The Hydraulic Cylinder Not Extending Fully Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. Verify that the connection between the hydraulic cylinder and the load is correct. One of the most common reasons. Hydraulic Cylinder Not Extending Fully.

From www.youtube.com

Cylinder Calculation Hydraulic Cylinder Calculation Pneumatic Hydraulic Cylinder Not Extending Fully With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. The pump is working fine and the lift is always to the same height when the. Hydraulic cylinders, such as those found on cranes, plows,. Hydraulic Cylinder Not Extending Fully.

From hyspechydraulicpumps.mystrikingly.com

Is Your Hydraulic Cylinder Leaking?Here's How to Tell... Hydraulic Cylinder Not Extending Fully Verify that the connection between the hydraulic cylinder and the load is correct. The pump is working fine and the lift is always to the same height when the. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. One of the most common reasons for hydraulic cylinder. Hydraulic Cylinder Not Extending Fully.

From www.haenchen-hydraulic.com

Rod elongation for hydraulic cylinder Hänchen Hydraulic Cylinder Not Extending Fully With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. The pump is working fine and the lift is always to the same height when the. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. The most common. Hydraulic Cylinder Not Extending Fully.

From www.chegg.com

Solved Item 2 2 of 5 Part A If the hydraulic cylinder AB is Hydraulic Cylinder Not Extending Fully The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. The pump is working fine and the lift is always to the same height when the.. Hydraulic Cylinder Not Extending Fully.

From www.anbaohydraulic.com

What Are The Parts Of A Hydraulic Cylinder? Anbao Hydraulic Hydraulic Cylinder Not Extending Fully One of the most common reasons for hydraulic cylinder failure is contaminated fluid. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. Incorrect connections can cause movement and jamming. The pump is working fine and the lift is always to the same height when the. Verify that the connection between. Hydraulic Cylinder Not Extending Fully.

From www.peninsularcylinders.com

Peninsular Cylinder Co. cylinder repair, hydraulic cylinder repair Hydraulic Cylinder Not Extending Fully The pump is working fine and the lift is always to the same height when the. Verify that the connection between the hydraulic cylinder and the load is correct. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. One of the most common reasons for hydraulic cylinder. Hydraulic Cylinder Not Extending Fully.

From www.chegg.com

Solved Hydraulic cylinder CA is pinned at C and is extending Hydraulic Cylinder Not Extending Fully The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. Verify that the connection between. Hydraulic Cylinder Not Extending Fully.

From www.youtube.com

Calculating Extension Force and Retraction Force for a Double Acting Hydraulic Cylinder Not Extending Fully Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. Verify that the connection between the hydraulic cylinder and the load is correct. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. With this in mind, a hydraulics technician and follower of mine wrote to me recently. Hydraulic Cylinder Not Extending Fully.

From hxeaebqxk.blob.core.windows.net

Hydraulic Cylinder Not Extending at Ethel Childress blog Hydraulic Cylinder Not Extending Fully The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Incorrect connections. Hydraulic Cylinder Not Extending Fully.

From hxeaebqxk.blob.core.windows.net

Hydraulic Cylinder Not Extending at Ethel Childress blog Hydraulic Cylinder Not Extending Fully The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. The pump is. Hydraulic Cylinder Not Extending Fully.

From www.chegg.com

Solved If the hydraulic cylinder AB is extending at a Hydraulic Cylinder Not Extending Fully Verify that the connection between the hydraulic cylinder and the load is correct. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. The pump is working fine and the lift is always to the same height when the. With this in mind, a hydraulics technician and follower of mine wrote. Hydraulic Cylinder Not Extending Fully.

From www.chegg.com

Solved The hydraulic Cylinder is extending with the velocity Hydraulic Cylinder Not Extending Fully The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter. Hydraulic Cylinder Not Extending Fully.

From www.hypercyl.com

Everything You Need to Know About HydraPneumatic Cylinders HyperCyl Hydraulic Cylinder Not Extending Fully One of the most common reasons for hydraulic cylinder failure is contaminated fluid. Incorrect connections can cause movement and jamming. Verify that the connection between the hydraulic cylinder and the load is correct. The pump is working fine and the lift is always to the same height when the. When foreign, abrasive particles become trapped in the fluid, they scratch. Hydraulic Cylinder Not Extending Fully.

From www.chegg.com

Solved It the hydraulic cylinder AB is extending at a Hydraulic Cylinder Not Extending Fully One of the most common reasons for hydraulic cylinder failure is contaminated fluid. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The pump is working fine and the lift is always to the same height when the. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a. Hydraulic Cylinder Not Extending Fully.

From www.researchgate.net

Schematic of the hydraulic cylinder (a) assembly structure, (b) piston Hydraulic Cylinder Not Extending Fully Incorrect connections can cause movement and jamming. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The most common causes. Hydraulic Cylinder Not Extending Fully.

From www.slideserve.com

PPT Hydraulic Cylinders and Cushioning Devices PowerPoint Hydraulic Cylinder Not Extending Fully Verify that the connection between the hydraulic cylinder and the load is correct. Incorrect connections can cause movement and jamming. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. The pump is working fine and the. Hydraulic Cylinder Not Extending Fully.

From www.hydraulicsupermarket.com

The Key to Understanding And Troubleshooting Hydraulic Cylinder Hydraulic Cylinder Not Extending Fully With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. The most common causes include a. Hydraulic Cylinder Not Extending Fully.

From www.numerade.com

SOLVED Draw a hydraulic circuit CYLINDER MOTOR MOTOR Motor 1 Hydraulic Cylinder Not Extending Fully Verify that the connection between the hydraulic cylinder and the load is correct. The pump is working fine and the lift is always to the same height when the. Incorrect connections can cause movement and jamming. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. One of. Hydraulic Cylinder Not Extending Fully.

From www.chegg.com

Solved Problem 5 The hydraulic cylinder is extending with a Hydraulic Cylinder Not Extending Fully One of the most common reasons for hydraulic cylinder failure is contaminated fluid. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. When foreign, abrasive particles become trapped. Hydraulic Cylinder Not Extending Fully.

From www.hydrauliccylindersinc.com

Understanding Why Your Hydraulic Cylinder Won’t Retract Hydraulic Cylinder Not Extending Fully The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. The pump is working fine and the lift is always to the same height when the. Verify that the connection between the hydraulic cylinder and the load is correct. When foreign, abrasive particles become trapped in the fluid,. Hydraulic Cylinder Not Extending Fully.

From diyquickly.com

How to Repair a Hydraulic Cylinder in 06 Easy Steps (2024) Hydraulic Cylinder Not Extending Fully One of the most common reasons for hydraulic cylinder failure is contaminated fluid. The pump is working fine and the lift is always to the same height when the. Verify that the connection between the hydraulic cylinder and the load is correct. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues. Hydraulic Cylinder Not Extending Fully.

From www.iqsdirectory.com

Hydraulic Cylinders Types, Configurations & Applications Hydraulic Cylinder Not Extending Fully With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. The pump. Hydraulic Cylinder Not Extending Fully.

From www.youtube.com

Double Acting Cylinder Hydraulic Circuit, Ladder Diagram and PLC Hydraulic Cylinder Not Extending Fully When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. Verify that the connection between the hydraulic cylinder and the load is correct. The pump is working fine and the lift is always to. Hydraulic Cylinder Not Extending Fully.

From diyquickly.com

How to Repair a Hydraulic Cylinder in 06 Easy Steps (2024) Hydraulic Cylinder Not Extending Fully Verify that the connection between the hydraulic cylinder and the load is correct. The most common causes include a lack of hydraulic fluid, a damaged or broken cylinder, or a blockage in the hydraulic system. Hydraulic cylinders, such as those found on cranes, plows, graders, and other heavy equipment, can encounter various issues that. With this in mind, a hydraulics. Hydraulic Cylinder Not Extending Fully.

From www.peninsularcylinders.com

Testing Hydraulic Cylinder Goes Wrong Fire Erupts Hydraulic Cylinder Not Extending Fully When foreign, abrasive particles become trapped in the fluid, they scratch the inside of. One of the most common reasons for hydraulic cylinder failure is contaminated fluid. With this in mind, a hydraulics technician and follower of mine wrote to me recently about a troubleshooting assignment involving a drifting. The most common causes include a lack of hydraulic fluid, a. Hydraulic Cylinder Not Extending Fully.