Arc Gouging Amperage . the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. amperage range is based on electrode diameter, see table 2.2. this publication establishes a method of conveying to the welder/operator the. Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece.

from www.hampdon.com.au

carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. amperage range is based on electrode diameter, see table 2.2. Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. this publication establishes a method of conveying to the welder/operator the. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece.

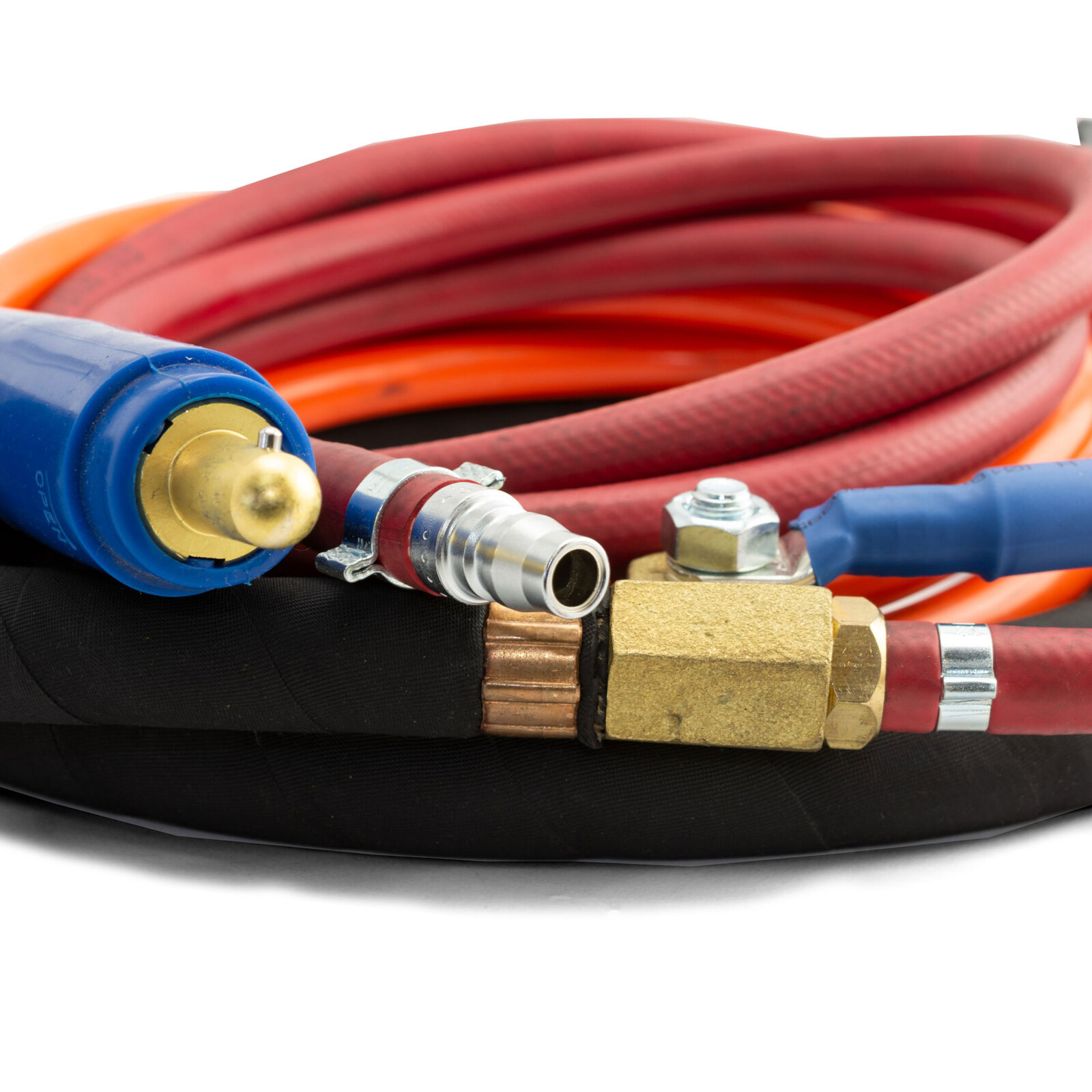

ARC Air Gouging Torch 1000 Amp Heavy Duty 2M

Arc Gouging Amperage carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. this publication establishes a method of conveying to the welder/operator the. Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. amperage range is based on electrode diameter, see table 2.2. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon.

From es.scribd.com

Arc Gouging Guide Welding Rectifier Prueba gratuita de 30 días Arc Gouging Amperage carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. Figure 3.2 air carbon arc with air stream location 3.3 for. gouging or. Arc Gouging Amperage.

From ronsonstorch.com

Air Carbon Gouging The Right Tool, The Right Time RonSon’s Torch Arc Gouging Amperage carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. Figure 3.2 air carbon arc with air stream location 3.3 for. the process parameters for carbon. Arc Gouging Amperage.

From www.hampdon.com.au

DC Gouging Carbons 6.5mm x 50 pack Carbon Arc Air Arc Rods Arc Gouging Amperage carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. amperage range is based on electrode diameter, see table 2.2. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. Figure 3.2 air carbon arc. Arc Gouging Amperage.

From www.youtube.com

Arc Gouging ROCKFORD, IL YouTube Arc Gouging Amperage the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. Figure 3.2 air carbon arc with air stream location 3.3 for. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. carbon arc. Arc Gouging Amperage.

From weldingweb.com

Carbon Arc Cutting with SA200 Arc Gouging Amperage carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter. Arc Gouging Amperage.

From ronsonstorch.com

Air Carbon Gouging The Right Tool, The Right Time RonSon’s Torch Arc Gouging Amperage carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. Figure 3.2 air carbon arc with air stream location 3.3 for. this publication establishes. Arc Gouging Amperage.

From www.ebay.com.au

PREMIUM Air ARC Gouging Torch 1000 Amp Heavy Duty 2M FREE CARBONS Arc Gouging Amperage gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. this publication establishes a method of conveying to the welder/operator the. carbon. Arc Gouging Amperage.

From www.marinelink.com

New Automatic Air CarbonArc Gouging System Arc Gouging Amperage the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. Figure 3.2 air carbon arc with air stream location 3.3 for. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. carbon arc. Arc Gouging Amperage.

From www.pinterest.com.au

Electrode Amperage Chart in 2022 Welding projects, Welding and Arc Gouging Amperage the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. amperage range is based on electrode diameter, see table 2.2. carbon arc. Arc Gouging Amperage.

From www.ebay.com

Carbon Arc Air Gouging Torch Arcair Gun with 7'' Cable 1000 AMP, K4000 Arc Gouging Amperage the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. amperage range is based on electrode diameter, see table 2.2. Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most. Arc Gouging Amperage.

From manualzz.com

Arcair® AngleArc Gouging Torches Manualzz Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. amperage range is based on electrode diameter, see table 2.2. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process. Arc Gouging Amperage.

From www.youtube.com

Arc air gouging YouTube Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. . Arc Gouging Amperage.

From www.scribd.com

Arcair gouging (air carbon arc gouging).pdf Steel Alloy Arc Gouging Amperage gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. this publication establishes a method of conveying to the welder/operator the. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. carbon. Arc Gouging Amperage.

From www.chicago-hvac.com

3/16″ x 12″ Carbon Gouging Electrodes 22033003X Amperage Rating 200 Arc Gouging Amperage this publication establishes a method of conveying to the welder/operator the. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. carbon arc gouging,. Arc Gouging Amperage.

From bakersgas.com

Arcair K4000 HeavyDuty Carbon Arc Gouging Torch 61082009 — Baker's Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. this publication establishes a method of conveying to the welder/operator the. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. gouging or cutting occurs when the intense heat of the arc between the carbon. Arc Gouging Amperage.

From www.ebay.com

PREMIUM Air ARC Gouging Torch 1000 Amp Heavy Duty 2M FREE CARBONS Arc Gouging Amperage amperage range is based on electrode diameter, see table 2.2. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. Figure 3.2 air carbon arc with air stream location 3.3 for. this publication establishes a method of conveying to the welder/operator the. the. Arc Gouging Amperage.

From fixwiringfiercely.z13.web.core.windows.net

Arc Welding Amperage Chart Arc Gouging Amperage amperage range is based on electrode diameter, see table 2.2. this publication establishes a method of conveying to the welder/operator the. Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. carbon. Arc Gouging Amperage.

From spectrumweldingsupplies.co.uk

815amp Lincoln Electric Idealarc DC 655 Sub Arc and Air Arc Gouging Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. carbon arc cutting. Arc Gouging Amperage.

From www.canadianmetalworking.com

Miller’s Deltaweld 500 power source offers high amperage and carbon arc Arc Gouging Amperage carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. amperage range is based on electrode diameter, see table 2.2. gouging or. Arc Gouging Amperage.

From www.lencocanada.com

3/8X12 DCCC POINTED (PKG 50) PointedCarbons Arc Gouging & Slice Arc Gouging Amperage amperage range is based on electrode diameter, see table 2.2. Figure 3.2 air carbon arc with air stream location 3.3 for. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process. Arc Gouging Amperage.

From spectrumweldingsupplies.co.uk

800amp ESAB LHF 800 Offshore Air Arc Gouging welder package 415V Arc Gouging Amperage this publication establishes a method of conveying to the welder/operator the. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. Figure 3.2 air carbon arc with air stream location 3.3 for. amperage range is based on electrode diameter, see table 2.2. carbon arc gouging,. Arc Gouging Amperage.

From www.safetyshorts.com

Arc Gouging and Arc Cutting Safety Online Video Safetyhub Arc Gouging Amperage this publication establishes a method of conveying to the welder/operator the. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. Figure 3.2 air. Arc Gouging Amperage.

From www.weldingsuppliesdirect.co.uk

Arc Air Gouging Gouging Carbons Welding Supplies Direct Arc Gouging Amperage carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current,. Arc Gouging Amperage.

From www.hampdon.com.au

ARC Air Gouging Torch 1000 Amp Heavy Duty 2M Arc Gouging Amperage carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. Figure 3.2 air carbon arc with air stream location 3.3 for. this publication. Arc Gouging Amperage.

From dxooyoqjo.blob.core.windows.net

Arc Welding Parameters Chart at Martha Schnell blog Arc Gouging Amperage amperage range is based on electrode diameter, see table 2.2. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. Figure. Arc Gouging Amperage.

From elisejoyce.z13.web.core.windows.net

Welding Rod Amperage Chart Pdf Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. the process parameters. Arc Gouging Amperage.

From paktechpoint.com

Air Carbon Arc Gouging and Cutting Process PAKTECHPOINT Arc Gouging Amperage carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. carbon arc cutting and gouging can cut or remove high amounts of metal relatively. Arc Gouging Amperage.

From canadaweldingsupply.ca

Arcair K4000 Angle Arc Gouging Torch Canada Welding Supply Inc. Arc Gouging Amperage carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. Figure 3.2 air carbon arc with air stream location 3.3 for. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. gouging or cutting occurs. Arc Gouging Amperage.

From es.scribd.com

Air Carbon Arc Gouging Data.pdf Alternating Current Metals Arc Gouging Amperage carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. Figure 3.2 air carbon arc with air stream location 3.3 for. amperage range is based on electrode diameter, see table 2.2. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current,. Arc Gouging Amperage.

From www.chapacash.com.pe

Soudage Métallurgie, brasage, soudage Autres K4000 type Arc Air Arc Gouging Amperage carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. Figure 3.2 air carbon arc with air stream location 3.3 for. the process parameters for carbon arc gouging include power source polarity, carbon rod diameter and current, carbon rod diameter and plate. carbon arc. Arc Gouging Amperage.

From www.indiamart.com

Carbon Arc Gouging Power Source Package Shyam Trading Corporation Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. gouging or. Arc Gouging Amperage.

From www.machinemfg.com

Carbon Arc Gouging An AllInclusive Guide MachineMFG Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. carbon arc cutting and gouging can cut or remove high amounts of metal relatively quickly due to the high amperage and. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. the process. Arc Gouging Amperage.

From www.brazosindustries.com

The Use of Air Arc Gouging Arc Gouging Amperage amperage range is based on electrode diameter, see table 2.2. carbon arc gouging, which includes back gouging and weld repair, is the fastest and most efficient way to remove unwanted. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. the process parameters. Arc Gouging Amperage.

From weldingpros.net

Carbon Arc Welding (CAW) Process Arc Gouging Amperage Figure 3.2 air carbon arc with air stream location 3.3 for. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. . Arc Gouging Amperage.

From www.manufacturingguide.com

Air arc gouging Find suppliers, processes & material Arc Gouging Amperage carbon arc gouging, also known as air carbon arc cutting, is a metal removal process that utilizes an electric arc between a carbon. amperage range is based on electrode diameter, see table 2.2. gouging or cutting occurs when the intense heat of the arc between the carbon electrode and the workpiece melts part of the workpiece. . Arc Gouging Amperage.