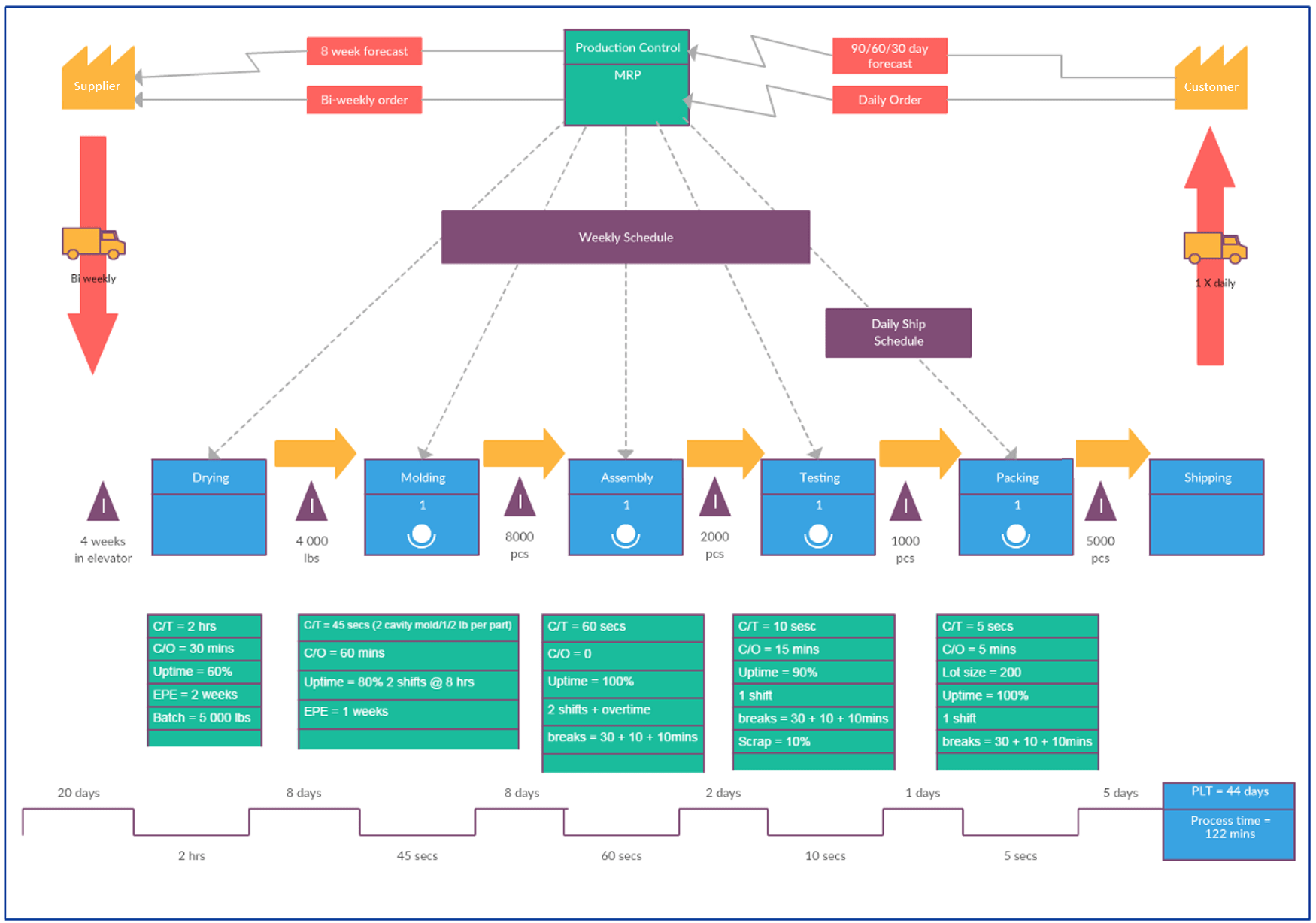

Material Handling Value Stream Mapping . the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process.

from engineeringpossibilities.ca

value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow.

The Complete Guide To Process Mapping Engineering Possibilities

Material Handling Value Stream Mapping value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow.

From www.lean.org

Value Stream Mapping Overview Lean Enterprise Institute Material Handling Value Stream Mapping value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a. Material Handling Value Stream Mapping.

From www.mbizm.com

Lean Six Sigma Tools Streamline, Improve and Optimize Material Handling Value Stream Mapping value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. the aim of value stream mapping is to build up a picture of how items (such as materials,. Material Handling Value Stream Mapping.

From www.aiophotoz.com

Number Slide Of Value Stream Map Diagram Slidemodel Images and Photos Material Handling Value Stream Mapping value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. the aim of value stream mapping is to build up a picture of how items (such as materials, designs,. Material Handling Value Stream Mapping.

From www.reliableplant.com

Value Stream Mapping Details and Examples Reliable Plant Material Handling Value Stream Mapping value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. in manufacturing, value stream mapping helps identify waste by analyzing each step of material. Material Handling Value Stream Mapping.

From www.pixazsexy.com

Value Stream Map Template And Example Value Stream Mapping Flow Map Map Material Handling Value Stream Mapping in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow.. Material Handling Value Stream Mapping.

From leanconstructionblog.com

VALUE STREAM MAPPING APPLIED TO LEAN CONSTRUCTION Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. . Material Handling Value Stream Mapping.

From workerbee.tv

Material Handling Workerbee.TV Material Handling Value Stream Mapping value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. . Material Handling Value Stream Mapping.

From fr.thptnganamst.edu.vn

Arriba 77+ imagen value stream map fr.thptnganamst.edu.vn Material Handling Value Stream Mapping value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. the aim of value stream mapping is to build up a picture of how items (such as. Material Handling Value Stream Mapping.

From www.researchgate.net

Material handling value stream mapCM cell (CM, crown machine Material Handling Value Stream Mapping value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping (vsm) is defined as a lean tool that employs a flowchart. Material Handling Value Stream Mapping.

From www.pinterest.com

Value Stream Mapping And Why It Matters In Business FourWeekMBA Material Handling Value Stream Mapping value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting. Material Handling Value Stream Mapping.

From www.excel-pmt.com

Value Stream Mapping How to analyze Process Quality with it Material Handling Value Stream Mapping value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping, or vsm, is a lean tool that helps manufacturers and other. Material Handling Value Stream Mapping.

From www.xeridia.co.uk

How to use Value Stream Mapping in a DevOps environment Xeridia Material Handling Value Stream Mapping in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream. Material Handling Value Stream Mapping.

From www.linkedin.com

What is Value Stream Mapping? Explained with help of Example. Material Handling Value Stream Mapping the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping (vsm) is defined as a lean tool that employs a flowchart. Material Handling Value Stream Mapping.

From www.conceptdraw.com

The Value Stream Mapping Process Value Stream Mapping Software Material Handling Value Stream Mapping the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase. Material Handling Value Stream Mapping.

From www.projectengineer.net

Steps to Powerful Value Stream Mapping Material Handling Value Stream Mapping value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs). Material Handling Value Stream Mapping.

From engineeringpossibilities.ca

The Complete Guide To Process Mapping Engineering Possibilities Material Handling Value Stream Mapping value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping. Material Handling Value Stream Mapping.

From workerbee.tv

SPE Energy Stream Workerbee.TV Material Handling Value Stream Mapping value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. the. Material Handling Value Stream Mapping.

From www.pinterest.com

A value stream map template to analyze and design the flow of materials Material Handling Value Stream Mapping in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping (vsm) is a lean management technique used to visualize the entire production process.. Material Handling Value Stream Mapping.

From www.conceptdraw.com

Value Stream Map VSM Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. . Material Handling Value Stream Mapping.

From blog.i-nexus.com

What is a value stream map & why is one important inexus Material Handling Value Stream Mapping the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping, or vsm, is a lean tool that helps manufacturers and other. Material Handling Value Stream Mapping.

From workerbee.tv

Energy Workerbee.TV Material Handling Value Stream Mapping in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various. Material Handling Value Stream Mapping.

From leanmanufacturingupdate.com

Value Stream Mapping Information Flow Material Handling Value Stream Mapping value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across various industries. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. . Material Handling Value Stream Mapping.

From templates.rjuuc.edu.np

Value Stream Mapping Free Template Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across. Material Handling Value Stream Mapping.

From bizagility.org

6 Steps to Enhance Gross sales & Operations Bizagility Material Handling Value Stream Mapping value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping. Material Handling Value Stream Mapping.

From www.mdpi.com

Applied Sciences Free FullText Value Stream Analysis in Military Material Handling Value Stream Mapping in manufacturing, value stream mapping helps identify waste by analyzing each step of material handling and information flow. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping. Material Handling Value Stream Mapping.

From shop.canna-innovations.com

Value Stream Mapping CAN Innovations Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. the aim of value stream mapping is to build up a picture of how items (such as materials,. Material Handling Value Stream Mapping.

From www.myxxgirl.com

Value Stream Map Template Example Value Stream Mapping Flow Map Map Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. in. Material Handling Value Stream Mapping.

From medium.com

The Ultimate Guide to Value Stream Mapping by Creately Thousand Material Handling Value Stream Mapping value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value. Material Handling Value Stream Mapping.

From boardmix.com

How to Do Value Stream Mapping in Excel? Material Handling Value Stream Mapping value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a powerful tool that is used to optimize processes and increase efficiency across. Material Handling Value Stream Mapping.

From workerbee.tv

Material Handling Workerbee.TV Material Handling Value Stream Mapping value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. the. Material Handling Value Stream Mapping.

From quality-one.com

Value Stream Mapping (VSM) Example QualityOne Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. the aim of value stream mapping is to build up a picture of how items (such as materials,. Material Handling Value Stream Mapping.

From www.lucidchart.com

How to Create a Value Stream Map Lucidchart Blog Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping, or vsm, is a lean tool that helps manufacturers and other. Material Handling Value Stream Mapping.

From www.sampletemplatess.com

Value Stream Map Template Excel SampleTemplatess SampleTemplatess Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping (vsm) is a powerful tool that is used to optimize processes. Material Handling Value Stream Mapping.

From txm.com

The Four Secrets of Successful Value Stream Mapping Material Handling Value Stream Mapping value stream mapping (vsm) is a lean management technique used to visualize the entire production process. the aim of value stream mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific. Material Handling Value Stream Mapping.

From hubpages.com

How to Create a Value Stream Map Mapping your value stream VSM Material Handling Value Stream Mapping value stream mapping (vsm) is defined as a lean tool that employs a flowchart documenting every step in the process. value stream mapping (vsm) is a lean management technique used to visualize the entire production process. value stream mapping, or vsm, is a lean tool that helps manufacturers and other organizations visualize a specific process. in. Material Handling Value Stream Mapping.