Turning Tool Geometry In Cnc . By comprehending the different tool. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Students should be able to identify. This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select the suitable one. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations.

from www.minaprem.com

This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Students should be able to identify. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. By comprehending the different tool. This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select the suitable one. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be.

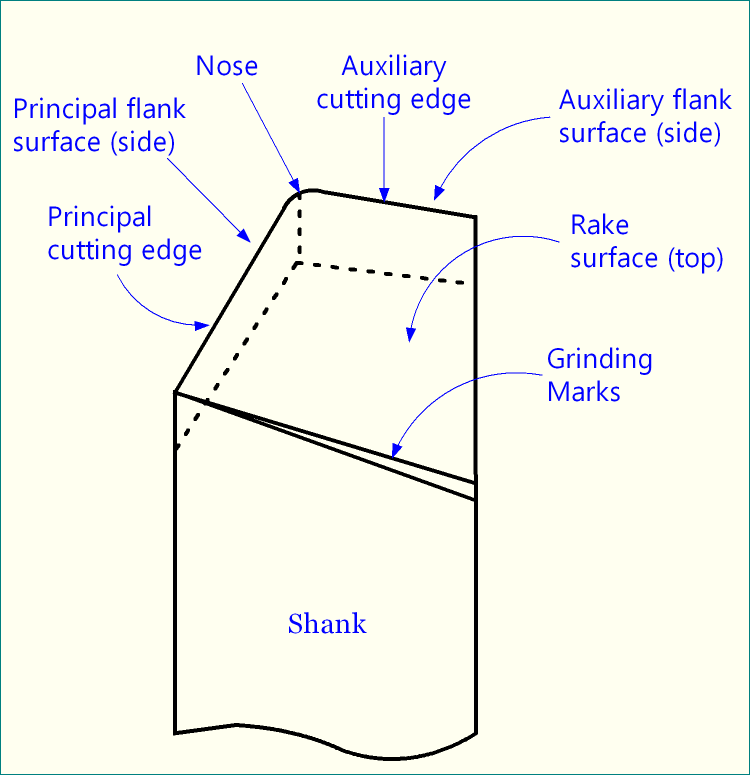

What is Single Point Turning Tool (SPTT)?

Turning Tool Geometry In Cnc The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. By comprehending the different tool. Students should be able to identify. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select the suitable one. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine.

From www.youtube.com

CNC Basics Turning tool,Offset,insert details Video2 YouTube Turning Tool Geometry In Cnc By comprehending the different tool. Students should be able to identify. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Understanding turning tool geometry is crucial for achieving optimal results in cnc. Turning Tool Geometry In Cnc.

From www.hubs.com

Introduction to CNC machining Hubs Turning Tool Geometry In Cnc Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. By comprehending the different tool. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. This class is intended. Turning Tool Geometry In Cnc.

From www.youtube.com

How to take Geometry offset of Grooving tool in CNC turning machine Tool Type to Grooving Turning Tool Geometry In Cnc The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. By comprehending the different tool. Students should be able. Turning Tool Geometry In Cnc.

From www.youtube.com

How to take offset on cnc Types of offset of in cnc Geometry Wear and work offset cnc Turning Tool Geometry In Cnc Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Students should be able to identify. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. By comprehending the. Turning Tool Geometry In Cnc.

From unitymanufacture.com

How To Use G41 And G42 In CNC Lathe? Unity Manufacture Turning Tool Geometry In Cnc The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the. Turning Tool Geometry In Cnc.

From www.china-machining.com

CNC Lathe Tools 6 Types for CNC Turning Projects Turning Tool Geometry In Cnc Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. By comprehending the different tool. Students should be able to identify. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be.. Turning Tool Geometry In Cnc.

From www.youtube.com

CNC basics turning tool types video 3 YouTube Turning Tool Geometry In Cnc Students should be able to identify. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations.. Turning Tool Geometry In Cnc.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Turning Tool Geometry In Cnc This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Students should be able to identify. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. This article provides a guide to the. Turning Tool Geometry In Cnc.

From www.hubs.com

Introduction to CNC machining Hubs Turning Tool Geometry In Cnc Students should be able to identify. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. By comprehending the different tool. This article provides a guide to the. Turning Tool Geometry In Cnc.

From www.youtube.com

CNC Tool Length Offsets Explained YouTube Turning Tool Geometry In Cnc Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. By comprehending the different tool. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select. Turning Tool Geometry In Cnc.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Geometry In Cnc This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. Students should be able. Turning Tool Geometry In Cnc.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature, Angle, PDF Learn Mechanical Turning Tool Geometry In Cnc The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. Students should be able to identify. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. This article provides a guide. Turning Tool Geometry In Cnc.

From www.researchgate.net

Geometry of singlepoint cutting tool Download Scientific Diagram Turning Tool Geometry In Cnc Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning. Turning Tool Geometry In Cnc.

From www.lctcarbide.com

How to choose right turning insert in CNC machining? Turning Tool Geometry In Cnc Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. Students should be able to identify. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. This class is intended for lathe operators and students in a turning operator training program who understand how to. Turning Tool Geometry In Cnc.

From www.cnctrainingcentre.com

CNC Lathe Tool Nose Radius Compensation CNC Training Centre Turning Tool Geometry In Cnc The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. This. Turning Tool Geometry In Cnc.

From www.youtube.com

Cnc turning Tool Offset geometry and program CTS YouTube Turning Tool Geometry In Cnc By comprehending the different tool. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Understanding turning tool geometry is crucial for achieving. Turning Tool Geometry In Cnc.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tool Geometry In Cnc Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Students should be able to identify. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators. Turning Tool Geometry In Cnc.

From www.china-machining.com

CNC Lathe Tools 6 Types for CNC Turning Projects Turning Tool Geometry In Cnc This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning. Turning Tool Geometry In Cnc.

From www.minaprem.com

What is Single Point Turning Tool (SPTT)? Turning Tool Geometry In Cnc The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. Students should be able to identify. By comprehending the different tool. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Understanding turning tool geometry is crucial for achieving optimal results in cnc. Turning Tool Geometry In Cnc.

From ecoreprap.com

Types of Lathe Tools Used in CNC Turning EcoReprap Turning Tool Geometry In Cnc This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select the suitable one. By comprehending the different tool. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. Understanding turning tool geometry is crucial for achieving optimal results in. Turning Tool Geometry In Cnc.

From www.youtube.com

Face grooving and Neutral CNC turning toolsAll tools of CNC holders & boring bar Turning Tool Geometry In Cnc Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. Students should be able. Turning Tool Geometry In Cnc.

From www.rapiddone.com

A Quick Selecting Guide for CNC Machine Tools RapidDone Turning Tool Geometry In Cnc This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select the suitable one. By comprehending the different tool. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. The variety of cutting. Turning Tool Geometry In Cnc.

From www.cnccookbook.com

New OD Turning Wizard and Chamfering Tool Geometry for GW Calculator CNCCookbook Be A Better Turning Tool Geometry In Cnc Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Students should be able to identify. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. By comprehending the different tool. This class is intended for lathe operators and students in a turning operator training. Turning Tool Geometry In Cnc.

From senjiblade.en.made-in-china.com

ISO Turning Inserts Ra Geometry Heavy Cutting Machining China CNC Tools and End Mill Turning Tool Geometry In Cnc Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run. Turning Tool Geometry In Cnc.

From www.researchgate.net

Turning tool edge for longitudinal turning a) geometric parameter of... Download Scientific Turning Tool Geometry In Cnc The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. By comprehending the different tool. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and. Turning Tool Geometry In Cnc.

From www.machining-custom.com

CNC Machining Knowledge of Geometric Angle Selection for Milling and Turning Machining Turning Tool Geometry In Cnc Students should be able to identify. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. By comprehending the different tool. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters. Turning Tool Geometry In Cnc.

From www.yg1.kr

YG1, The Art of Threading Turning Tool Geometry In Cnc The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. By comprehending the different tool. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool. Turning Tool Geometry In Cnc.

From www.metalworkingworldmagazine.com

Mechanical loads and cutting geometries in turning operations Metal Working World Magazine Turning Tool Geometry In Cnc The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. This article provides a. Turning Tool Geometry In Cnc.

From dajinprecision.com

CNC Turning Cutting Tools Types, Classifications & How to Select Best CNC Cutting Tools for Turning Tool Geometry In Cnc This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing. Turning Tool Geometry In Cnc.

From www.iqsdirectory.com

CNC Machining What Is It? How Does It Work? Types, Codes Turning Tool Geometry In Cnc This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. This article provides a. Turning Tool Geometry In Cnc.

From machiningtool.blogspot.com

Machining Turning Tools and Geometry Turning Tool Geometry In Cnc This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select the suitable one. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different diameters on the workpiece, optimizing efficiency. Students should be able to identify. The right turning inserts can significantly enhance overall. Turning Tool Geometry In Cnc.

From jvprecision.en.made-in-china.com

Complex Geometry CNC Automatic Lathe Turning Parts China Aluminum Prototype and Auto Parts Turning Tool Geometry In Cnc The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how to select the suitable one.. Turning Tool Geometry In Cnc.

From machiningtool.blogspot.com

Machining Turning Tools and Geometry Turning Tool Geometry In Cnc The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Cnc lathes, for instance, can automatically adjust the rpm as the cutting tool traverses different. Turning Tool Geometry In Cnc.

From www.machinemetrics.com

CNC Turning and CNC Turning Center Basics Turning Tool Geometry In Cnc This class is intended for lathe operators and students in a turning operator training program who understand how to set up and run a turning machine. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. This article provides a guide to the diverse range of lathe cutting tools utilized in cnc turning and explains how. Turning Tool Geometry In Cnc.

From www.youtube.com

How to take Geometry offset of drill tool in CNC turning machine Tool Type to Drilling Tool Turning Tool Geometry In Cnc The variety of cutting tools available for modern cnc turning centers makes it imperative for machine operators to be. By comprehending the different tool. Understanding turning tool geometry is crucial for achieving optimal results in cnc turning operations. The right turning inserts can significantly enhance overall machining performance by reducing wear and increasing efficiency. This article provides a guide to. Turning Tool Geometry In Cnc.