Welding Stick Keeps Sticking . Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Understanding these reasons is pivotal to effectively addressing the issue. Adjust the amperage, maintain a short. During stick welding, you should typically keep an angle of 20 to 30 degrees. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Are you using the right type. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Welding rod sticking to the base metal occurs due to several key factors. Let’s say you are using a 5/64 inch e6013 rod at the right.

from www.industar.lv

Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Adjust the amperage, maintain a short. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Understanding these reasons is pivotal to effectively addressing the issue. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Let’s say you are using a 5/64 inch e6013 rod at the right. During stick welding, you should typically keep an angle of 20 to 30 degrees. Welding rod sticking to the base metal occurs due to several key factors.

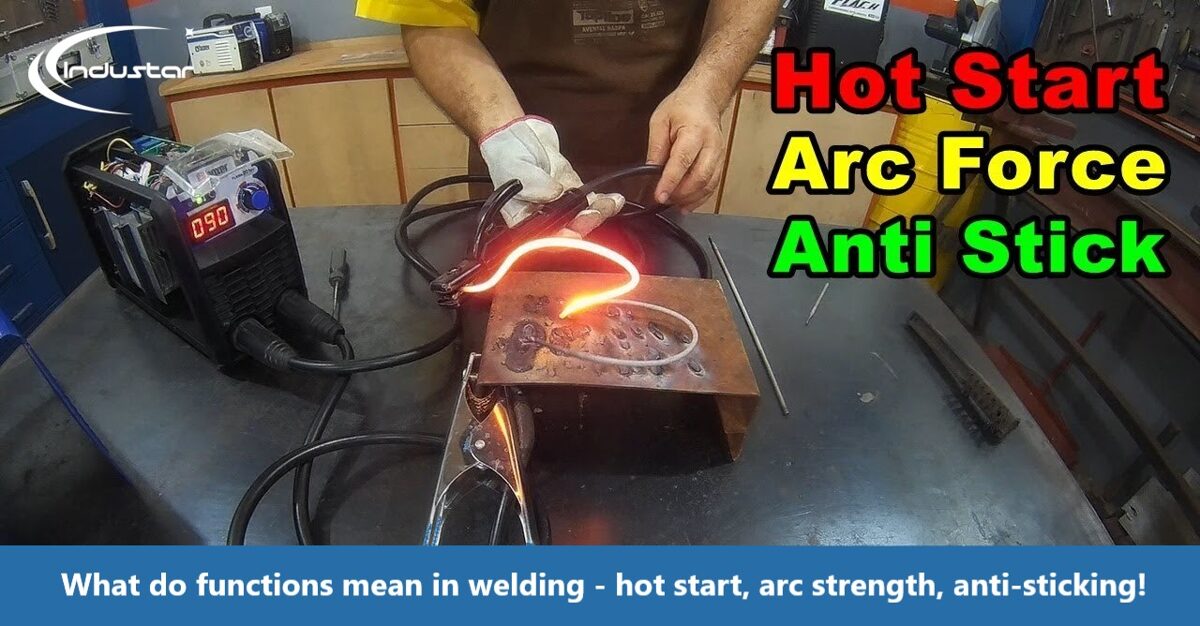

Very simple! What do functions mean in welding hot start, arc

Welding Stick Keeps Sticking Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Welding rod sticking to the base metal occurs due to several key factors. During stick welding, you should typically keep an angle of 20 to 30 degrees. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Adjust the amperage, maintain a short. Let’s say you are using a 5/64 inch e6013 rod at the right. Are you using the right type. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Understanding these reasons is pivotal to effectively addressing the issue. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly.

From giogmtaje.blob.core.windows.net

Stick Welding Rod Keeps Sticking at Timothy Marriott blog Welding Stick Keeps Sticking Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Understanding these reasons is. Welding Stick Keeps Sticking.

From www.youtube.com

STICK WELDING 101 Getting Started With SMAW YouTube Welding Stick Keeps Sticking During stick welding, you should typically keep an angle of 20 to 30 degrees. Let’s say you are using a 5/64 inch e6013 rod at the right. Are you using the right type. Adjust the amperage, maintain a short. Understanding these reasons is pivotal to effectively addressing the issue. Maintaining proper electrode angles when stick welding is one approach to. Welding Stick Keeps Sticking.

From www.reddit.com

Cold welder FR9700A r/Welding Welding Stick Keeps Sticking Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Are you using the right type. Maintaining proper electrode angles when stick welding is one approach. Welding Stick Keeps Sticking.

From www.youtube.com

amazing video of electric stick welding for flux core YouTube Welding Stick Keeps Sticking Are you using the right type. Let’s say you are using a 5/64 inch e6013 rod at the right. Adjust the amperage, maintain a short. During stick welding, you should typically keep an angle of 20 to 30 degrees. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work. Welding Stick Keeps Sticking.

From weldinguru.com

Welding Rod Keeps Sticking Right thing to do! Weldinguru Welding Stick Keeps Sticking Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Welding rod sticking to the base metal occurs due to several key factors. A thick rod selection for welding. Welding Stick Keeps Sticking.

From www.weldingcity.com

3/32" x 12" WeldingCity® E309L16 Stainless Steel Stick Welding Welding Stick Keeps Sticking A thick rod selection for welding thin sheets can also cause electrode sticking issues. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Adjust the amperage, maintain a short. During stick welding,. Welding Stick Keeps Sticking.

From www.aliexpress.com

NewMultifunctionalOilyOriginalGlueSuperStrongAdhesiveGlue Welding Stick Keeps Sticking Let’s say you are using a 5/64 inch e6013 rod at the right. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Adjust the amperage, maintain a short. Explore how incorrect amperage. Welding Stick Keeps Sticking.

From blog.thepipingmart.com

How to Stick Weld Thin Metal An Overview Welding Stick Keeps Sticking Are you using the right type. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Let’s say you are using a. Welding Stick Keeps Sticking.

From www.greentractortalk.com

Welder sticky hairs/stragglers Green Tractor Talk Welding Stick Keeps Sticking A thick rod selection for welding thin sheets can also cause electrode sticking issues. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Explore how. Welding Stick Keeps Sticking.

From weldinguru.com

Welding Rod Keeps Sticking Right thing to do! Weldinguru Welding Stick Keeps Sticking Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Are you using the right type. During stick welding, you should typically keep an angle of 20 to 30 degrees. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage. Welding Stick Keeps Sticking.

From www.reddit.com

Cold welder FR9700A r/Welding Welding Stick Keeps Sticking Let’s say you are using a 5/64 inch e6013 rod at the right. Welding rod sticking to the base metal occurs due to several key factors. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Understanding these reasons is pivotal to effectively addressing the issue. A thick rod selection for welding thin sheets can. Welding Stick Keeps Sticking.

From www.reddit.com

Cold welder FR9700A r/Welding Welding Stick Keeps Sticking Understanding these reasons is pivotal to effectively addressing the issue. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Adjust the amperage, maintain a short. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Rod sticking during stick welding can be due. Welding Stick Keeps Sticking.

From www.walmart.com

E7018 3/32" 1/8" 5/32" x 10 lb Premium Arc Stick electrodes welding Welding Stick Keeps Sticking Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Are you using the right type. During stick welding, you should typically keep an angle of 20 to 30 degrees. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Understanding these reasons is pivotal to effectively addressing the issue. Let’s. Welding Stick Keeps Sticking.

From giogmtaje.blob.core.windows.net

Stick Welding Rod Keeps Sticking at Timothy Marriott blog Welding Stick Keeps Sticking Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Are you using the right type. A thick rod selection for welding thin sheets can also. Welding Stick Keeps Sticking.

From weldingempire.com

Stop Your Welding Rod Sticking Welding Stick Keeps Sticking Welding rod sticking to the base metal occurs due to several key factors. During stick welding, you should typically keep an angle of 20 to 30 degrees. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Let’s say you are using a 5/64 inch e6013 rod at the right. A. Welding Stick Keeps Sticking.

From weldinguru.com

Welding Rod Keeps Sticking Right thing to do! Weldinguru Welding Stick Keeps Sticking Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Are you using the right type. During stick welding, you should typically keep an angle of 20 to 30 degrees. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it. Welding Stick Keeps Sticking.

From giogmtaje.blob.core.windows.net

Stick Welding Rod Keeps Sticking at Timothy Marriott blog Welding Stick Keeps Sticking Welding rod sticking to the base metal occurs due to several key factors. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Let’s say you. Welding Stick Keeps Sticking.

From www.weldingtipsandtricks.com

Stick Welding Tips for a 4g Overhead Weld Test Welding Stick Keeps Sticking Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Adjust the amperage, maintain a short. Let’s say you are using a 5/64 inch e6013 rod at the right. Are you using the right type. Among all the reasons why your welding rod is sticking to the metal, the most common. Welding Stick Keeps Sticking.

From www.youtube.com

6013 Stick Welding Problem Fixed YouTube Welding Stick Keeps Sticking Welding rod sticking to the base metal occurs due to several key factors. Adjust the amperage, maintain a short. Are you using the right type. During stick welding, you should typically keep an angle of 20 to 30 degrees. Let’s say you are using a 5/64 inch e6013 rod at the right. Among all the reasons why your welding rod. Welding Stick Keeps Sticking.

From www.pinterest.com

First time stainless stick welding Thoughts? Welding tools, Welding Welding Stick Keeps Sticking Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Adjust the amperage, maintain a short. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Understanding these reasons. Welding Stick Keeps Sticking.

From weldinguru.com

Welding Rod Keeps Sticking Right thing to do! Weldinguru Welding Stick Keeps Sticking A thick rod selection for welding thin sheets can also cause electrode sticking issues. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Adjust the amperage, maintain a short. Welding rod sticking to the base metal occurs due to several key factors. Are you using the right. Welding Stick Keeps Sticking.

From www.industar.lv

Very simple! What do functions mean in welding hot start, arc Welding Stick Keeps Sticking Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a. Welding Stick Keeps Sticking.

From www.walmart.com

Upgraded Stainless Steel Barbecue Skewer Shish Kabob Set, 15pcs 5"L Welding Stick Keeps Sticking Welding rod sticking to the base metal occurs due to several key factors. Are you using the right type. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Let’s say you are using a 5/64 inch e6013 rod at the right. During stick welding, you should typically keep an angle. Welding Stick Keeps Sticking.

From www.youtube.com

Helpful Tool for Stick Welding STICK WELDER HOLDER YouTube Welding Stick Keeps Sticking Let’s say you are using a 5/64 inch e6013 rod at the right. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Understanding these reasons is pivotal to. Welding Stick Keeps Sticking.

From weldguru.com

MIG vs Stick Welding Which is Better? (Pros & Cons) Welding Stick Keeps Sticking Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Understanding these reasons is pivotal to effectively addressing the issue. Welding rod sticking to the base metal occurs due to several key factors. Adjust the amperage, maintain a short. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to. Welding Stick Keeps Sticking.

From www.reddit.com

Cold welder FR9700A r/Welding Welding Stick Keeps Sticking Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Understanding these reasons is pivotal to effectively addressing the issue. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. During stick welding, you should typically. Welding Stick Keeps Sticking.

From www.familyhandyman.com

Here's What You Need to Know About Stick Welding Pros, Cons, Cost and Welding Stick Keeps Sticking Let’s say you are using a 5/64 inch e6013 rod at the right. Are you using the right type. Understanding these reasons is pivotal to effectively addressing the issue. During stick welding, you should typically keep an angle of 20 to 30 degrees. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle,. Welding Stick Keeps Sticking.

From weldingblos.netlify.app

Welding Rod Keeps Sticking Welding Stick Keeps Sticking Are you using the right type. Let’s say you are using a 5/64 inch e6013 rod at the right. During stick welding, you should typically keep an angle of 20 to 30 degrees. Adjust the amperage, maintain a short. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work. Welding Stick Keeps Sticking.

From www.reddit.com

Cold welder FR9700A r/Welding Welding Stick Keeps Sticking Are you using the right type. During stick welding, you should typically keep an angle of 20 to 30 degrees. Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Adjust the amperage, maintain a short. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Understanding these reasons is pivotal. Welding Stick Keeps Sticking.

From www.youtube.com

How to Strike an Arc Stick Welding Basics for Beginners YouTube Welding Stick Keeps Sticking Adjust the amperage, maintain a short. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Welding rod sticking to the base metal occurs due to several key factors. Are you using the right type. During stick welding, you should typically keep an angle of 20 to 30 degrees. Rod sticking during stick welding can be. Welding Stick Keeps Sticking.

From www.youtube.com

Stick Welding Tips 3 welders YouTube Welding Stick Keeps Sticking A thick rod selection for welding thin sheets can also cause electrode sticking issues. Rod sticking during stick welding can be due to low amperage, improper arc length, excessive rod angle, or a dirty work surface. Let’s say you are using a 5/64 inch e6013 rod at the right. Explore how incorrect amperage settings can cause the welding rod to. Welding Stick Keeps Sticking.

From giogmtaje.blob.core.windows.net

Stick Welding Rod Keeps Sticking at Timothy Marriott blog Welding Stick Keeps Sticking Welding rod sticking to the base metal occurs due to several key factors. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Adjust the amperage, maintain a short. During stick welding, you should typically keep an angle of 20 to 30 degrees. Understanding these reasons is pivotal to effectively addressing. Welding Stick Keeps Sticking.

From dailywelding.com

Why Does My Welding Rod Keep Sticking Welding Stick Keeps Sticking Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Welding rod sticking to the base metal occurs due to several key factors. Let’s say you are using a 5/64 inch e6013 rod at the right. Adjust the amperage, maintain a short. Rod sticking during stick welding can. Welding Stick Keeps Sticking.

From www.reddit.com

Cold welder FR9700A r/Welding Welding Stick Keeps Sticking Maintaining proper electrode angles when stick welding is one approach to prevent rod sticking polarity. Explore how incorrect amperage settings can cause the welding rod to stick and learn how to adjust it properly. Understanding these reasons is pivotal to effectively addressing the issue. Welding rod sticking to the base metal occurs due to several key factors. Rod sticking during. Welding Stick Keeps Sticking.

From www.reddit.com

Cold welder FR9700A r/Welding Welding Stick Keeps Sticking Welding rod sticking to the base metal occurs due to several key factors. A thick rod selection for welding thin sheets can also cause electrode sticking issues. Among all the reasons why your welding rod is sticking to the metal, the most common one would be low amperage values. Maintaining proper electrode angles when stick welding is one approach to. Welding Stick Keeps Sticking.