Steel Plate Surface Defects . Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The four classes of surface condition are: Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Have you ever wondered why some steel products have surface imperfections? The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,.

from www.mdpi.com

Have you ever wondered why some steel products have surface imperfections? Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The four classes of surface condition are: Second, we presented a detailed comparison of the key hardware of the surface defect detection system.

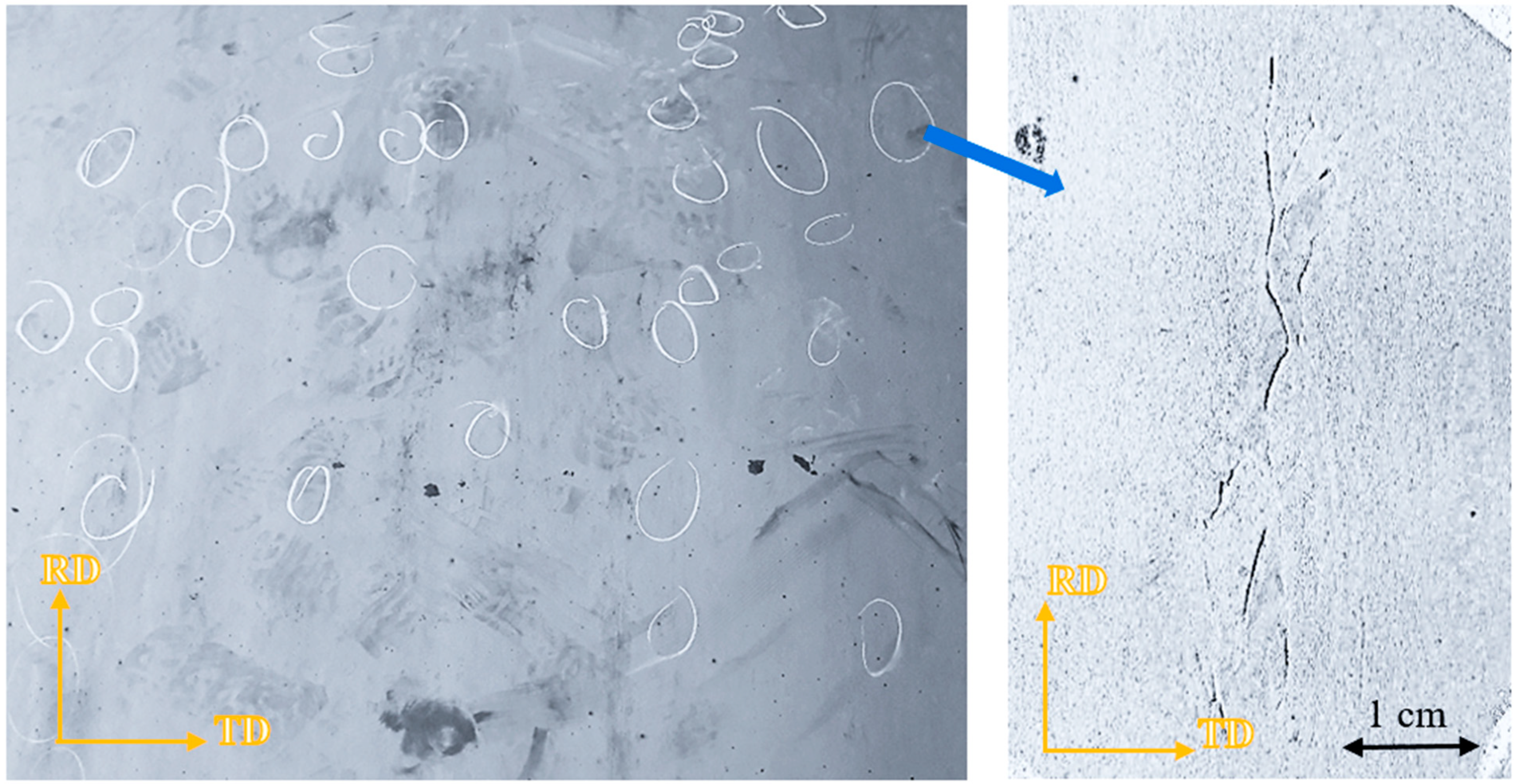

Metals Free FullText Root Cause Analysis of Surface Cracks in

Steel Plate Surface Defects Have you ever wondered why some steel products have surface imperfections? The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Second, we presented a detailed comparison of the key hardware of the surface defect detection system. The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The four classes of surface condition are: Have you ever wondered why some steel products have surface imperfections? First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories.

From www.steelwarehouse.com

Steelmaking Defects Steel Warehouse Steel Plate Surface Defects Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Have you ever wondered why some steel products have surface imperfections? The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. First, this paper summarized the difficulties of steel surface defect recognition, and then. Steel Plate Surface Defects.

From www.researchgate.net

Schematic diagram of steel plate defect recognition. Download Steel Plate Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. The surface defects of steel plate are characterized. Steel Plate Surface Defects.

From cherryamrit.blogspot.com

Steel Pipe Surface Defects CherryAmrit Steel Plate Surface Defects Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The dataset includes ten types. Steel Plate Surface Defects.

From mungfali.com

Metal Surface Defects Steel Plate Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? The dataset includes ten types of defects found on the surface of steel plates, including various punching. Steel Plate Surface Defects.

From www.kaggle.com

Metal Surface Defects Dataset Kaggle Steel Plate Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Class a. Steel Plate Surface Defects.

From www.researchgate.net

Four typical steel plate defects. (A) Pit defect, (B) Edge crack, (C Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. Second, we presented a detailed comparison of the key hardware of the surface defect detection system. The four classes of surface. Steel Plate Surface Defects.

From encyclopedia.pub

Defect Synthesis for Automated Visual Inspection Encyclopedia MDPI Steel Plate Surface Defects The four classes of surface condition are: Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Have you ever wondered why some steel products have surface imperfections? Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect. Steel Plate Surface Defects.

From www.semanticscholar.org

Figure 4 from Feature Extraction and Classification of Steel Plate Steel Plate Surface Defects Have you ever wondered why some steel products have surface imperfections? The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Second, we presented a detailed comparison of the key hardware of the surface defect detection. Steel Plate Surface Defects.

From www.semanticscholar.org

Figure 1 from Application of bandelet transform to surface defect Steel Plate Surface Defects The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The four classes of surface condition are: First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The surface defects of steel plate are characterized. Steel Plate Surface Defects.

From www.researchgate.net

Some samples of Metallic surface defects. (a) Crazing. (b) Inclusion Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? The four classes of surface condition are: Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy. Steel Plate Surface Defects.

From www.steelwarehouse.com

Hot Rolling Defects Steel Warehouse Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The surface defects of steel plate are characterized by multiple types, complex and irregular shapes,. Steel Plate Surface Defects.

From eziil.com

8 Welding Defects To Look Out For! (Detailed Images) Steel Plate Surface Defects Have you ever wondered why some steel products have surface imperfections? The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The four classes of surface condition are: Class a (plates) shallow. Steel Plate Surface Defects.

From www.steelwarehouse.com

Hot Rolling Defects Steel Warehouse Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. Second, we presented a detailed comparison of the key hardware of the surface defect detection system. The four classes of surface condition are: Common surface defects. Steel Plate Surface Defects.

From www.researchgate.net

Samples of six kinds of typical surface defects on NEU surface defect Steel Plate Surface Defects The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Common surface defects in steel include cracks, scratches, folds, ears,. Steel Plate Surface Defects.

From www.researchgate.net

Different types of steel plate surface defects Download Scientific Steel Plate Surface Defects Second, we presented a detailed comparison of the key hardware of the surface defect detection system. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. Have you ever wondered why some steel products have surface imperfections? Common surface defects in steel include cracks, scratches,. Steel Plate Surface Defects.

From www.researchgate.net

Various filtering effects for images of cracked steel plate surface Steel Plate Surface Defects The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Have you ever wondered why some steel products have surface imperfections? Class a (plates) shallow depth imperfections, other than cracks, shell and. Steel Plate Surface Defects.

From www.steelwarehouse.com

Hot Rolling Defects Steel Warehouse Steel Plate Surface Defects The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. Second, we presented a detailed comparison of the key hardware of the surface defect detection system. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect. Steel Plate Surface Defects.

From www.researchgate.net

Surface defects of steel plate. Download Scientific Diagram Steel Plate Surface Defects The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The four classes of surface condition are: First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. Have you ever wondered why some steel products. Steel Plate Surface Defects.

From www.steelwarehouse.com

Steelmaking Defects Steel Warehouse Steel Plate Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale. Steel Plate Surface Defects.

From www.researchgate.net

The pictures of surface defects in heavy and medium plate. Download Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. The four classes of surface condition are: Common surface defects in steel include cracks, scratches,. Steel Plate Surface Defects.

From www.mdpi.com

Symmetry Free FullText XSDD A New Benchmark for Hot Rolled Steel Steel Plate Surface Defects Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Have you ever wondered why some steel products have surface imperfections? First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. Second, we presented a detailed comparison. Steel Plate Surface Defects.

From www.mermecgroup.com

SurfaceCheck inspection system Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Second, we presented a detailed comparison of the key hardware of the surface defect detection system. The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The four classes of surface condition are: First, this paper. Steel Plate Surface Defects.

From www.researchgate.net

Various filtering effects for images of cracked steel plate surface Steel Plate Surface Defects First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have. Steel Plate Surface Defects.

From www.silcotek.com

Identify and Fix Common Stainless Steel Surface Defects Steel Plate Surface Defects Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Have you ever wondered why some steel products have surface imperfections? The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The four classes of surface condition are: Class a (plates) shallow depth imperfections,. Steel Plate Surface Defects.

From www.mdpi.com

Applied Sciences Free FullText Periodic Surface Defect Detection Steel Plate Surface Defects First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. The dataset includes ten types of defects found on the surface of steel plates, including various punching hole, weld line,. The. Steel Plate Surface Defects.

From www.mdpi.com

Applied Sciences Free FullText Surface Defect Detection of Rolled Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? Second, we presented a detailed comparison of the key hardware of the surface defect detection system. The four classes of surface condition are: The surface defects of steel plate are characterized by multiple types, complex. Steel Plate Surface Defects.

From www.steeldata.info

Macro Defects in Steel Steel Plate Surface Defects Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The surface defects of steel. Steel Plate Surface Defects.

From www.mdpi.com

Metals Free FullText Root Cause Analysis of Surface Cracks in Steel Plate Surface Defects The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The. Steel Plate Surface Defects.

From www.researchgate.net

Four typical steel plate defects. (A) Pit defect, (B) Edge crack, (C Steel Plate Surface Defects Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why some steel products have surface imperfections? Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Second, we presented a detailed comparison of the key hardware of the surface defect detection system. The. Steel Plate Surface Defects.

From www.researchgate.net

(PDF) Typical Engineering Steel Defects Steel Plate Surface Defects Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Have you ever wondered why some steel products have surface imperfections? The surface defects of steel plate are characterized by multiple types, complex and irregular shapes, large scale range, and high. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are. Steel Plate Surface Defects.

From www.steelwarehouse.com

Hot Rolling Defects Steel Warehouse Steel Plate Surface Defects First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. The four classes. Steel Plate Surface Defects.

From mungfali.com

Metal Surface Defects Steel Plate Surface Defects Have you ever wondered why some steel products have surface imperfections? Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. The dataset includes ten types of defects found on the surface of steel plates, including. Steel Plate Surface Defects.

From www.mdpi.com

Applied Sciences Free FullText Periodic Surface Defect Detection Steel Plate Surface Defects Second, we presented a detailed comparison of the key hardware of the surface defect detection system. The four classes of surface condition are: Common surface defects in steel include cracks, scratches, folds, ears, scabs (heavy skin), welding scars, and end burrs. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. Have you ever wondered why. Steel Plate Surface Defects.

From www.mdpi.com

Applied Sciences Free FullText An Improved MBLBP Defect Steel Plate Surface Defects Have you ever wondered why some steel products have surface imperfections? Second, we presented a detailed comparison of the key hardware of the surface defect detection system. Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel. Steel Plate Surface Defects.

From www.vrogue.co

Classification Of Defects In Steel Structures Downloa vrogue.co Steel Plate Surface Defects First, this paper summarized the difficulties of steel surface defect recognition, and then counted the surface types of steel and the corresponding surface defect categories. The four classes of surface condition are: Class a (plates) shallow depth imperfections, other than cracks, shell and seams, are acceptable;. The dataset includes ten types of defects found on the surface of steel plates,. Steel Plate Surface Defects.