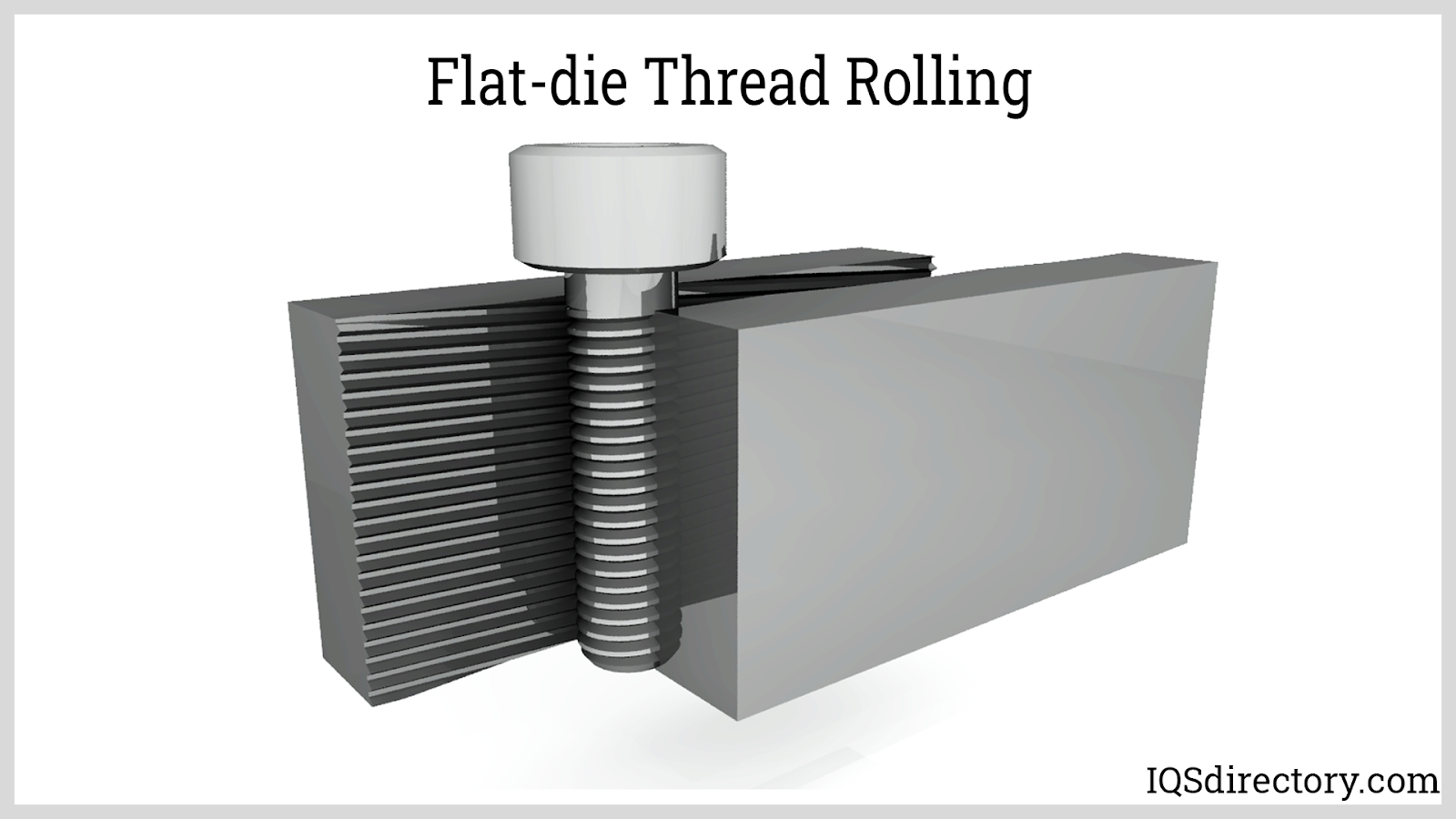

Thread Rolling Process . Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. At the core of thread rolling is the process of forming threads on a workpiece. The results and findings obtained from the parametric study should help to improve current understanding of how critical. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is not a metal cutting process. Rolling changes physical properties, hardening and. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part.

from www.iqsdirectory.com

As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Rolling changes physical properties, hardening and. At the core of thread rolling is the process of forming threads on a workpiece. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). The results and findings obtained from the parametric study should help to improve current understanding of how critical. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Thread rolling is not a metal cutting process.

Thread Rolling What Is It? How Does It Work? Process, Types

Thread Rolling Process Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. Rolling changes physical properties, hardening and. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. Thread rolling is not a metal cutting process. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). The results and findings obtained from the parametric study should help to improve current understanding of how critical. At the core of thread rolling is the process of forming threads on a workpiece. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process The results and findings obtained from the parametric study should help to improve current understanding of how critical. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to.. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. These threads serve as mating surfaces for threaded fasteners, allowing for. Thread Rolling Process.

From www.manufacturingguide.com

Thread Rolling Find suppliers, processes & material Thread Rolling Process Rolling changes physical properties, hardening and. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The results and findings obtained from the parametric study should help to improve current understanding of how critical. Thread rolling is a cold working process where a machined blank is compressed. Thread Rolling Process.

From www.evirtitalia.com

Thread Rolling Evirt Italia Thread Rolling Process Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. The results and findings obtained from the parametric study should help to improve current understanding of how critical. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. At the. Thread Rolling Process.

From thegatewaymag.com

Applying Pressure The Benefits of Thread Rolling The Gateway to New Thread Rolling Process Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is not. Thread Rolling Process.

From www.kinefac.com

Thread Rolling Process Thread Rolling Process Thread rolling is not a metal cutting process. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Rolling changes physical. Thread Rolling Process.

From www.andre-laurent.com

cold thread rolling process ANDRE LAURENT Thread Rolling Process The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). The results and findings obtained from the parametric study should help to improve current understanding of how critical. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into. Thread Rolling Process.

From brooksforgings.co.uk

Thread Rolling Gallery Brooks Thread Rolling Process Thread rolling is not a metal cutting process. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. As the blank cylinder is penetrated by the dies, the metal flows into the die. Thread Rolling Process.

From www.behance.net

Tesker Thread Rolling Process on Behance Thread Rolling Process As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is not a metal cutting process. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). At the core of thread rolling is the. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Thread rolling is not a metal cutting process. Rolling changes physical properties, hardening and. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts. Thread Rolling Process.

From superiorthread.com

Honing Superior Thread Rolling Company Thread Rolling Process Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. The results and findings obtained from the parametric study should help to improve current understanding of how critical. Thread rolling is a cold working process where a. Thread Rolling Process.

From mikehardware.com

Thread Rolling Process of Screws The Basics MIKEHARDWARE Thread Rolling Process Rolling changes physical properties, hardening and. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help. Thread Rolling Process.

From jbcmachine.com

Threading Services JBC Machine, Inc. Thread Rolling Process At the core of thread rolling is the process of forming threads on a workpiece. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Rolling changes physical properties, hardening and. Thread rolling is not a metal cutting process. The results and findings obtained from the. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Rolling changes physical properties, hardening and. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. Thread rolling is not a metal cutting process. In this “how it works”. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process At the core of thread rolling is the process of forming threads on a workpiece. The results and findings obtained from the parametric study should help to improve current understanding of how critical. Rolling changes physical properties, hardening and. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). As. Thread Rolling Process.

From horstengineering.com

Thread Rolling & Grinding Horst Engineering Thread Rolling Process Rolling changes physical properties, hardening and. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms. Thread Rolling Process.

From brooksforgings.co.uk

Thread Rolling Gallery Brooks Thread Rolling Process As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. The results and findings obtained from the parametric study should help to improve current understanding of how critical. Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Thread rolling is not a metal cutting process. Rolling changes physical properties, hardening and. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Rolling changes physical properties, hardening and. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. The threads are formed on the rod or wire. Thread Rolling Process.

From www.powertransmission.com

Precision Thread Rolling Process for HighAccuracy Lead Screws Thread Rolling Process The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). Rolling changes physical properties, hardening and. At the core of thread rolling is the process of forming threads on a workpiece. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers. Thread Rolling Process.

From www.evirtitalia.com

Thread Rolling Evirt Italia Thread Rolling Process These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part.. Thread Rolling Process.

From animalia-life.club

Rolling Process Animation Thread Rolling Process Rolling changes physical properties, hardening and. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. The results and findings obtained from the parametric study should help to improve current understanding of how critical. At the core of thread rolling is the process of forming threads on a workpiece. Thread rolling. Thread Rolling Process.

From www.slideserve.com

PPT ME 350 Lecture 21 Chapter 19 PowerPoint Presentation, free Thread Rolling Process Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. The results and findings obtained from the parametric study should help to improve current understanding of how critical. Rolling changes physical properties, hardening and. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process The results and findings obtained from the parametric study should help to improve current understanding of how critical. Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. Thread rolling is not a metal cutting process. Threads are. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. At the core of thread rolling is the process of forming threads on a workpiece. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Rolling changes physical properties, hardening and. At the core of thread rolling is the process of forming threads on a workpiece. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. The threads are. Thread Rolling Process.

From www.researchgate.net

Contact state between billet and dies in thread rolling process using Thread Rolling Process In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). Thread rolling is not a metal cutting process. At the core of thread rolling is the process. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. Thread rolling is not a metal cutting process. As the blank cylinder is penetrated by the dies, the metal flows into the die cavities and forms the thread profile into the part. The results and findings obtained from the parametric study should help. Thread Rolling Process.

From www.youtube.com

Tesker Thread Rolling Process YouTube Thread Rolling Process In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.).. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Thread rolling is not a metal cutting process. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. The results and findings obtained from the parametric study should help to improve current understanding of how critical. Rolling changes physical properties, hardening and. Thread rolling is a cold working process where a. Thread Rolling Process.

From www.rolledthreads.com

How Does the Thread Rolling Process Work? Thread Rolling Process Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. At the core of thread rolling is the process of forming threads on a workpiece. The results and findings obtained from the parametric study should help to improve current understanding of how critical. These. Thread Rolling Process.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Rolling Process Rolling changes physical properties, hardening and. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. Thread rolling is not a metal cutting process. In this “how it works” note, we explain the thread rolling process, its advantages, and how we help customers engineer their parts to. At the core of. Thread Rolling Process.

From www.mech4study.com

Rolling Process Types, Working, Terminology and Application mech4study Thread Rolling Process The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. These threads serve as mating surfaces for threaded fasteners, allowing for secure connections and assemblies in various mechanical applications. The results and findings. Thread Rolling Process.

From www.slideserve.com

PPT Bulk Deformation Processes in Metal Forming Chapter 19 Part 1 Thread Rolling Process Rolling changes physical properties, hardening and. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface. Thread rolling is a cold working process where a machined blank is compressed between rotating or reciprocating dies, whose thread profile is ground into the dies. As the blank cylinder is penetrated by the dies, the metal. Thread Rolling Process.

From prochain-cnc.com

4 common thread processing methods you must know PROCHAIN PRECISION Thread Rolling Process The threads are formed on the rod or wire with each stroke of a pair of flat reciprocating dies (fig.). Thread rolling is not a metal cutting process. At the core of thread rolling is the process of forming threads on a workpiece. Threads are helical ridges or grooves that wrap around the circumference of a cylindrical or conical surface.. Thread Rolling Process.