How To Flare Brass Tubing . Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Learn to flare soft metal tubing using a brasscraft flaring tool. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. In this quick tip, we take a look at how to flare tubing for an fittings. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. Flare connections work by creating a seal between the flare nut and the flare fitting. The copper tube must be cut square using. Once the nut is placed on the pipe, a special tool called a flaring tool is used. For more information about brasscraft products, please. The flare nut has a tapered bore that fits over the end of the pipe.

from exortvwux.blob.core.windows.net

Learn to flare soft metal tubing using a brasscraft flaring tool. The flare nut has a tapered bore that fits over the end of the pipe. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. The copper tube must be cut square using. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Flare connections work by creating a seal between the flare nut and the flare fitting. In this quick tip, we take a look at how to flare tubing for an fittings. Once the nut is placed on the pipe, a special tool called a flaring tool is used. For more information about brasscraft products, please. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared.

Flare Connection Gas Line at John Fulford blog

How To Flare Brass Tubing The copper tube must be cut square using. Once the nut is placed on the pipe, a special tool called a flaring tool is used. The flare nut has a tapered bore that fits over the end of the pipe. Learn to flare soft metal tubing using a brasscraft flaring tool. Flare connections work by creating a seal between the flare nut and the flare fitting. For more information about brasscraft products, please. In this quick tip, we take a look at how to flare tubing for an fittings. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. The copper tube must be cut square using. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared.

From www.finehomebuilding.com

Make a Flare Connection Fine Homebuilding How To Flare Brass Tubing The copper tube must be cut square using. Learn to flare soft metal tubing using a brasscraft flaring tool. The flare nut has a tapered bore that fits over the end of the pipe. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Once the nut is placed on the. How To Flare Brass Tubing.

From www.hioutlet.com

Union, 3/8inch Flared Brass Flare Fittings How To Flare Brass Tubing It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Learn to flare soft metal tubing using a brasscraft flaring tool. It's placed around the diameter of the pipe near the end in a hole appropriate to. How To Flare Brass Tubing.

From hvacrschool.com

Making a Flare Quick Tips HVAC School How To Flare Brass Tubing It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Once the nut is placed on the pipe,. How To Flare Brass Tubing.

From www.supercheapauto.com.au

How to Create a Tube Flare How To Flare Brass Tubing Flare connections work by creating a seal between the flare nut and the flare fitting. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. It's placed around the diameter of the pipe near the end in. How To Flare Brass Tubing.

From www.amazon.ca

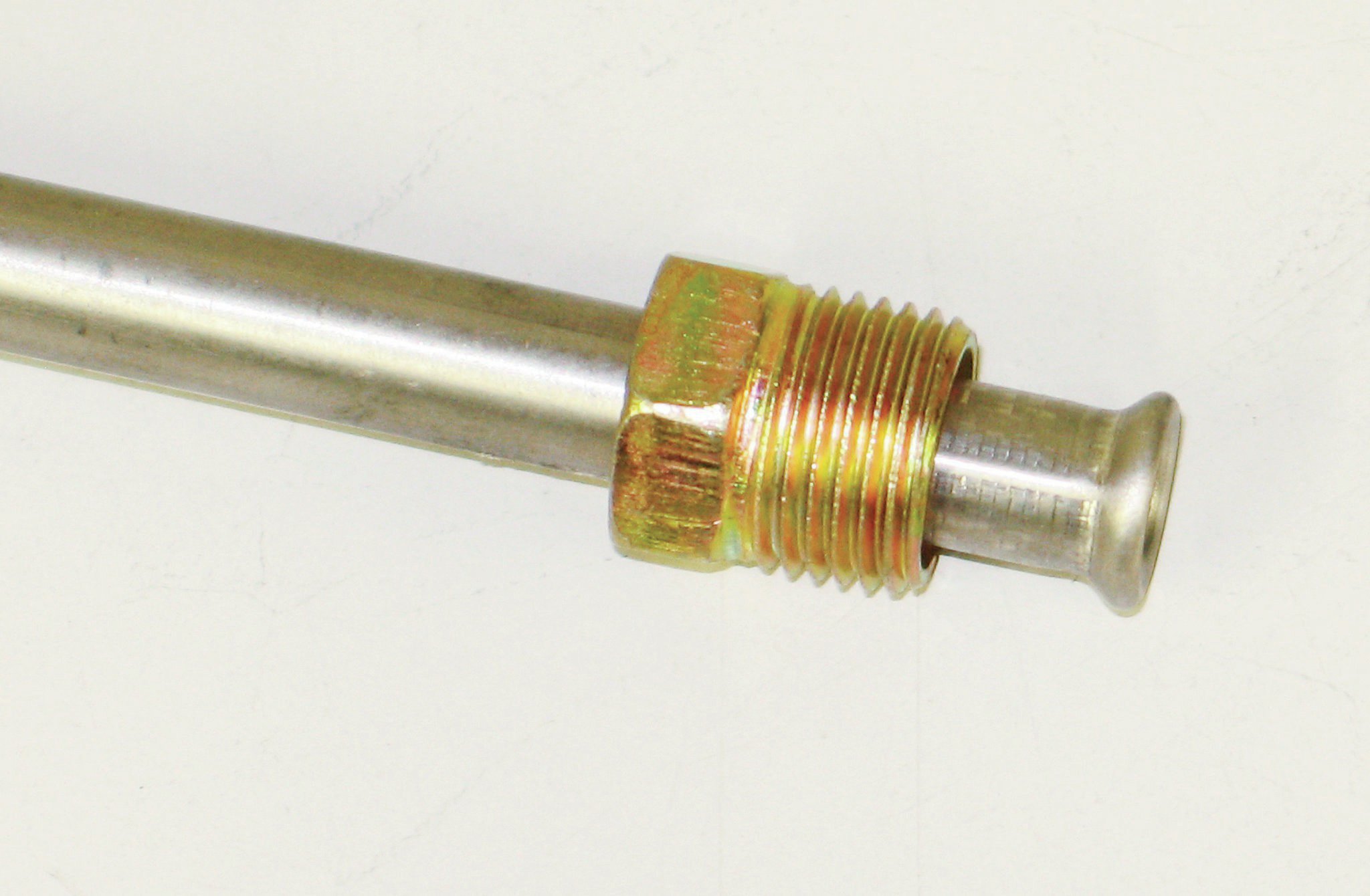

Generic Brass 3/8" OD Short SAE 45° Flare Nut ,Brass Flare Tube Fitting (Pack of 10? Amazon.ca How To Flare Brass Tubing The copper tube must be cut square using. Learn to flare soft metal tubing using a brasscraft flaring tool. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. It's placed around the diameter of the pipe. How To Flare Brass Tubing.

From www.homedepot.com

Everbilt 1/2 in. Flare Brass Coupling Fitting 801279 The Home Depot How To Flare Brass Tubing Flare connections work by creating a seal between the flare nut and the flare fitting. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. It is possible. How To Flare Brass Tubing.

From www.hvacrschool.com

Making a Flare Quick Tips HVAC School How To Flare Brass Tubing Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Once the nut is placed on the pipe, a special tool called a flaring tool is used. In this quick tip, we take a look at how to flare tubing for an fittings. Learn to flare soft metal tubing using a. How To Flare Brass Tubing.

From www.supercheapauto.com.au

How to Create a Tube Flare How To Flare Brass Tubing In this quick tip, we take a look at how to flare tubing for an fittings. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. Learn to flare soft metal tubing using a brasscraft flaring tool. Once the nut is placed on the pipe, a special. How To Flare Brass Tubing.

From hvacseer.com

How To Flare Copper Tubing [A Detailed Guide For Beginners] How To Flare Brass Tubing Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. The copper tube must be cut square using. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. Learn to flare soft metal tubing using a brasscraft flaring. How To Flare Brass Tubing.

From snapklik.com

Breezliy 3/8 Inch Male Flare X 1/2 Inch Male Flare Connector Gas Adapter Union How To Flare Brass Tubing The copper tube must be cut square using. The flare nut has a tapered bore that fits over the end of the pipe. Flare connections work by creating a seal between the flare nut and the flare fitting. In this quick tip, we take a look at how to flare tubing for an fittings. It is possible to flare types. How To Flare Brass Tubing.

From www.air-way.com

Flares for Tubing AirWay Manufacturing How To Flare Brass Tubing For more information about brasscraft products, please. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Once the nut is placed on the pipe, a special tool called a flaring tool is used. Flare connections work by creating a seal between the flare nut and the flare fitting. In this. How To Flare Brass Tubing.

From www.homedepot.com

Everbilt 1/4 in. Flare Brass Nut Fitting 801559 The Home Depot How To Flare Brass Tubing It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. The flare nut has a tapered bore that. How To Flare Brass Tubing.

From inthegaragemedia.com

Tubing Flares Made The Correct Way Simple Tips For Any DIYer How To Flare Brass Tubing Learn to flare soft metal tubing using a brasscraft flaring tool. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. The copper tube must be cut square using. Once the nut is placed on the pipe,. How To Flare Brass Tubing.

From www.plumbingsupply.com

How to Use a Pipe Flaring Tool How To Flare Brass Tubing The flare nut has a tapered bore that fits over the end of the pipe. The copper tube must be cut square using. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel. How To Flare Brass Tubing.

From exojdadff.blob.core.windows.net

Flared Pipe Fitting Sizes at Rosemarie Raposo blog How To Flare Brass Tubing For more information about brasscraft products, please. Learn to flare soft metal tubing using a brasscraft flaring tool. Flare connections work by creating a seal between the flare nut and the flare fitting. Once the nut is placed on the pipe, a special tool called a flaring tool is used. It's placed around the diameter of the pipe near the. How To Flare Brass Tubing.

From www.qualitysupplyandtool.com

Brass SAE Flare Tubing Connections, Adapter, 500 PSIG, CGA295 to 1/4 in NPT(M) How To Flare Brass Tubing For more information about brasscraft products, please. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Once the nut is placed on the pipe, a special tool called a flaring tool is used. In this quick tip, we take a look at how to flare tubing for an fittings. The. How To Flare Brass Tubing.

From www.walmart.com

Double and Single Flaring Tool Set Tube Flaring Tools Brass Tubing Tool for Air Conditioning How To Flare Brass Tubing For more information about brasscraft products, please. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. The flare nut has a tapered bore that fits over the end of the pipe. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for. How To Flare Brass Tubing.

From hvacseer.com

How To Flare Copper Tubing [A Detailed Guide For Beginners] How To Flare Brass Tubing The flare nut has a tapered bore that fits over the end of the pipe. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. For more information about brasscraft products, please. Flare connections work by creating a seal between the flare nut and the flare fitting.. How To Flare Brass Tubing.

From www.plumbingsupply.com

How to Use a Pipe Flaring Tool How To Flare Brass Tubing Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. The flare nut has a tapered bore that fits over the end of the pipe. In this quick tip, we take a look at how to flare tubing for an fittings. Learn to flare soft metal tubing using a brasscraft flaring. How To Flare Brass Tubing.

From www.amazon.ca

Anderson Metals Brass Tube Fitting, HalfUnion, 1/2" Flare x 1/2" Male Pipe Amazon.ca Tools How To Flare Brass Tubing Learn to flare soft metal tubing using a brasscraft flaring tool. The flare nut has a tapered bore that fits over the end of the pipe. For more information about brasscraft products, please. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. In this quick tip, we take a look. How To Flare Brass Tubing.

From hvacseer.com

How To Flare Copper Tubing [A Detailed Guide For Beginners] How To Flare Brass Tubing Once the nut is placed on the pipe, a special tool called a flaring tool is used. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Learn how to install a flare fitting onto copper, brass,. How To Flare Brass Tubing.

From www.walmart.com

Brass Pipe fitting, 1/4 SAE Flare Male to 1/4NPT Female Thread, Tubing Adapter, for Air How To Flare Brass Tubing Once the nut is placed on the pipe, a special tool called a flaring tool is used. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to. How To Flare Brass Tubing.

From support.celestialfireglass.com

How to Measure Gas Pipe Size for your Fire Pit How To Flare Brass Tubing Flare connections work by creating a seal between the flare nut and the flare fitting. Once the nut is placed on the pipe, a special tool called a flaring tool is used. Learn to flare soft metal tubing using a brasscraft flaring tool. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information. How To Flare Brass Tubing.

From www.jmesales.com

GasFlo Brass SAE 45° Flare 90° Elbow Flare to Male Pipe Elbow Fitting John M. Ellsworth Co How To Flare Brass Tubing It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Flare connections work by creating a seal between the flare nut and the flare fitting. Learn to flare soft metal tubing using a brasscraft flaring tool. The. How To Flare Brass Tubing.

From exortvwux.blob.core.windows.net

Flare Connection Gas Line at John Fulford blog How To Flare Brass Tubing Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. Flare connections work by creating a seal between the flare nut and the flare fitting. In this quick. How To Flare Brass Tubing.

From brass-fitting.en.made-in-china.com

SAE Standard Pipe 90 Elbow 45° Flare to Mptgas Flare Connector Brass Flare Tube Fitting China How To Flare Brass Tubing The copper tube must be cut square using. Once the nut is placed on the pipe, a special tool called a flaring tool is used. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. Learn to. How To Flare Brass Tubing.

From www.walmart.com

Brass Pipe fitting, 3/8 SAE Flare to 1/4NPT Male Thread, Tubing Adapter, for Air Conditioner How To Flare Brass Tubing It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. For more information about brasscraft products, please. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Once. How To Flare Brass Tubing.

From inthegaragemedia.com

Tubing Flares Made The Correct Way Simple Tips For Any DIYer How To Flare Brass Tubing In this quick tip, we take a look at how to flare tubing for an fittings. Once the nut is placed on the pipe, a special tool called a flaring tool is used. Flare connections work by creating a seal between the flare nut and the flare fitting. It is possible to flare types k, l or m rigid or. How To Flare Brass Tubing.

From www.qchydraulics.com

flare vs compression fittings QC Hydraulics How To Flare Brass Tubing The flare nut has a tapered bore that fits over the end of the pipe. In this quick tip, we take a look at how to flare tubing for an fittings. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the. How To Flare Brass Tubing.

From wintecheng.com.my

Flare Tube Connector & Insert Fittings Wintech Engineering Supply How To Flare Brass Tubing In this quick tip, we take a look at how to flare tubing for an fittings. The flare nut has a tapered bore that fits over the end of the pipe. It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the. How To Flare Brass Tubing.

From blog.thepipingmart.com

How to Bend Brass Tubing An Overview How To Flare Brass Tubing In this quick tip, we take a look at how to flare tubing for an fittings. Flare connections work by creating a seal between the flare nut and the flare fitting. Learn to flare soft metal tubing using a brasscraft flaring tool. The flare nut has a tapered bore that fits over the end of the pipe. It is possible. How To Flare Brass Tubing.

From www.supercheapauto.com.au

How to Create a Tube Flare How To Flare Brass Tubing In this quick tip, we take a look at how to flare tubing for an fittings. Flare connections work by creating a seal between the flare nut and the flare fitting. Learn to flare soft metal tubing using a brasscraft flaring tool. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about. How To Flare Brass Tubing.

From nbstandard.en.made-in-china.com

Brass Flare Brass Pipe Fitting China Pipe Fitting and Gas Fittings How To Flare Brass Tubing Flare connections work by creating a seal between the flare nut and the flare fitting. It's placed around the diameter of the pipe near the end in a hole appropriate to that size of pipe, with a flared. The copper tube must be cut square using. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel. How To Flare Brass Tubing.

From www.brass-tubefitting.com

3/8 Inch Flare X 3/8 Inch Flare Brass Tube Fitting Hex Nipple brass How To Flare Brass Tubing In this quick tip, we take a look at how to flare tubing for an fittings. Learn how to install a flare fitting onto copper, brass, aluminum or welded steel tubing.for more information about brasscraft. Learn to flare soft metal tubing using a brasscraft flaring tool. For more information about brasscraft products, please. Flare connections work by creating a seal. How To Flare Brass Tubing.

From klalammed.blob.core.windows.net

How To Make A Double Flare On Copper Tubing at William Fugate blog How To Flare Brass Tubing It is possible to flare types k, l or m rigid or hard temper tube, though prior to flaring it is usually necessary to anneal the end of the tube to be flared. In this quick tip, we take a look at how to flare tubing for an fittings. Learn how to install a flare fitting onto copper, brass, aluminum. How To Flare Brass Tubing.