Stabilizer Tower . A heat exchanger may be used before the tower or. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. The main component of a condensate stabilization unit is a distillation column or tower. Trays, structured packing, or random packing in. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter.

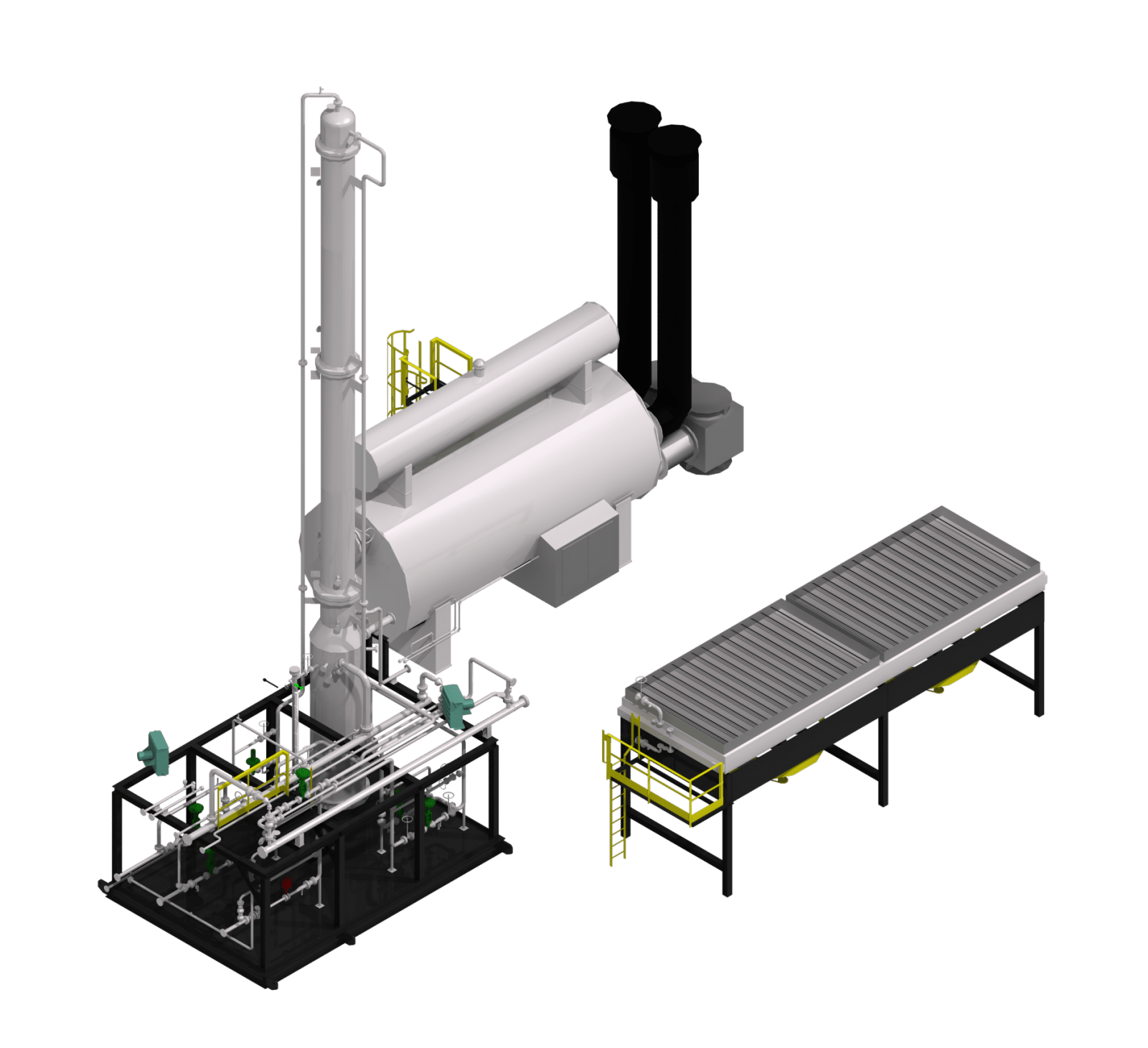

from 5blue.com

In general, a crude stabilizer should be designed to operate between 100 and 200 psig. A heat exchanger may be used before the tower or. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. Trays, structured packing, or random packing in. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The main component of a condensate stabilization unit is a distillation column or tower. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid.

Condensate Stabilizer Project 5Blue

Stabilizer Tower Trays, structured packing, or random packing in. Trays, structured packing, or random packing in. The main component of a condensate stabilization unit is a distillation column or tower. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. A heat exchanger may be used before the tower or. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter.

From www.powercellperformance.com

PowerCell Replacement Stabilizer Tower Kit PowerCell Performance Stabilizer Tower The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. The main component of a condensate stabilization unit is a distillation column or tower. In general, a crude stabilizer. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower The main component of a condensate stabilization unit is a distillation column or tower. A heat exchanger may be used before the tower or. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6.. Stabilizer Tower.

From www.protowermfg.com

Sector Frame Stabilizers Pro Tower Manufacturing Stabilizer Tower Trays, structured packing, or random packing in. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. A heat exchanger may be used before the tower or. In general,. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. The main component of a condensate stabilization unit is a distillation column or tower. The. Stabilizer Tower.

From www.linkedin.com

Sandeep V. Ramachandran, P.E. on LinkedIn pressurevessels stabilizer Stabilizer Tower The main component of a condensate stabilization unit is a distillation column or tower. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of. Stabilizer Tower.

From hollywooddj.com

ProX XTAC463X2 Pair of Vertical truss towers outrigger Leg Stabilizer Stabilizer Tower In general, a crude stabilizer should be designed to operate between 100 and 200 psig. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations.. Stabilizer Tower.

From www.freiheitaluminiumscaffolding.com

Mobile Scaffold Tower Mobile Scaffold Tower with Stabilizers Stabilizer Tower The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and. Stabilizer Tower.

From 5blue.com

Condensate Stabilizer Project 5Blue Stabilizer Tower The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. The main component of a condensate stabilization unit is a distillation column or tower. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. In general, a crude stabilizer should be designed to. Stabilizer Tower.

From musicredone.com

ProX XTAC463X2 Pair of Vertical Truss Towers Outrigger Leg Stabilizer Stabilizer Tower A heat exchanger may be used before the tower or. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. Trays, structured packing, or random packing in. As a leader in the midstream market for gas processing. Stabilizer Tower.

From inmasteel.com

Columns, Towers etc Inma Steel Stabilizer Tower The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. Condensate stabilization units are an important tool in making condensate from natural gas streams easier. Stabilizer Tower.

From 5blue.com

Condensate Stabilizer Project 5Blue Stabilizer Tower As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. Trays, structured packing, or random packing in. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. The purpose of the liquid product stabilizing system is to reduce the vapor. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. Trays, structured packing, or random packing in. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. Condensate stabilization units are an important tool in making condensate from natural. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. The purpose of the liquid product stabilizing system is. Stabilizer Tower.

From www.thermodesign.com

Case Studies Crude Stabilization Thermo Design Engineering TDE Stabilizer Tower The main component of a condensate stabilization unit is a distillation column or tower. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter.. Stabilizer Tower.

From deepsouthcrane.com

Refinery Tower Haul & Lift Refinery Combination Tower Transport Stabilizer Tower The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. Condensate stabilization units are an important tool in making condensate from natural gas streams. Stabilizer Tower.

From eu.duratruss.com

DT Rear Stabilizer PA Tower 1 Tower Produkte DuraTruss B.V. Stabilizer Tower The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. The main component. Stabilizer Tower.

From veqtoscaffolding.com

Mobile Tower With Stabilizers Stabilizer Tower Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. Trays, structured packing, or random packing in.. Stabilizer Tower.

From www.oilfieldlogic.com

Stabilizer, 2000 bpd Oilfield Logic Stabilizer Tower In general, a crude stabilizer should be designed to operate between 100 and 200 psig. The main component of a condensate stabilization unit is a distillation column or tower. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. Condensate stabilization units are an important. Stabilizer Tower.

From ekme.gr

AT A GLANCE EKME Stabilizer Tower Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous. Stabilizer Tower.

From www.piercemfg.com

4 Benefits of HStyle Aerial Stabilizers Stabilizer Tower A heat exchanger may be used before the tower or. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. Trays, structured packing, or random packing in. In general,. Stabilizer Tower.

From petrosaman.com

Fixed Equipment Stabilizer Tower Trays, structured packing, or random packing in. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6.. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. A heat exchanger may be used before the tower or. The purpose of the liquid product stabilizing system. Stabilizer Tower.

From www.amazon.co.uk

First 5 Stabilisers for DIY Aluminium Scaffold Tower (Tower NOT Stabilizer Tower Trays, structured packing, or random packing in. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. A heat exchanger may be used before the tower or. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. The stabilizer. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The main component of a condensate stabilization unit is a distillation column or tower.. Stabilizer Tower.

From en.wikipedia.org

Vertical stabilizer Wikipedia Stabilizer Tower A heat exchanger may be used before the tower or. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. Trays, structured packing, or random packing in. The purpose of the liquid product stabilizing system is to reduce the. Stabilizer Tower.

From acueexpress.com

Ground Support Tower Stabilizer Arm Acue Express Stabilizer Tower Trays, structured packing, or random packing in. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. A heat exchanger may be used before. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower In general, a crude stabilizer should be designed to operate between 100 and 200 psig. A heat exchanger may be used before the tower or. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower The main component of a condensate stabilization unit is a distillation column or tower. A heat exchanger may be used before the tower or. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. In general, a crude stabilizer should be designed to operate between 100 and 200 psig. As a leader in. Stabilizer Tower.

From shopbrp.com

BRP Bar Mounts, Stabilizer & Tower Kit CRF 250R Stabilizer Tower Trays, structured packing, or random packing in. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. The main component of a condensate stabilization unit is a distillation column or tower. As a. Stabilizer Tower.

From www.oilfieldlogic.com

Stabilizer, 2000 bpd Oilfield Logic Stabilizer Tower The main component of a condensate stabilization unit is a distillation column or tower. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. A heat exchanger may be. Stabilizer Tower.

From armouree.com

ARMOUREE CONDENSATE STABILIZER TOWER Stabilizer Tower The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. Trays, structured packing, or random packing in. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed. Stabilizer Tower.

From www.cableandwireshop.com

ROHN TA656 65G Tower Torque Arm Stabilizer Assembly fits 65G Stabilizer Tower Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. Trays, structured packing, or random packing in. The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. In general, a crude stabilizer should be designed to operate between 100 and 200 psig.. Stabilizer Tower.

From www.primuselectronics.com

VSTABILIZER TOWER KIT Primus Electronics Stabilizer Tower As a leader in the midstream market for gas processing facilities, saulsbury has successfully integrated and installed condensate stabilization systems of numerous sizes and configurations. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover. Stabilizer Tower.

From www.mrscaffold.com.au

3.4M Aluminium Mobile ScaffoldingSingle Width Mr Scaffold Stabilizer Tower The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. The stabilizer column is a fractionation tower using trays or packing, as shown in figure 2.6. The main component of a condensate stabilization unit is a distillation column or tower. A heat exchanger may be used before the tower. Stabilizer Tower.

From scafeastsydney.com.au

Stabilizers / Outriggers 2500mm (adjustable) for Mobile Scaffold Towers Stabilizer Tower The purpose of the liquid product stabilizing system is to reduce the vapor pressure of the hydrocarbon liquid by removing lighter. Condensate stabilization units are an important tool in making condensate from natural gas streams easier to manage. The size and design of a stabilization tower (or column) has a substantial impact on its ability to recover liquid. The main. Stabilizer Tower.