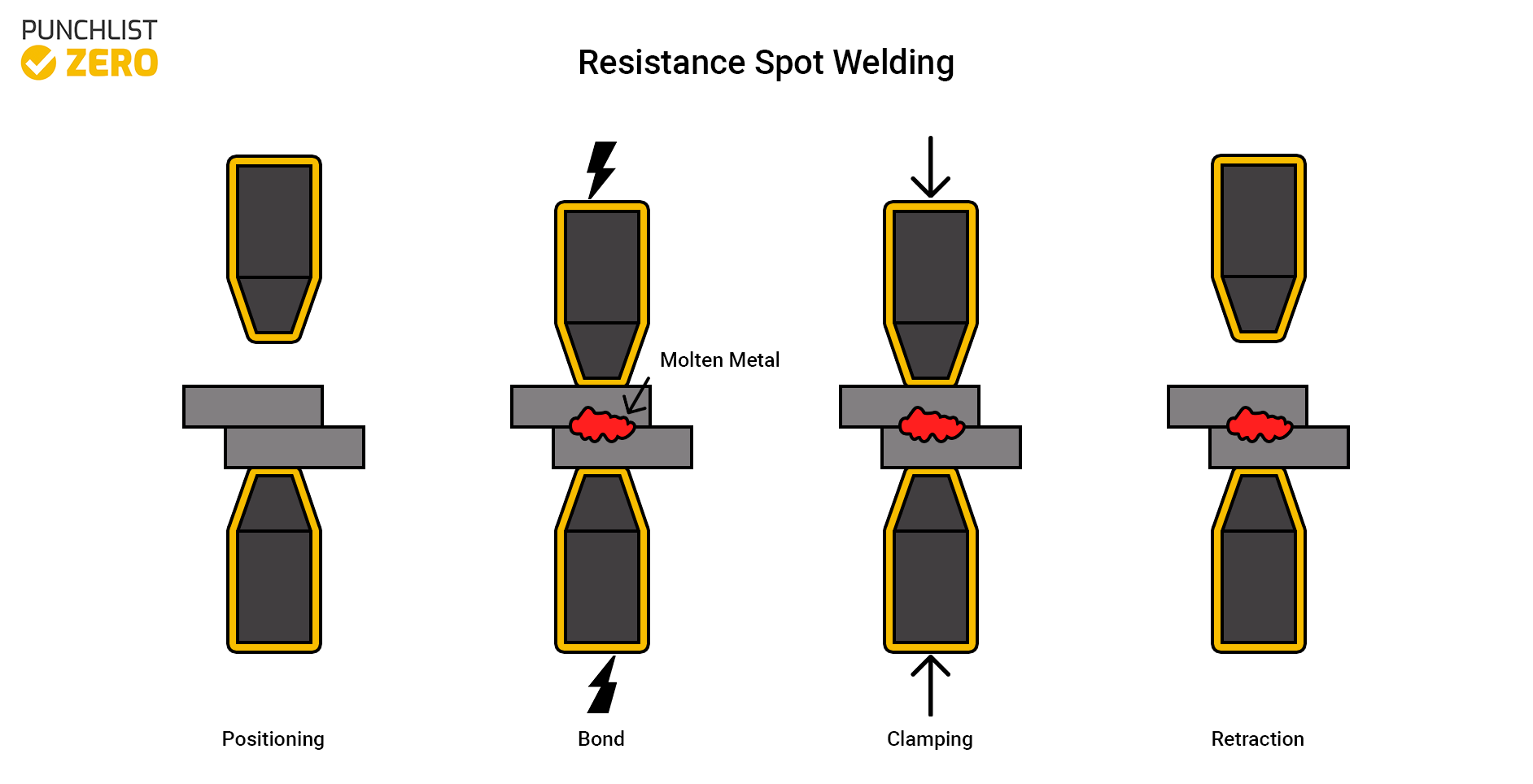

Spot Welding Thickness . At its most rudimentary level, spot. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. common problems and how to address them. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. Get expert tips and tricks from industry professionals for flawless. This welding process is used primarily for welding two or more metal sheets. spot welding (also known as resistance spot welding) is a resistance welding process. learn the best spot welding methods and techniques to create strong, precise bonds.

from punchlistzero.com

spot welding (also known as resistance spot welding) is a resistance welding process. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. common problems and how to address them. learn the best spot welding methods and techniques to create strong, precise bonds. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. Get expert tips and tricks from industry professionals for flawless. This welding process is used primarily for welding two or more metal sheets. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the.

Explaining Spot Welding Process How It Works

Spot Welding Thickness through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. Get expert tips and tricks from industry professionals for flawless. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. spot welding (also known as resistance spot welding) is a resistance welding process. common problems and how to address them. learn the best spot welding methods and techniques to create strong, precise bonds. At its most rudimentary level, spot. This welding process is used primarily for welding two or more metal sheets. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points.

From www.eng-tips.com

Maximum weld thickness Welding, Bonding & Fastener engineering EngTips Spot Welding Thickness This welding process is used primarily for welding two or more metal sheets. At its most rudimentary level, spot. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. learn the best spot welding methods. Spot Welding Thickness.

From www.protocase.com

Spot Welding for Your Custom Enclosure Spot Welding Thickness The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. learn the best spot welding methods and techniques to create strong, precise bonds. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. In summary, tables 1 and 2 provide the aws c1.1. Spot Welding Thickness.

From hogaki.com

Resistance Spot Welding Machine 230V/110V Welding Thickness 1.5+1.5mm Spot Welding Thickness when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. spot welding (also known as resistance spot welding) is a resistance welding process. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. Get expert tips and tricks from industry professionals for flawless. In summary,. Spot Welding Thickness.

From ahssinsights.org

Spot Welds Fatigue Strength AHSS Guidelines Spot Welding Thickness when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces. Spot Welding Thickness.

From marinerspointpro.com

Spot Welding Marinerspoint Pro Spot Welding Thickness This welding process is used primarily for welding two or more metal sheets. common problems and how to address them. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. learn the best spot welding methods and techniques to create strong, precise bonds. when spot welding thin. Spot Welding Thickness.

From blog.thepipingmart.com

How to Spot Weld with Sheet Metal A Complete Guide Spot Welding Thickness Get expert tips and tricks from industry professionals for flawless. spot welding (also known as resistance spot welding) is a resistance welding process. learn the best spot welding methods and techniques to create strong, precise bonds. At its most rudimentary level, spot. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to. Spot Welding Thickness.

From www.machinemfg.com

Spot Welding InDepth Guide & Techniques Revealed MachineMFG Spot Welding Thickness common problems and how to address them. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more. Spot Welding Thickness.

From www.howtoresistanceweld.info

What is the pitch between Arc and Spot welding? HowTo Resistance Weld Spot Welding Thickness common problems and how to address them. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the.. Spot Welding Thickness.

From spotweldinc.com

SetUp Guides Spot Weld, Inc. Spot Welding Thickness At its most rudimentary level, spot. Get expert tips and tricks from industry professionals for flawless. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. learn the best spot welding methods and techniques to. Spot Welding Thickness.

From www.thefabricator.com

Resistance spot welding and what to know about the technology Spot Welding Thickness This welding process is used primarily for welding two or more metal sheets. common problems and how to address them. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. At its most rudimentary level, spot. In summary, tables 1 and 2 provide the. Spot Welding Thickness.

From fractory.com

Spot Welding Explained Fractory Spot Welding Thickness the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. common problems and how to address them. This welding process is used primarily for welding two or more metal sheets. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. spot welding. Spot Welding Thickness.

From www.lowcostwelder.com

Spot welding parameters setting optimal values for spotwelding Spot Welding Thickness At its most rudimentary level, spot. Get expert tips and tricks from industry professionals for flawless. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of. Spot Welding Thickness.

From blog.thepipingmart.com

Spot Welding vs Tack Welding What's the Difference Spot Welding Thickness learn the best spot welding methods and techniques to create strong, precise bonds. This welding process is used primarily for welding two or more metal sheets. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance. Spot Welding Thickness.

From www.pngitem.com

Laser Spot Welding Different Thickness, HD Png Download , Transparent Spot Welding Thickness In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. common problems and how to address them. Get expert tips and tricks from industry professionals for flawless. learn the best spot welding methods and techniques to. Spot Welding Thickness.

From www.youtube.com

Basic Spot Welding YouTube Spot Welding Thickness when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. This welding process is used primarily for welding two or more metal sheets. the depth of depression on the sheet surfaces caused by welding electrodes. Spot Welding Thickness.

From hogaki.com

Resistance Spot Welding Machine 230V/110V Welding Thickness 1.5+1.5mm Spot Welding Thickness The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. Get expert tips and tricks from industry professionals for flawless. spot welding (also known as resistance spot welding) is a resistance welding process. At its most rudimentary level, spot. learn the best spot welding methods and techniques to create strong, precise bonds.. Spot Welding Thickness.

From www.researchgate.net

Schematic of setup for (a) resistance spot welding and (b) peel test Spot Welding Thickness Get expert tips and tricks from industry professionals for flawless. At its most rudimentary level, spot. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. spot welding (also known as resistance spot welding) is a resistance welding process. learn the best spot welding methods and techniques to. Spot Welding Thickness.

From www.amazon.com

Resistance Spot Welding Machine Welding Thickness 1.5+1.5mm Steel Plat Spot Welding Thickness through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. Get expert tips. Spot Welding Thickness.

From www.eng-tips.com

Maximum weld thickness Welding, Bonding & Fastener engineering EngTips Spot Welding Thickness spot welding (also known as resistance spot welding) is a resistance welding process. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. This welding process is used. Spot Welding Thickness.

From punchlistzero.com

Explaining Spot Welding Process How It Works Spot Welding Thickness spot welding (also known as resistance spot welding) is a resistance welding process. learn the best spot welding methods and techniques to create strong, precise bonds. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines. Spot Welding Thickness.

From exyyaidzo.blob.core.windows.net

Resistance Welding Parameters at Donita Zook blog Spot Welding Thickness The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. spot welding (also known as resistance spot welding) is a resistance welding process. At its most rudimentary level, spot. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. the depth of depression on. Spot Welding Thickness.

From blog.thepipingmart.com

How to Spot Weld Sheet Metal? Spot Welding Thickness The welding process is particularly used in industries such as automotive manufacturing, electronics, and appliance production. Get expert tips and tricks from industry professionals for flawless. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines. Spot Welding Thickness.

From academy.ampcometal.com

The advantages of spot welding Spot Welding Thickness This welding process is used primarily for welding two or more metal sheets. learn the best spot welding methods and techniques to create strong, precise bonds. Get expert tips and tricks from industry professionals for flawless. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. through the. Spot Welding Thickness.

From www.mdpi.com

Metals Free FullText Resistance Spot Welding of Aluminum Alloy and Spot Welding Thickness Get expert tips and tricks from industry professionals for flawless. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. learn the best spot welding methods and techniques to create strong, precise bonds. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more. Spot Welding Thickness.

From www.pinterest.fr

Spot, Seam, Stud Welding Symbols Interpretation of Metal Fab Drawings Spot Welding Thickness At its most rudimentary level, spot. This welding process is used primarily for welding two or more metal sheets. Get expert tips and tricks from industry professionals for flawless. spot welding (also known as resistance spot welding) is a resistance welding process. learn the best spot welding methods and techniques to create strong, precise bonds. through the. Spot Welding Thickness.

From www.researchgate.net

Conventional solid spot welding electrodes used in the study Spot Welding Thickness learn the best spot welding methods and techniques to create strong, precise bonds. spot welding (also known as resistance spot welding) is a resistance welding process. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. the depth of depression on the sheet surfaces caused by welding electrodes should. Spot Welding Thickness.

From blog.thepipingmart.com

How to SpotWeld Copper A StepByStep Guide Spot Welding Thickness learn the best spot welding methods and techniques to create strong, precise bonds. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. This welding process is used primarily for welding two or more metal sheets. spot welding (also known as resistance spot welding) is a resistance welding process. At its most. Spot Welding Thickness.

From www.howtoresistanceweld.info

What is the formula to calculate nugget diameter in resistance welding Spot Welding Thickness At its most rudimentary level, spot. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. Get expert tips and tricks from industry professionals for flawless. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. spot welding (also known as resistance spot. Spot Welding Thickness.

From rime.de

Spot welding process description and application Spot Welding Thickness This welding process is used primarily for welding two or more metal sheets. common problems and how to address them. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5 to 1.0 mm. through the precise application. Spot Welding Thickness.

From ahssinsights.org

Spot Weld Strength Improvement by PWHT AHSS Guidelines Spot Welding Thickness common problems and how to address them. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. Get expert tips and tricks from industry professionals for flawless. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. . Spot Welding Thickness.

From www.mechstudies.com

Spot Welding How to Spot Welding? Types, Process, Stages www Spot Welding Thickness common problems and how to address them. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. when spot welding thin plate structural parts, the assembly gap. Spot Welding Thickness.

From www.eng-tips.com

Maximum weld thickness Welding, Bonding & Fastener engineering EngTips Spot Welding Thickness In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. At its most rudimentary level, spot. This welding process is used primarily for welding two or more metal sheets. Get expert tips and tricks from industry professionals for flawless. when spot welding thin plate structural parts, the assembly gap should not exceed 0.5. Spot Welding Thickness.

From www.youtube.com

Seam Welding Steel Sheets (Roll Spot and AC Seam Welds) YouTube Spot Welding Thickness learn the best spot welding methods and techniques to create strong, precise bonds. the depth of depression on the sheet surfaces caused by welding electrodes should never exceed 25 percent of the. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. Get. Spot Welding Thickness.

From www.canadianmetalworking.com

The pros and cons of spot welding vs.clinching Spot Welding Thickness In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. This welding process is used primarily for welding two or more metal sheets. spot welding (also known as resistance spot welding) is a resistance welding process. common problems and how to address them. the depth of depression on the sheet surfaces. Spot Welding Thickness.

From app.aws.org

MIG settings for welding different thickness mild steel Spot Welding Thickness In summary, tables 1 and 2 provide the aws c1.1 spot welding parameter guidelines link to. spot welding (also known as resistance spot welding) is a resistance welding process. through the precise application of heat and pressure, resistance spot welding creates localized welds, by bonding two or more metal pieces at specific points. when spot welding thin. Spot Welding Thickness.