Zinc Plating Operating Temperature . Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Of a chloride zinc bath. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process.

from www.mdpi.com

Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. This article describes the steps involved in the zinc electroplating process. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Of a chloride zinc bath. Its salt concentration is low so the. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current.

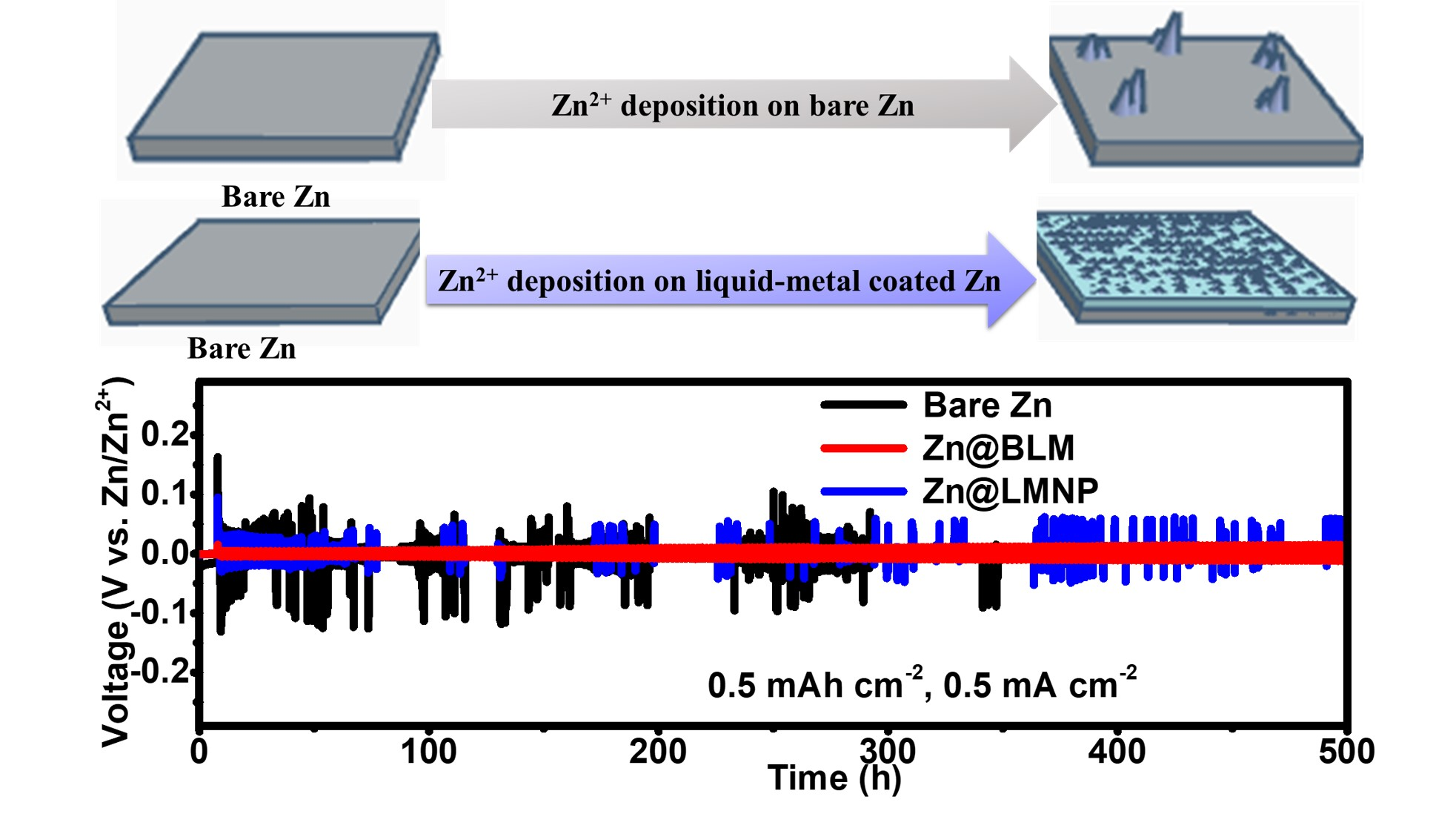

Batteries Free FullText RoomTemperature LiquidMetal Coated Zn

Zinc Plating Operating Temperature Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Of a chloride zinc bath. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process.

From www.slideserve.com

PPT Decoding the Diversity of Zinc Plating Types of Zinc Plating Zinc Plating Operating Temperature Of a chloride zinc bath. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome.. Zinc Plating Operating Temperature.

From www.frost.co.uk

Zinc Post Plating Solution for Cadmium Zinc Plating (5 Litres) Zinc Plating Operating Temperature Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. This article describes the steps involved in the zinc electroplating process. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation. Zinc Plating Operating Temperature.

From www.guganengg.com

Alkaline Zinc plating Guganengg The Leading Manufacturer Zinc Plating Operating Temperature The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Of a chloride zinc bath. This article describes the steps involved in the zinc electroplating process. Its salt concentration is low so the. Zinc electroplating. Zinc Plating Operating Temperature.

From benchmarkinstitute.org

difference between zinc and nickel plating Cheaper Than Retail Price Zinc Plating Operating Temperature Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Employing galvanic zinc plating under constant voltage. Zinc Plating Operating Temperature.

From socratic.org

Can you describe the process that releases electrons in a zinc copper Zinc Plating Operating Temperature Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process. Plating efficiency of cyanide. Zinc Plating Operating Temperature.

From mechanicalfinishersinc.blogspot.com

The Different Steps Involved In The Zinc Plating Process Zinc Plating Operating Temperature Of a chloride zinc bath. This article describes the steps involved in the zinc electroplating process. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Its salt concentration is low so the. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Zinc. Zinc Plating Operating Temperature.

From twbfinishing.co.uk

Zinc Plating TWB Finishing Zinc Plating Operating Temperature Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. This article describes the steps involved in the zinc electroplating process. Its salt concentration is low so the. The process uses. Zinc Plating Operating Temperature.

From www.sarcoatings.com

Zinc Plating Zinc Plating Service Sar Coatings Zinc Plating Operating Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Its salt concentration is low so the. Of a chloride zinc bath. This article describes the steps involved in the zinc electroplating process. Employing galvanic. Zinc Plating Operating Temperature.

From finishingandcoating.com

High Current Density on Electroplating Smooth Alkaline Zinc Coating Zinc Plating Operating Temperature Of a chloride zinc bath. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. This article describes the steps involved in the zinc electroplating process. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Its salt concentration is low. Zinc Plating Operating Temperature.

From www.advatechplating.co.uk

Zinc Plating Service Advatech Ltd, Thetford, Norfolk Zinc Plating Operating Temperature Its salt concentration is low so the. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Temperature — the temperature of the plating bath will also have a direct impact on the. Zinc Plating Operating Temperature.

From elmplating.com

ZINC BARREL PLATING Elm Plating Company Zinc Plating Operating Temperature Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Of a chloride zinc. Zinc Plating Operating Temperature.

From www.youtube.com

Tank zincplating tutorial how to zincplate mechanical components Zinc Plating Operating Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Of a chloride zinc bath. Its salt concentration is low so the. The process uses a mixed salt bath comprising of. Zinc Plating Operating Temperature.

From www.youtube.com

Alkaline Zinc Plating (Noncyanide) II Electroplating Process II🔥 Zinc Plating Operating Temperature Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Its salt concentration is low so the. Zinc electroplating is the most commonly used process for coating metals in order to. Zinc Plating Operating Temperature.

From www.slideserve.com

PPT Decoding the Diversity of Zinc Plating Types of Zinc Plating Zinc Plating Operating Temperature Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Its salt concentration is low so the. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature. Zinc Plating Operating Temperature.

From www.deepakfasteners.com

Deepak Fasteners Limited Zinc Electroplating Zinc Plating Operating Temperature Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process. Of a chloride zinc bath. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and. Zinc Plating Operating Temperature.

From mantavya.com

What Is Electroplating & How does it work 2021 Guide Mantavya Zinc Plating Operating Temperature Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Employing galvanic zinc plating. Zinc Plating Operating Temperature.

From sharp-industries.in

Zinc Electroplating Sharp Industries Zinc Plating Operating Temperature Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Its salt concentration is low so the. Of a chloride zinc bath. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Temperature — the temperature of the plating bath will also. Zinc Plating Operating Temperature.

From proper-cooking.info

Zinc Plating Zinc Plating Operating Temperature This article describes the steps involved in the zinc electroplating process. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Its salt concentration is low so the. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Plating efficiency of cyanide. Zinc Plating Operating Temperature.

From blog.thepipingmart.com

Zinc Plating vs Anodizing What’s the Difference Zinc Plating Operating Temperature Its salt concentration is low so the. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Of a chloride zinc bath. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation. Zinc Plating Operating Temperature.

From www.mdpi.com

Coatings Free FullText Effects of Organic Additives on Alkaline Zinc Plating Operating Temperature Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. This article describes the steps involved in the zinc electroplating process. Of a chloride zinc bath. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Employing galvanic zinc plating under constant voltage. Zinc Plating Operating Temperature.

From blog.thepipingmart.com

Can You Zinc Plate Stainless Steel? Zinc Plating Operating Temperature Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. This article describes the steps involved in the zinc electroplating process. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry,. Zinc Plating Operating Temperature.

From www.mdpi.com

Batteries Free FullText RoomTemperature LiquidMetal Coated Zn Zinc Plating Operating Temperature This article describes the steps involved in the zinc electroplating process. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Its salt concentration is low so the. Of a chloride zinc bath. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Zinc electroplating. Zinc Plating Operating Temperature.

From www.slideserve.com

PPT The Different Steps Involved In The Zinc Plating Process Zinc Plating Operating Temperature Its salt concentration is low so the. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Of a chloride zinc bath. This article describes the steps involved in the zinc electroplating process.. Zinc Plating Operating Temperature.

From vietnamese.electroplatingchemistry.com

JC9 Zinc Electroplating Chemicals Carrier High Temperature Tolerance Zinc Plating Operating Temperature Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Of a chloride zinc bath.. Zinc Plating Operating Temperature.

From proper-cooking.info

Zinc Plating Zinc Plating Operating Temperature Its salt concentration is low so the. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Of a chloride zinc bath. Zinc electroplating is the most commonly used process for coating metals in order. Zinc Plating Operating Temperature.

From www.researchgate.net

Effect of temperature on the recovery of zinc from zinc concentrate Zinc Plating Operating Temperature Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Of a chloride zinc bath. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Employing galvanic. Zinc Plating Operating Temperature.

From www.researchgate.net

(PDF) Solvation Structure and Interfacial Regulation for Extremely Zinc Plating Operating Temperature Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. This article describes the steps involved in the zinc electroplating process. Its salt concentration is low so the. Of a chloride zinc bath. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome.. Zinc Plating Operating Temperature.

From blog.thepipingmart.com

Zinc Plating vs Black Oxide What's the Difference Zinc Plating Operating Temperature Its salt concentration is low so the. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between. Zinc Plating Operating Temperature.

From www.machinedesign.com

What Engineers Should Know about ZincNickel Coatings Machine Design Zinc Plating Operating Temperature Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Its salt concentration is low so the. This article describes the steps involved in the zinc electroplating process. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. Employing galvanic zinc plating under. Zinc Plating Operating Temperature.

From www.mdpi.com

Metals Free FullText Rapid Electrodeposition and Corrosion Zinc Plating Operating Temperature This article describes the steps involved in the zinc electroplating process. Of a chloride zinc bath. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Zinc electroplating is the most commonly used process for coating metals in order to provide protection against corrosion. Plating efficiency of cyanide zinc baths varies. Zinc Plating Operating Temperature.

From pvl.co.uk

Zinc Plating vs. Zinc Flake Coating What’s the Difference? PVL Zinc Plating Operating Temperature This article describes the steps involved in the zinc electroplating process. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Zinc electroplating is the most commonly used process for coating metals in order. Zinc Plating Operating Temperature.

From www.pinterest.com

Sintered NdFeB Axially Ring N40M Zinc Plating Zinc Plating Operating Temperature Of a chloride zinc bath. Its salt concentration is low so the. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Plating efficiency of cyanide zinc baths varies greatly depending. Zinc Plating Operating Temperature.

From www.sarcoatings.com

Understand the Electroplating with Zinc Plating Barrels Zinc Plating Operating Temperature Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Temperature — the temperature of the plating bath will also have a direct impact on the zinc plating outcome. The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. This article describes the steps. Zinc Plating Operating Temperature.

From blog.thepipingmart.com

Advantages and Disadvantages of Zinc Plating Zinc Plating Operating Temperature The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Its salt concentration is low so the. Employing galvanic zinc plating under constant voltage with varying plating durations unveiled a correlation between coating thickness and electrolyte composition. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the. Zinc Plating Operating Temperature.

From sendcutsend.com

Zinc Plating vs Powder Coating for Corrosion Resistance SendCutSend Zinc Plating Operating Temperature The process uses a mixed salt bath comprising of sodium or potassium chloride and ammonium chloride. Of a chloride zinc bath. Its salt concentration is low so the. Plating efficiency of cyanide zinc baths varies greatly depending on the bath chemistry, plating temperature and the plating current. This article describes the steps involved in the zinc electroplating process. Zinc electroplating. Zinc Plating Operating Temperature.