End Milling Process Geometry . This is in contrast to end mills which. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. It is used to cut or shape materials using a. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. This paper presents a generalized mathematical model of most helical end mills used in industry. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. Drills are equipped with sharp ends that are meant to make the hole creation process easier.

from www.hobby-machinist.com

This is in contrast to end mills which. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. This paper presents a generalized mathematical model of most helical end mills used in industry. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. It is used to cut or shape materials using a. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. Drills are equipped with sharp ends that are meant to make the hole creation process easier.

What end mill for brass? Copper? Page 2 The HobbyMachinist

End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. This paper presents a generalized mathematical model of most helical end mills used in industry. Drills are equipped with sharp ends that are meant to make the hole creation process easier. It is used to cut or shape materials using a. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. This is in contrast to end mills which. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope.

From www.researchgate.net

Main parameters of the endmilling process. (a) Top view, (b) front End Milling Process Geometry This paper presents a generalized mathematical model of most helical end mills used in industry. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. In milling process, reduction in cutting forces and having stable cutting condition,. End Milling Process Geometry.

From www.transtutors.com

(Solved) Question 1 By using a labelled diagram describe the function End Milling Process Geometry It is used to cut or shape materials using a. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. This is in contrast to end mills which. Drills are equipped with sharp ends that are meant to make the hole creation process easier. This paper presents a generalized mathematical model of. End Milling Process Geometry.

From www.researchgate.net

Schematic of cutting edges and process geometry in flatend milling End Milling Process Geometry The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. Ordinary end mills are “right cutting edge” and “left cutting edge” are very. End Milling Process Geometry.

From www.researchgate.net

Endmilling cutter geometry and coordinate system a schematic of an End Milling Process Geometry This is in contrast to end mills which. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. Drills are equipped with sharp. End Milling Process Geometry.

From www.researchgate.net

Ballend milling process geometry — step over... Download Scientific End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. It is used to cut or shape materials using a. This paper presents a generalized mathematical model of most helical end mills used in industry. This is in contrast to. End Milling Process Geometry.

From www.researchgate.net

Ballend milling process geometry — step over... Download Scientific End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. This paper presents a generalized mathematical model of. End Milling Process Geometry.

From www.mmc-carbide.com

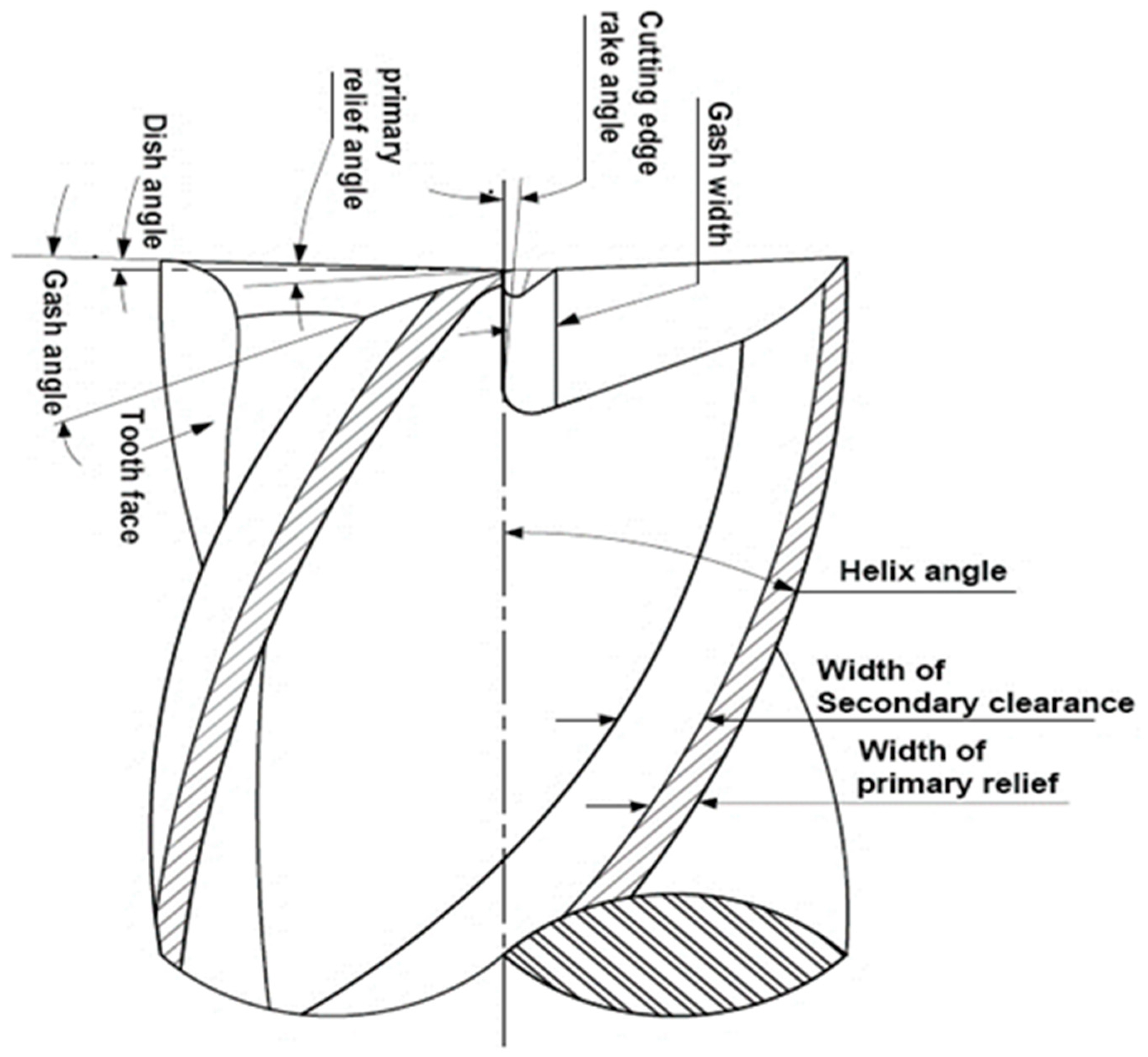

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI End Milling Process Geometry This is in contrast to end mills which. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. In milling process, reduction in cutting. End Milling Process Geometry.

From www.researchgate.net

Ballend milling process geometry — step over... Download Scientific End Milling Process Geometry The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. This paper presents a generalized mathematical model of most helical end mills used. End Milling Process Geometry.

From www.researchgate.net

Geometry and processing of flatend mill. Download Scientific Diagram End Milling Process Geometry Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. This is in contrast to end mills which. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. It is used to cut or. End Milling Process Geometry.

From www.redlinetools.com

Endmill Selection Guide RedLine Tools Redline Tools End Milling Process Geometry In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. Drills are equipped with sharp ends that are meant to make the hole creation process easier. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. This is in contrast to end mills which.. End Milling Process Geometry.

From www.researchgate.net

Ballend milling tool geometry. Download Scientific Diagram End Milling Process Geometry Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. This is in contrast to end mills which. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. End milling. End Milling Process Geometry.

From www.researchgate.net

The description of the geometry in end milling process. a Side view. b End Milling Process Geometry This is in contrast to end mills which. It is used to cut or shape materials using a. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. This paper presents a generalized mathematical model of most helical end mills used in industry. End milling is a machining process used in metalworking, woodworking, and other material. End Milling Process Geometry.

From www.researchgate.net

Coordinate system and endmilling geometry. Download Scientific Diagram End Milling Process Geometry Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. This is in contrast to end mills which. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. It. End Milling Process Geometry.

From toolnotes.com

End Mills ToolNotes End Milling Process Geometry This paper presents a generalized mathematical model of most helical end mills used in industry. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. It is used to cut or shape materials using a. Drills are equipped with sharp ends that are meant to make the hole creation process easier. In milling process, reduction in. End Milling Process Geometry.

From toolnotes.com

End Mills ToolNotes End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. This is in contrast to end mills which. It is used to cut or shape materials using a. This paper presents a generalized mathematical model of most helical end mills used in industry. In milling process, reduction in cutting forces and having stable cutting. End Milling Process Geometry.

From www.researchgate.net

General tool geometry and surfaces of the various end mills. a General... End Milling Process Geometry End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. It is used to cut or shape materials using a. This paper presents a generalized mathematical model of most helical end mills used in industry. In milling process, reduction in cutting. End Milling Process Geometry.

From www.slideserve.com

PPT Milling Machines PowerPoint Presentation, free download ID9714434 End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. This paper presents a generalized mathematical model of most helical end mills used in industry. End milling is a machining process used in metalworking, woodworking, and. End Milling Process Geometry.

From www.researchgate.net

Ball end milling cutter geometry. 16 Download Scientific Diagram End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. It is used to cut or shape materials using a. In milling process, reduction in cutting. End Milling Process Geometry.

From www.researchgate.net

(PDF) Cutting force prediction for circular end milling process End Milling Process Geometry It is used to cut or shape materials using a. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. Drills are equipped with sharp ends that are meant to make the hole creation process easier. This paper presents a generalized mathematical model of most helical end mills used in industry. End. End Milling Process Geometry.

From www.researchgate.net

(PDF) Cutting force prediction for circular end milling process End Milling Process Geometry The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. Drills are equipped with sharp ends that are meant to make the hole creation process easier. This is in contrast to end mills which. In milling process, reduction in cutting forces and. End Milling Process Geometry.

From www.canadianmetalworking.com

End mill geometry boosts trochoidal milling Canadian Metalworking End Milling Process Geometry Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. This paper presents a generalized mathematical model of most helical end mills used in industry. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. Currently, there. End Milling Process Geometry.

From www.researchgate.net

Ballend milling tool geometry. Download Scientific Diagram End Milling Process Geometry In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. Drills are equipped with sharp ends that are meant to make the hole creation process easier. End milling is a machining process used in. End Milling Process Geometry.

From www.researchgate.net

The description of the geometry in end milling process. a Side view. b End Milling Process Geometry Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. It is used to cut or shape materials using a. Drills are equipped with sharp ends that are meant to make the hole creation process easier. Ordinary. End Milling Process Geometry.

From www.hobby-machinist.com

What end mill for brass? Copper? Page 2 The HobbyMachinist End Milling Process Geometry In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. Drills are equipped with sharp ends that are meant. End Milling Process Geometry.

From www.researchgate.net

The description of the geometry in end milling process. a Side view. b End Milling Process Geometry End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. Drills are equipped with sharp ends that are meant to make the hole creation process easier. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. The end mill geometry is modeled by helical flutes wrapped around. End Milling Process Geometry.

From www.researchgate.net

Ballend milling process geometry — step over... Download Scientific End Milling Process Geometry Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. It is used to cut or shape materials using a. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. This is in contrast to end mills which. The end mill geometry is modeled by helical flutes wrapped. End Milling Process Geometry.

From www.researchgate.net

Schematic representation for end milling of different geometry and End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. This paper presents a generalized mathematical model of most helical end mills used in industry. This is in contrast to end mills which. It is used to cut or shape. End Milling Process Geometry.

From www.researchgate.net

Coordinate system and endmilling geometry. Download Scientific Diagram End Milling Process Geometry In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. This paper presents a generalized mathematical model of most helical end mills used in industry. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. The end mill geometry is modeled by helical flutes wrapped around a. End Milling Process Geometry.

From www.researchgate.net

Geometry of the end milling process. Download Scientific Diagram End Milling Process Geometry It is used to cut or shape materials using a. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality.. End Milling Process Geometry.

From www.researchgate.net

Schematics of micro end milling process (a) 2D model, and (b) 3D model End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. It is used to cut or shape materials using a. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. This is in contrast to end. End Milling Process Geometry.

From www.researchgate.net

Illustration of end milling process. Download Scientific Diagram End Milling Process Geometry The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. It is used to cut or shape materials using a. This paper presents a generalized mathematical model of most helical end mills used in industry. End milling is a machining process used. End Milling Process Geometry.

From www.researchgate.net

Geometry of linear and circular end milling process. Download End Milling Process Geometry In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. Drills are equipped with sharp ends that are meant to make the hole creation process easier. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. This is in contrast to end mills which. It is used to. End Milling Process Geometry.

From www.researchgate.net

Sketch map of ballend milling operation with different machining End Milling Process Geometry Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. End milling is a machining process used in metalworking, woodworking, and other material shaping/removal processes. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. It is used to cut or shape materials using a. This is in. End Milling Process Geometry.

From www.researchgate.net

Geometry model of ballend milling cutter. Download Scientific Diagram End Milling Process Geometry Ordinary end mills are “right cutting edge” and “left cutting edge” are very rare. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. In milling process, reduction in cutting forces and having stable cutting condition, improves the efficiency and part quality. It is used to cut or shape materials using a. This paper presents a. End Milling Process Geometry.

From www.researchgate.net

Schematic view of the endmilling process geometry and coordinate End Milling Process Geometry Drills are equipped with sharp ends that are meant to make the hole creation process easier. Currently, there is a lack of comprehensive studies that thoroughly investigate the impact of end mill geometry on. The end mill geometry is modeled by helical flutes wrapped around a parametric envelope. This is in contrast to end mills which. This paper presents a. End Milling Process Geometry.