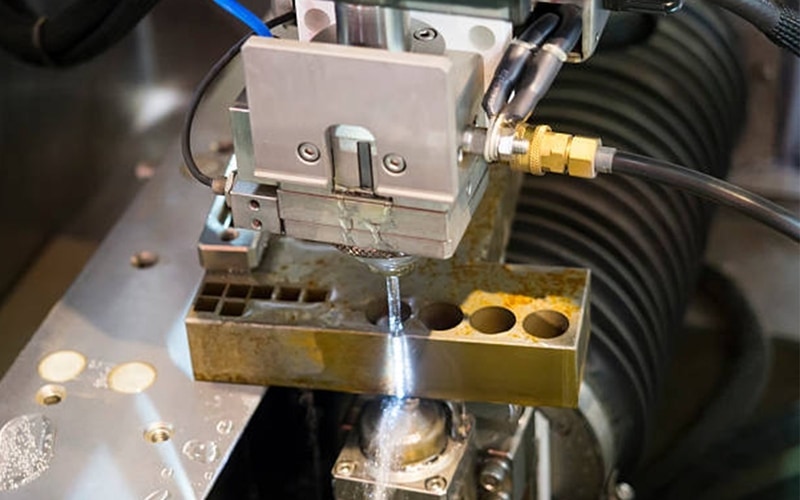

Wire Cut Edm Process . Wire edm uses electrolytic machining principles to cut complex. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. This technology stands out due to its ability to cut. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. Slow, expensive, and limited to conductive materials. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Can create complex shapes, smooth finishes, and high precision. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks.

from www.teamrapidtooling.com

Slow, expensive, and limited to conductive materials. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. This technology stands out due to its ability to cut. Can create complex shapes, smooth finishes, and high precision. Wire edm uses electrolytic machining principles to cut complex.

Wire EDM Machining The Components and How it Works

Wire Cut Edm Process Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. Slow, expensive, and limited to conductive materials. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Wire edm uses electrolytic machining principles to cut complex. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Can create complex shapes, smooth finishes, and high precision. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. This technology stands out due to its ability to cut.

From www.engineersrail.com

Electrical Discharge Machining Definition, Types, Parts, Working and Wire Cut Edm Process The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. This technology stands out due to its ability to cut. Wire edm uses electrolytic machining principles to cut complex. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Can. Wire Cut Edm Process.

From prototype-shortrun.com

What is Wire EDM Electrical Discharge Machining American Wire EDM Wire Cut Edm Process This technology stands out due to its ability to cut. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Slow, expensive, and limited to conductive materials. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Can create complex shapes, smooth finishes, and high precision. Wire. Wire Cut Edm Process.

From www.manufacturingguide.com

Wire EDM Find suppliers, processes & material Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Slow, expensive, and limited to conductive materials. Wire edm uses electrolytic machining principles to cut complex. This technology. Wire Cut Edm Process.

From dyna-techmfg.com

Wire Edc Electrical Discharge Machining, Rush Orders, Charlotte, NC Wire Cut Edm Process A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. This technology stands out due to its ability to cut. Slow, expensive, and limited to conductive materials. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Wire edm (electrical discharge machining) is a precise machining process. Wire Cut Edm Process.

From aneelaaryan.blogspot.com

10+ Wire Edm Tooling AneelaAryan Wire Cut Edm Process The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. This technology stands out due to its ability to cut. Slow, expensive, and limited to conductive materials. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric. Wire Cut Edm Process.

From enggkatta.com

WireCut Electrical Discharge Machining (WEDM) EnggKatta Wire Cut Edm Process Slow, expensive, and limited to conductive materials. This technology stands out due to its ability to cut. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Can create complex shapes, smooth finishes, and high precision. A cnc machining method that uses a charged metal wire to cut conductive materials with. Wire Cut Edm Process.

From www.teamrapidtooling.com

Wire EDM Machining The Components and How it Works Wire Cut Edm Process The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Wire edm uses electrolytic machining principles to cut complex. Can create complex shapes, smooth finishes, and high precision. This technology. Wire Cut Edm Process.

From at-machining.com

Electrical Discharge Machining A Complete Overview of the EDM Machining Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Slow, expensive, and limited. Wire Cut Edm Process.

From electricalworkbook.com

What is Wire EDM (Wire Electric Discharge Machining)? Process, Diagram Wire Cut Edm Process Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Wire edm uses electrolytic machining principles to cut complex. This technology stands out due to its ability to cut. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. The wire edm process works by generating a. Wire Cut Edm Process.

From www.youtube.com

Wire Electric Discharge Machining (Wire EDM) YouTube Wire Cut Edm Process A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Slow, expensive, and limited to conductive materials. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. This technology stands out due to its ability to cut. Can create complex shapes, smooth finishes,. Wire Cut Edm Process.

From www.wevolver.com

Electrical Discharge Machining (EDM) The Ultimate Guide Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Wire edm uses electrolytic machining principles to cut complex. Learn how wire edm works, what materials it can cut, and what. Wire Cut Edm Process.

From keenhome.io

An Intro To Electrical Discharge Machining Keen Home Wire Cut Edm Process This technology stands out due to its ability to cut. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. Can create complex shapes, smooth finishes,. Wire Cut Edm Process.

From www.mdi-llc.net

Wire EDM Electrical Discharge Machines Medical Device & Implants Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Wire edm uses electrolytic machining principles to cut complex. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. This technology stands out due to its. Wire Cut Edm Process.

From www.rejtool.com

EDM Machining — rejtool Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Wire edm uses electrolytic machining principles to cut complex. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. A cnc machining method that uses a. Wire Cut Edm Process.

From fractory.com

Electrical Discharge Machining EDM Process Explained Fractory Wire Cut Edm Process Slow, expensive, and limited to conductive materials. This technology stands out due to its ability to cut. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. The wire edm. Wire Cut Edm Process.

From www.youtube.com

Electrical Discharge Machining wire EDM working principle, animation Wire Cut Edm Process The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Slow, expensive, and limited to conductive materials. A cnc machining method that uses a charged metal. Wire Cut Edm Process.

From enggkatta.com

WireCut Electrical Discharge Machining (WEDM) EnggKatta Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Can create complex shapes, smooth finishes, and high precision. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Wire edm (electrical discharge machining) is a precise machining process that uses. Wire Cut Edm Process.

From prototype-shortrun.com

Wire EDM Machines & Electrical Discharge Machining Prototype Wire Cut Edm Process A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Slow, expensive, and limited to conductive. Wire Cut Edm Process.

From www.fastradius.com

Electrical Discharge Machining 101 Resources Fast Radius Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Can create complex shapes, smooth finishes, and high precision. This technology stands out due to its ability to cut. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Wire edm. Wire Cut Edm Process.

From www.youtube.com

Wire Cut Electro Discharge Machining Process Working Animation Video Wire Cut Edm Process Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving. Wire Cut Edm Process.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Cut Edm Process Wire edm uses electrolytic machining principles to cut complex. Can create complex shapes, smooth finishes, and high precision. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Learn how wire edm works, what materials. Wire Cut Edm Process.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking Wire Cut Edm Process The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Can create complex shapes, smooth finishes, and high precision. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. This technology stands out due to its ability to cut. Wire edm. Wire Cut Edm Process.

From fractory.com

Electrical Discharge Machining EDM Process Explained Fractory Wire Cut Edm Process Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. This technology stands out due to its ability to cut. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Can create complex shapes, smooth finishes, and high precision. A cnc machining method that. Wire Cut Edm Process.

From consuelobarger.blogspot.com

wire edm machine how it works Consuelo Barger Wire Cut Edm Process The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Slow, expensive, and limited to conductive materials. Can create complex shapes, smooth finishes, and high precision.. Wire Cut Edm Process.

From mwi-inc.com

What are the advantages of using wire EDM machining? MWI, Inc. Wire Cut Edm Process Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. This technology stands out due to its ability to cut. Can create complex shapes, smooth finishes, and high precision. Wire edm uses electrolytic machining principles to cut complex. Slow, expensive, and limited to conductive materials. A cnc machining method that uses a charged. Wire Cut Edm Process.

From www.electricaldischargemachining.com

Arizona Electrical Discharge Machining Wire Cut Edm Process A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Can create complex shapes, smooth finishes, and high precision. Wire edm uses electrolytic machining principles to cut complex. Slow, expensive, and limited to conductive materials. The wire. Wire Cut Edm Process.

From www.open.edu

Electrical Discharge Wire Cutting (EDWC) and Sawing (EDS) OpenLearn Wire Cut Edm Process Slow, expensive, and limited to conductive materials. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. Wire edm uses electrolytic machining principles to cut complex. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. A cnc machining method. Wire Cut Edm Process.

From abfmfg.com

Wire Cut EDM (Electrical Discharge Machining) ABF MFG Group Inc. Wire Cut Edm Process This technology stands out due to its ability to cut. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Wire edm uses electrolytic machining principles to cut complex. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. Wire edm (electrical. Wire Cut Edm Process.

From apacinfrastructure.com.au

Electrical Discharge Machining (EDM) Services Fabrication Services Wire Cut Edm Process The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. This technology stands out due to its ability to cut. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Wire edm uses electrolytic machining principles to cut complex. The wire edm. Wire Cut Edm Process.

From medium.com

An Intro To Electrical Discharge Machining Keen Home Medium Wire Cut Edm Process Wire edm uses electrolytic machining principles to cut complex. Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. A cnc machining method that uses a charged metal. Wire Cut Edm Process.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden Wire Cut Edm Process This technology stands out due to its ability to cut. Can create complex shapes, smooth finishes, and high precision. Wire edm uses electrolytic machining principles to cut complex. Slow, expensive, and limited to conductive materials. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. A cnc machining method. Wire Cut Edm Process.

From abfmfg.com

Wire Cut EDM (Electrical Discharge Machining) ABF MFG Group Inc. Wire Cut Edm Process Wire edm uses electrolytic machining principles to cut complex. Slow, expensive, and limited to conductive materials. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. This technology stands out. Wire Cut Edm Process.

From www.cncsourced.com

Wire EDM A Complete Guide to Wire Electric Discharge Machining Wire Cut Edm Process Wire edm (electrical discharge machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. The sparks melt and vaporize material in a precise pattern by eroding the workpiece along the path of the moving wire. The wire edm process. Wire Cut Edm Process.

From www.youtube.com

SODICK AG600L CNC 5AXIS WIRE CUT ELECTRICAL DISCHARGE MACHINE (EDM Wire Cut Edm Process Slow, expensive, and limited to conductive materials. This technology stands out due to its ability to cut. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Learn how wire edm works, what materials it can cut, and what are its advantages and limitations. Wire edm uses. Wire Cut Edm Process.

From mechanicalinventions.blogspot.com

Electrical Discharge Machining (EDM) Principles Mechanical Engineering Wire Cut Edm Process Slow, expensive, and limited to conductive materials. A cnc machining method that uses a charged metal wire to cut conductive materials with sparks. The wire edm process works by generating a series of rapid, repeating electrical discharges between the wire and workpiece submerged in dielectric fluid. Can create complex shapes, smooth finishes, and high precision. This technology stands out due. Wire Cut Edm Process.