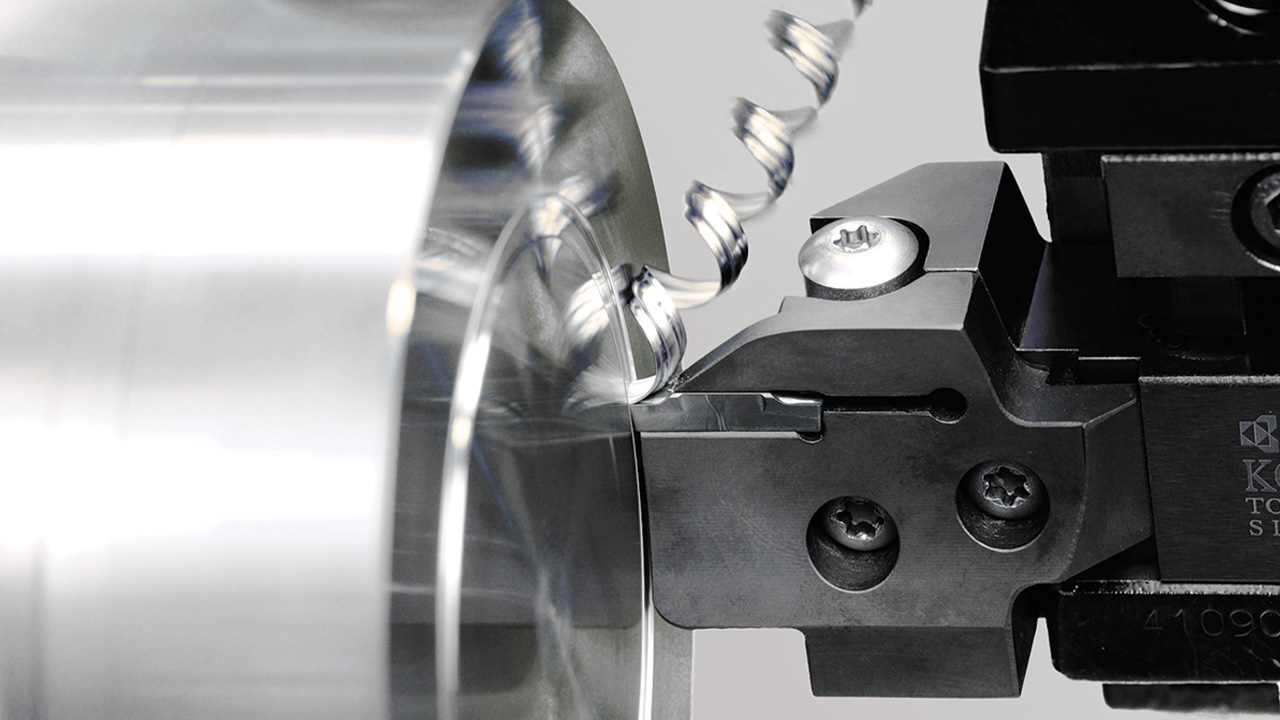

Face Grooving Techniques . Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. in this article, we have explored the world of face grooving tools for cnc turning. We have examined the different types of tools, their. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. The bending radius of the groove will. Face grooving is not always a straightforward process. When making an axial groove on the face of a component, it is important to choose the correct tools. face grooving is not always a straightforward process.

from www.ksptg.com

Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. The bending radius of the groove will. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; techniques include straight turning, face grooving, and contouring, each suited to specific requirements. face grooving is not always a straightforward process. Face grooving is not always a straightforward process. When making an axial groove on the face of a component, it is important to choose the correct tools. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. We have examined the different types of tools, their. in this article, we have explored the world of face grooving tools for cnc turning.

Avoid Tool Interference and Part Damage when Face Grooving

Face Grooving Techniques Face grooving is not always a straightforward process. face grooving is not always a straightforward process. Face grooving is not always a straightforward process. When making an axial groove on the face of a component, it is important to choose the correct tools. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; The bending radius of the groove will. in this article, we have explored the world of face grooving tools for cnc turning. We have examined the different types of tools, their. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining.

From proleantech.com

A Comprehensive Comparison of Grooving and Threading Techniques Face Grooving Techniques in this article, we have explored the world of face grooving tools for cnc turning. We have examined the different types of tools, their. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; face grooving is not always a straightforward process. techniques include straight turning, face grooving, and contouring, each. Face Grooving Techniques.

From dokumen.tips

(PDF) GROOVING SOLUTIONS MADE SIMPLE ATP Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; face grooving is not always a straightforward process. When making an axial groove on the face of a component, it is important to choose the correct tools. Face grooving is not always a straightforward process. Speeds and feeds, chip evacuation, tool wear, and. Face Grooving Techniques.

From tungaloy.com

FaceMiniCut Grooving Products Tungaloy Corporation Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. The bending radius of the groove will. Speeds and feeds, chip evacuation, tool wear, and tool. Face Grooving Techniques.

From tungaloy.com

AddForceCut Boosts Productivity in Deep Face Grooving TungaloyNTK Face Grooving Techniques this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. in this article, we have explored the world of face grooving tools for cnc turning. techniques. Face Grooving Techniques.

From forums.autodesk.com

How to create a Face Grooving with a curved profile Autodesk Community Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. in this article, we have explored the world of face grooving tools for cnc turning.. Face Grooving Techniques.

From www.sandvik.coromant.com

Face grooving Face Grooving Techniques face grooving is not always a straightforward process. in this article, we have explored the world of face grooving tools for cnc turning. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. Face grooving is not always a straightforward process. We have examined the different types of tools, their. When making an axial. Face Grooving Techniques.

From www.youtube.com

CAMWorks Turning Tutorial 4 Face Grooving & Some Tricks YouTube Face Grooving Techniques When making an axial groove on the face of a component, it is important to choose the correct tools. face grooving is not always a straightforward process. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. Face grooving is not. Face Grooving Techniques.

From www.youtube.com

CoroBore® face grooving Sandvik Coromant YouTube Face Grooving Techniques in this article, we have explored the world of face grooving tools for cnc turning. When making an axial groove on the face of a component, it is important to choose the correct tools. The bending radius of the groove will. We have examined the different types of tools, their. techniques include straight turning, face grooving, and contouring,. Face Grooving Techniques.

From navfreedom.weebly.com

Lathe Face Grooving Tool navfreedom Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; in this article, we have explored the world of face grooving tools for cnc turning. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. We have examined the different types of tools, their. techniques include straight turning,. Face Grooving Techniques.

From www.alamy.com

Face grooving Stock Photo Alamy Face Grooving Techniques face grooving is not always a straightforward process. We have examined the different types of tools, their. The bending radius of the groove will. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. in this article, we have explored. Face Grooving Techniques.

From www.ksptg.com

Avoid Tool Interference and Part Damage when Face Grooving Face Grooving Techniques techniques include straight turning, face grooving, and contouring, each suited to specific requirements. face grooving is not always a straightforward process. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. Whether you’re machining circular grooves into the face of. Face Grooving Techniques.

From www.youtube.com

Innovative Applications of Special Face Grooving Tool YouTube Face Grooving Techniques Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; The bending radius of the groove will. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing. Face Grooving Techniques.

From chansmachining.com

Understanding Grooving the type, techniques, and Tools for CNC Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; face grooving is not always a straightforward process. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. in this article, we have explored. Face Grooving Techniques.

From ts-machinetools.com

Ten Soon Machine Tools, Inc. Face Grooving Tools (D Tools) Face Grooving Techniques The bending radius of the groove will. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. We have examined the different types of tools, their. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. in. Face Grooving Techniques.

From www.youtube.com

Face grooving and Neutral CNC turning toolsAll tools of CNC machine Face Grooving Techniques face grooving is not always a straightforward process. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. When making an axial groove on the face of a component, it is important to choose the correct tools. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; this. Face Grooving Techniques.

From www.youtube.com

Tooling Design I Parting & External Grooving Details l Grooving tool Face Grooving Techniques We have examined the different types of tools, their. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. Face grooving is not always a straightforward process. The bending radius of the groove will. When making an axial groove on the face of a component, it is important to choose the correct tools. Whether you’re machining. Face Grooving Techniques.

From www.practicalmachinist.com

BIG KAISER Introduces High Precision Face Grooving System Practical Face Grooving Techniques this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. face grooving is not always a straightforward process. The bending radius of the groove will. When making. Face Grooving Techniques.

From www.youtube.com

Tooling Design I FACE GROOVING TOOL APPLICATION YouTube Face Grooving Techniques When making an axial groove on the face of a component, it is important to choose the correct tools. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. The bending radius of the groove will. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. Face grooving is not always a. Face Grooving Techniques.

From www.shantradingco.com

Face Grooving Shan Technical Trading Company Face Grooving Techniques face grooving is not always a straightforward process. We have examined the different types of tools, their. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining.. Face Grooving Techniques.

From keironkerena.blogspot.com

7+ Face Grooving Tool KeironKerena Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; We have examined the different types of tools, their. The bending radius of the groove will. face grooving is not always a straightforward process. Face grooving is not always a straightforward process. in this article, we have explored the world of face. Face Grooving Techniques.

From www.qualiturn.co.uk

Face Grooving Face Grooving Techniques Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. The bending radius of the groove will. face grooving is not always a straightforward process. When making an axial groove on the face of a component, it is important to choose. Face Grooving Techniques.

From www.youtube.com

G74 Face Grooving Cycle in Fanuc System. G74 Cycle. G74. Face Grooving Face Grooving Techniques When making an axial groove on the face of a component, it is important to choose the correct tools. Face grooving is not always a straightforward process. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. face grooving is not. Face Grooving Techniques.

From ts-machinetools.com

Ten Soon Machine Tools, Inc. Face Grooving Tools (D Tools) Face Grooving Techniques Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; in. Face Grooving Techniques.

From insight-t.com

MFGR micro solid carbide bar for face grooving INSIGHT TOOLS Face Grooving Techniques Face grooving is not always a straightforward process. When making an axial groove on the face of a component, it is important to choose the correct tools. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. The bending radius of the. Face Grooving Techniques.

From www.youtube.com

Mastercm Lathe Tungaloy 3D TungCut Face Grooving Tools CAM Face Grooving Techniques face grooving is not always a straightforward process. We have examined the different types of tools, their. When making an axial groove on the face of a component, it is important to choose the correct tools. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing. Face Grooving Techniques.

From www.productionmachining.com

A New Face Grooving Technique for Mills Production Machining Face Grooving Techniques Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. The bending radius of the groove will. When making an axial groove on the face of a component, it is important to choose the correct tools. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; techniques include straight. Face Grooving Techniques.

From www.youtube.com

Face Grooving Tool Selection Optimal Diameter Ranges YouTube Face Grooving Techniques Face grooving is not always a straightforward process. face grooving is not always a straightforward process. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. When. Face Grooving Techniques.

From www.youtube.com

face grooving tool YouTube Face Grooving Techniques Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. The bending radius of the groove will. face grooving is not always a straightforward process. Face grooving is not always a straightforward process. this article elucidates crucial insights into both. Face Grooving Techniques.

From dokumen.tips

(PDF) MODULAR Turning & Grooving System · 20190916 · Kool CutTM Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; The bending radius of the groove will. We have examined the different types of tools, their. When making an axial groove on the face of a component, it is important to choose the correct tools. techniques include straight turning, face grooving, and contouring,. Face Grooving Techniques.

From www.ingersoll-imc.com

FaceFlex SFeedUP Face Grooving Techniques Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. in this article, we have explored the world of face grooving tools for cnc turning. We have examined the different types of tools, their. Face grooving is not always a straightforward process. techniques include straight turning, face grooving, and contouring, each suited to specific. Face Grooving Techniques.

From www.ksptg.com

Avoid Tool Interference and Part Damage when Face Grooving Face Grooving Techniques Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. face. Face Grooving Techniques.

From www.youtube.com

WIDIA Ranger Face Grooving Adjustment Instructions. YouTube Face Grooving Techniques We have examined the different types of tools, their. face grooving is not always a straightforward process. When making an axial groove on the face of a component, it is important to choose the correct tools. Face grooving is not always a straightforward process. The bending radius of the groove will. in this article, we have explored the. Face Grooving Techniques.

From forums.autodesk.com

Solved Lathe Face Grooving Autodesk Community Face Grooving Techniques We have examined the different types of tools, their. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; The bending radius of the groove will. Speeds and feeds, chip evacuation, tool wear, and tool rigidity all play important roles. face grooving is not always a straightforward process. When making an axial groove. Face Grooving Techniques.

From exofptrqx.blob.core.windows.net

Mitsubishi Face Grooving Tools at Michelle Holbrook blog Face Grooving Techniques The bending radius of the groove will. Face grooving is not always a straightforward process. this article elucidates crucial insights into both selecting optimal face grooving tools and mastering the key principles of face grooving itself, providing indispensable guidance for precision machining. techniques include straight turning, face grooving, and contouring, each suited to specific requirements. face grooving. Face Grooving Techniques.

From ts-machinetools.com

Ten Soon Machine Tools, Inc. Face Grooving Tools (D Tools) Face Grooving Techniques The bending radius of the groove will. Whether you’re machining circular grooves into the face of a workpiece or widening the initial groove; techniques include straight turning, face grooving, and contouring, each suited to specific requirements. We have examined the different types of tools, their. Face grooving is not always a straightforward process. in this article, we have. Face Grooving Techniques.