Actuator Failure Modes . A fmeda is one of the steps taken to. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The following designs are adopted to achieve one of the failure modes. These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. Commonly, the failure modes of actuators are achieved as either fail open or fail close. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. Here are some common pneumatic actuator failure modes:

from www.semanticscholar.org

These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The following designs are adopted to achieve one of the failure modes. Here are some common pneumatic actuator failure modes: The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). A fmeda is one of the steps taken to. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. Commonly, the failure modes of actuators are achieved as either fail open or fail close.

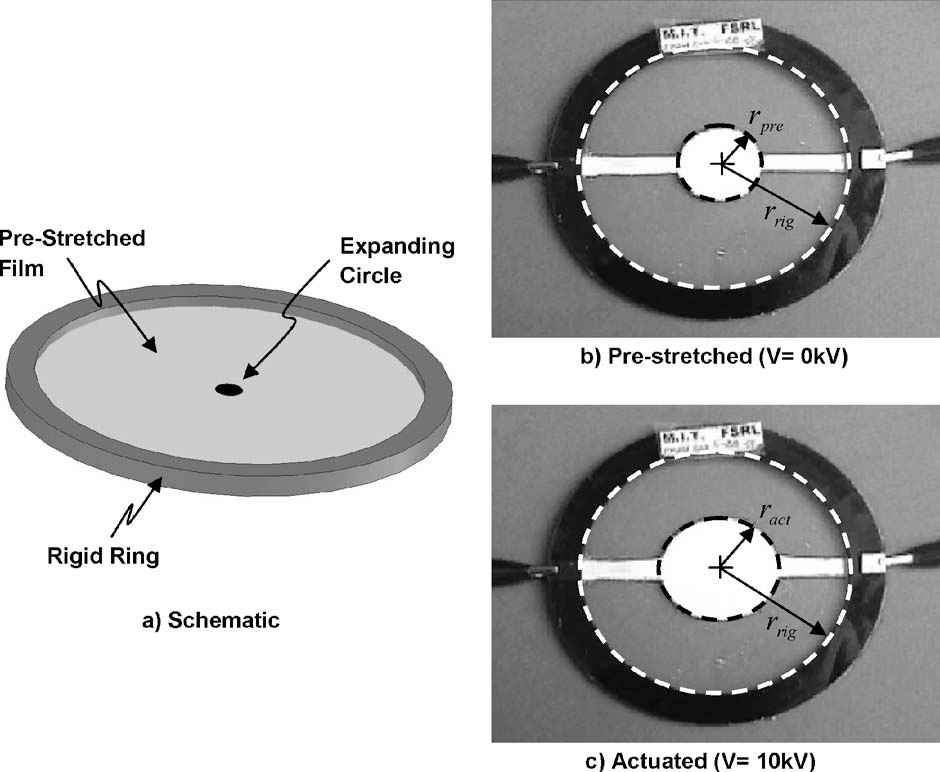

Figure 1 from Largescale failure modes of dielectric elastomer

Actuator Failure Modes The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The following designs are adopted to achieve one of the failure modes. A fmeda is one of the steps taken to. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. Here are some common pneumatic actuator failure modes: Commonly, the failure modes of actuators are achieved as either fail open or fail close.

From www.researchgate.net

(PDF) Electromechanical response and failure modes of a dielectric Actuator Failure Modes A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. Here are some common pneumatic actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. Commonly,. Actuator Failure Modes.

From www.researchgate.net

failure modes and failure mechanism analysis results. Download Actuator Failure Modes These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A fmeda is one of the steps taken to. Here are some common pneumatic actuator failure modes: Commonly, the. Actuator Failure Modes.

From www.ureason.com

Failure Modes of Electric Actuators Actuator Failure Modes The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). Here are some common pneumatic actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. A sudden loss of air supply to the actuator can result in a. Actuator Failure Modes.

From onlyvalves.com

Failure Modes of Pneumatic Actuators Actuator Failure Modes The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). Commonly, the failure modes of actuators are achieved as either fail open or fail close. A fmeda is one of the steps taken to. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The failure modes in the. Actuator Failure Modes.

From www.slideserve.com

PPT Control Valve Actuators Types and Failure Modes PowerPoint Actuator Failure Modes The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. Here are some common pneumatic actuator failure modes: Commonly, the failure modes of actuators are achieved. Actuator Failure Modes.

From automationforum.co

Failure modes in Control valve actuators AutomationForum Actuator Failure Modes A fmeda is one of the steps taken to. Here are some common pneumatic actuator failure modes: A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. The following designs are adopted to achieve one of the failure modes. These failure modes can vary depending. Actuator Failure Modes.

From www.researchgate.net

System identification and actuator failure scenario; Comparison between Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. Commonly, the failure modes of actuators are achieved as either fail open or fail close. The following. Actuator Failure Modes.

From control.com

Valve Failure Modes Basic Principles of Control Valves and Actuators Actuator Failure Modes Commonly, the failure modes of actuators are achieved as either fail open or fail close. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. A. Actuator Failure Modes.

From cncontrolvalve.com

Control Valve Failure Position 101 THINKTANK Actuator Failure Modes The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). Commonly, the failure modes of actuators are achieved as either fail open or fail close. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The following designs are adopted to achieve one of the failure modes. Here are. Actuator Failure Modes.

From www.researchgate.net

Deflections of actuators in direct lift mode (failure). Download Actuator Failure Modes The following designs are adopted to achieve one of the failure modes. Here are some common pneumatic actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). A. Actuator Failure Modes.

From www.mdpi.com

Applied Sciences Free FullText A Study on Failure Analysis and Actuator Failure Modes Commonly, the failure modes of actuators are achieved as either fail open or fail close. Here are some common pneumatic actuator failure modes: These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: The main purpose of failure modes is to maintain safety and prevent equipment damage. Actuator Failure Modes.

From www.transmittershop.com

Control Valve Actuators Different Types and Failure Modes Discussed Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A fmeda is one of the steps taken to. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. The failure modes in the control valve actuator. Actuator Failure Modes.

From www.andrews-cooper.com

Failure Modes & Analysis Infographic Andrews Cooper Actuator Failure Modes These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: Here are some common pneumatic actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. A sudden loss. Actuator Failure Modes.

From issuu.com

Control Valve Actuators Types and Failure Modes by Transmitter Shop Actuator Failure Modes Commonly, the failure modes of actuators are achieved as either fail open or fail close. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. A fmeda is one of the steps. Actuator Failure Modes.

From www.researchgate.net

The actuator failure and its recognition Download Scientific Diagram Actuator Failure Modes The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. A fmeda is one of the steps taken to. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). The main purpose of failure modes is to maintain safety and prevent. Actuator Failure Modes.

From www.researchgate.net

EMAS response in failure modes 3 and 4 motor current and aerodynamic Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. These failure modes can vary depending on the type and design of the actuator, but here are. Actuator Failure Modes.

From automationforum.co

Failure modes in Control valve actuators AutomationForum Actuator Failure Modes The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck. Actuator Failure Modes.

From www.researchgate.net

(PDF) Failure modes and probabilities of a high redundancy actuator Actuator Failure Modes The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A sudden loss of air supply to the actuator can result in a loss of control. Actuator Failure Modes.

From www.youtube.com

What is Fail safe modes in Actuator? Learn Instrumentation Actuator Failure Modes The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The following designs are adopted to achieve one of the failure modes. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). Here are some common pneumatic actuator failure modes: The. Actuator Failure Modes.

From www.researchgate.net

The estimations of actuator failure factor ρ. Download Scientific Diagram Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. Here are some common pneumatic actuator failure modes: A fmeda is one of the steps taken. Actuator Failure Modes.

From 123dok.com

Proposed Actuator Failure Compensator Design Actuator Failure Modes The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting. Actuator Failure Modes.

From www.researchgate.net

EMAS response in failure modes 3 and 4 actuator position and motor Actuator Failure Modes A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. A fmeda is one of the steps taken to. Here are some common pneumatic actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator. Actuator Failure Modes.

From www.researchgate.net

Pressure error and control input of actuator partial failure after Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). A fmeda is. Actuator Failure Modes.

From dokumen.tips

(PDF) Largescale failure modes of dielectric elastomer actuators Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). Here are some common. Actuator Failure Modes.

From www.researchgate.net

EMAS response in failure modes 3 and 4 motor current and aerodynamic Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. The following designs are adopted to achieve one of the failure modes. Here are some common pneumatic. Actuator Failure Modes.

From www.researchgate.net

Schematic representation of different failure modes under uniaxial Actuator Failure Modes The following designs are adopted to achieve one of the failure modes. Here are some common pneumatic actuator failure modes: Commonly, the failure modes of actuators are achieved as either fail open or fail close. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). A sudden loss of air supply to the actuator can result in. Actuator Failure Modes.

From www.scribd.com

Actuators Uses, Types and Failure Modes Posted by Ankit Chugh On 1157 Actuator Failure Modes The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). A fmeda is one of the steps taken to. Here are some common pneumatic actuator failure modes: The following designs are adopted to achieve one of the failure modes. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong.. Actuator Failure Modes.

From www.researchgate.net

Initial Failure Mode and Effects Analysis (FMEA) for ElectroMechanical Actuator Failure Modes The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). Here are some common pneumatic actuator failure modes: These failure modes can vary depending on the type and design of the. Actuator Failure Modes.

From www.researchgate.net

(PDF) Failure modes in surface micromachined microelectromechanical Actuator Failure Modes Here are some common pneumatic actuator failure modes: A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. Commonly, the failure modes of actuators are achieved as either fail open or fail close. The main purpose of failure modes is to maintain safety and prevent. Actuator Failure Modes.

From www.semanticscholar.org

Figure 1 from Largescale failure modes of dielectric elastomer Actuator Failure Modes The following designs are adopted to achieve one of the failure modes. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. Commonly, the failure modes of actuators are achieved as either fail open or fail close. The failure modes in the control valve actuator is achieved by combining direct acting or. Actuator Failure Modes.

From dokumen.tips

(PDF) Actuator Failure Identification and Compensation Through Sliding Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. The following designs are adopted to achieve one of the failure modes. A fmeda is one of the steps taken to. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck. Actuator Failure Modes.

From instrumentationtools.com

How to Select Control Valve Failure Mode Instrumentation Tools Actuator Failure Modes The following designs are adopted to achieve one of the failure modes. The hardware assessment consists of a failure modes, effects and diagnostics analysis (fmeda). A fmeda is one of the steps taken to. The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body.. Actuator Failure Modes.

From www.researchgate.net

EMAS response in failure modes 1 and 2 actuator position and motor Actuator Failure Modes These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes: The failure modes in the control valve actuator is achieved by combining direct acting or reverse acting actuator and direct acting or reverse acting valve body. The following designs are adopted to achieve one of the failure. Actuator Failure Modes.

From www.scribd.com

Failure Modes of Actuator PDF International Standard Serial Number Actuator Failure Modes The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong. A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. The following designs are adopted to achieve one of the failure modes. The failure modes in the. Actuator Failure Modes.

From www.researchgate.net

failure modes, effects and severity analysis results of solenoid Actuator Failure Modes Here are some common pneumatic actuator failure modes: A sudden loss of air supply to the actuator can result in a loss of control or the actuator becoming stuck in its current position. A fmeda is one of the steps taken to. The main purpose of failure modes is to maintain safety and prevent equipment damage when something goes wrong.. Actuator Failure Modes.